Chip recovery device for machine tool machining

A technology for recycling devices and chips, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems affecting recycling and chip corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

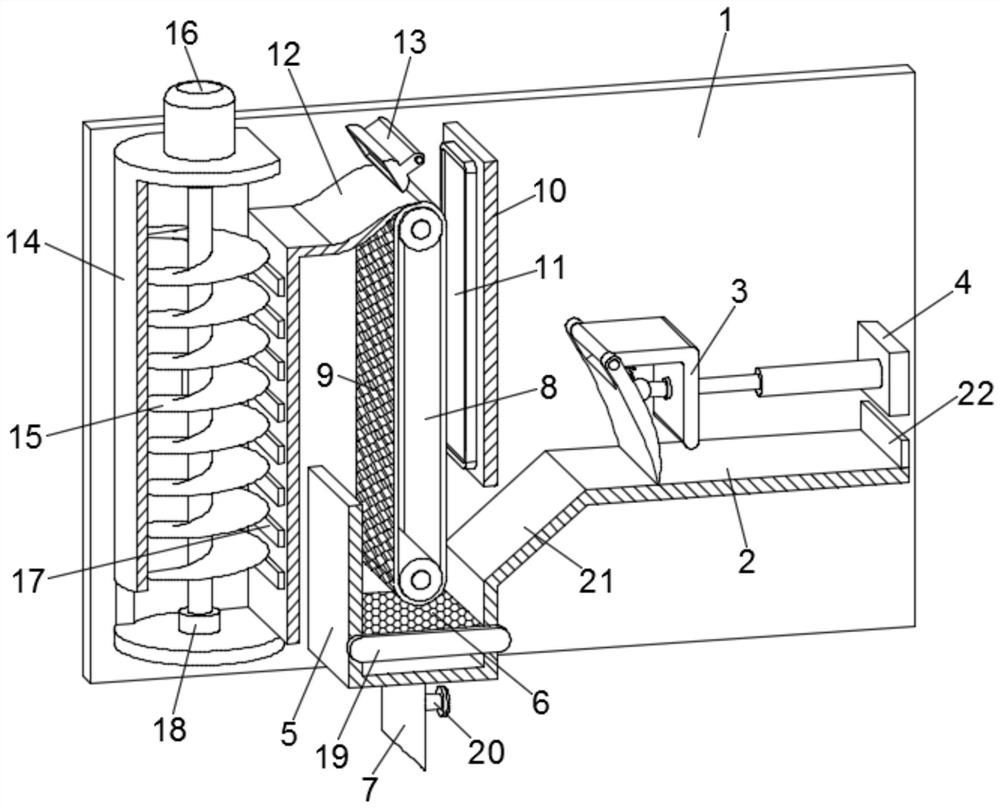

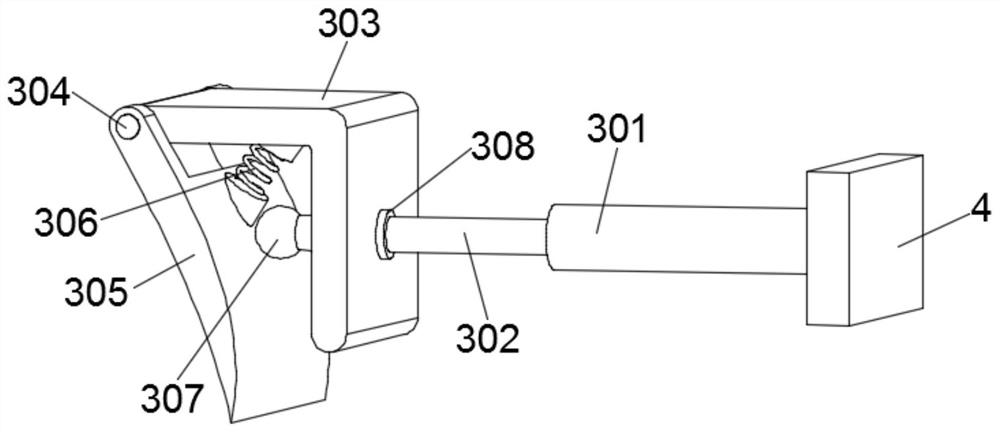

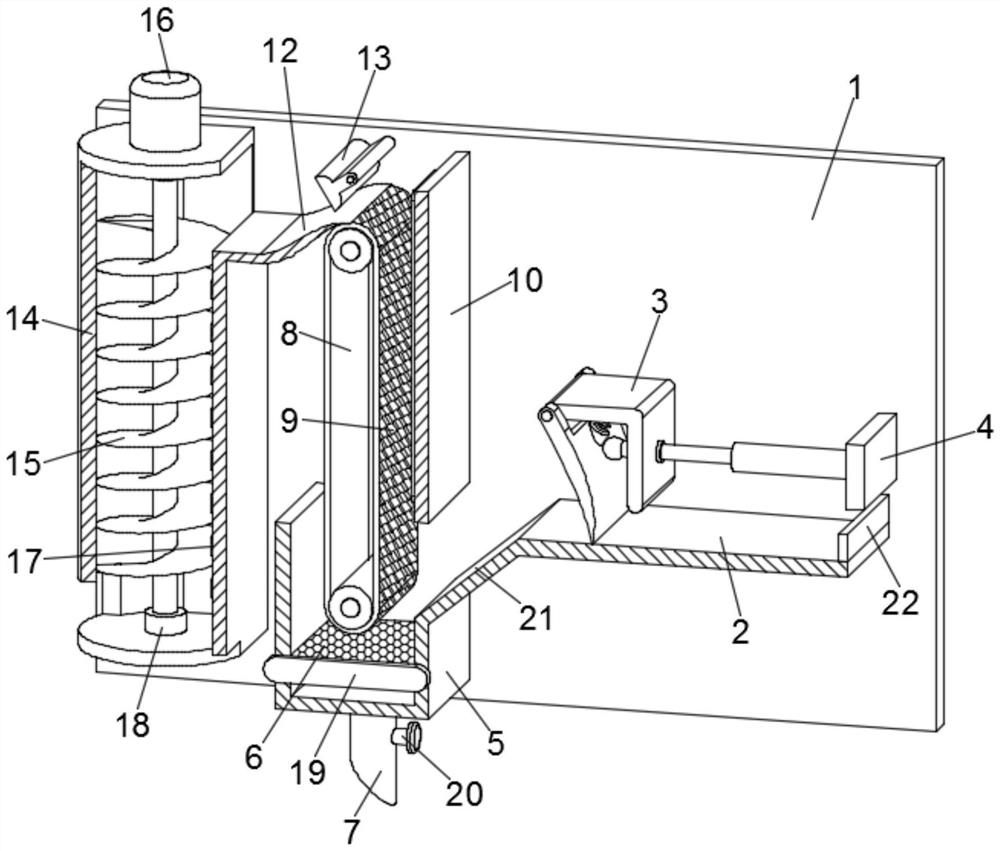

[0024] see Figure 1-2 , a chip recovery device for machine tool processing, comprising a backboard 1 and a platform 2, a pusher mechanism 3 is arranged above the platform 2, and the pusher mechanism 3 is installed on the backboard 1 through a mounting plate 4, and the pusher The material mechanism 3 includes a fixed sleeve 301, a telescopic column 302, a bracket 303 and a push plate 305. The fixed sleeve 301 is fixedly installed on the end surface of one side of the mounting plate 4, and the movable sleeve of the fixed sleeve 3 is provided with a telescopic column. 302, the top ball 307 is fixed at the end of the telescopic column 302, and a bracket 303 is movable on the telescopic column 302. The end of the bracket 303 away from the telescopic column 302 is rotated by a rotating shaft 304 and a push plate 305 is installed. Both sides of the plate 305 are against the back plate 1, and a return spring 306 is connected between the push plate 305 and the bracket 303;

[0025] W...

Embodiment 2

[0038] In order to facilitate the cleaning and replacement of the filter screen 6, this embodiment has made further improvements on the basis of Embodiment 1. The improvement is: the horizontal movable card of the filter screen 6 is set in the chip collection groove 5, and the filter screen 6 The extension end is provided with a push-pull plate 19, through which the filter screen 6 can be easily inserted into the chip collection groove 5 or extracted from the chip collection groove 5, thereby facilitating the cleaning and replacement of the filter screen 6 and improving maintenance efficiency.

[0039] The chip recovery device for machine tool processing first pushes the chips and coolant on the platform 2 into the chip collection groove 5 through the pushing mechanism 3. When the pushing plate 305 in the pushing mechanism 3 advances, it contacts with the surface of the platform 2 to ensure that the chips The cleaning is thorough. When the push plate 305 returns, it will be sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com