Method for improving sodium sulfide solution concentration by leaching black ash for three times

A solution concentration, sodium sulfate solution technology, applied in chemical instruments and methods, alkali metal sulfide/polysulfide, inorganic chemistry, etc., can solve the problems of low concentration of sodium sulfide solution, high evaporation cost of 60 alkali, etc., to reduce evaporation The effect of increasing the concentration of sodium sulfide solution and reducing the cost of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The resulting barium sulfide and sodium sulfate solution reacted to form barium sulfate and sodium sulfide solution after soaking black ash with water, the concentration of sodium sulfide solution is 4%.

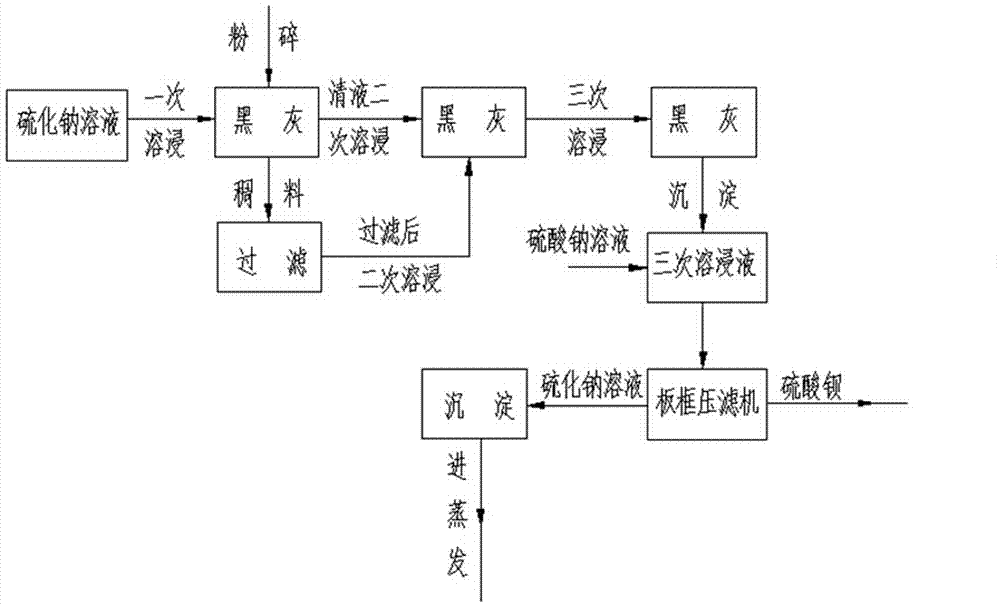

[0017] The black ash was leached three times with a sodium sulfide solution with a concentration of 4%, and the steps were as follows:

[0018] ① first crush the black ash, and then use 4% sodium sulfide solution for a leaching; ② precipitate and separate the leached solution to obtain the mother liquor I; ③ use the mother liquor Ⅰ to continue the second leaching of the black ash, The leached solution is subjected to secondary precipitation and separation to obtain mother liquor II; ④ three times of leaching with mother liquor II, and the solution after three leachings is subjected to precipitation and separation to obtain mother liquor III; ⑤ mother liquor III contains S 2- 、Na + 、Ba 2+ ions, react with sodium sulfate solution to form barium sulfate and sodium sulf...

Embodiment 2

[0024] The resulting barium sulfide and sodium sulfate solution reacted to form barium sulfate and sodium sulfide solution after soaking black ash with water, the concentration of sodium sulfide solution is 5%.

[0025] The black ash is leached three times with sodium sulfide solution, the steps are as follows:

[0026] ① first crush the black ash, and then use 5% sodium sulfide solution for a leaching; ② precipitate and separate the leached solution to obtain the mother liquor I; ③ use the mother liquor Ⅰ to continue the second leaching of the black ash, The leached solution is subjected to secondary precipitation and separation to obtain mother liquor II; ④ three times of leaching with mother liquor II, and the solution after three leachings is subjected to precipitation and separation to obtain mother liquor III; ⑤ mother liquor III contains S 2- 、Na + 、Ba 2+ ions, react with sodium sulfate solution to form barium sulfate and sodium sulfide solution; ⑥The concentration of...

Embodiment 3

[0032] The resulting barium sulfide and sodium sulfate solution reacted to form barium sulfate and sodium sulfide solution after soaking black ash with water, the concentration of sodium sulfide solution is 4.8%.

[0033] The black ash is leached three times with sodium sulfide solution, the steps are as follows:

[0034] ① first crush the black ash, and then use 4.8% sodium sulfide solution for a leaching; ② precipitate and separate the leached solution to obtain the mother liquor Ⅰ; ③ use the mother liquor Ⅰ to continue to leaching the black ash twice, The leached solution is subjected to secondary precipitation and separation to obtain mother liquor II; ④ three times of leaching with mother liquor II, and the solution after three leachings is subjected to precipitation and separation to obtain mother liquor III; ⑤ mother liquor III contains S 2- 、Na + 、Ba 2+ ions, react with sodium sulfate solution to form barium sulfate and sodium sulfide solution; ⑥The concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com