Patents

Literature

47results about How to "Good for cleaning and recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

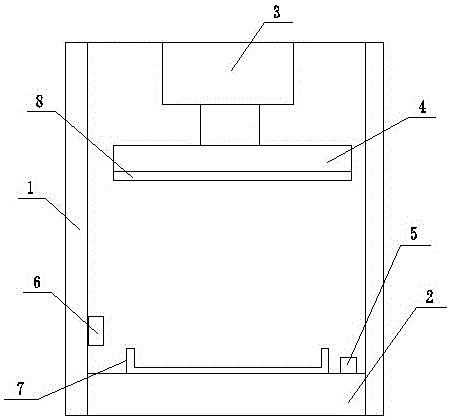

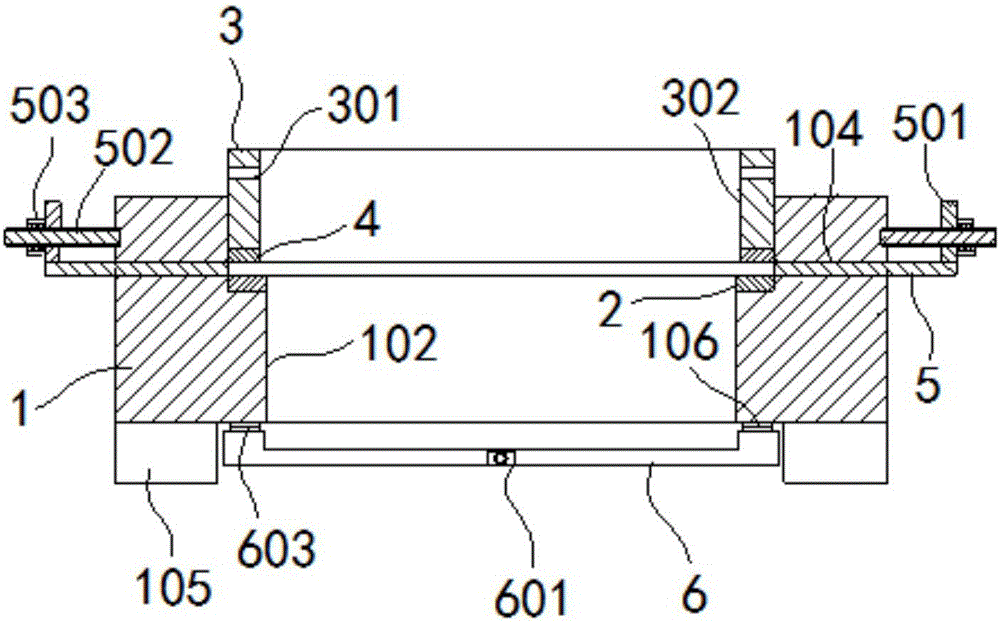

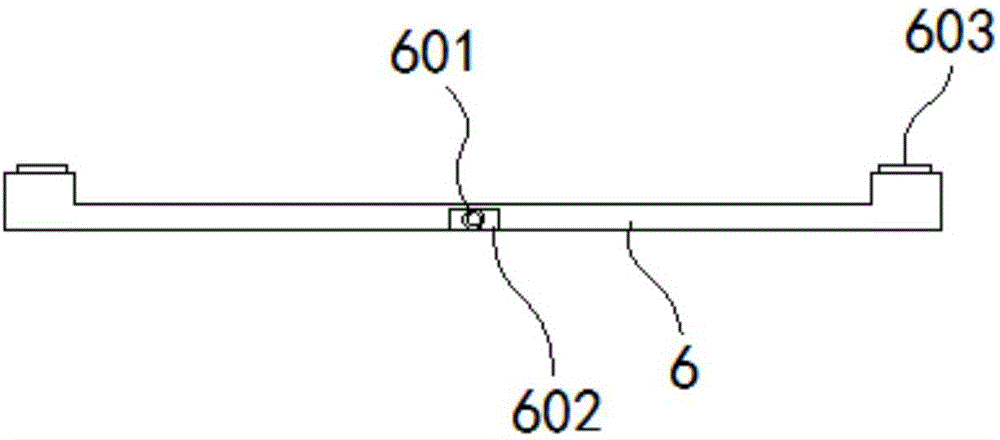

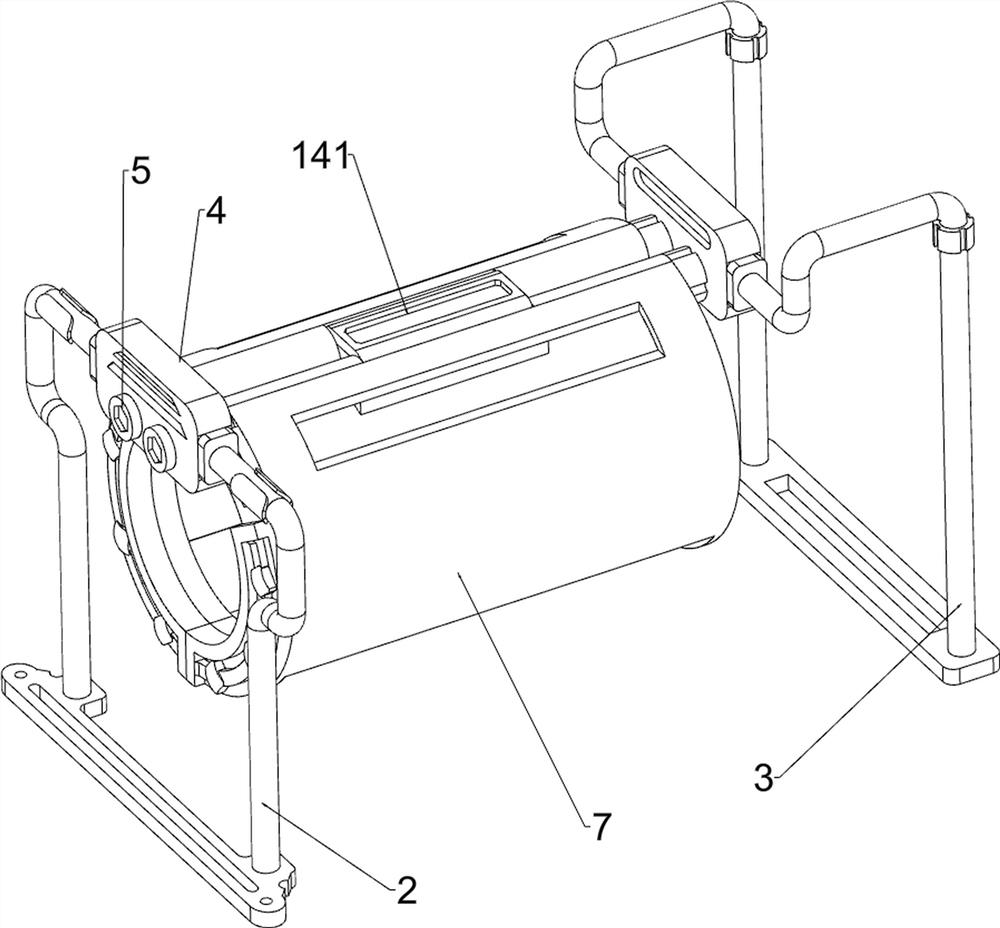

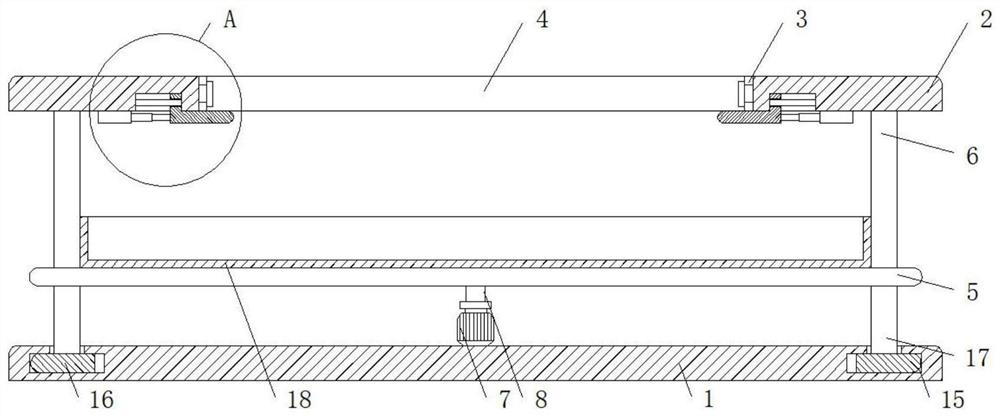

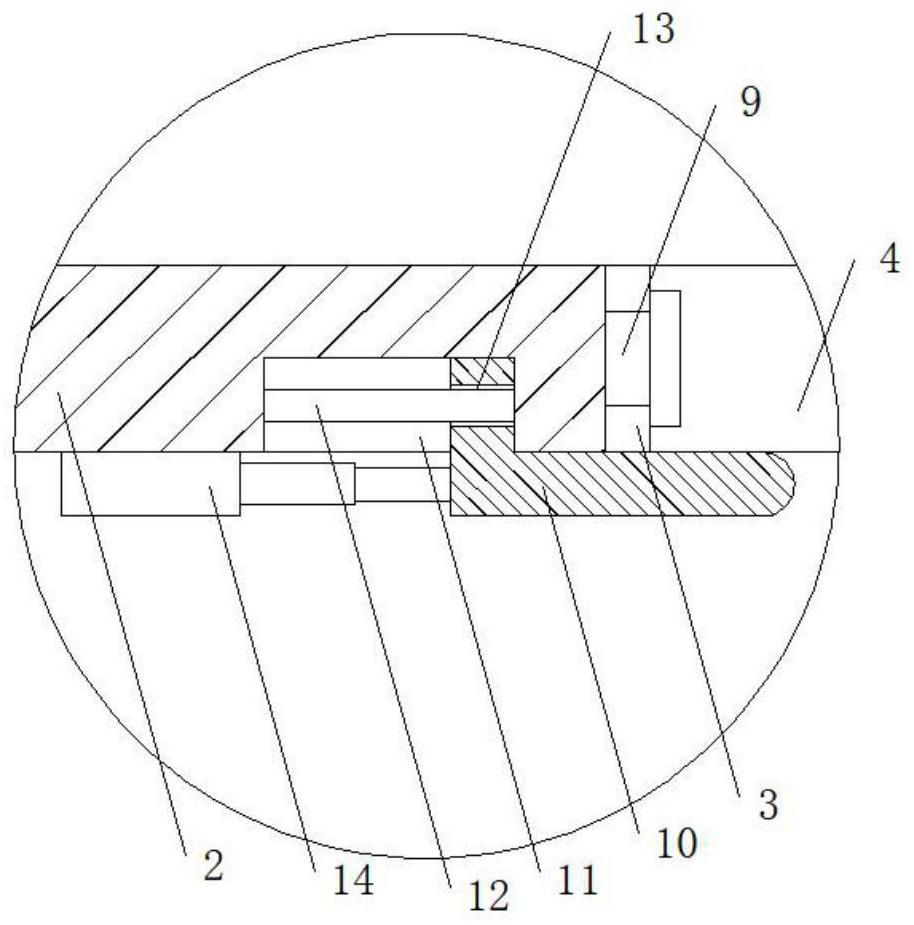

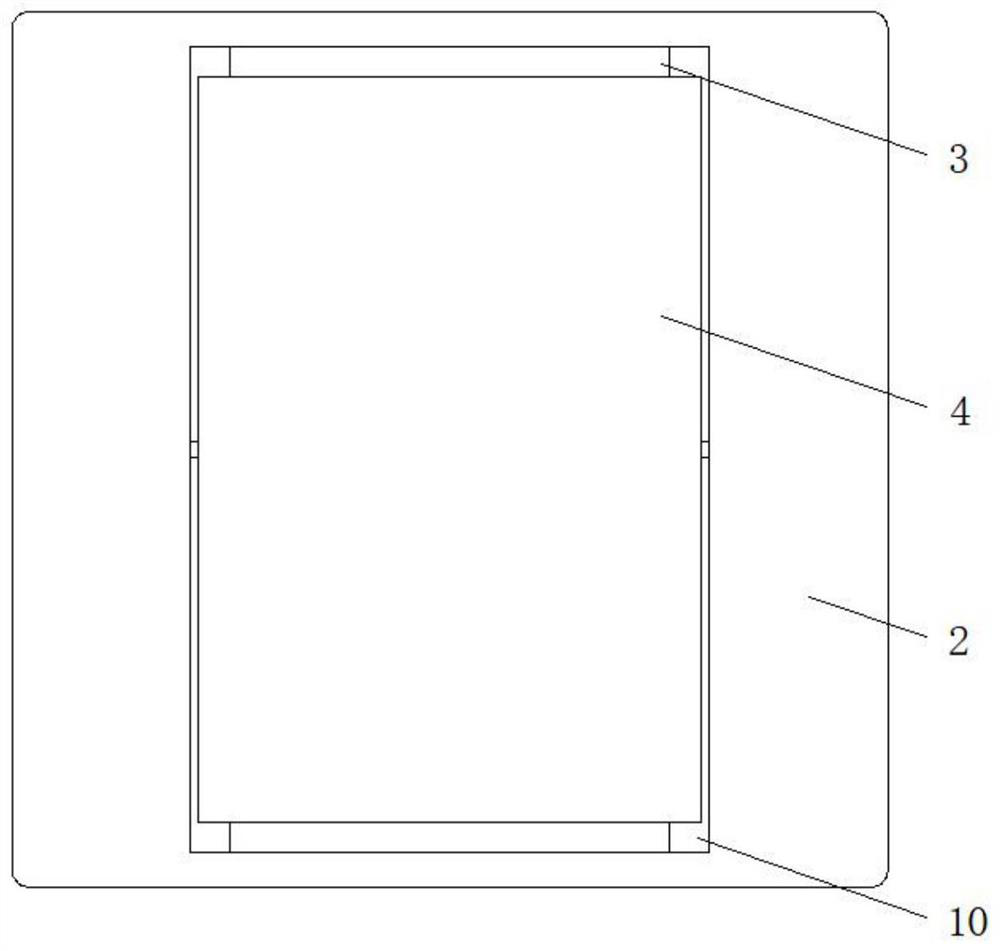

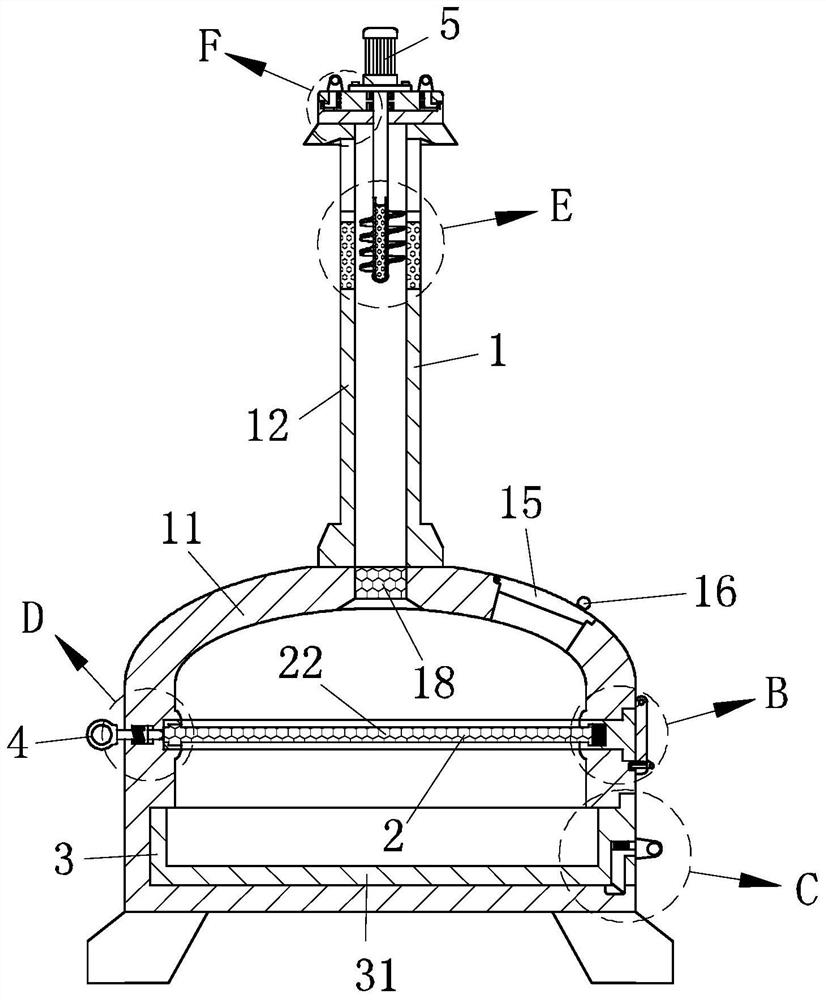

Package sealing airtightness detection device

InactiveCN105136396APrevent leakageGood for cleaning and recyclingUsing mechanical meansFluid-tightness measurement using fluid/vacuumEngineeringAir tightness

The invention discloses a package sealing airtightness detection device, and the device comprises a rack, a supporting platform disposed on the rack, an air cylinder disposed on the rack, a pressure plate which is connected with the air cylinder and located exactly above the supporting plate, a pressure sensor which is disposed on the supporting platform, and an image collection sensor which is disposed on the rack and faces the supporting platform. The pressure plate is used for applying pressure to a package bag, and the pressure sensor detects the value of the pressure. The image collection sensor monitors the condition of the package bag, thereby judging whether the sealing of the package bag meets the requirements.

