Wing plate type stock bin discharging device

A discharger and flap-type technology, which is applied in the field of flap-type silo dischargers, can solve problems such as uneven discharge, low operating efficiency, and easy bridging, so as to ensure the discharge effect, improve the discharge efficiency, and avoid bridging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

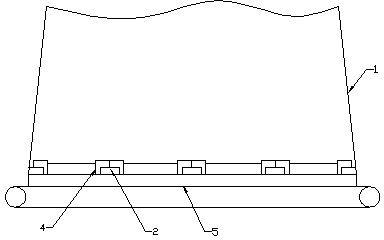

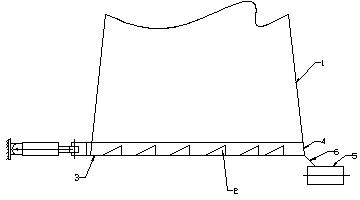

[0011] As shown in the figure, the wing-type silo discharger includes a silo body 1, which is a cone with a rectangular cross-section, a small upper opening and a large lower opening, and several rows of wing plates are arranged side by side at the bottom. 2. Each row of wing plates is connected to a slide bar 3 that can move back and forth longitudinally, and a discharge port 4 is provided on the front side of the bin body facing the wing plates, and a horizontal conveyor belt 5 is provided in front of the discharge port.

[0012] The front side of the wing plate 2 is a vertical surface, and the back side of the wing plate is a slope, so that the material will not be brought back when the wing plate retreats. An inclined material guide plate 6 is arranged between the discharge port 4 and the conveyor belt 5 . The slide bar 3 is driven by an oil cylinder 7 positioned at the rear side of the bin body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com