Preparation method of edible mushroom high-viscosity concentrated solution

A technology of edible fungi and concentrated liquid, which is applied in application, food processing, food extraction, etc., can solve the problems of no preparation method for high-viscosity concentrated liquid of edible fungi, affecting the flavor and taste of high-viscosity concentrated liquid of edible fungi, and inconvenience of industrial production, etc. Achieve the effect of easy one-time pass, reduce evaporation cost, and shorten extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

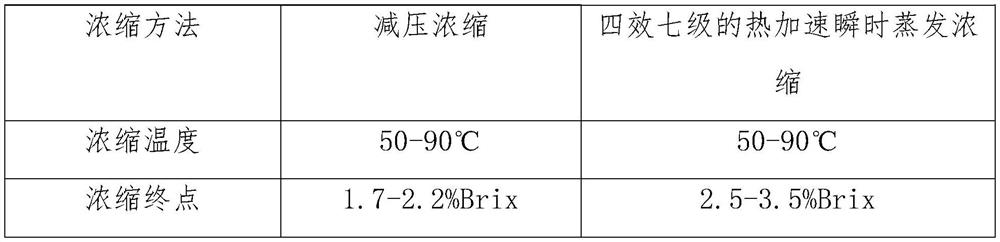

[0028] A method for preparing edible fungus high-viscosity concentrate, specifically: after washing the edible fungus with water, ultrasonic countercurrent extraction, vibrating screen and disc centrifuge filtration, UHT sterilization, four-effect seven-stage heat-accelerated instantaneous evaporation and concentration container concentration, aseptic filling; its specific preparation steps are as follows:

[0029] Step S1: Soak the edible fungus for 5-20 minutes and then wash to remove surface sediment;

[0030] Step S2: Cut the cleaned edible fungi into cubes of 0.5cm×0.5cm; find a method for preparing a high-viscosity concentrated liquid of edible fungi described in 1, characterized in that in step S2, the washed edible Bacteria are cut into cubes of 0.5×0.5cm for the convenience of subsequent filtration. If they are powdered for extraction, the subsequent powder will become a paste, and the filtration resistance will be greatly increased. It is necessary to increase the ro...

Embodiment 1

[0040] A method for preparing edible fungus high-viscosity concentrated liquid, the specific steps are as follows:

[0041] (1) Soak the edible fungus for 10 minutes and then wash to remove surface silt and other sundries;

[0042] (2) Cut the cleaned edible fungus into cubes of 0.5cm×0.5cm;

[0043] (3) put into the ultrasonic countercurrent extraction after mixing the cut cubes and 12 times the weight of water;

[0044] (4) Filter the obtained extract with a vibrating sieve first, and then carry out secondary filtration with a disc centrifuge. The rotational speed of centrifugation is 3300r / min, and a 100-mesh filter is selected to separate excess solids to obtain edible Bacteria clear juice;

[0045] (5) UHT sterilization treatment is carried out on the filtered material, the sterilization temperature is 135°C, and the sterilization time is 7s;

[0046] (6) Concentrate the sterilized material with a four-effect seven-stage heat-accelerated instantaneous evaporation conce...

Embodiment 2

[0050] A method for preparing edible fungus high-viscosity concentrated liquid, the specific steps are as follows:

[0051] (1) Soak the edible fungus for 20 minutes and then wash it to remove surface silt and other sundries;

[0052] (2) Cut the cleaned edible fungus into cubes of 0.5cm×0.5cm;

[0053] (3) put the water that cut into cube and 15 times of weight into ultrasonic countercurrent extraction;

[0054] (4) Filter the obtained extract with a vibrating sieve first, and then carry out secondary filtration with a disc centrifuge. The rotational speed of centrifugation is 3500r / min, and a 120-mesh filter is selected to separate excess solids to obtain edible Bacteria clear juice;

[0055] (5) UHT sterilization treatment is carried out on the filtered material, the sterilization temperature is 140°C, and the sterilization time is 10s;

[0056] (6) Concentrate the sterilized material with a four-effect seven-stage heat-accelerated instantaneous evaporation concentrator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com