Owner:ANHUI YUANHONG MACHINERY AUTOMATION

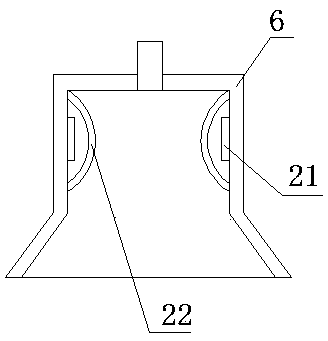

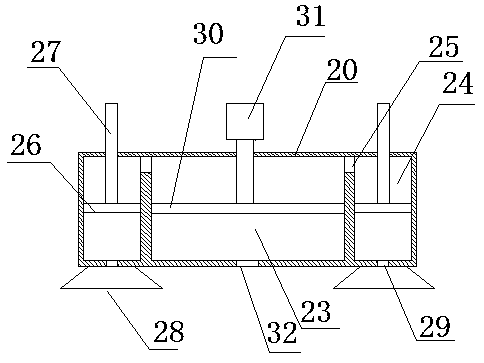

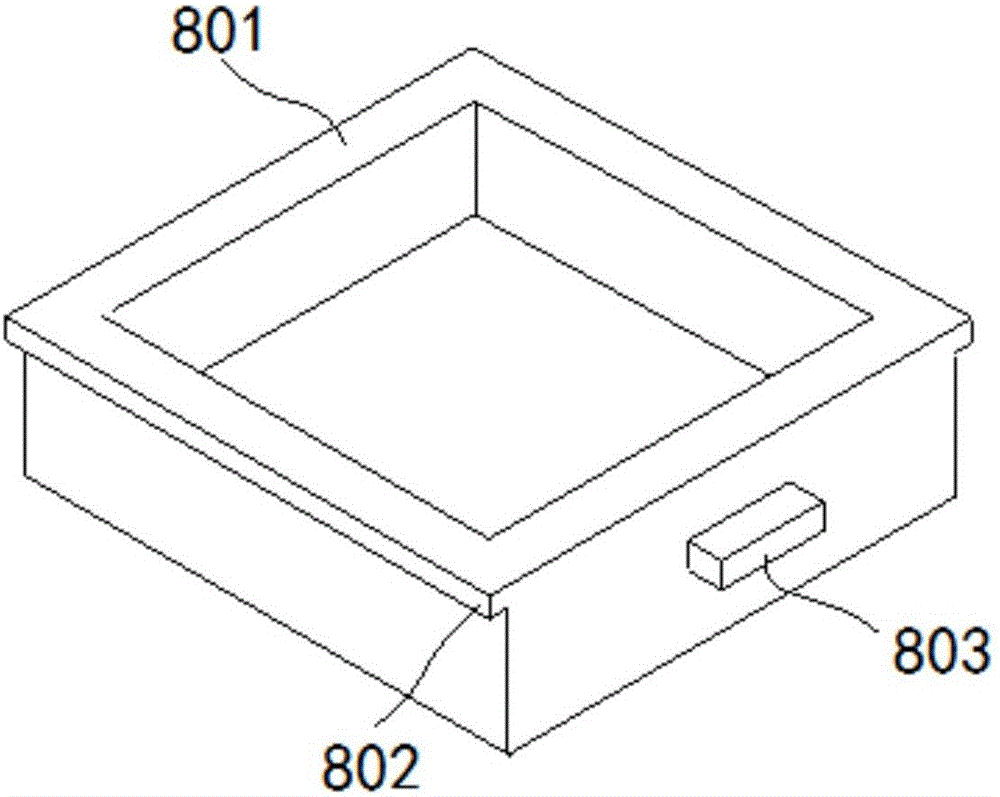

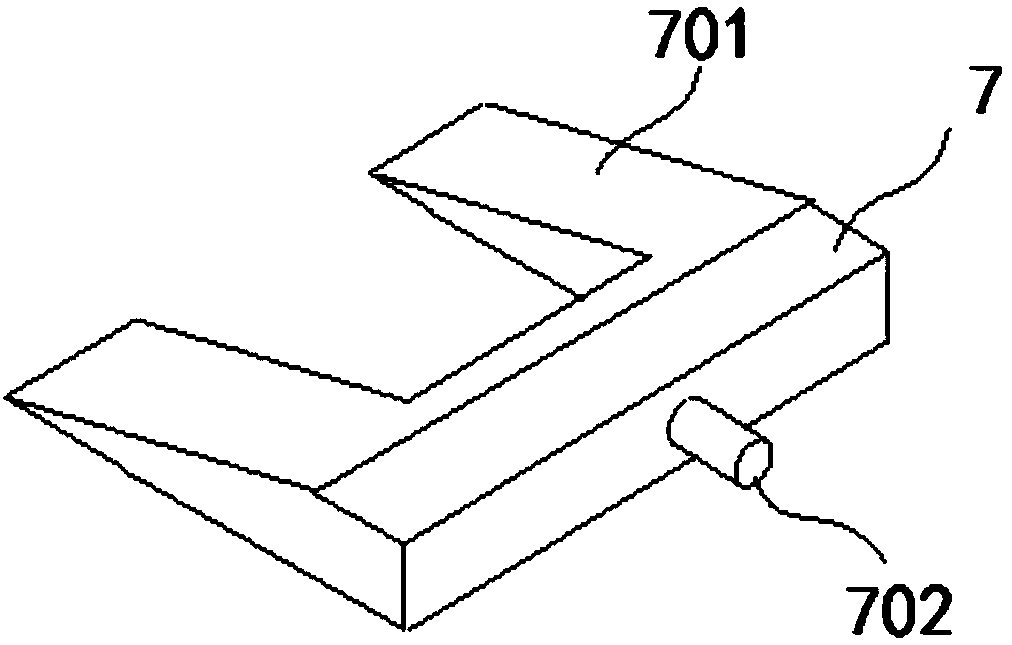

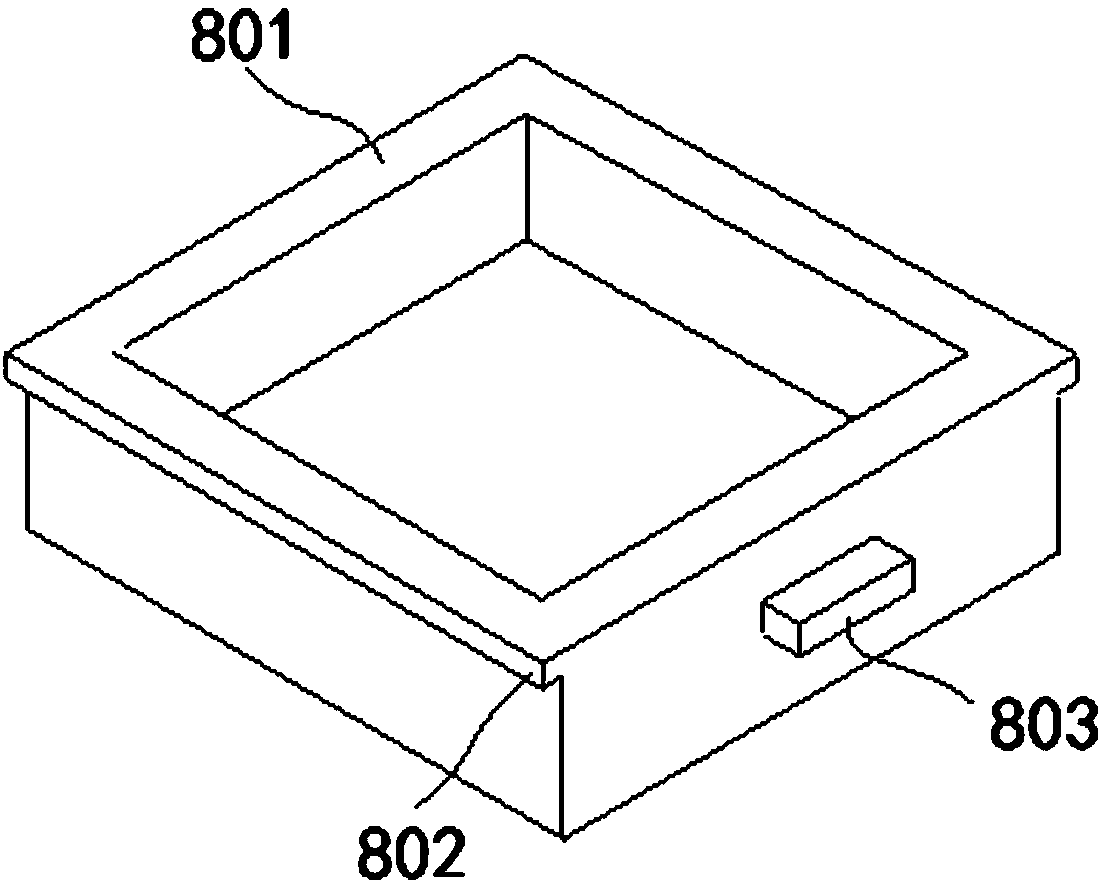

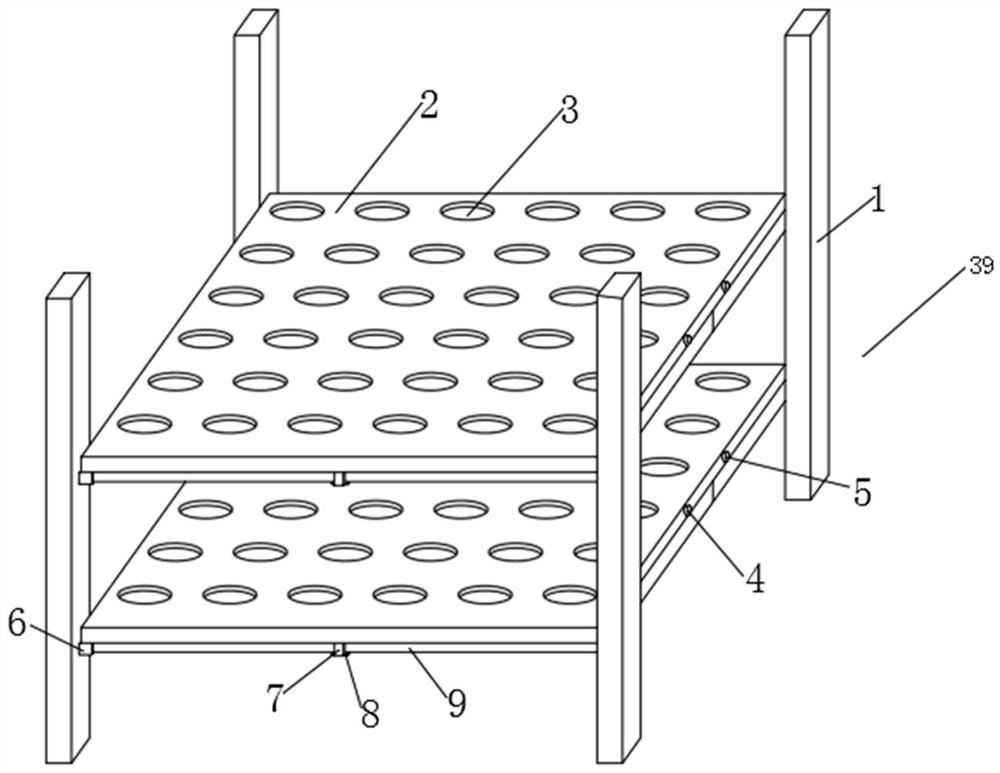

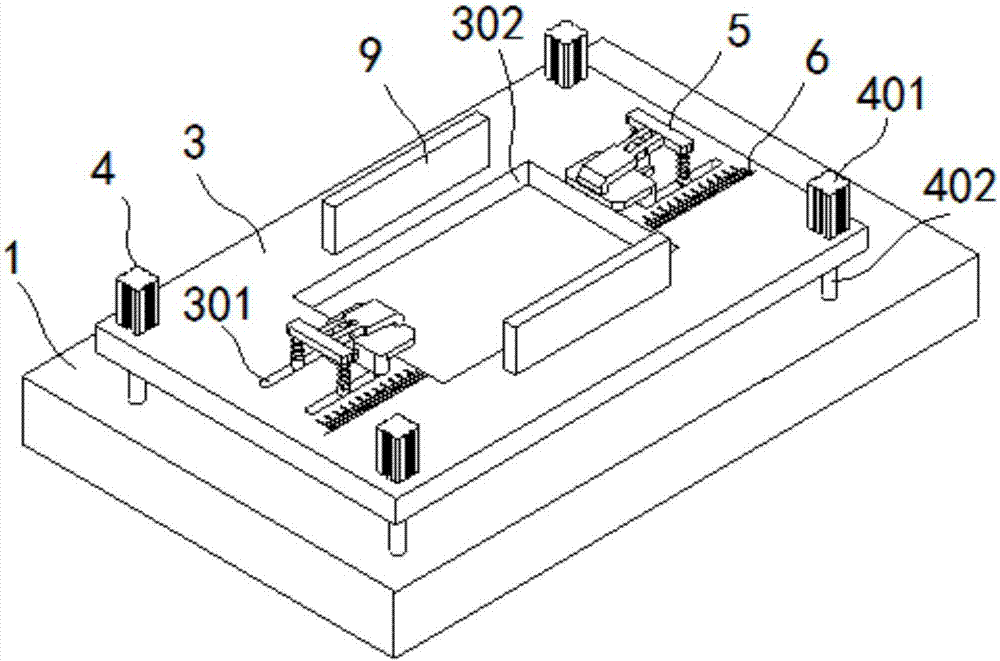

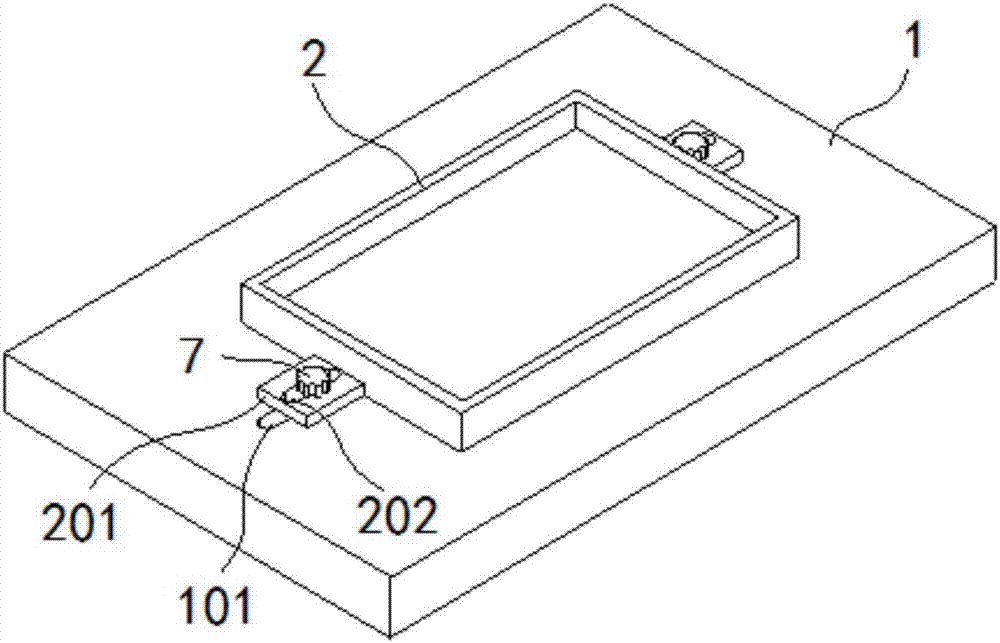

Plate clamping device for laser cutting equipment

InactiveCN106312340AEasy to installEasy to disassembleWelding/cutting auxillary devicesAuxillary welding devicesBiochemical engineeringLaser cutting

The invention discloses a plate clamping device for laser cutting equipment. The device comprises a bottom plate, a discharging box, a processing plate, lifting cylinders, clamping seats and baffles. By means of the clamping seats arranged on the processing plate, a plate can be conveniently mounted and dismounted, the clamping is reliable, and the stability is high; besides, the clamping seats can be moved according to the size of the plate, therefore, the application range is broad. By the arrangement of the discharging box which is equipped with a mounting plate and is detachably arranged on the bottom plate, waste can be cleaned and recycled conveniently. The device is simple in structure, convenient to operate, high in reliability and good in stability.

Owner:重庆聚纵贸易有限公司

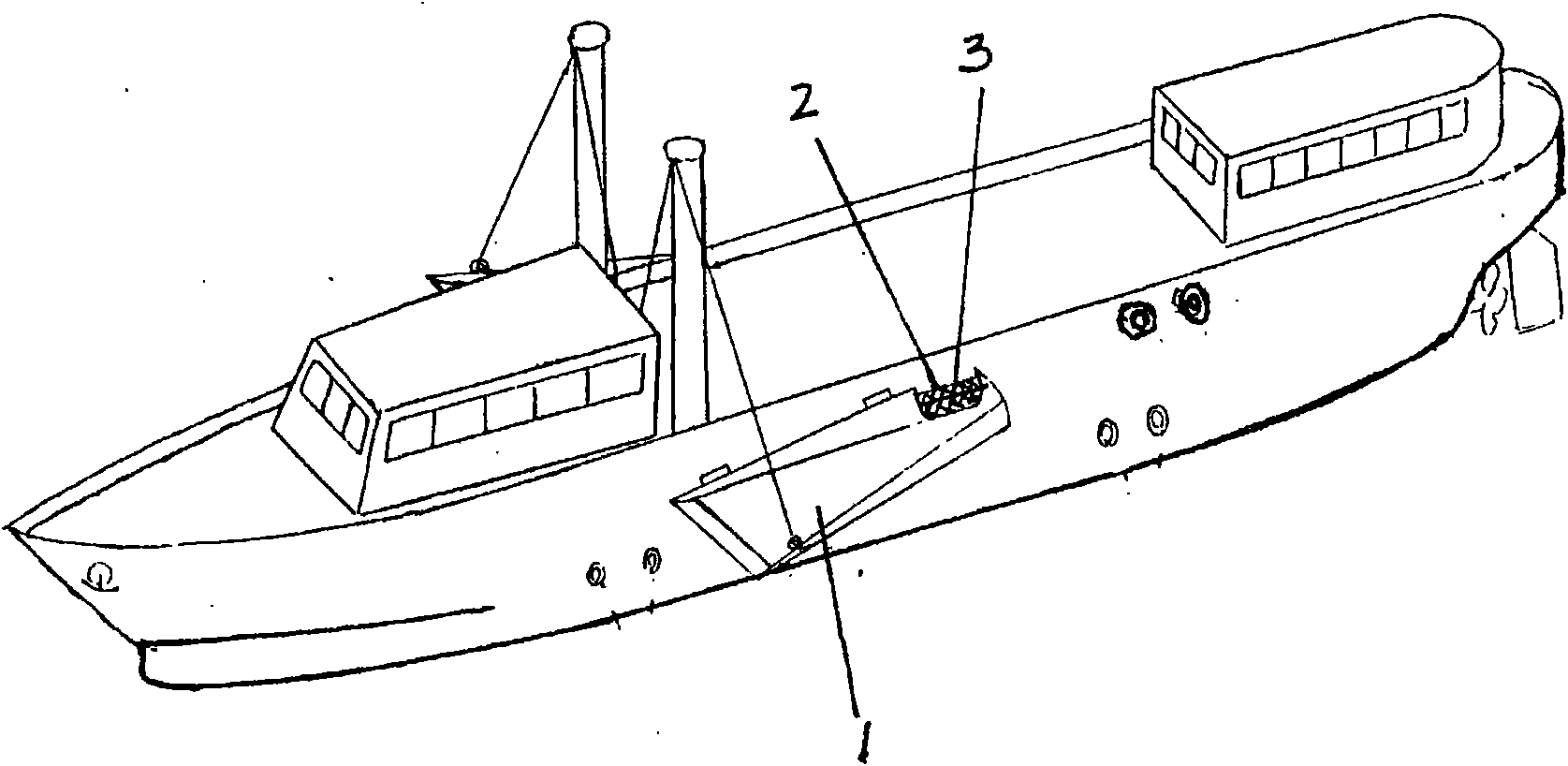

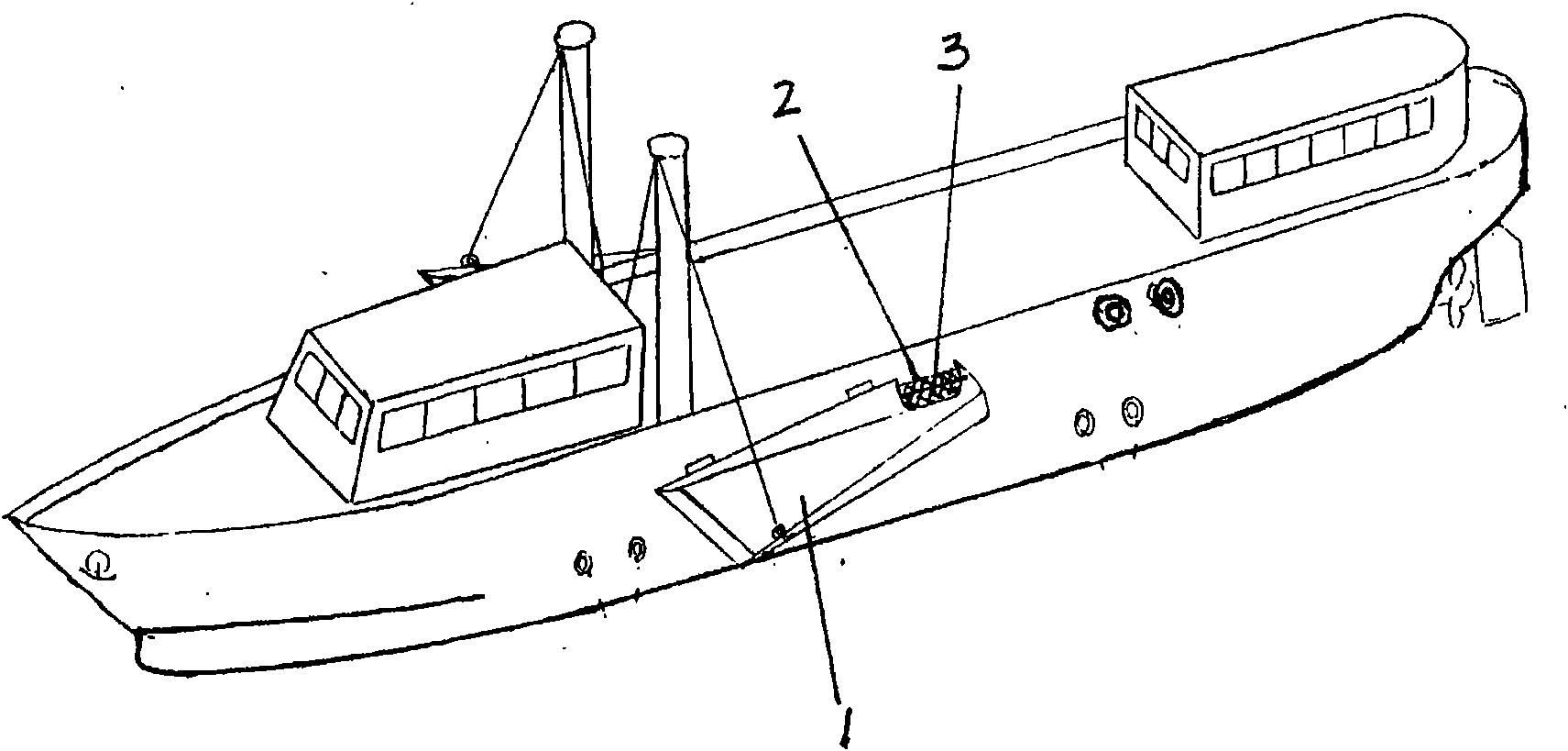

Oil slick collecting ship

InactiveCN101920767AGood for cleaning and recyclingWater cleaningWaterborne vesselsMarine engineering

