Method for recovering and separating potassium salt and sodium salt from waste incineration fly ash

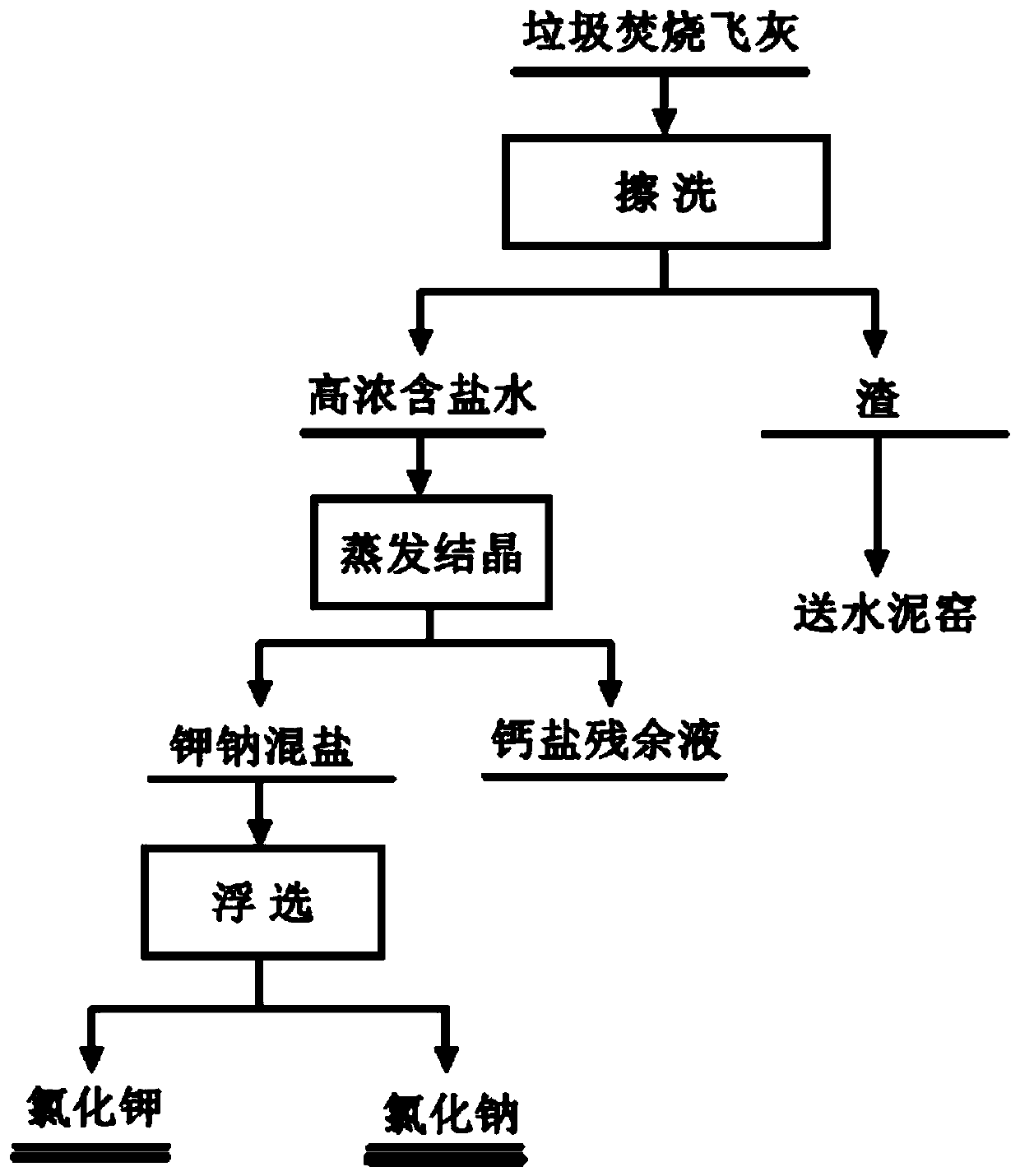

A technology of waste incineration fly ash and potassium salt, which is applied in the direction of calcium/strontium/barium halide, alkali metal chloride, calcium/strontium/barium chloride, etc. It can reduce the consumption cost of chemicals, reduce the production cost and reduce the evaporation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

