Carbon dioxide recovery system

A carbon dioxide recovery system technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems such as increased recovery costs, waste of energy, work impact, etc., achieve great economic and social benefits, and improve adsorption and purification Effect, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

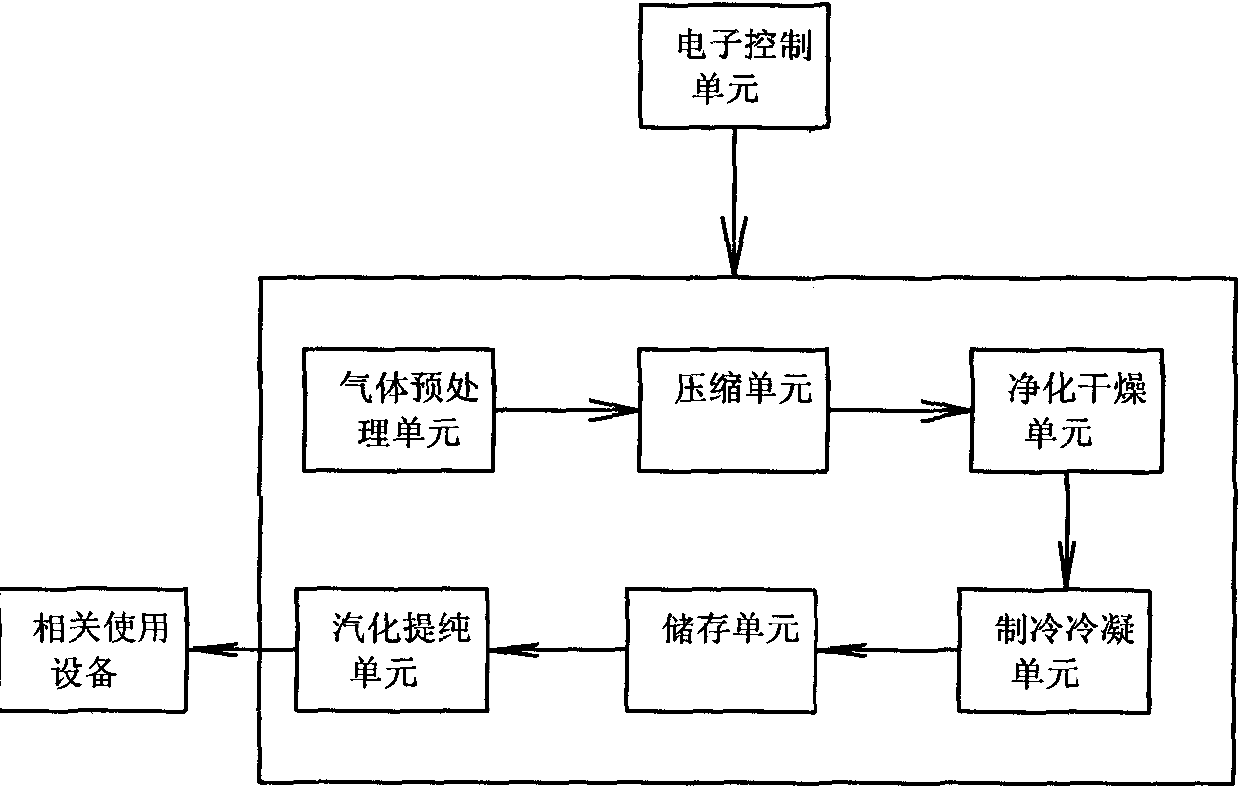

[0017] The system is controlled by Siemens plc. Through the optimal control of the system, the various parts of the system can work in harmony, always running in an economical state, so that the power consumption of the system is the lowest; the system has perfect safety protection measures, and the system can be mastered at any time through various detection devices The operating status of the equipment ensures the safe operation of the equipment and the personal safety of the operators.

[0018] System composition:

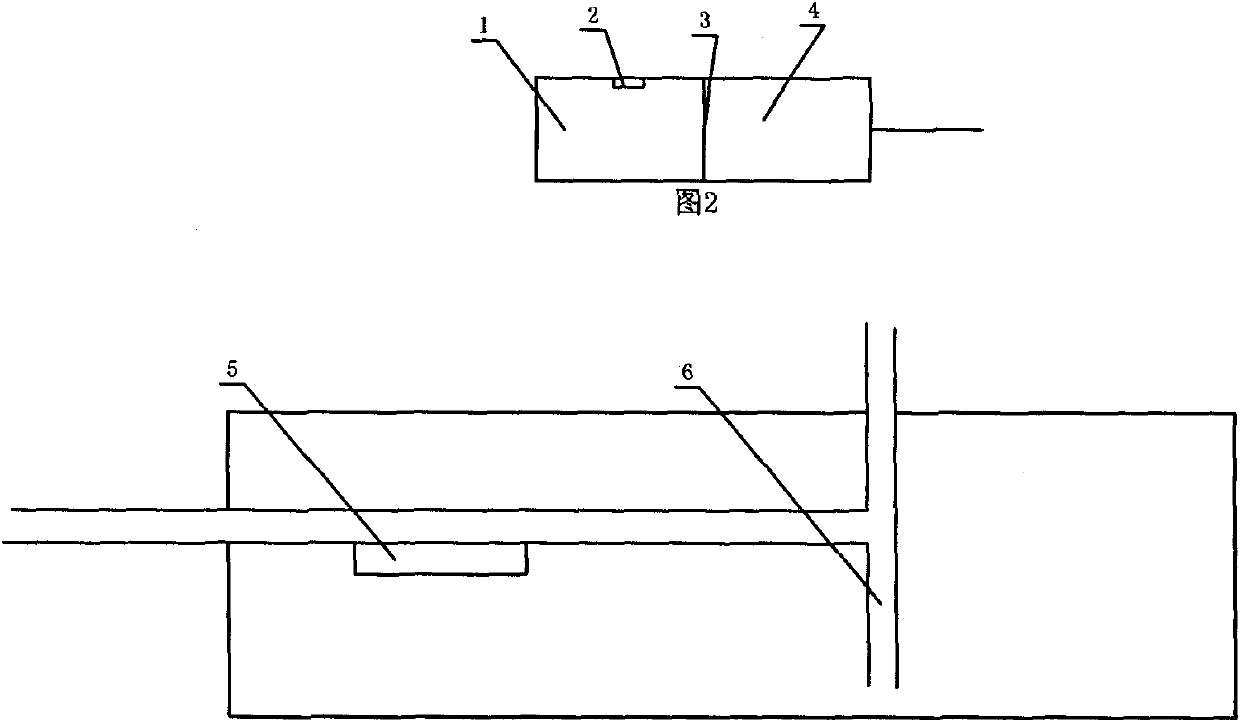

[0019] 1) Pretreatment and purification unit: including demister 1, air bag 4, washing tower, etc., through the pretreatment system, impurities in the carbon dioxide recovery gas are removed, the system pressure is stabilized and balanced, and the compressor unit has good working and operating conditions.

[0020] 1.1 Demister 1: The foam detection and control system of the imported gas is sprayed with water to achieve the purpose of effectively removing foam. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com