Owner:季纯一

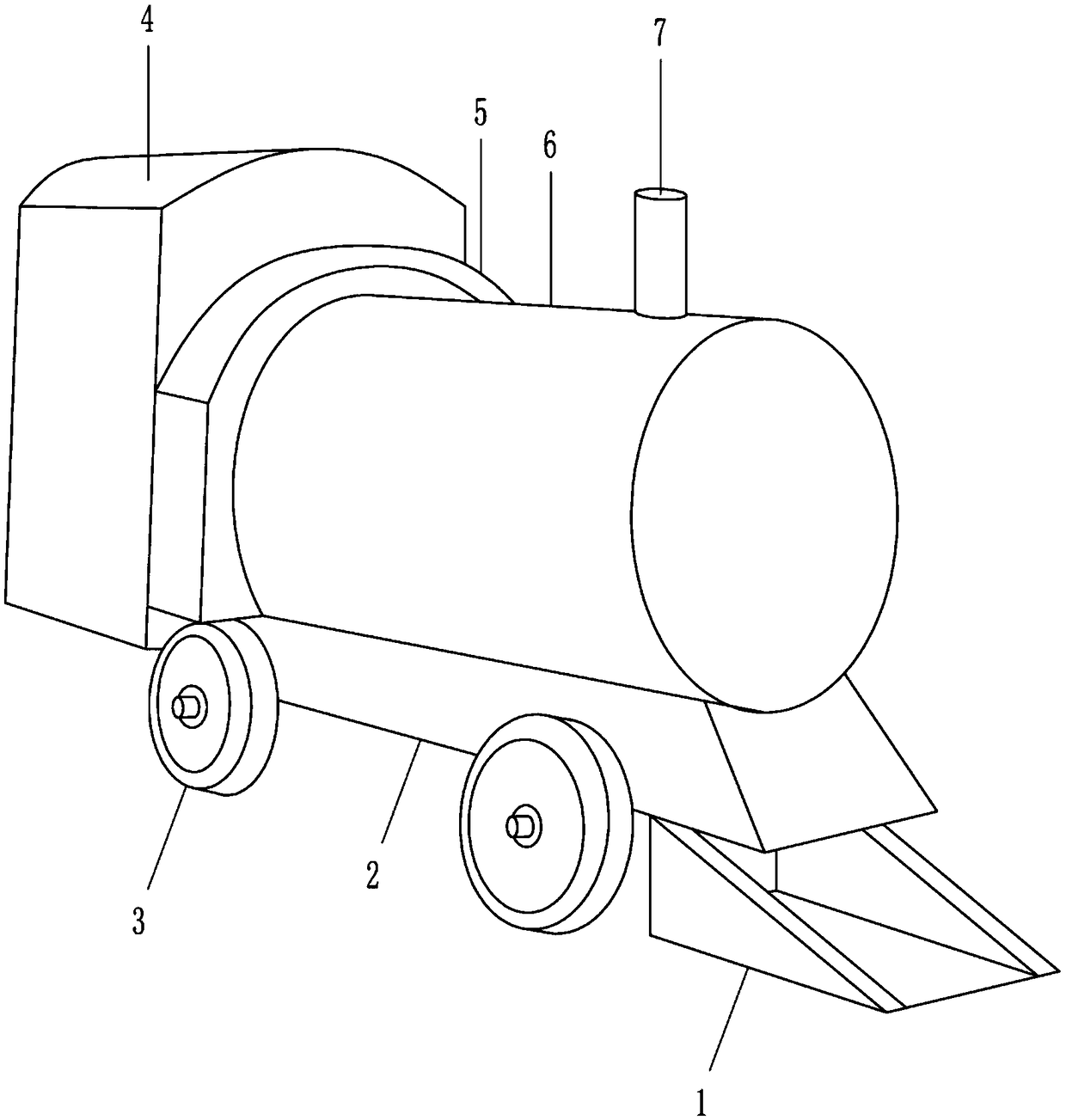

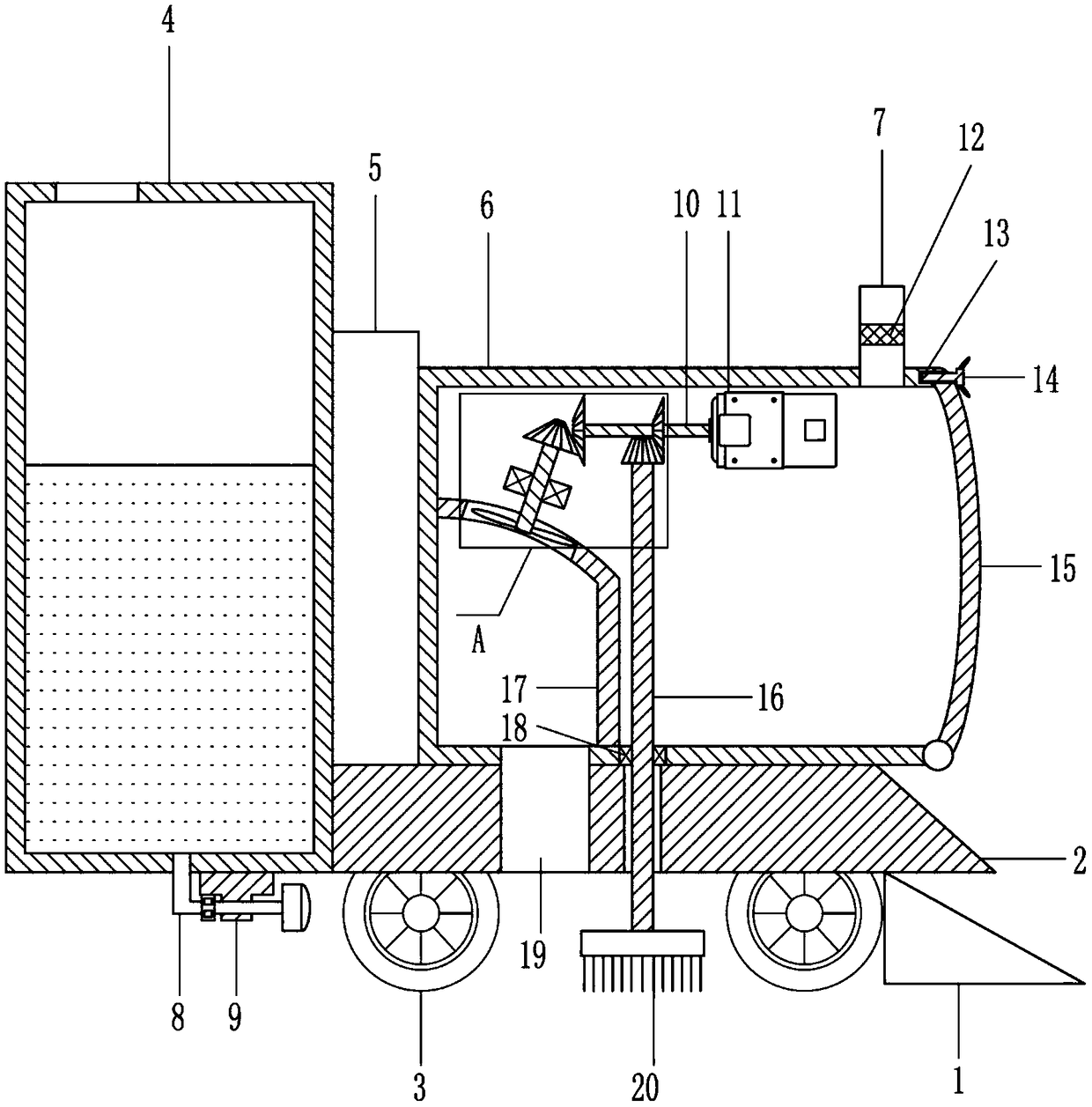

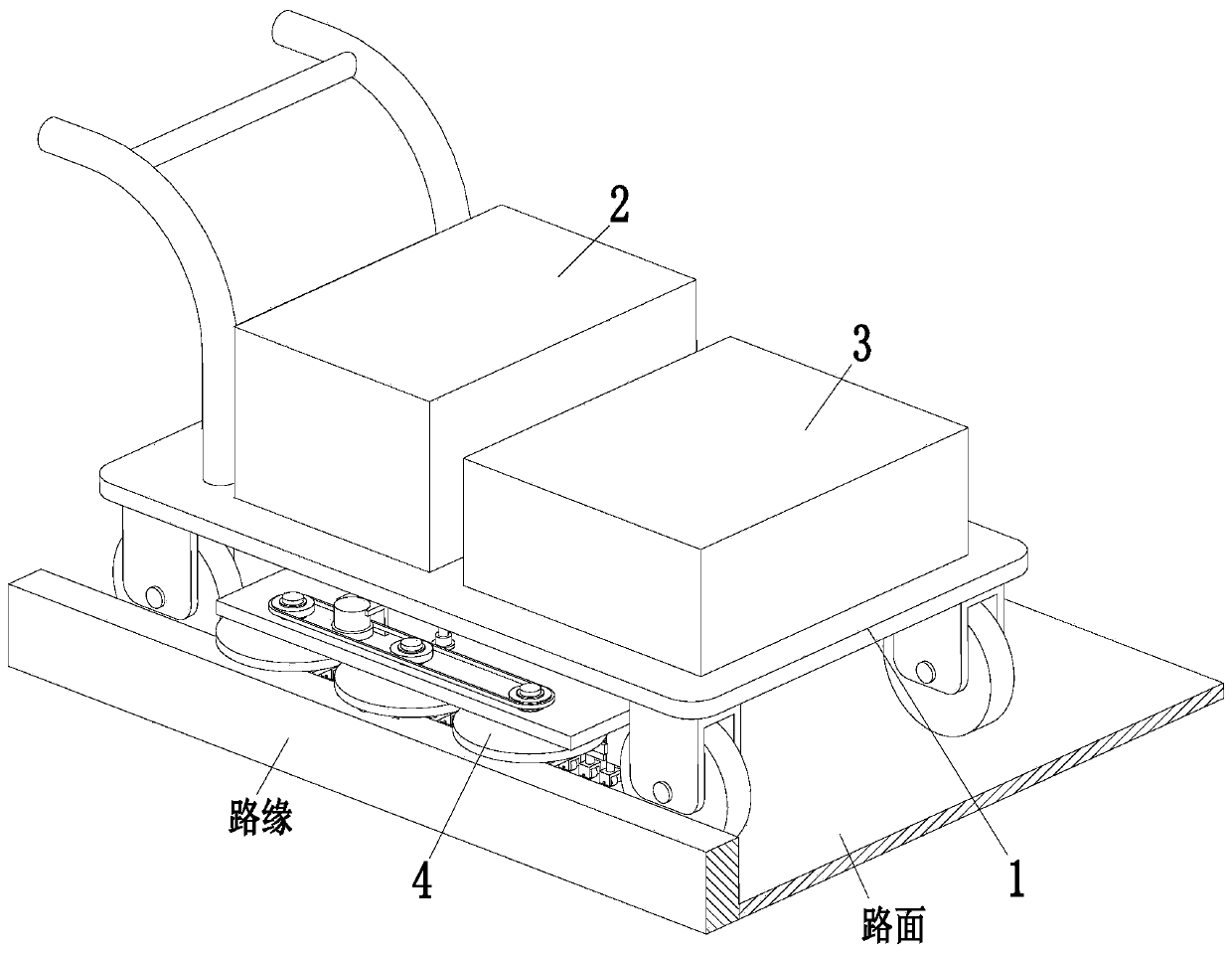

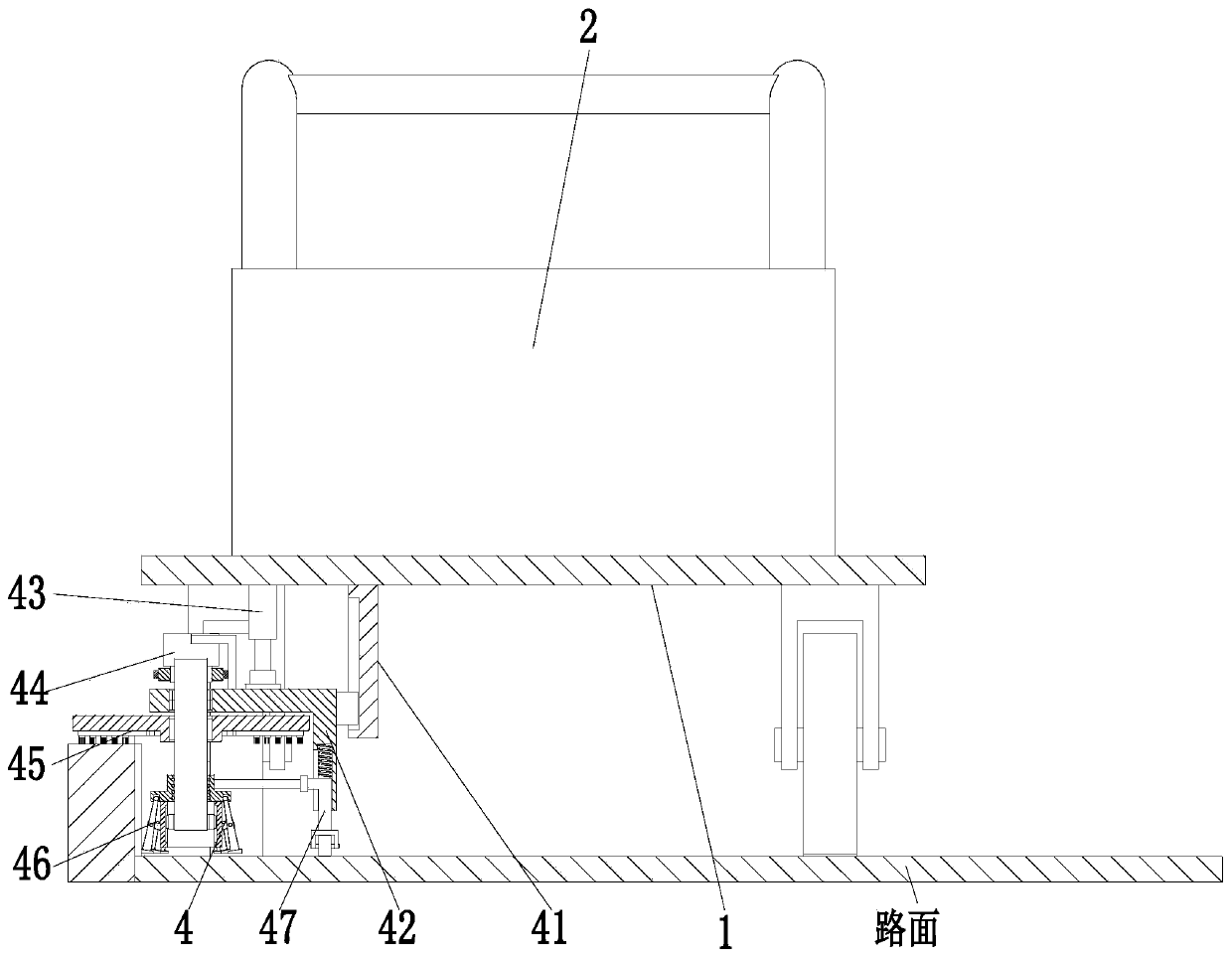

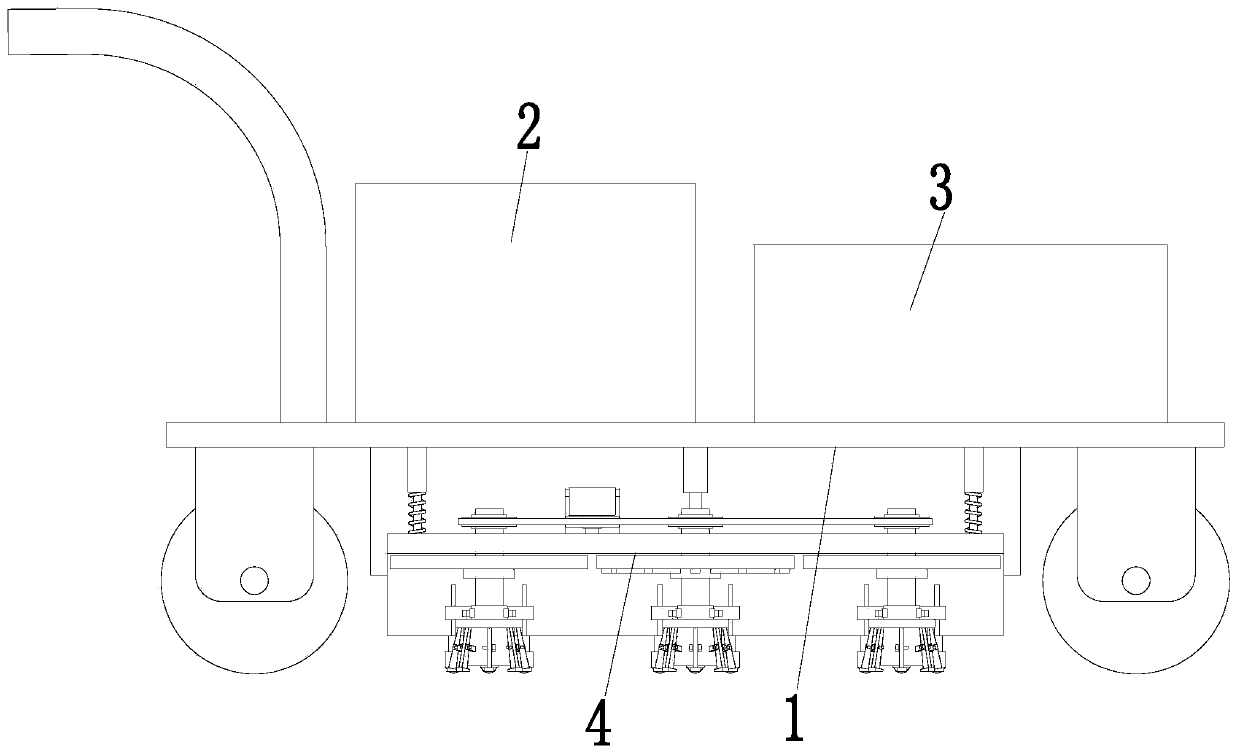

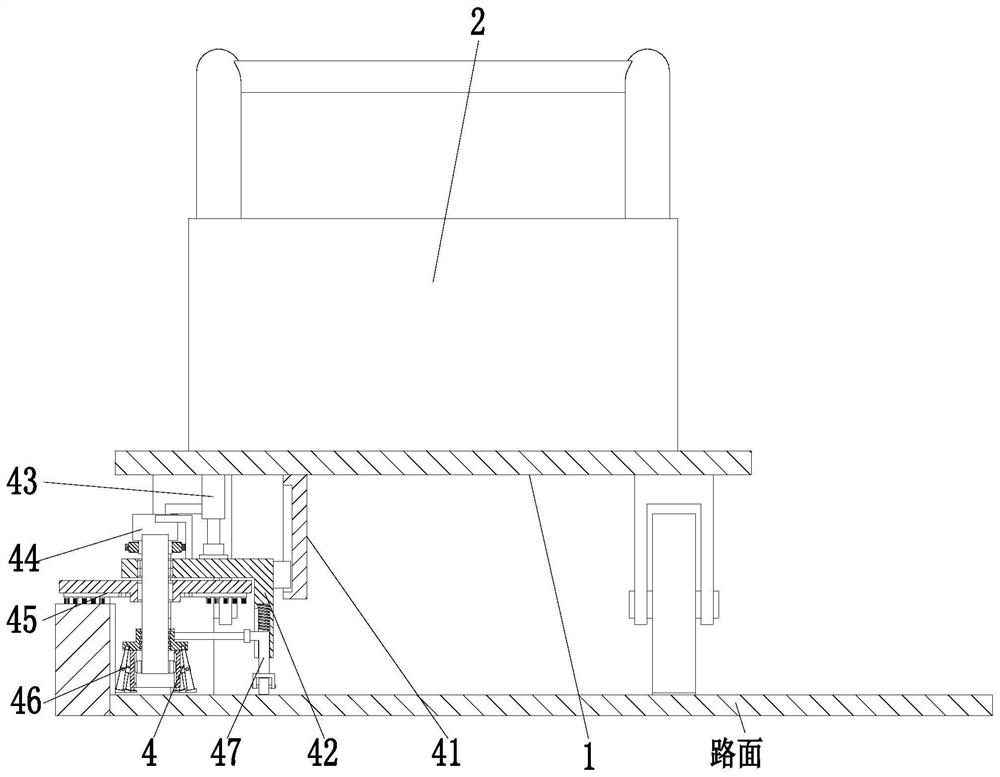

Self-propelled bridge surface cleaning vehicle

ActiveCN108824309AGood for cleaning and recyclingInhibition is effectiveRoad cleaningWater storageSurface cleaning

The invention relates to the field of bridges, in particular to a self-propelled bridge surface cleaning vehicle. The invention aims at providing the self-propelled bridge surface cleaning vehicle which is safe, reliable and capable of conveniently cleaning up and recycling garbage on a bridge surface. The self-propelled bridge surface cleaning vehicle includes an object shoveling bucket, a mounting plate, electric wheels, a water storage bucket, a partition plate, a garbage recycling box, an air exhaust pipe, an electric spray gun, a fixing base, a first rotation shaft, a motor, a first wetting mesh plate, a butterfly-shaped bolt, a cover plate, a second rotation shaft, a mounting hood, a first bearing base, a first brush plate, a first bevel gear, a second bevel gear, a third bevel gear,a fourth bevel gear, a third rotation shaft, a second bearing base and fan blades. The self-propelled bridge surface cleaning vehicle is safe, reliable and capable of conveniently cleaning up and recycling the garbage on the bridge surface and can effectively treat and inhibit dust on the bridge surface.

Owner:GUANGZHOU RAPID TRANSIT CONSTR

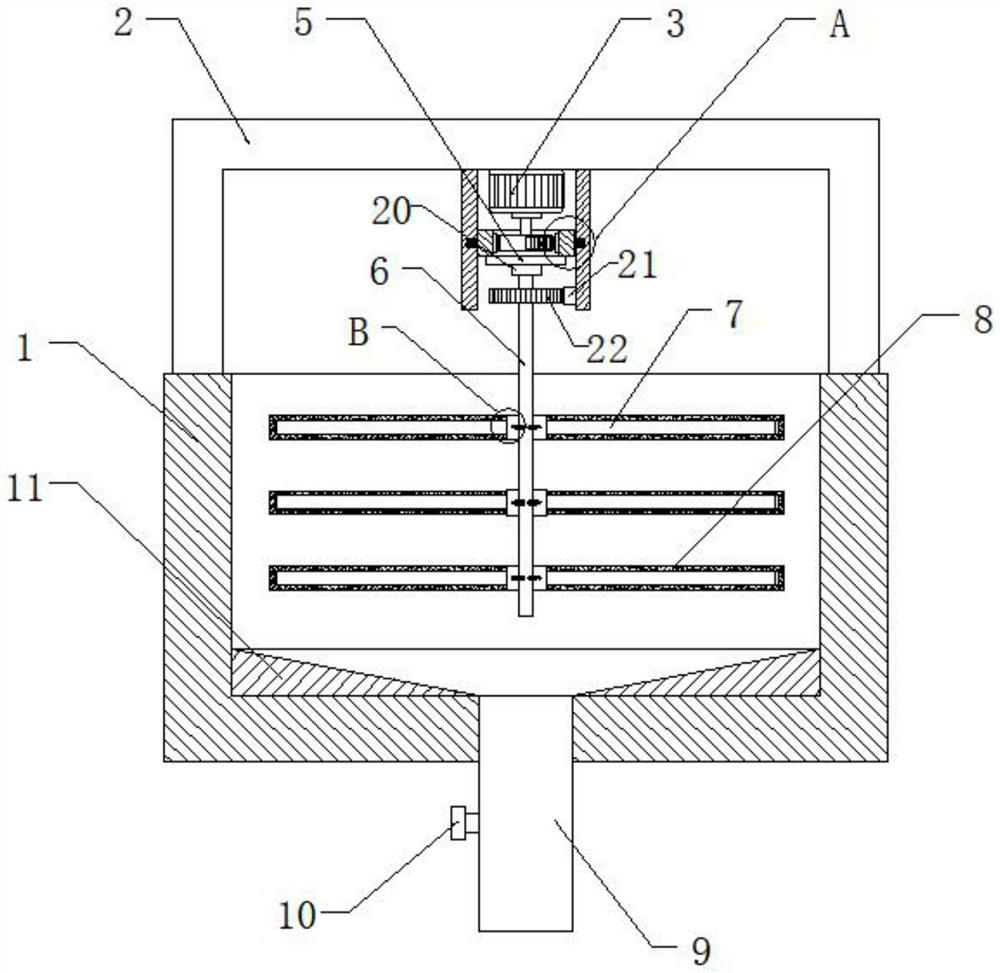

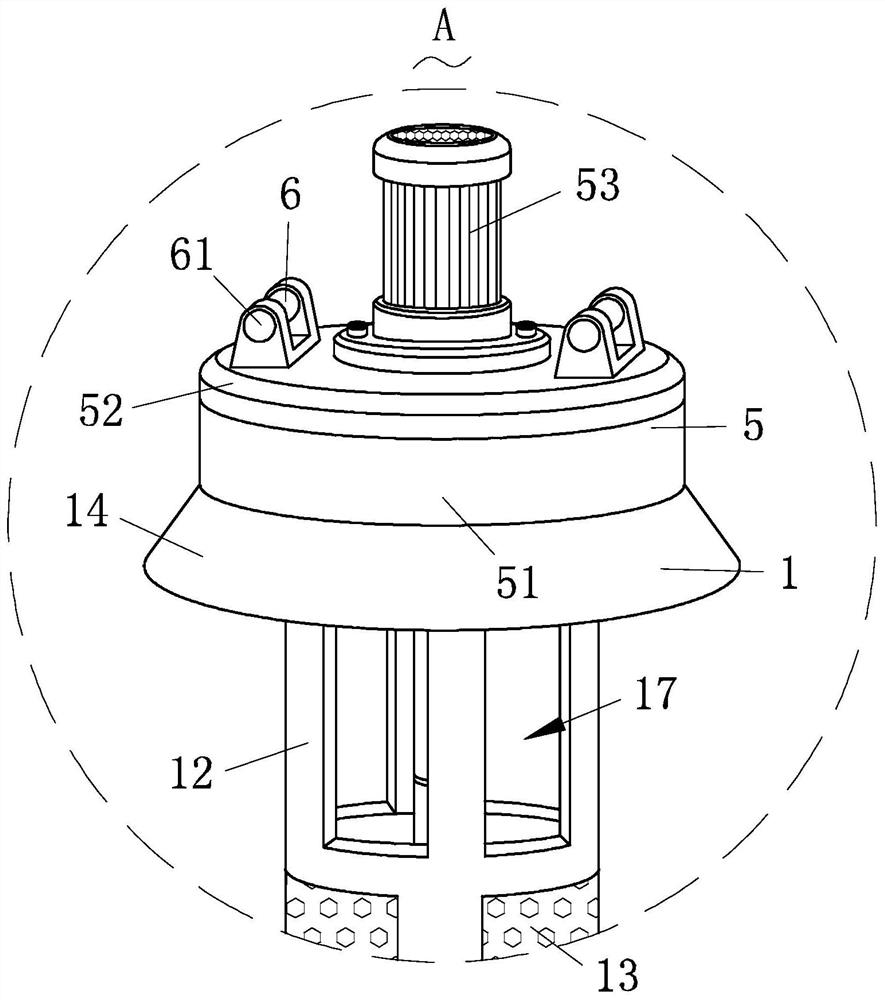

Dedusting device for crusher

InactiveCN110694783AGood for cleaning and recyclingEasy to repair and replaceCombination devicesDirt cleaningElectric machineryDust control

The invention relates to the technical field of dedusting, in particular to a dedusting device for a crusher. The device comprises a box and a base, the box comprises an upper box body and a lower boxbody, and the left and right sides of the lower box body are provided with supporting plates; the upper sides of the supporting plates are provided with first electric retractable mechanisms, the upper ends of the first electric retractable mechanisms are provided with mounting bases, and a rotation motor is installed on the mounting base of the right side and connected with the upper box body; the right side of the upper box body is provided with a rotation shaft, and the right end of the rotation shaft is connected with the mounting base through a bearing pedestal. Through structural arrangement of the device, after dedusting work is completed, through the first electric retractable mechanisms, the upper box body and the lower box body can be separated, the rotation motor drives the upper box body to rotate so as to adjust the angle of the upper box, iron scraps are conveniently removed and recycled, the time and labor are saved, convenience is also provided for following maintenance and replacement, and the practicability is high.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Road surface sweeping and cleaning environmental sanitation equipment

The invention relates to road surface sweeping and cleaning environmental sanitation equipment. The equipment comprises a moving frame, a dust collecting box, a water tank and a cleaning device, rollers are symmetrically mounted at the lower end of the moving frame, the dust collecting box is mounted on the left side of the upper end of the moving frame, the water tank is mounted on the right sideof the upper end of the moving frame, and the cleaning device is mounted on the front side of the lower end of the moving frame. When the existing equipment is used for cleaning a road surface, the sweeping is poor in effect, the included angle between the road surface and the curb cannot be effectively swept, and a large amount of dust is left in the included angle between the road surface and the curb and the cleaning effect of the road surface is affected, the problems that when an existing device is used for sweeping the road surface, garbage on the upper layer of the curb cannot be swept, the device cannot perform quick adjustment according to the height of the curb and the height of the road surface, and the using effect of the equipment is affected are solved.