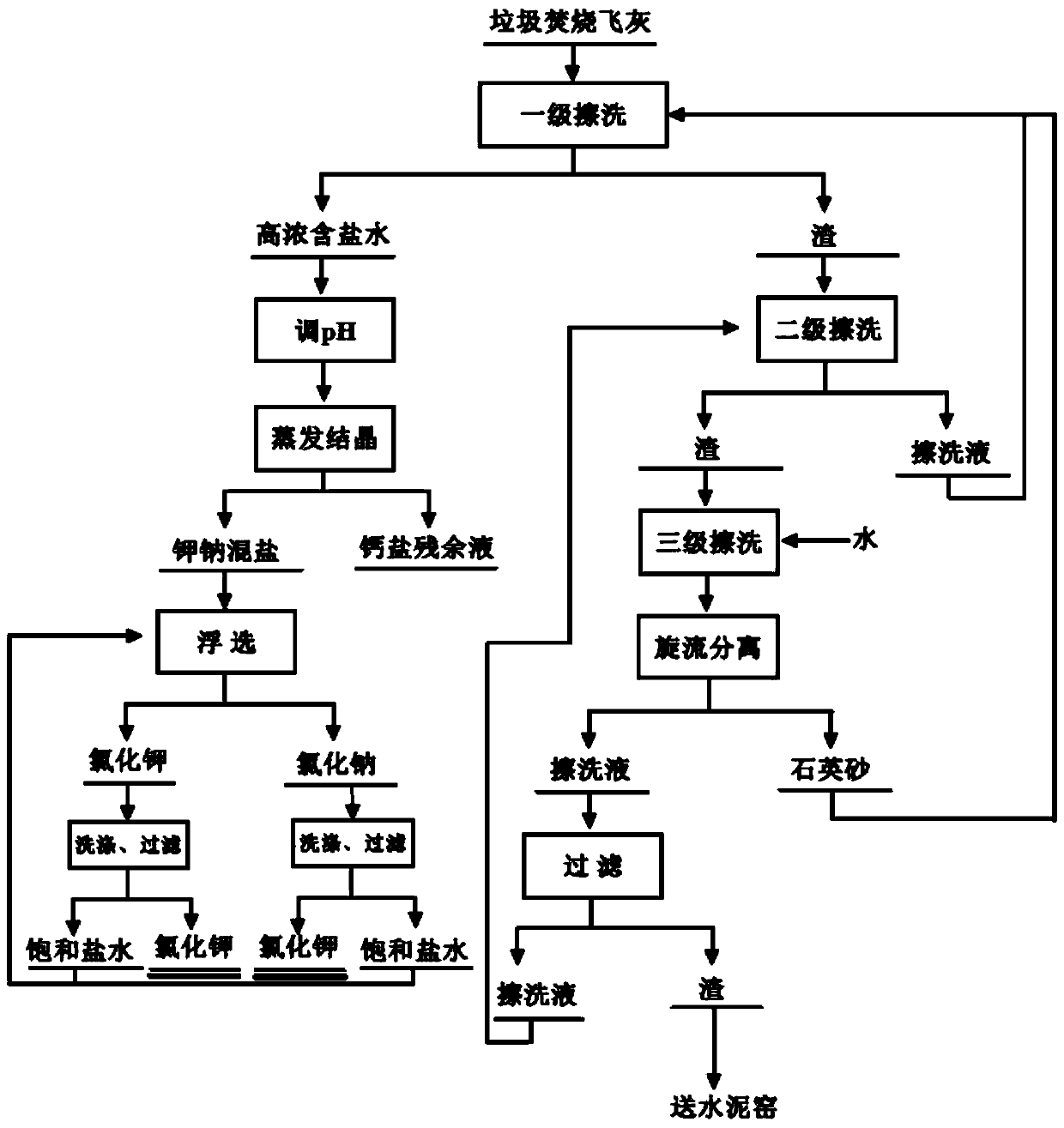

[0028] (1) Stir and scrub the quartz sand with a particle size of 40-60 mesh and fly ash at a mass ratio of 0.5:1, and fly ash and water at a mass ratio of 1:4. The stirring speed is 300r·min-1, stirring The cleaning time is 30 minutes, after filtering, repeat scrubbing for 2 times, and the scrubbing solution is returned to the previous level for repeated use until the salt content in the high-concentration brine obtained from the first level of scrubbing reaches 20-30%. After the last level of scrubbing, the fly ash is The cyclone separates the quartz sand and returns it to the process for continued use;

[0029] (2) adjust the pH of the high-concentration salt water obtained in step (1) to 5 with hydrochloric acid, and obtain potassium-sodium mixed salt and residual calcium chloride saturated solution by evaporating and concentrating. In the potassium-sodium mixed salt, the calcium chloride content is 6.15%, and the remaining Calcium chloride content in calcium chloride satu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com