Owner:成都子阳清洁服务有限公司

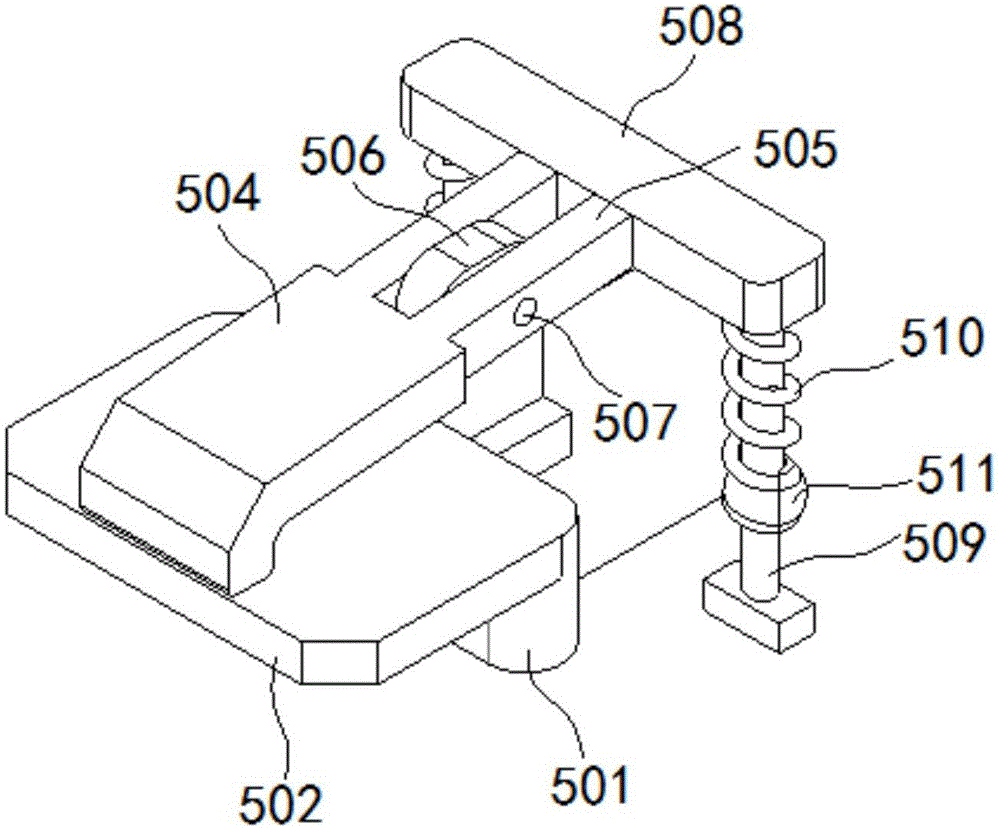

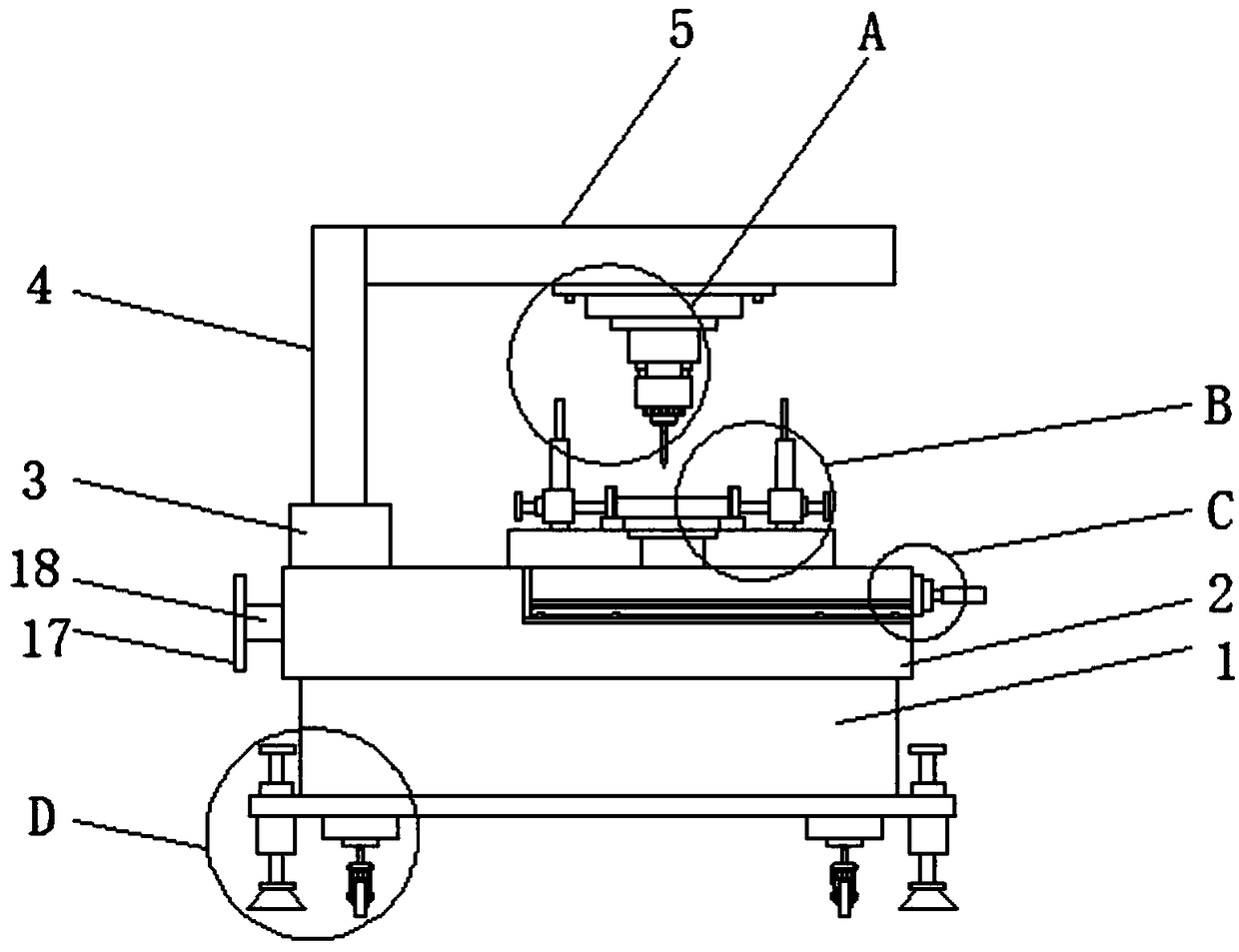

Bearing drilling equipment facilitating waste removal

PendingCN108637305AEasy to cleanEasy to operateBearing componentsLarge fixed membersThreaded rodPetroleum engineering

The invention relates to the technical field of bearing machining equipment, and discloses bearing drilling equipment facilitating waste removal. The bearing drilling equipment comprises a storage battery body, a working table is fixedly connected to the top of a bottom box, a fixing base is fixedly connected to one side of the top of the working table, a supporting column is fixedly connected tothe top of the fixing base, a transverse beam is fixedly connected to one side of the supporting column, and the bottom of the transverse beam is in threaded connection with a connecting plate througha bolt. According to the bearing drilling equipment facilitating waste removal, a bearing body is placed on the top of a support block through a clamping mechanism, a first threaded rod is manually adjusted, the bearing body is clamped through a clamping block, the position of the bearing body is fixed, running of a drilling mechanism is facilitated, and the bearing body is drilled; a leakage groove and a connecting pipe are matched, and therefore scrap iron generated by drilling is attracted by a magnet of a collecting device to enter a drawer body; and a roller facilitates holding of a holding handle for pushing, puling , cleaning and recovering, and the aim of facilitating cleaning is achieved.

Owner:ZHEJIANG DEMEI BEARING

Planar rotary capacitor welding manipulator

PendingCN113878194AImprove welding precisionPlay the role of positioningWelding/soldering/cutting articlesMetal working apparatusPhysicsCircular disc

The invention discloses a planar rotary capacitor welding manipulator which comprises a mounting plate, a disc is fixedly connected to the surface of the mounting plate, a connecting shaft is fixedly connected to the disc, a rotating seat is fixedly connected to the connecting shaft, a plurality of clamping blocks are fixedly mounted on the surface of the rotating seat, heat insulation plates are fixedly connected to the surfaces of the clamping blocks, and welding grooves are formed in the two sides of each heat insulation plate. The welding grooves are fixedly connected to the surfaces of the clamping blocks, a connecting seat is fixedly connected to the mounting plate, and a welding device is fixedly mounted on the connecting seat; and compared with the prior art, the surface of one end of a capacitor can extrude one side of a buffer plate, limiting holes in the buffer plate can play a role in positioning, welding pins of the capacitor can penetrate through the limiting holes, when an operator does not align at the limiting holes, the surface of the buffer plate can incline to a certain degree, the capacitor can not move inwards, the reminding effect is achieved, and the situation that welding precision is poor in the welding process, and welding efficiency and quality are affected is avoided.

Owner:祁红业

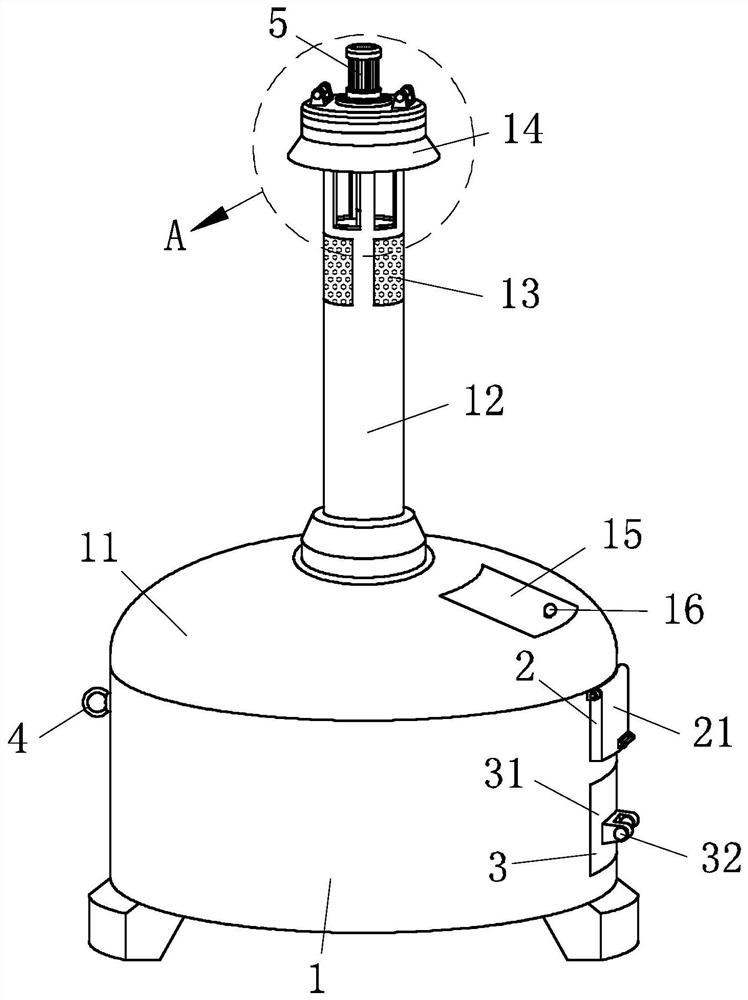

Self-flowing sewage treatment process for fixed sewage treatment plant on lake

InactiveCN111661973AImprove filtering effectEasy to cleanMixing methodsTransportation and packagingSludgeFiltration

The invention discloses a self-flowing sewage treatment process for a fixed sewage treatment plant on a lake. According to the sewage treatment process, filtration and aeration work are carried out inan integrated sewage treatment device at the same time, sewage is filtered firstly and then subjected to aeration work, the integrated sewage treatment device comprises a channel, and two first vertical plates are vertically and symmetrically arranged on the upper surface of the channel. The invention relates to the technical field of sewage treatment. One side of a scraping plate is in close contact with one side surface of a grid, after the grid works for a period of time, sludge and garbage can be accumulated in a net cage, then under rotation of a servo motor, the garbage and the sludge can be lifted up, manual cleaning is facilitated, in the lifting process, and the scraping plate can scrape off the garbage on the grid and enable the garbage to fall into the net cage, so the filtering effect of the grid can be improved.

Owner:WUHAN YONGQING ENVIRONMENTAL PROTECTION TECH ENG

Pipeline detector for surveying and mapping and use method thereof

PendingCN114637055AGood for cleaning and recyclingAchieve recyclingRoad cleaningGeological measurementsDisplay deviceEngineering

The invention relates to a surveying and mapping pipeline detector and a using method thereof, and relates to the field of pipeline detectors, the surveying and mapping pipeline detector comprises a transmitter and a receiver, the receiver comprises a receiver body, a handle and a display, the handle is fixedly arranged on one side of the upper end part of the receiver body, and the display is fixedly arranged at one end, away from the receiver body, of the handle; a powder box is arranged on one side of the lower end of the receiver body, a discharging port is formed in the lower end of the powder box, the receiver body is provided with a driving device for driving the discharging port to be opened and closed, the receiver body is provided with a fan, one air opening of the fan is communicated with a first air pipe, and the end, away from the fan, of the first air pipe extends to the lower end of the receiver body. Before powder is scattered and marked, the fan can be used for blowing air to the ground for cleaning, and the effect that the powder is convenient to clean and recycle is achieved.

Owner:烟台市地理信息中心 +1

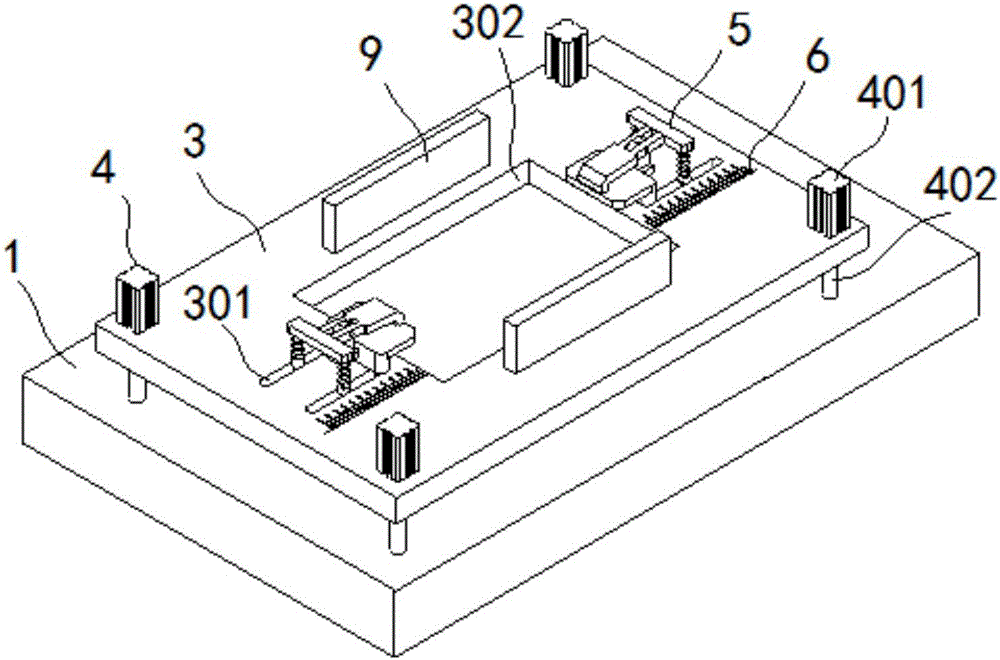

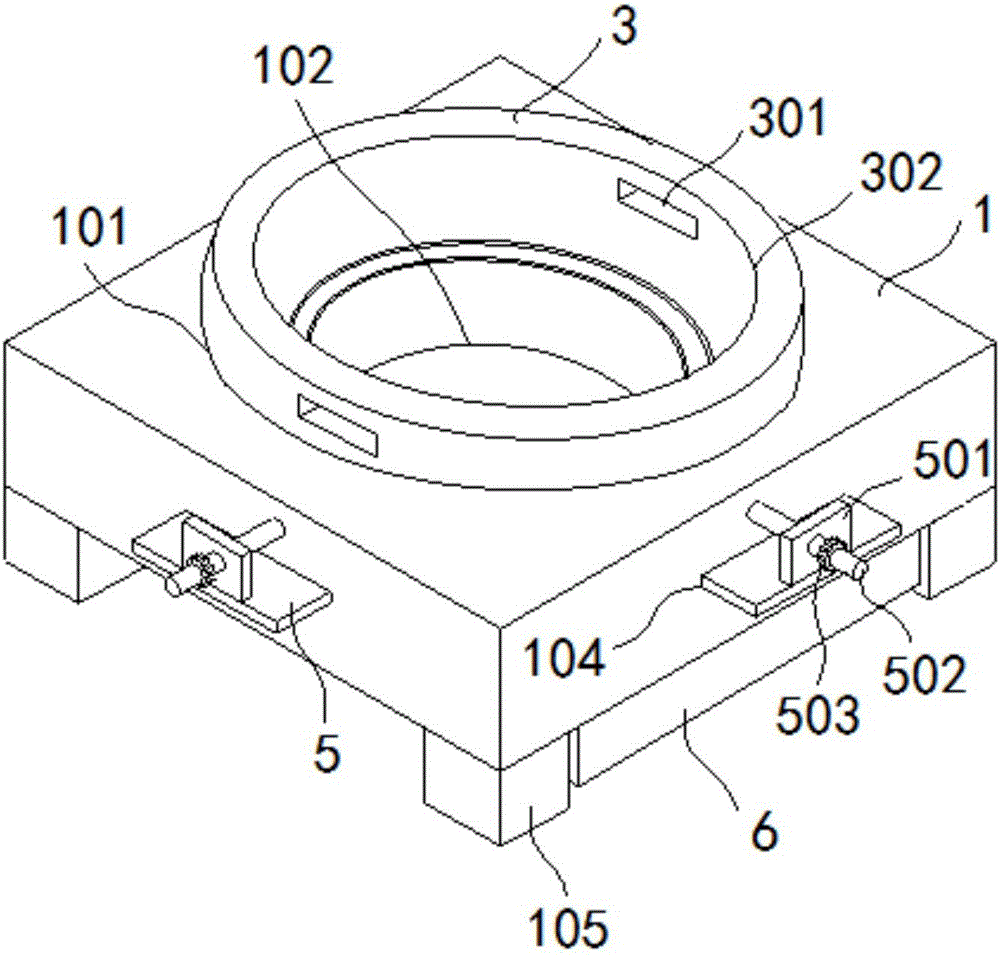

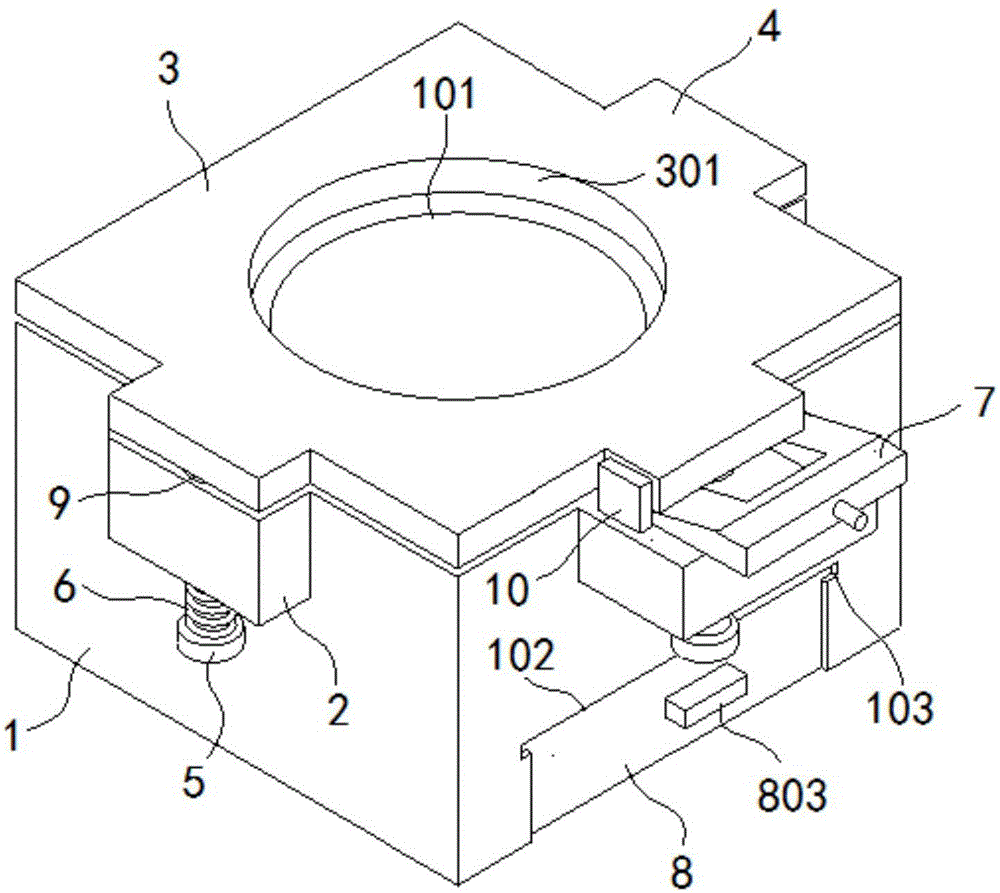

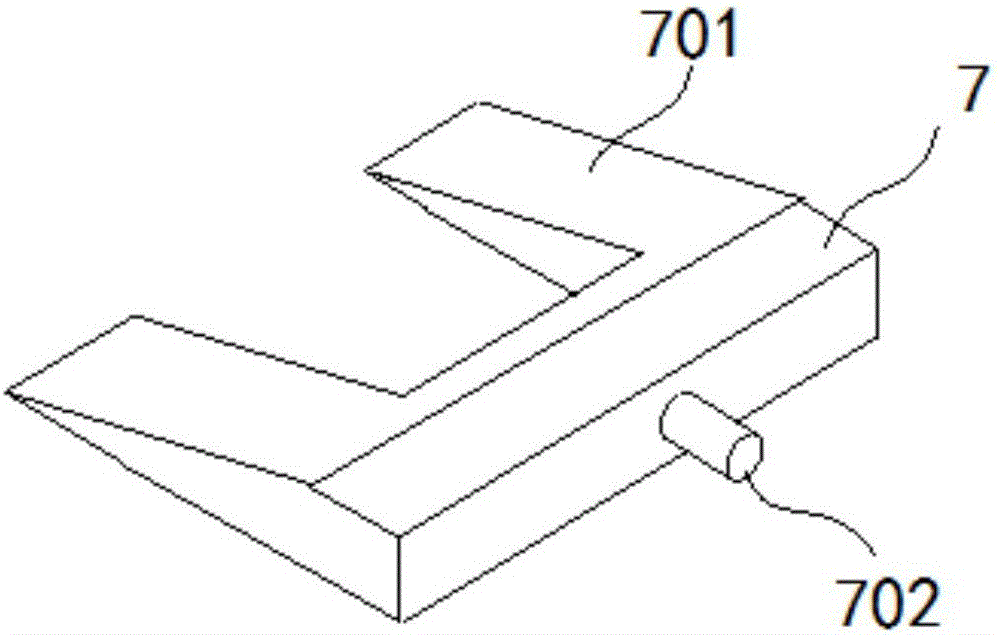

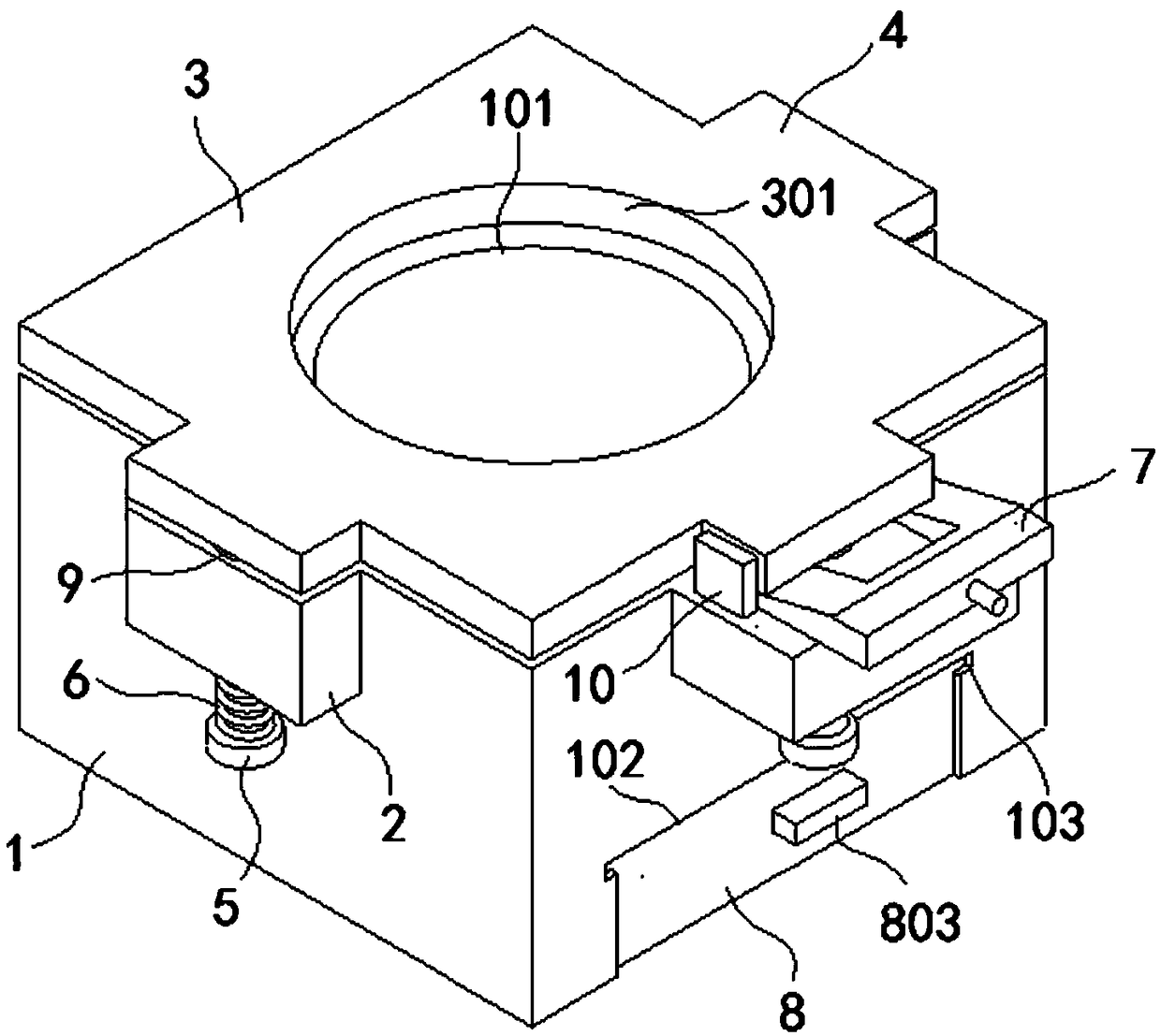

Work fixture on laser cutting device

ActiveCN106425138AEasy to clamp and fixEasy to cleanWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

The invention discloses a work fixture on a laser cutting device. The work fixture on the laser cutting device comprises a base, a first magnetic sucker, a fixing base, a second magnet sucker, a positioning block and a material discharging case. By the arrangement of the magnetic suckers arranged on a cushion cap and the fixing base, a metal plate can be conveniently clamped and fixed to guarantee flatness and stability of the metal plate, and cutting quality is high; by the arrangement of the positioning block, the position of the metal plate can be adjusted to facilitate cutting, and processing quality is further improved; through the material discharging case arranged on the lower part of the base, waste materials after processing can be conveniently removed and recycled. The work fixture on the laser cutting device is simple in structure, convenient to operate, high in processing efficiency and high in processing quality, and is suitable for large-scale production.

Owner:天润智能科技(昆山)有限公司

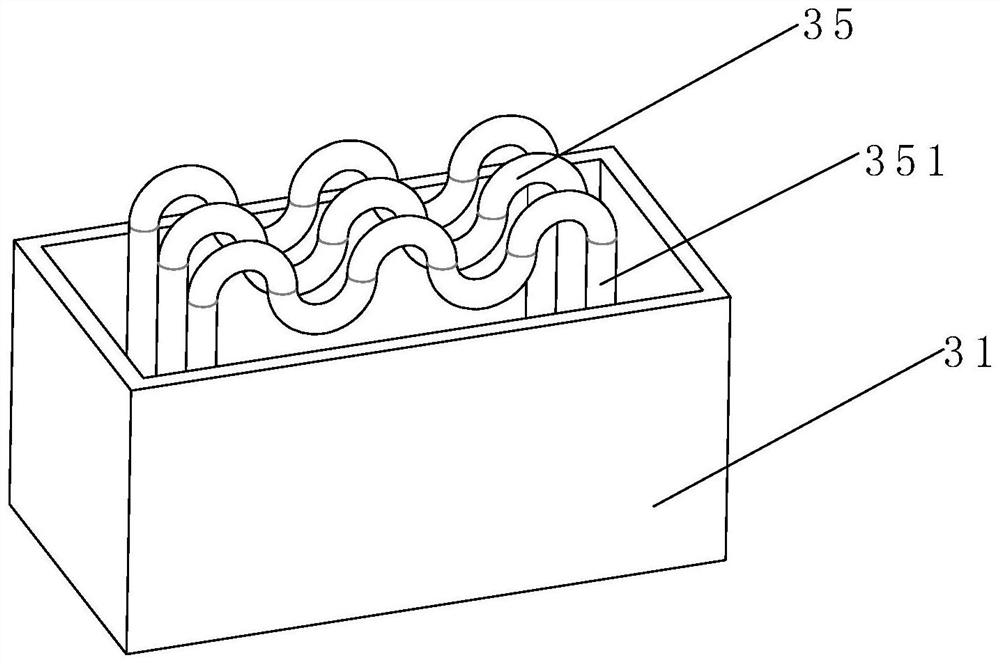

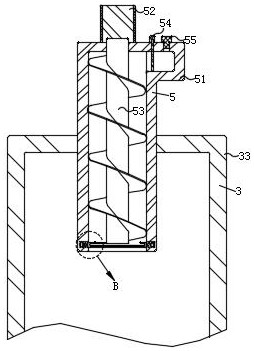

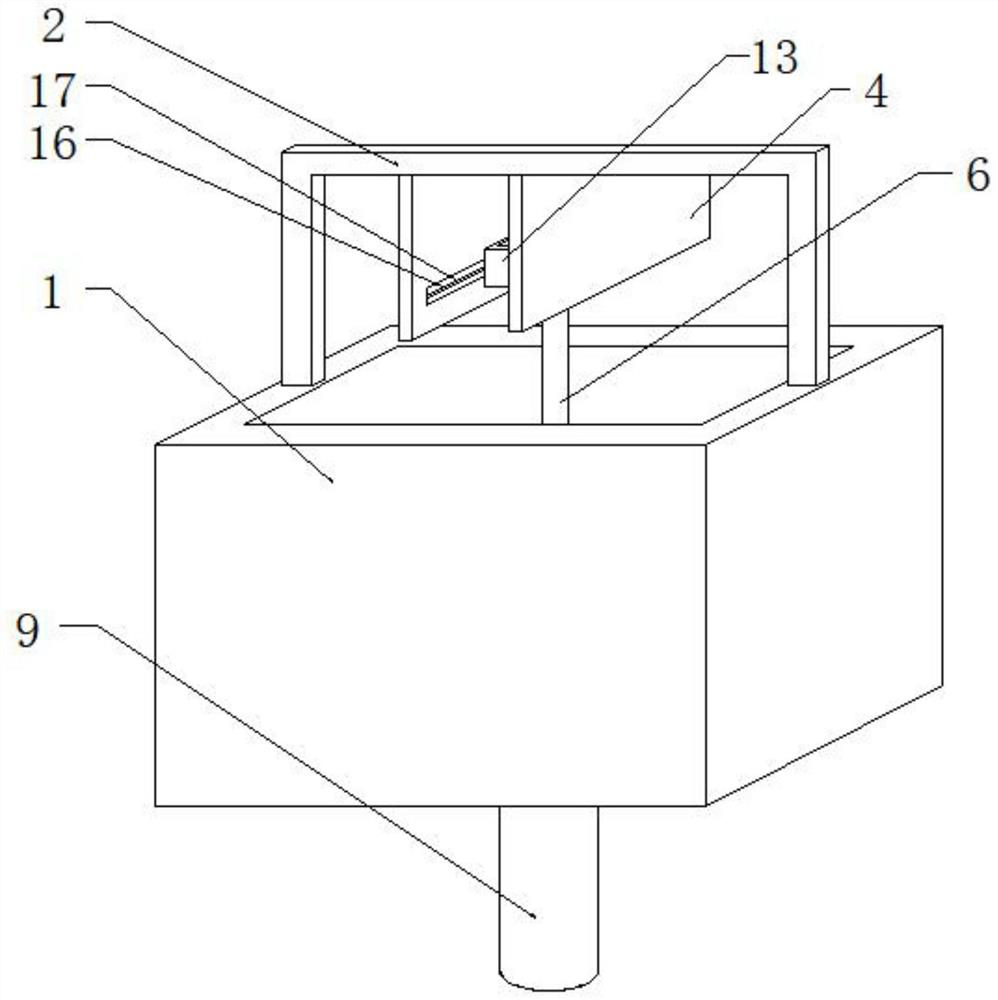

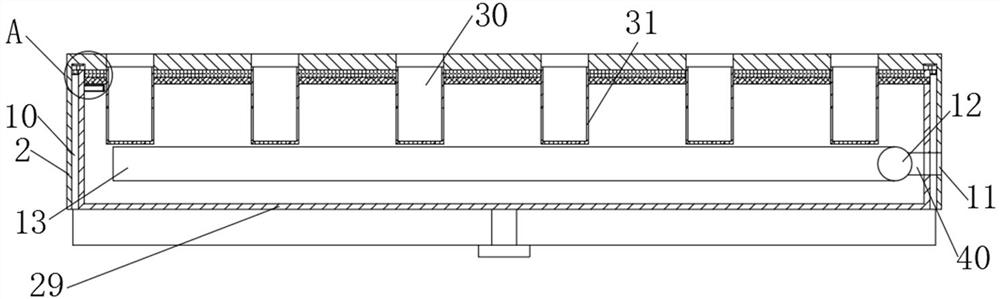

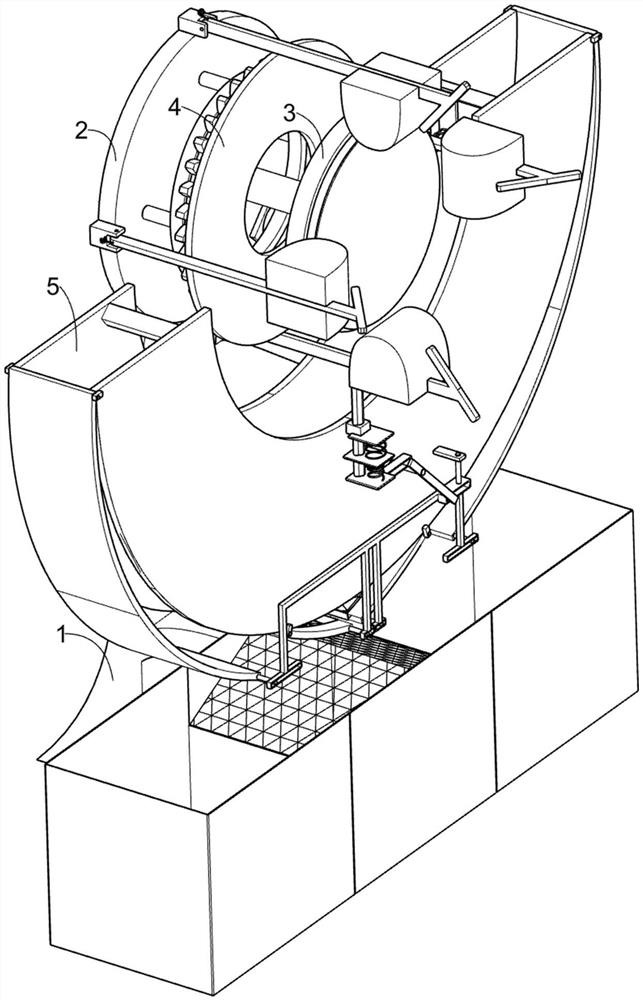

Cleaning and recycling device for garbage incinerator

InactiveCN112212342ABurn completelyPlay the role of stirring and turningIncinerator apparatusSolid removalElectric machineryEnvironmental engineering

The invention relates to the technical field of incinerators, in particular to a cleaning and recycling device for a garbage incinerator. The cleaning and recycling device comprises an incinerator body, a feeding mechanism, a treatment mechanism, a cleaning mechanism, an adding mechanism and a discharging mechanism. During use, the feeding mechanism is arranged at the top of a main device body, and through corresponding motor transmission and stirring assemblies, garbage can be stirred and turned over conveniently in the garbage incineration process, so that garbage incineration is more sufficient; the cleaning mechanism is arranged at the bottom of one side of the treatment mechanism, and impurities attached to the inner wall of the treatment mechanism can be conveniently removed during use through a corresponding fan assembly and a corresponding scraping rod, so that cleaning and recovering of waste gas and dust are guaranteed; and the adding mechanism is arranged at the top of the middle of the treatment mechanism, and corresponding additives are conveniently, uniformly and quantitatively added to the treatment mechanism through corresponding spiral transmission and cam assemblies, so that the dust can be more conveniently cleaned and recovered.

Owner:杭州心米商贸有限公司

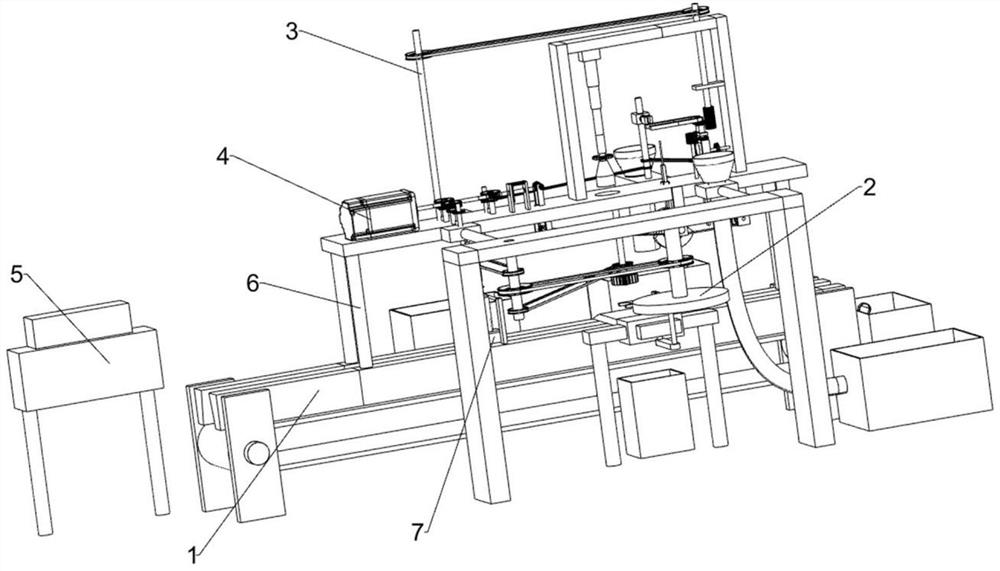

Antique-finishing treatment device for jean fabric processing of textile fabric

ActiveCN112267246AReduce labor burdenReduced disengagementMechanical cleaningPressure cleaningDenimEconomic benefits

The invention discloses an antique-finishing treatment device for jean fabric processing of a textile fabric, and relates to the technical field of textile fabric processing. The antique-finishing treatment device for the jean fabric processing for the textile fabric comprises a base; a clamping mechanism, a pushing mechanism, a dust collection mechanism, a treatment mechanism, a driving mechanismand a bearing table are arranged on the base; a mounting frame and a hydraulic rod are welded to the outer surface of the top of the base; a fixing frame is arranged in the mounting frame; and the hydraulic rod is located under the fixing frame, and the free end of the hydraulic rod is welded to the outer surface of the bottom of the fixing frame. According to the antique-finishing treatment device for the jean fabric processing for the textile fabric, the labor burden of an operator is relieved, the rejection rate and the reject ratio are reduced, the product quality is guaranteed, the preparation time required before and after treatment is shortened, more economic benefits are brought, the negative effects on the body health of the operator and the surrounding environment are reduced, and promotion and use are facilitated.

Owner:TAIAN DONGSHENG CLOTHING CO LTD

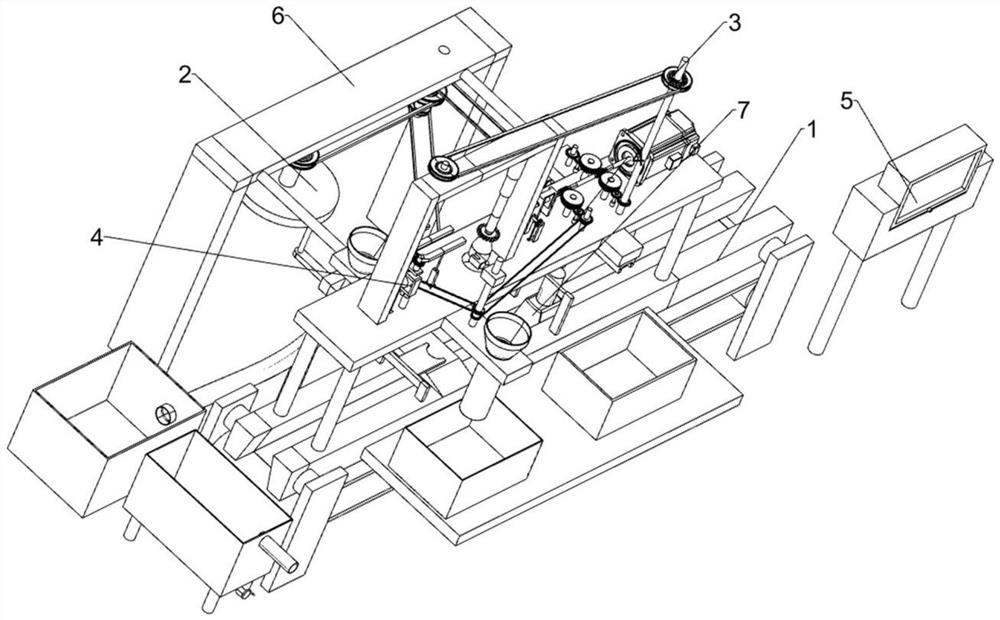

Study article recycling and processing device

InactiveCN111872049AIntegrity guaranteedAvoid pollutionSolid waste disposalPlastic recyclingProcess engineeringManufacturing engineering

The invention relates to the field of stationery recycling, in particular to a study article recycling and processing device. The technical problem to be solved by the invention is to provide the study article recycling and processing device. According to the technical scheme, the study article recycling and processing device comprises a transportation limiting and uncovering mechanism, a cutting,separating and fastening mechanism, a clamping and rotating mechanism, an ejection mechanism, a control display screen, a workbench and correction fluid. The transportation limiting and uncovering mechanism is connected with the cutting, separating and fastening mechanism; and the transportation limiting and uncovering mechanism is connected with the clamping and rotating mechanism. According tothe study article recycling and processing device, separation of all parts of the correction fluid is achieved, cleaning and recycling can be conveniently conducted according to all the parts in the later period, the completeness of an iron needle tube on the upper portion of the correction fluid during recycling, processing and separating is guaranteed, and pollution to the environment can be avoided by separating all the parts of the correction fluid.

Owner:李文坤

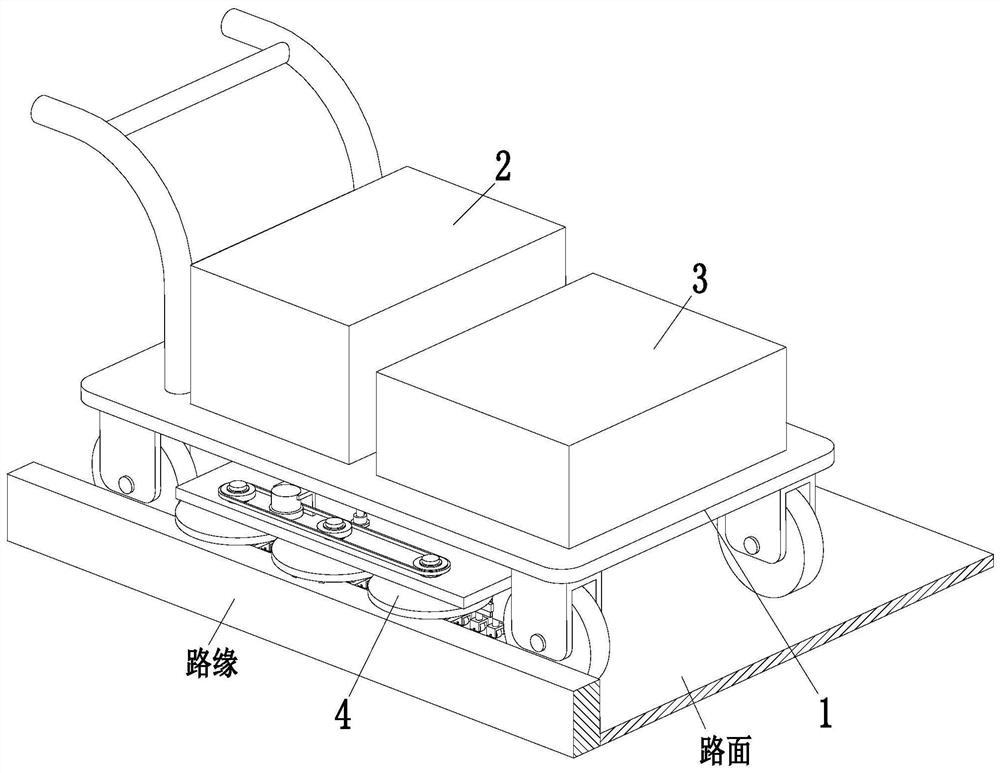

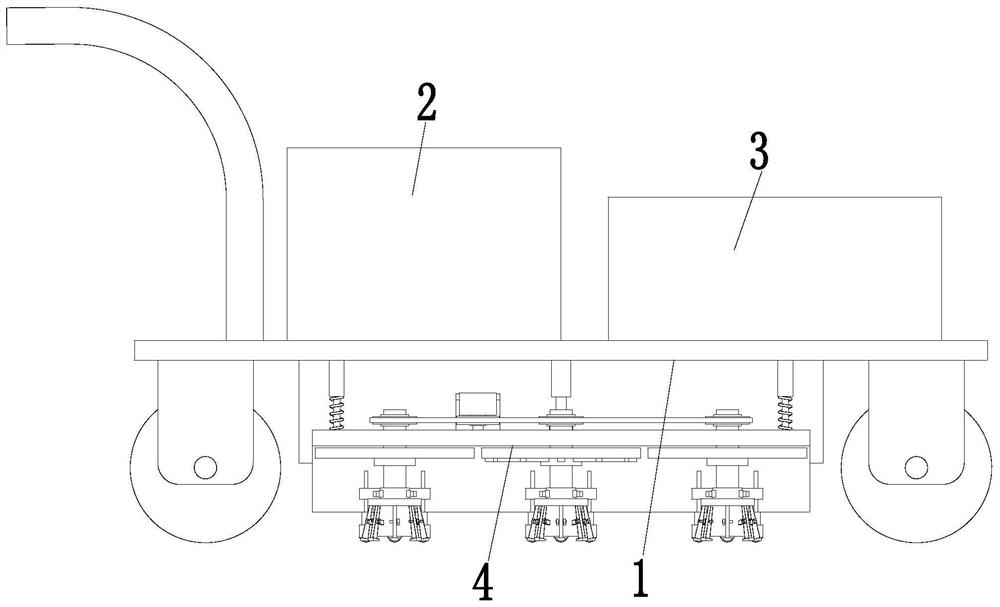

A road surface cleaning and sanitation equipment

ActiveCN111058409BAvoid accumulationEasy to useRoad cleaningEnvironmental resource managementRoad surface

The invention relates to a cleaning and sanitation equipment for road surface, which comprises a mobile frame, a dust collection box, a water tank and a cleaning device. The lower end of the mobile frame is symmetrically equipped with rollers, the left side of the upper end of the mobile frame is equipped with a dust collection box, and the upper end of the mobile frame is A water tank is installed on the right side, and a cleaning device is installed on the front side of the lower end of the mobile frame. The present invention can solve the problem that the existing equipment has poor cleaning effect when cleaning the road surface, and cannot effectively clean the angle between the road surface and the curb, resulting in that the angle between the road surface and the curb is easy to remain A lot of dust affects the cleaning effect of the road surface, and when the existing equipment cleans the road surface, it cannot clean the garbage on the upper layer of the curb, and cannot quickly adjust the height of the curb and the road surface, which affects the equipment. The use effect and other problems.

Owner:成都子阳清洁服务有限公司

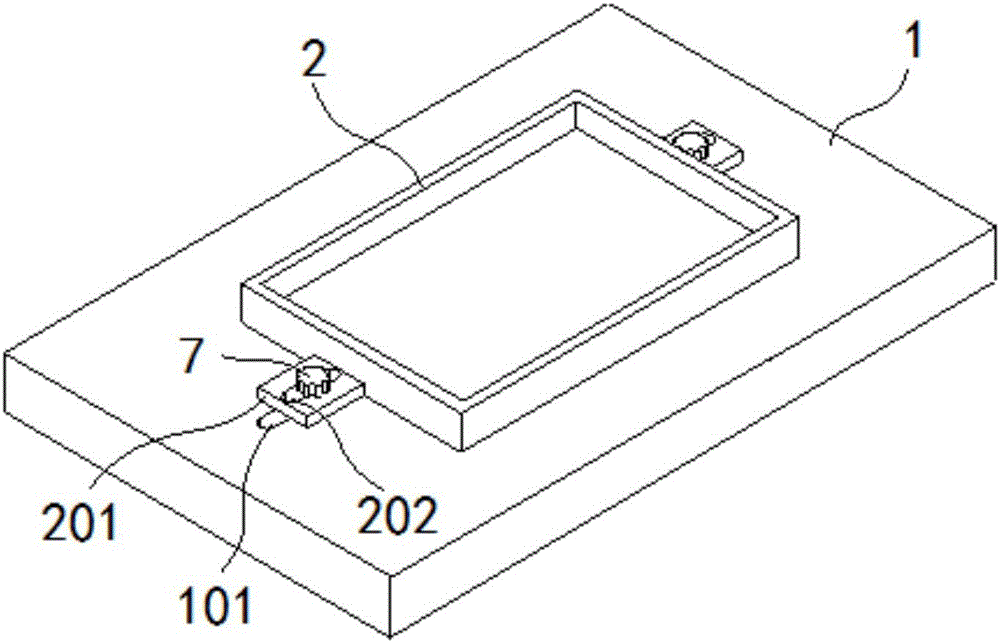

Steel sheet clamping device for laser cutting

ActiveCN106425117AEasy to clamp and fixEasy to operateLaser beam welding apparatusLaser cuttingArchitectural engineering

The invention discloses a steel sheet clamping device for laser cutting. The steel sheet clamping device comprises a base, a first bump, an upper pressure plate, a second bump, a guide post, a compression spring, a wedge block and a waste box. The device can conveniently clamp and fix a steel sheet and can realize position adjustment and unloading of the steel sheet; the operation is convenient, the working efficiency is high, the flatness and stability of the steel sheet are guaranteed, and the cutting quality is high; and moreover, through a waste tank at the lower end of the base, the waste can be conveniently cleared and recycled, and the whole laser cutting device is protected from smog. The device has the advantages of simple structure, convenience in operation, high processing efficiency and high processing quality.

Owner:山东颐杰鸿丰能源装备有限公司

Three-way elbow forming and processing integration equipment

ActiveCN110732881AReduce entryKeep healthyOther manufacturing equipments/toolsMetal working apparatusScrew threadIndustrial engineering

The invention discloses three-way elbow forming and processing integration equipment which comprises a base, a second water delivery pipe, a third water delivery pipe and a fourth water delivery pipe,wherein a first slideway is arranged in the base; a bellows is arranged on the right side of a withdrawal box; a waste gas treatment tank cover is connected on the front side of a waste gas treatmenttank by screw threads; a first electric expansion link is fixed on the upper side of the base; a material suction port is formed at one end of the bellows in a penetrating manner; a fixing plate is arranged on the right side of the first electric expansion link; a second slideway is arranged in the fixing plate; a second electric expansion link is fixed on the lower side of a sliding block; a first conveying belt is inserted at the upper end of the base; a three-way elbow die groove is formed on the upper side in a lower die block; and a filter screen is arranged at the lower end of the leftside of a first water delivery pipe. The three-way elbow forming and processing integration equipment is provided with the withdrawal box, so that scraps generated during pipeline cutting fall into the withdrawal box by a hole in the base to be stored.

Owner:江苏新泰隆管件有限公司

Wood board polishing device

InactiveCN112405150ANot easy to crush and damageImprove grinding efficiencyGrinding carriagesGrinding drivesWood plankVacuum pump

The invention discloses a wood board polishing device. The wood board polishing device comprises a workbench of a hollow structure and a polishing box installed on one side of the top face of the workbench, wherein a vacuum pump is fixedly installed on one side of the workbench; a plurality of negative pressure suction cups evenly distributed below the polishing box are installed on the table topof the workbench; the vacuum pump communicates with the negative pressure suction cups through guide pipes; a feeding port leading to the position below the polishing box is formed in the joint of thepolishing box and the workbench; and a polishing mechanism located above the negative pressure suction cups is installed in the polishing box. According to the wood board polishing device, the suction cups are connected with the vacuum pump, air between a wood board and the suction cups is extracted, and therefore the wood board is fixed through vacuum adsorption, the wood board does not need tobe fixed through an extrusion structure, and the wood board is not prone to being extruded and damaged; meanwhile, no obstacle exists on the surface of the wood board, and the polishing mechanism canpolish the surface of the wood board conveniently; and the height and position of a polishing wheel are adjusted through hydraulic drive and lead screw drive, and therefore automatic polishing can beachieved, and the wood board polishing efficiency is improved.

Owner:瑞昌市华中国际木业有限公司

A steel sheet clamping device for laser cutting

ActiveCN106425117BEasy to clamp and fixGood for cleaning and recyclingLaser beam welding apparatusArchitectural engineeringLaser cutting

The invention discloses a steel sheet clamping device for laser cutting. The steel sheet clamping device comprises a base, a first bump, an upper pressure plate, a second bump, a guide post, a compression spring, a wedge block and a waste box. The device can conveniently clamp and fix a steel sheet and can realize position adjustment and unloading of the steel sheet; the operation is convenient, the working efficiency is high, the flatness and stability of the steel sheet are guaranteed, and the cutting quality is high; and moreover, through a waste tank at the lower end of the base, the waste can be conveniently cleared and recycled, and the whole laser cutting device is protected from smog. The device has the advantages of simple structure, convenience in operation, high processing efficiency and high processing quality.

Owner:山东颐杰鸿丰能源装备有限公司

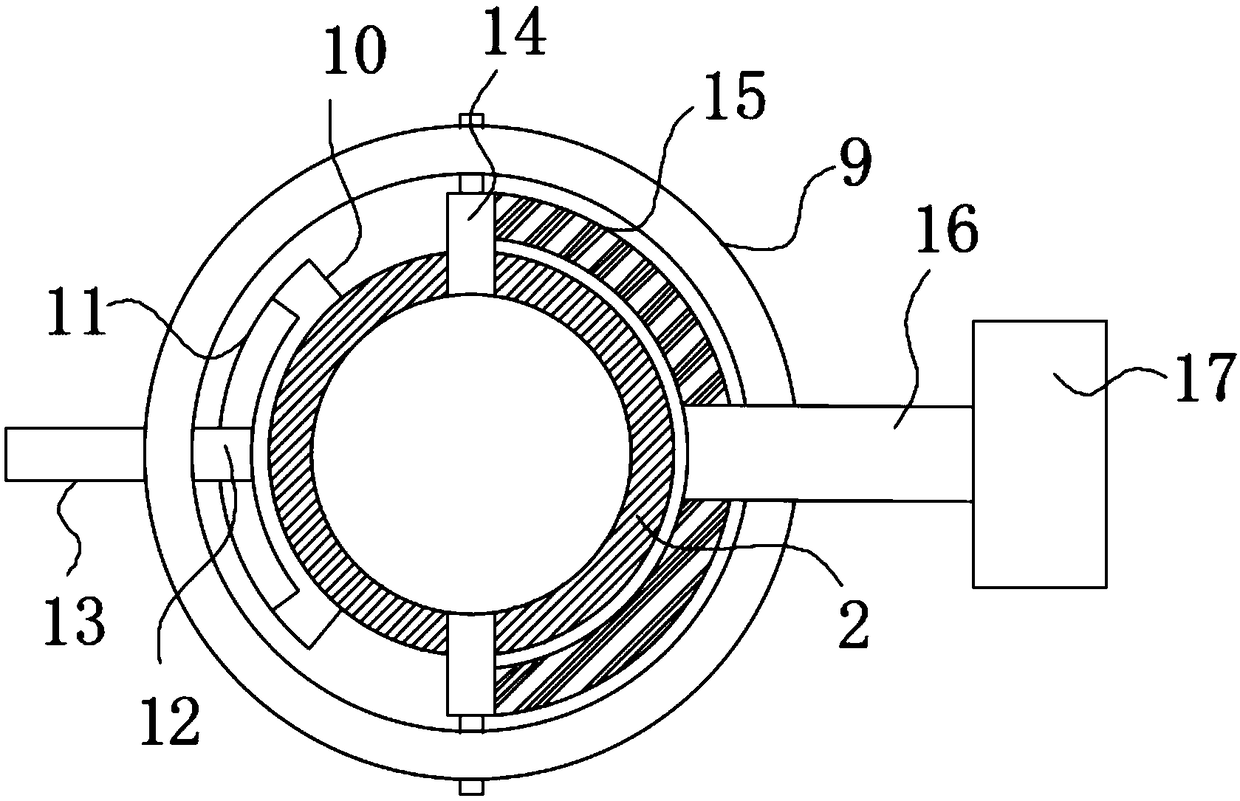

Waste yarn cleaning device for spinning equipment

InactiveCN108856163AAvoid flying waste yarnEasy to clean up and recycleDirt cleaningCleaning using gasesYarnEngineering

The invention discloses a waste yarn cleaning device for spinning equipment and relates to the technical field of spinning equipment. The waste yarn cleaning device for the spinning equipment comprises a textile equipment main body, a cleaning box and a liquid storage tank. The cleaning box is located on one side of the textile equipment main body. The bottom end of the cleaning box is fixedly connected with the liquid storage tank. A cleaning device is arranged on the outer side of the upper end of the cleaning box. A liquid feeding pipe is fixedly connected to the middle of the top end of the cleaning box. An atomization sprayer is fixedly connected to the bottom end of the liquid feeding pipe. A liquid storage cavity is formed inside the liquid storage tank. An exhaust fan is fixedly connected to the upper end of one side of the liquid storage tank. A cleaning liquid is stored in the liquid storage cavity. According to the waste yarn cleaning device for the spinning equipment, the cleaning device is arranged on the cleaning box; waste yarn in the textile equipment main body can be adsorbed by the cleaning device; the effect of cleaning the spinning equipment is achieved; the atomization sprayer is arranged in the cleaning box; the waste yarn can be wet out by the atomization sprayer, and flying of the waste yarn is avoided; the cleaning liquid is stored in the liquid storagetank; the waste yarn enters the cleaning liquid; and cleaning and recycling are convenient to conduct.

Owner:ANJI FENGYUAN TEXTILE

Novel plastic particle processing and feeding device

PendingCN114212560AAffect processing qualityIncrease reachMagnetic separationLoading/unloadingElectric machineGear wheel

The invention relates to the technical field of processing and feeding, and discloses a novel plastic particle processing and feeding device which comprises a feeding box used for containing plastic particles, the feeding box is of a box body structure with an opening in the upper end, the box bottom of the feeding box is connected with a discharging assembly used for discharging the plastic particles, and a box opening of the feeding box is connected with a supporting frame. An impurity removing mechanism used for removing metal impurities in the plastic particles is installed on the inner top of the supporting frame. The impurity removing mechanism comprises a driving motor, the output end of the driving motor is connected with a reciprocating driving assembly, the reciprocating driving assembly comprises a half-circle gear, the output end of the driving motor is connected with the half-circle gear through a coupler, and the half-circle gear is sleeved with a driving frame. Racks are fixedly connected to the two sides of the driving frame along the inner frame wall in the horizontal longitudinal direction and are symmetrical about the half-circle gear. According to the novel plastic particle processing and feeding device, metal impurities in plastic particles are removed, and the processing quality of plastic products is improved.

Owner:鹰潭和明科技股份有限公司

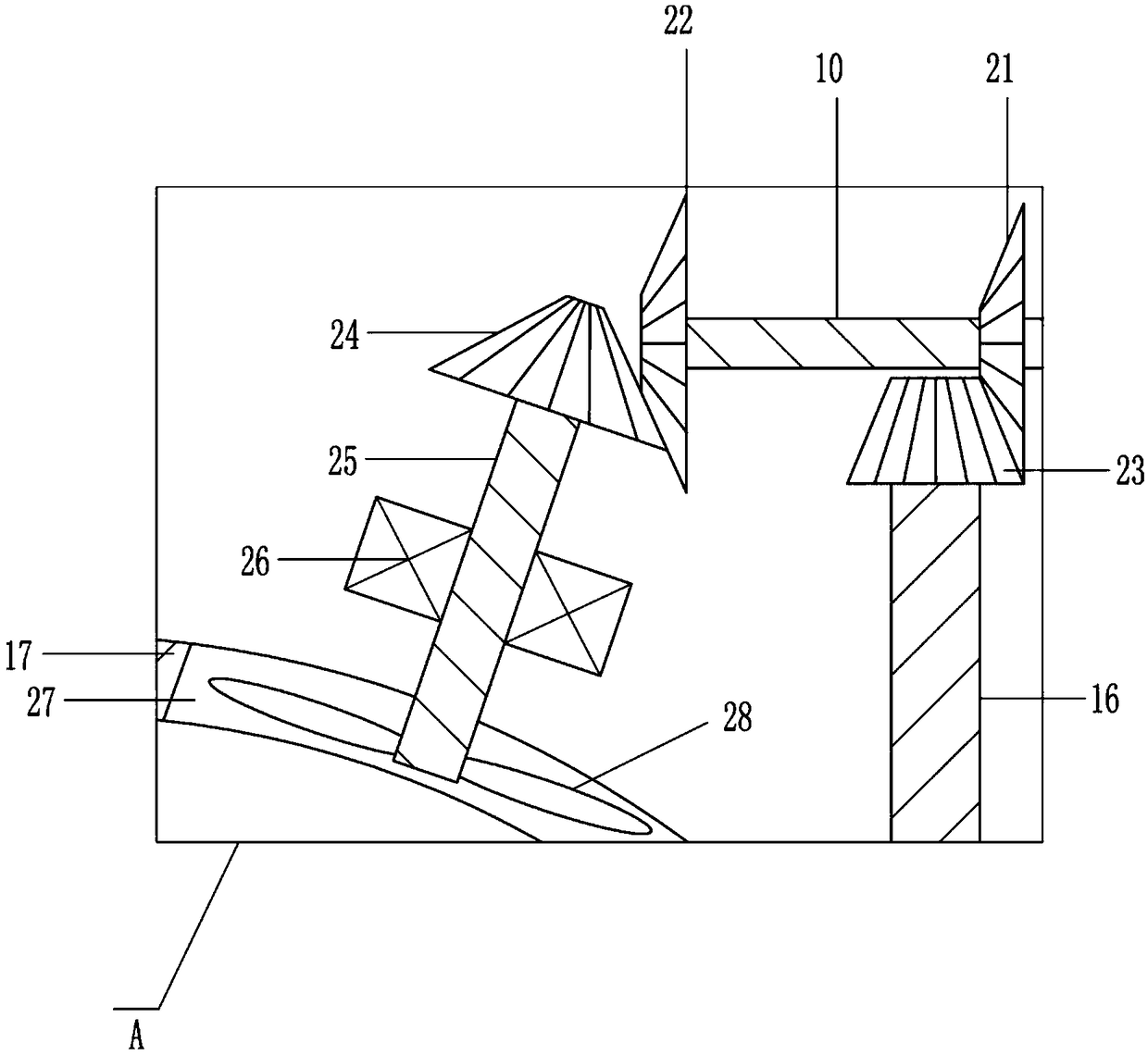

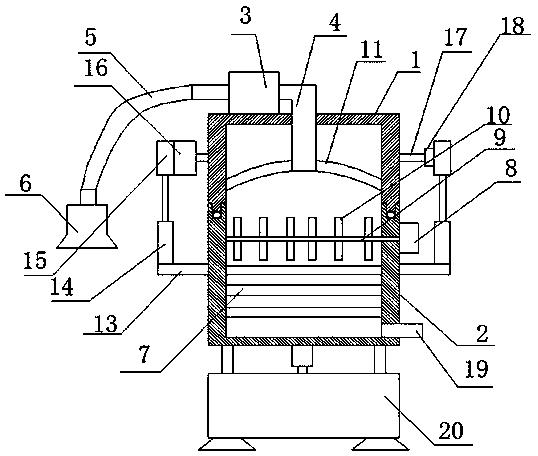

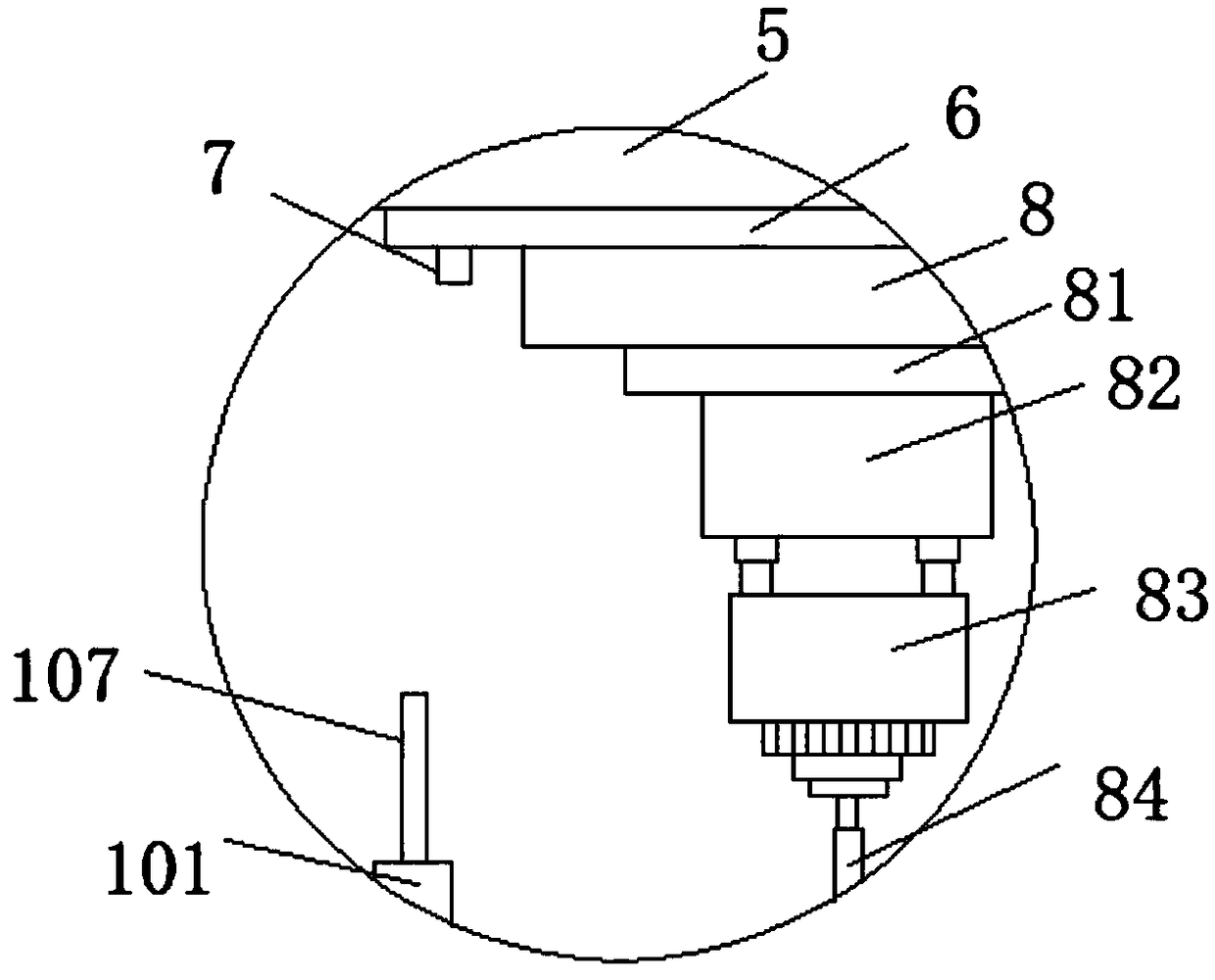

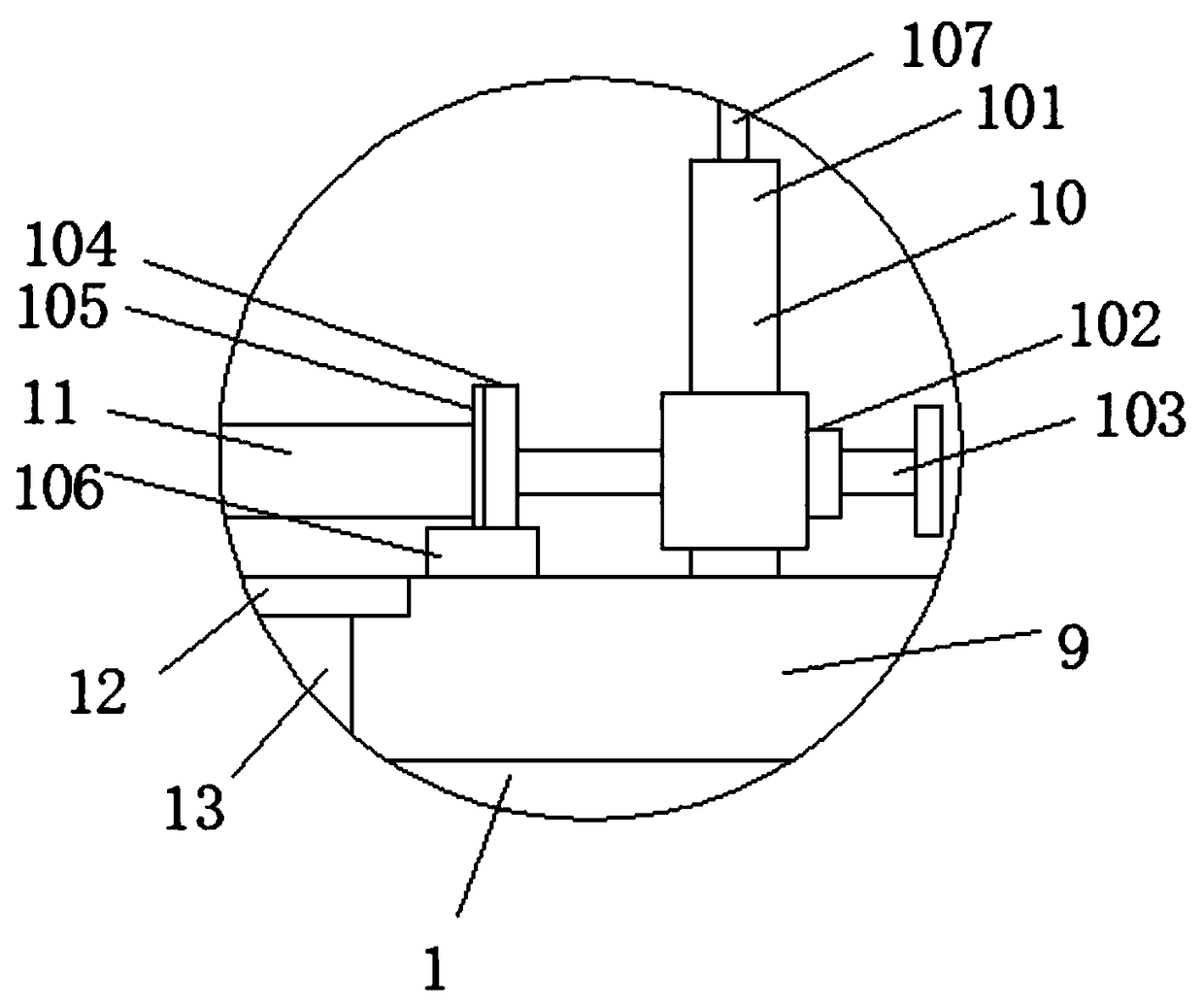

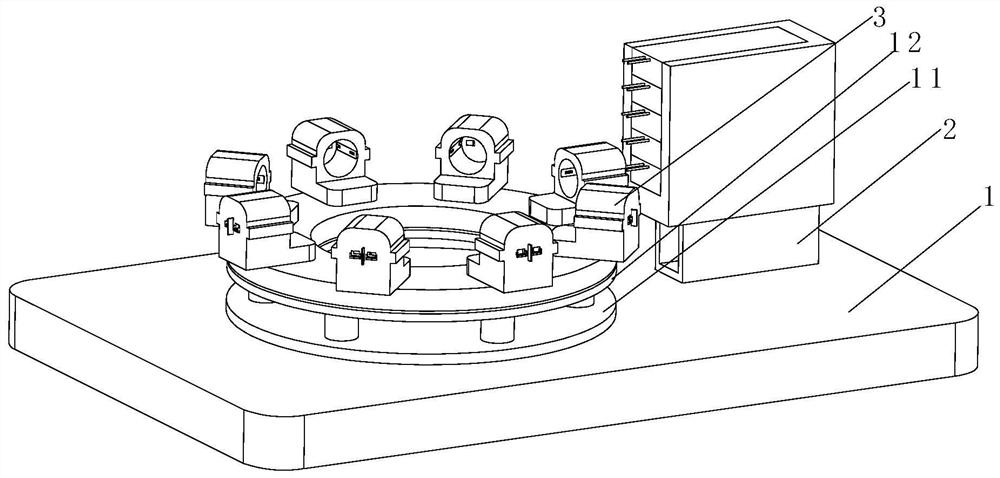

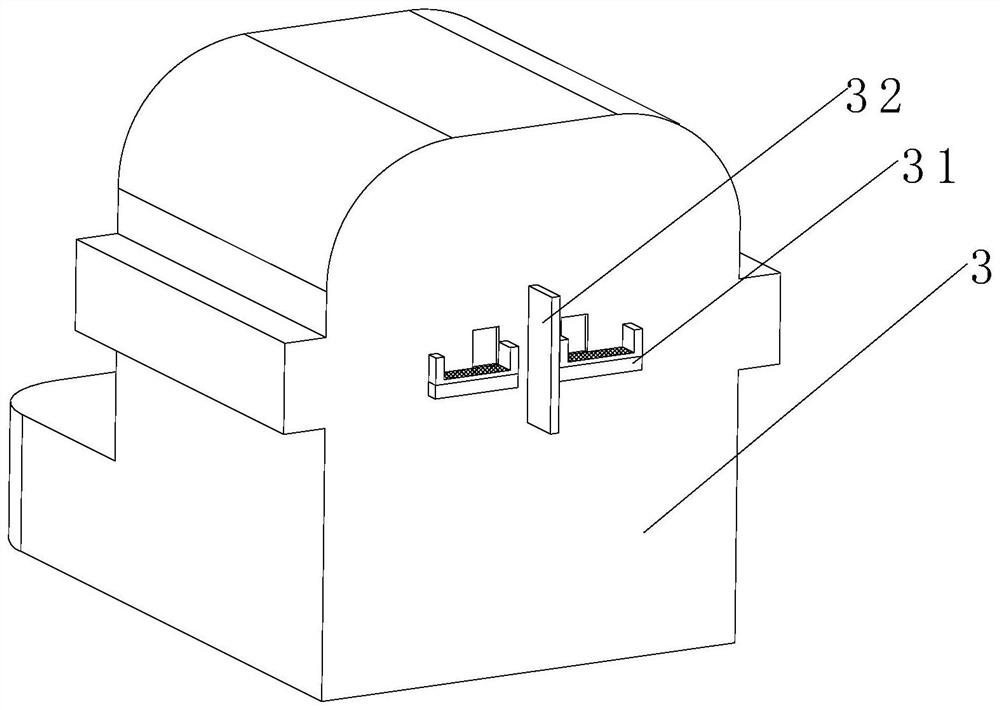

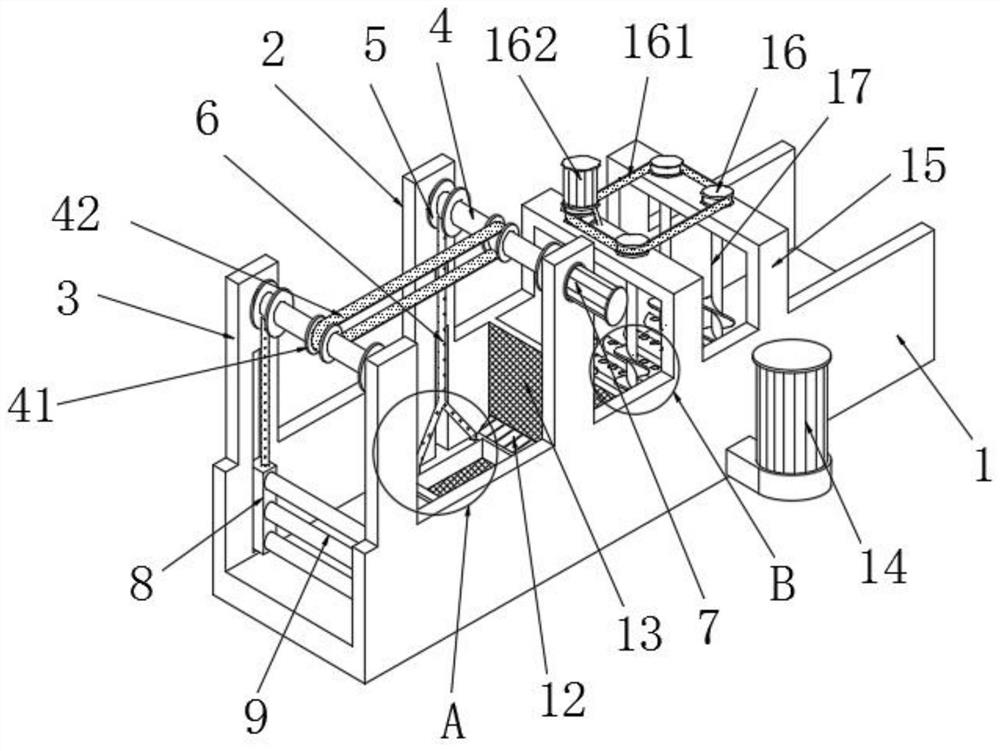

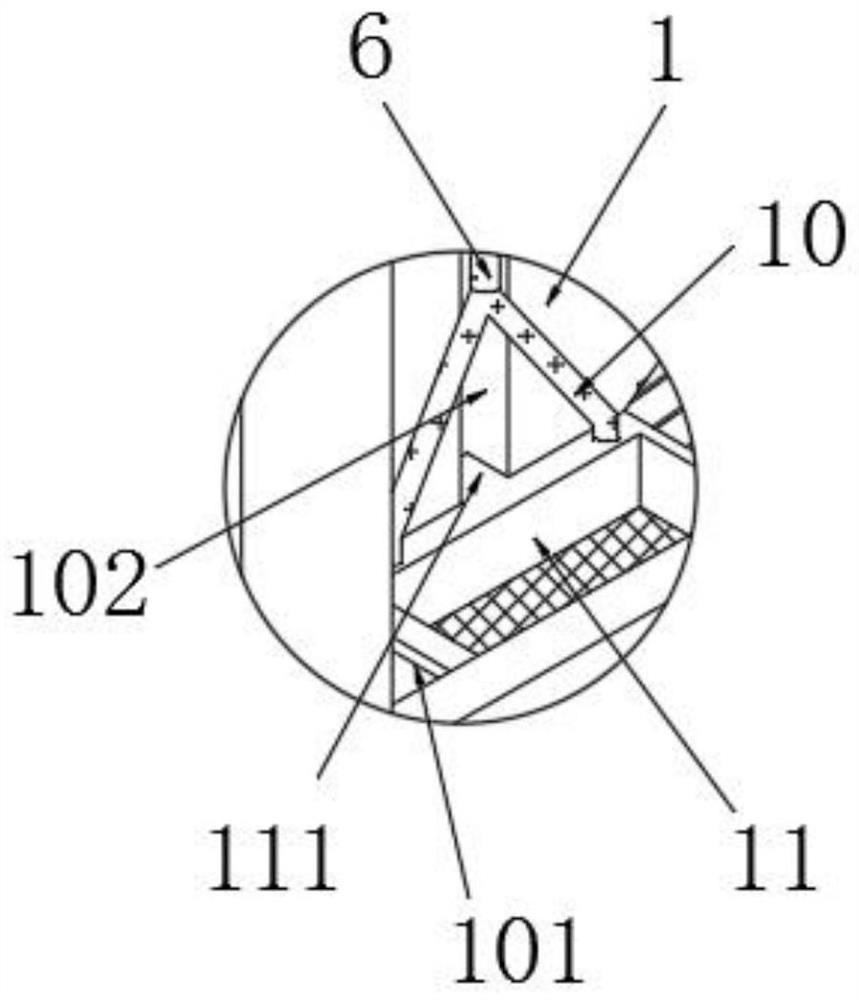

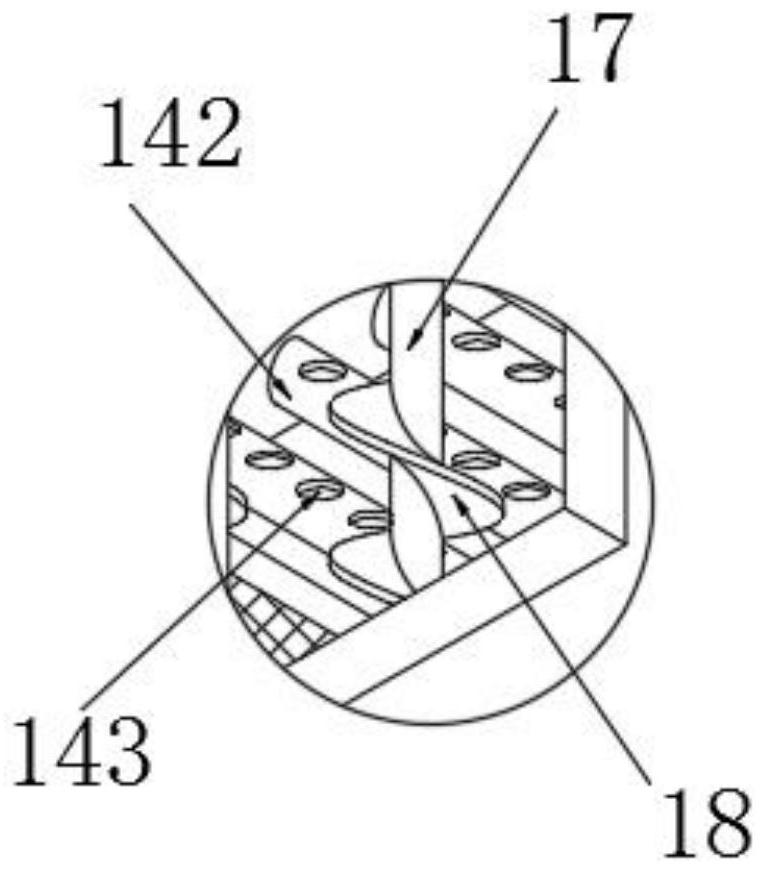

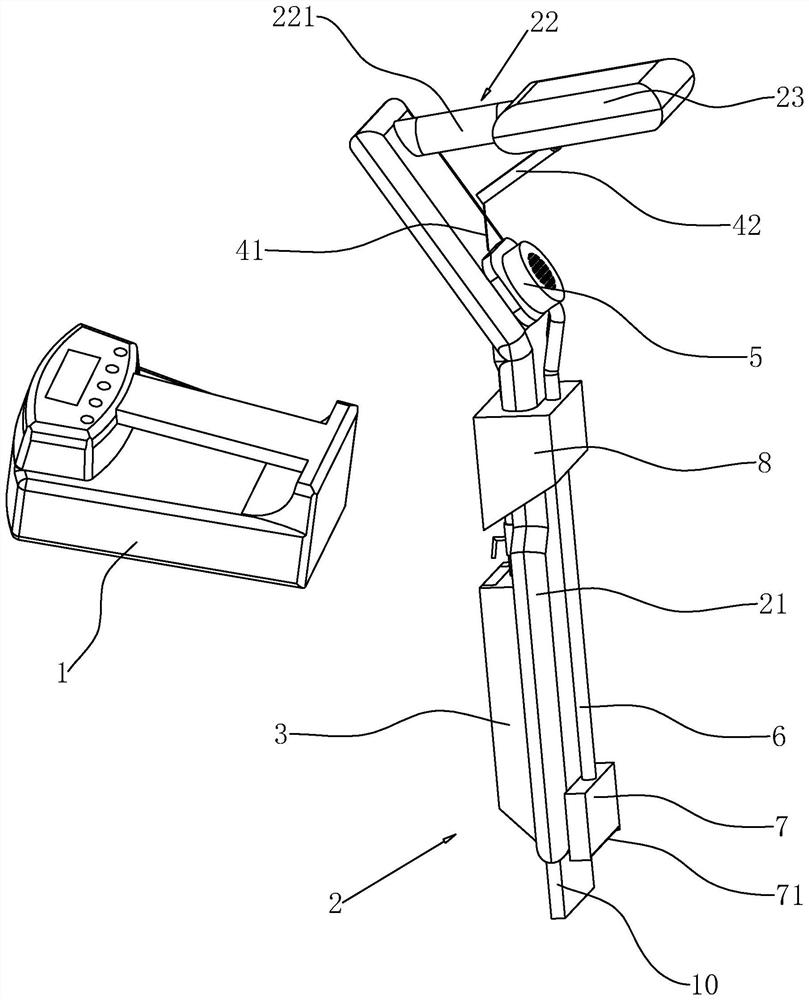

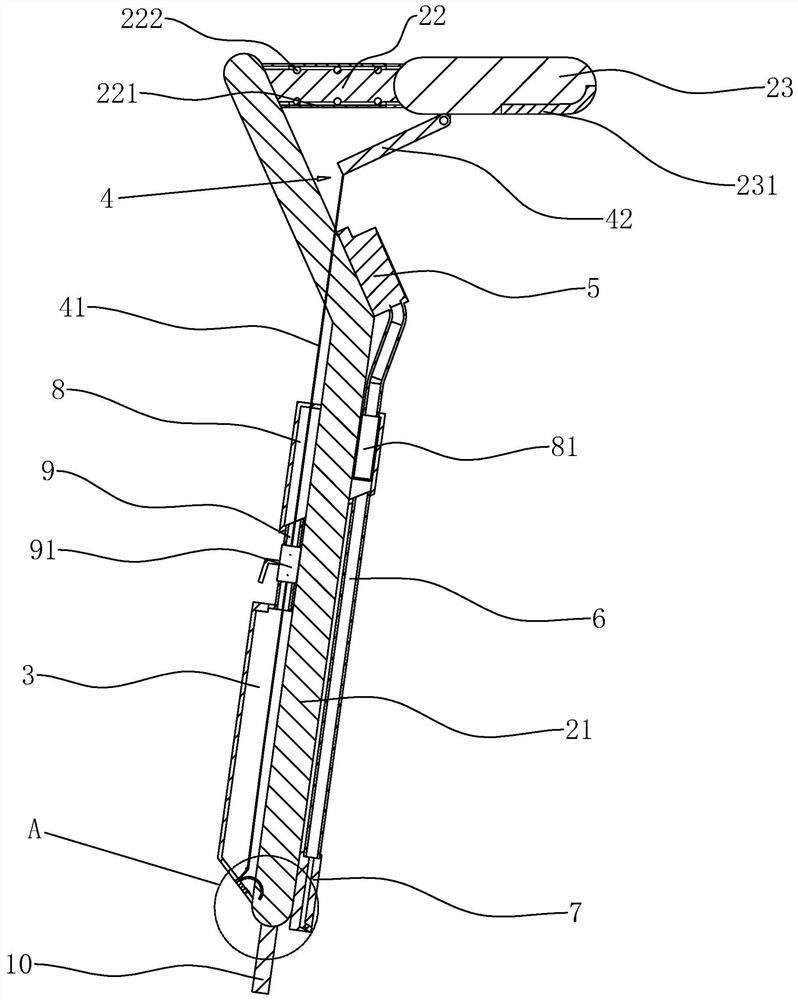

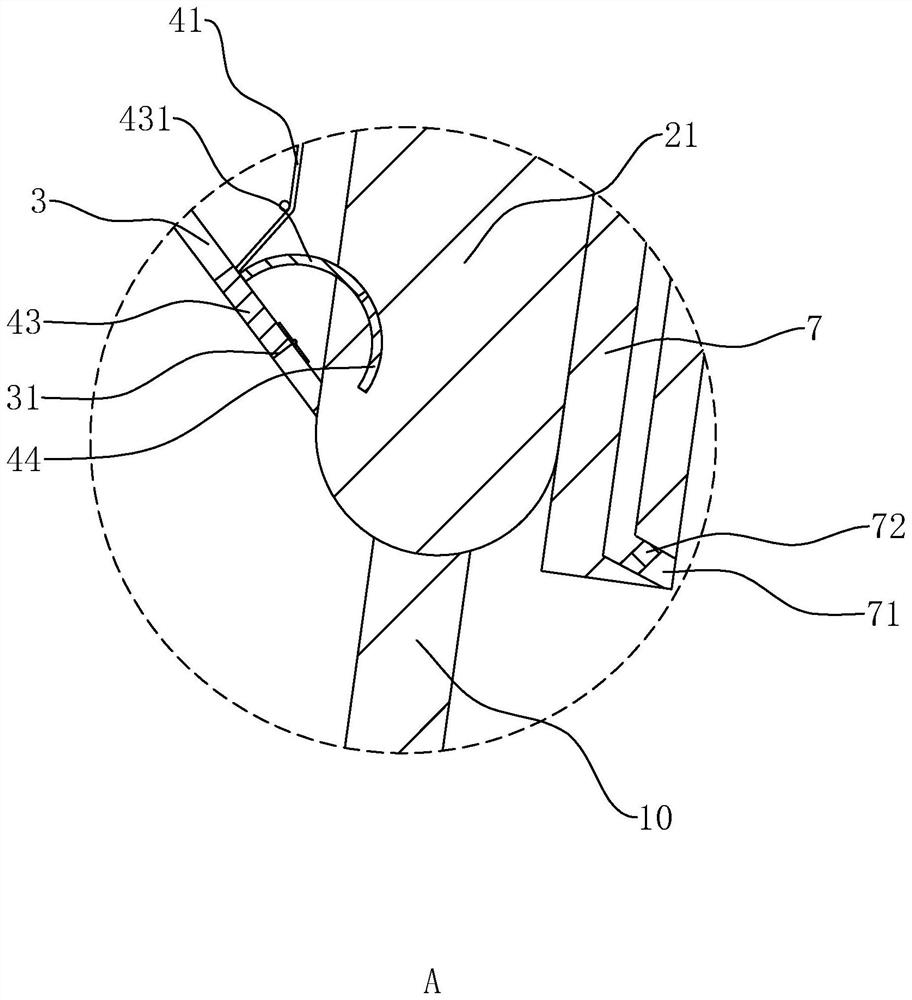

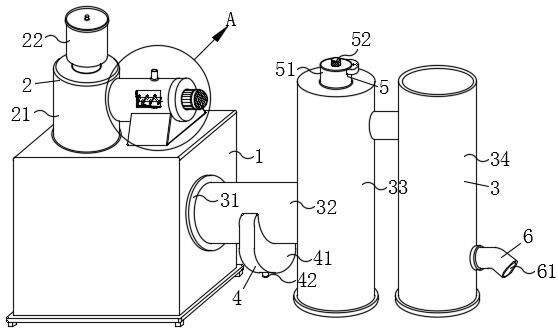

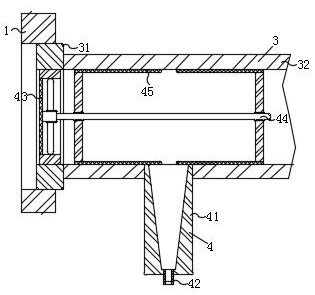

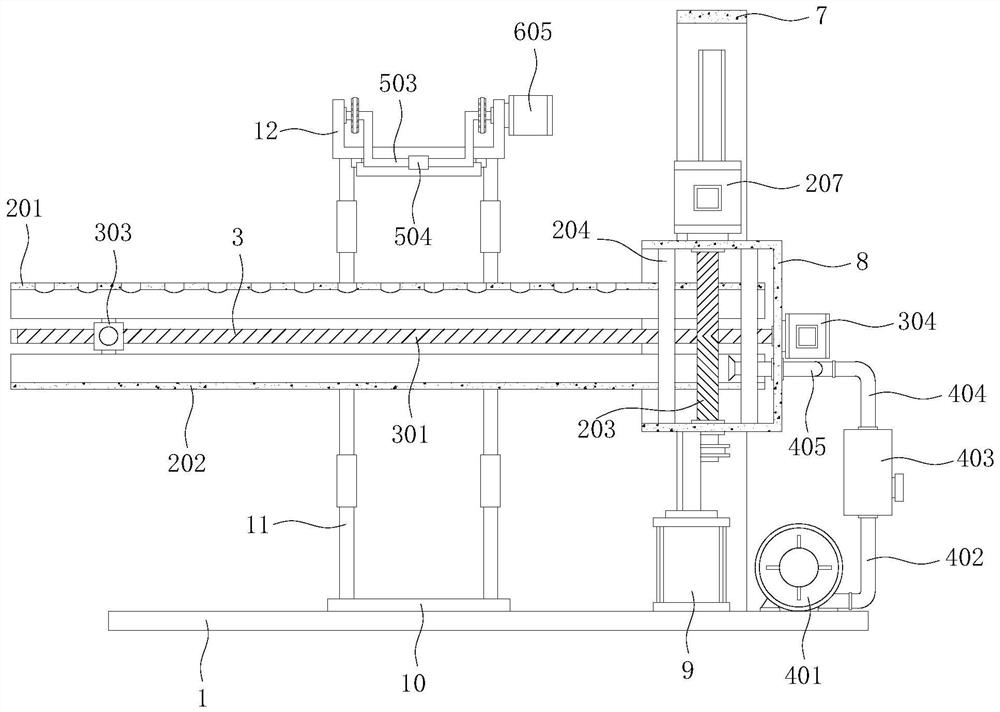

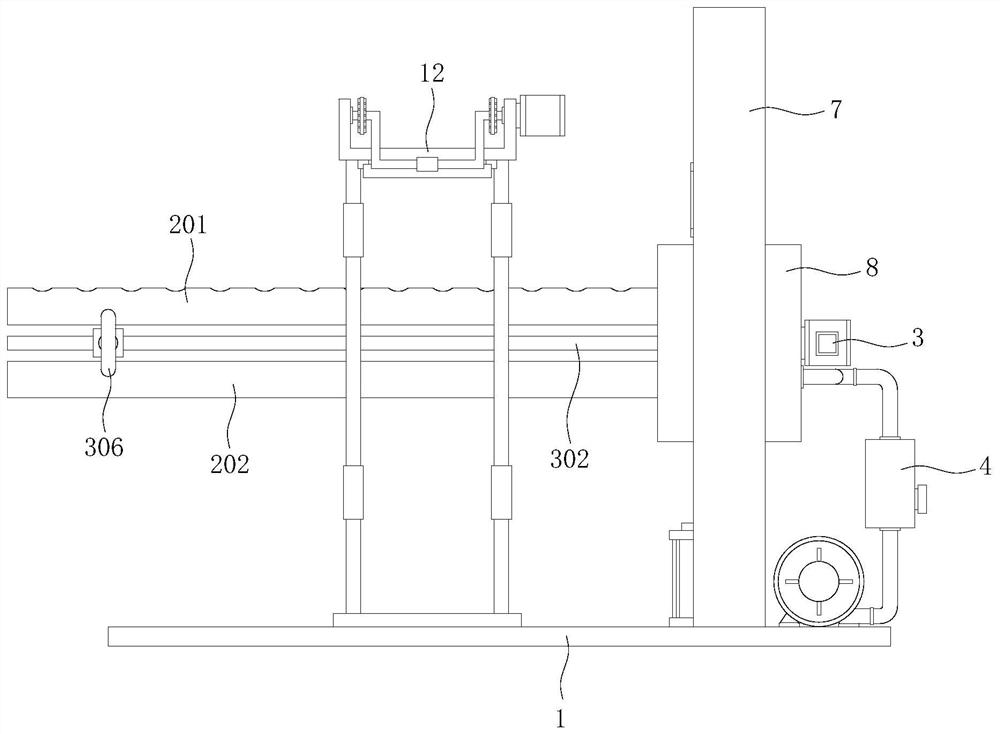

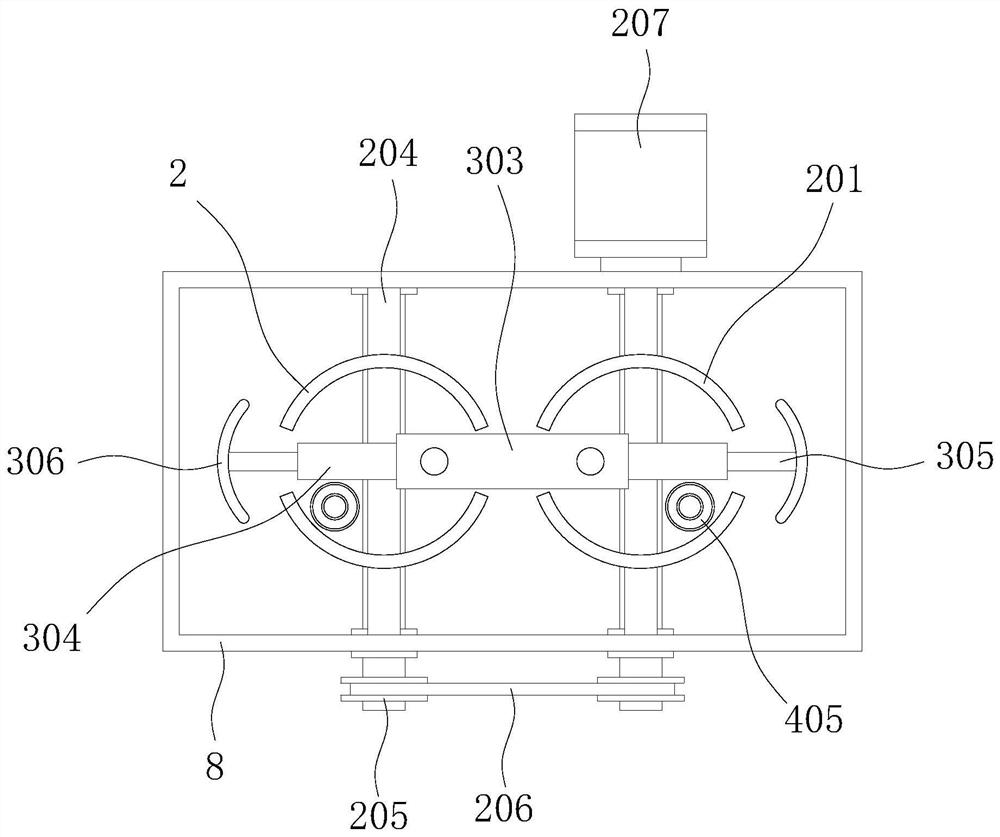

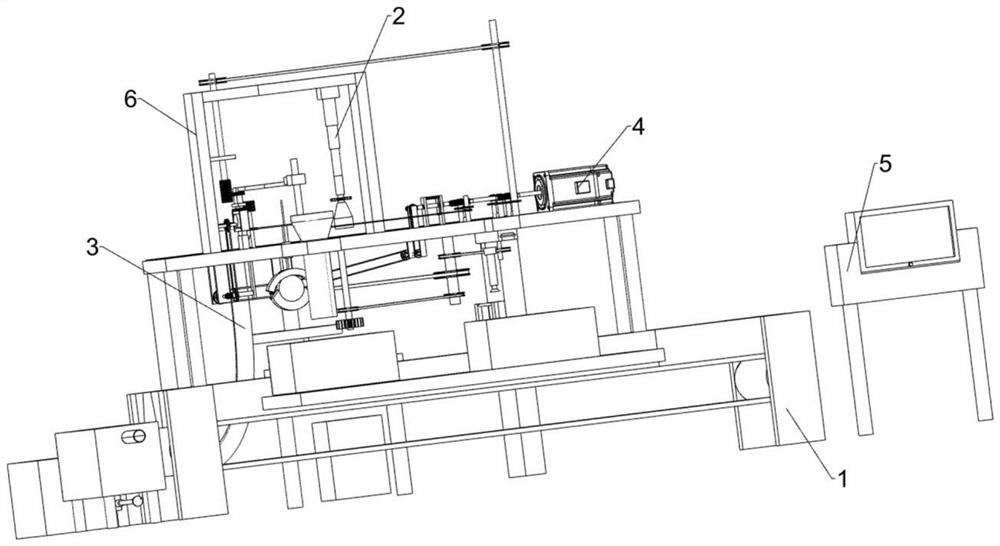

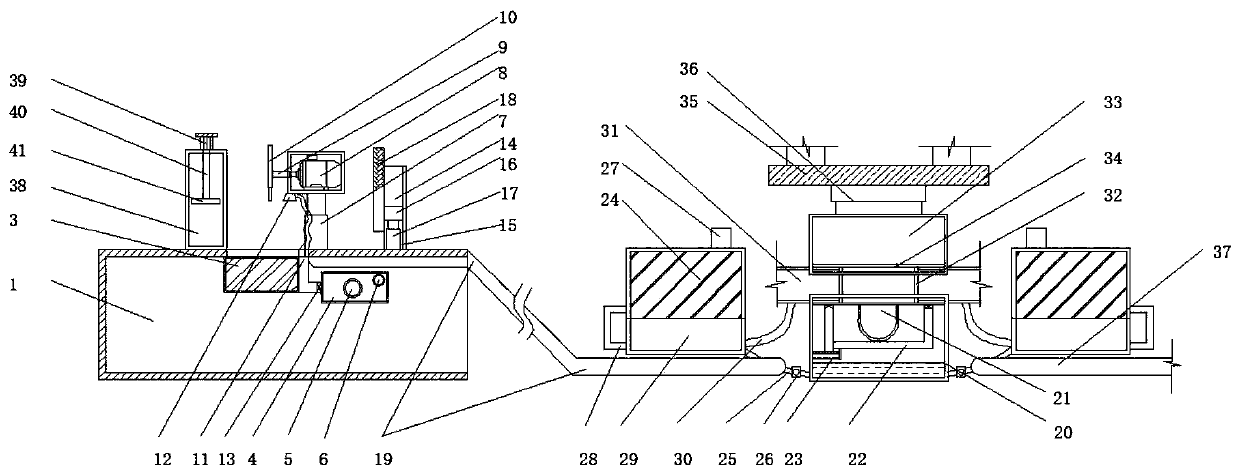

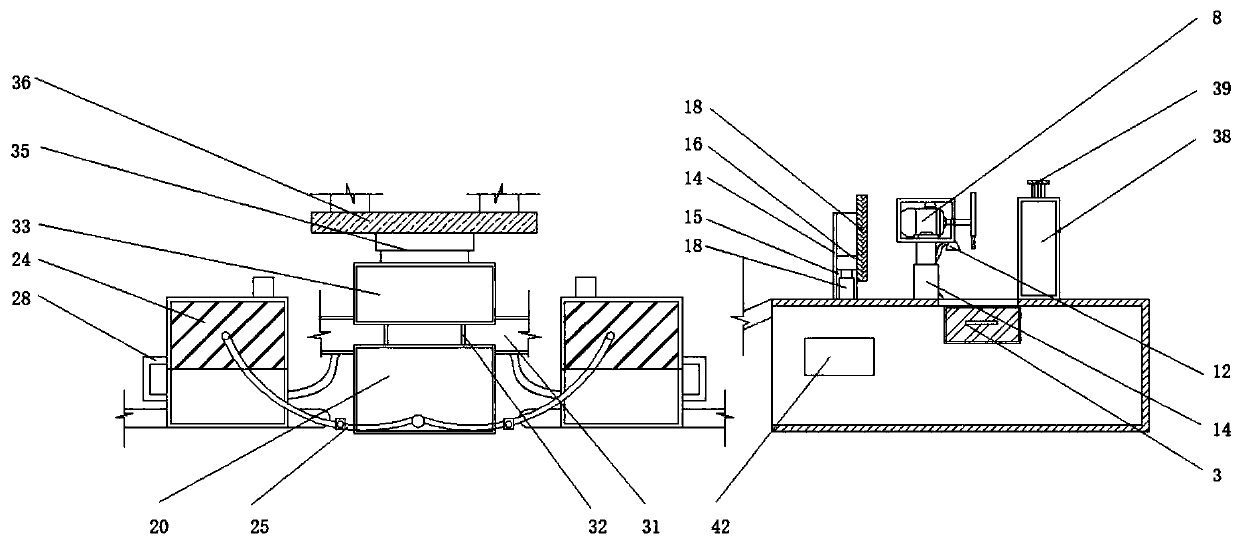

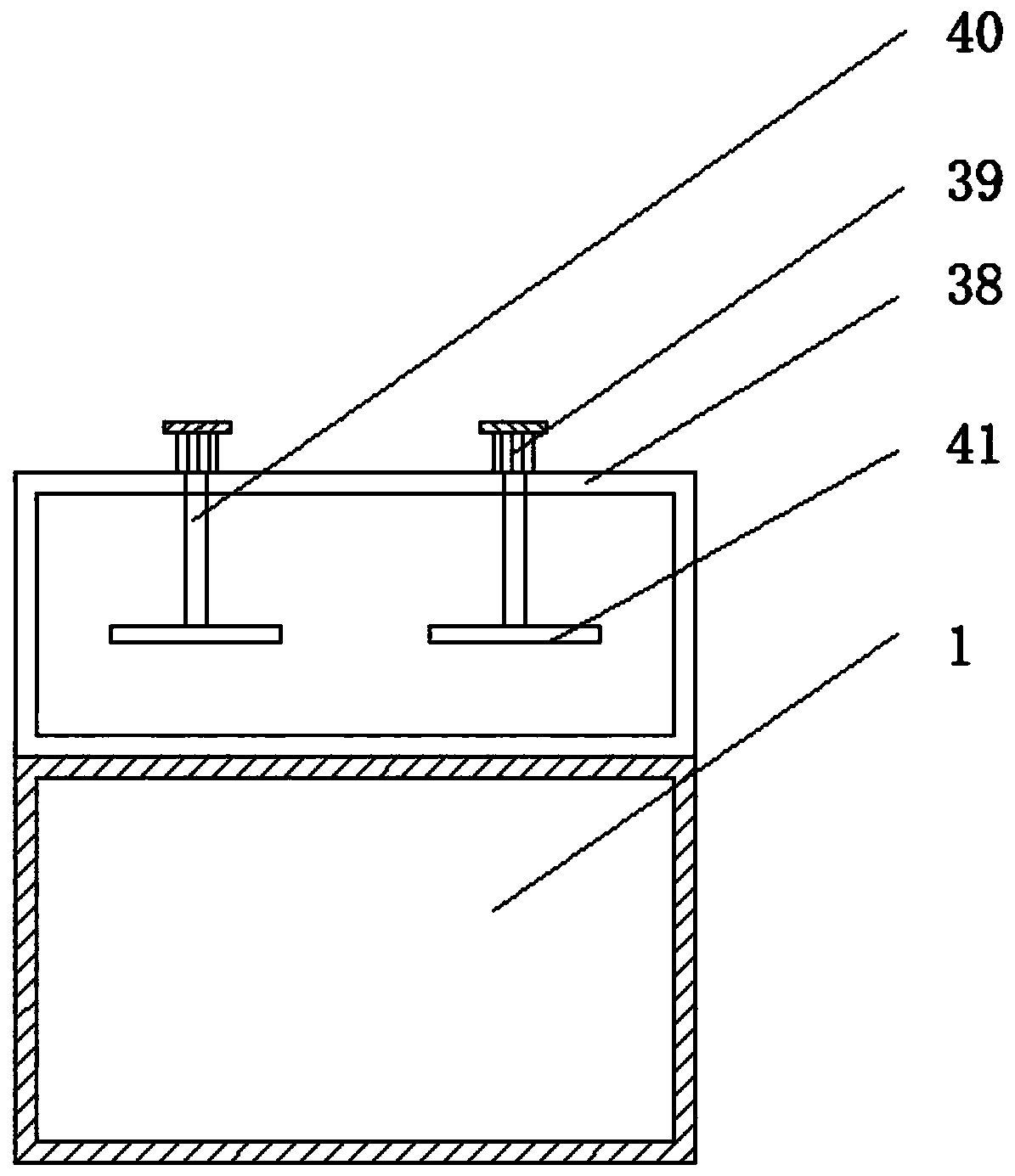

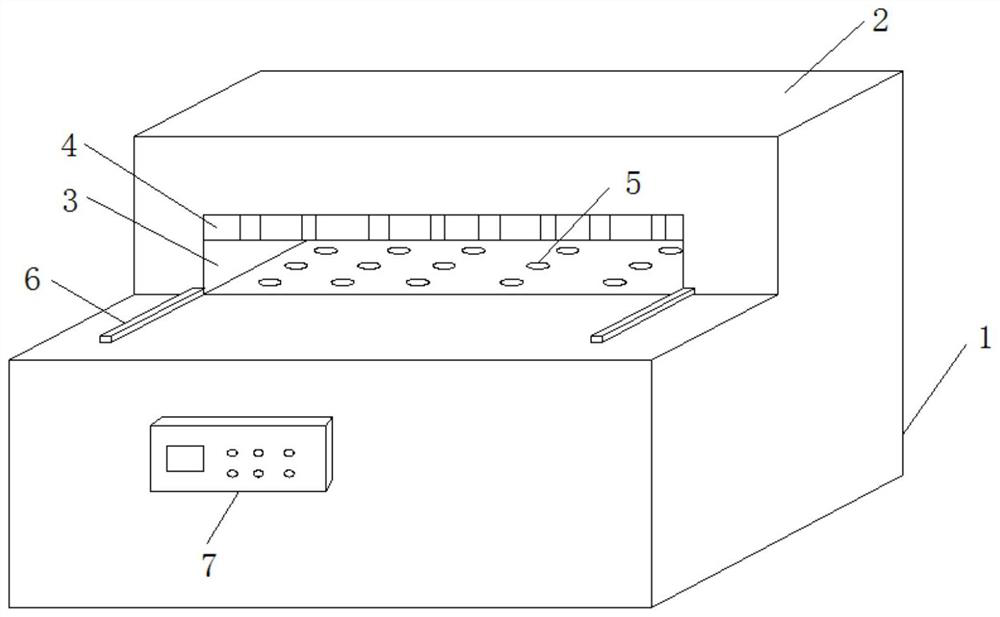

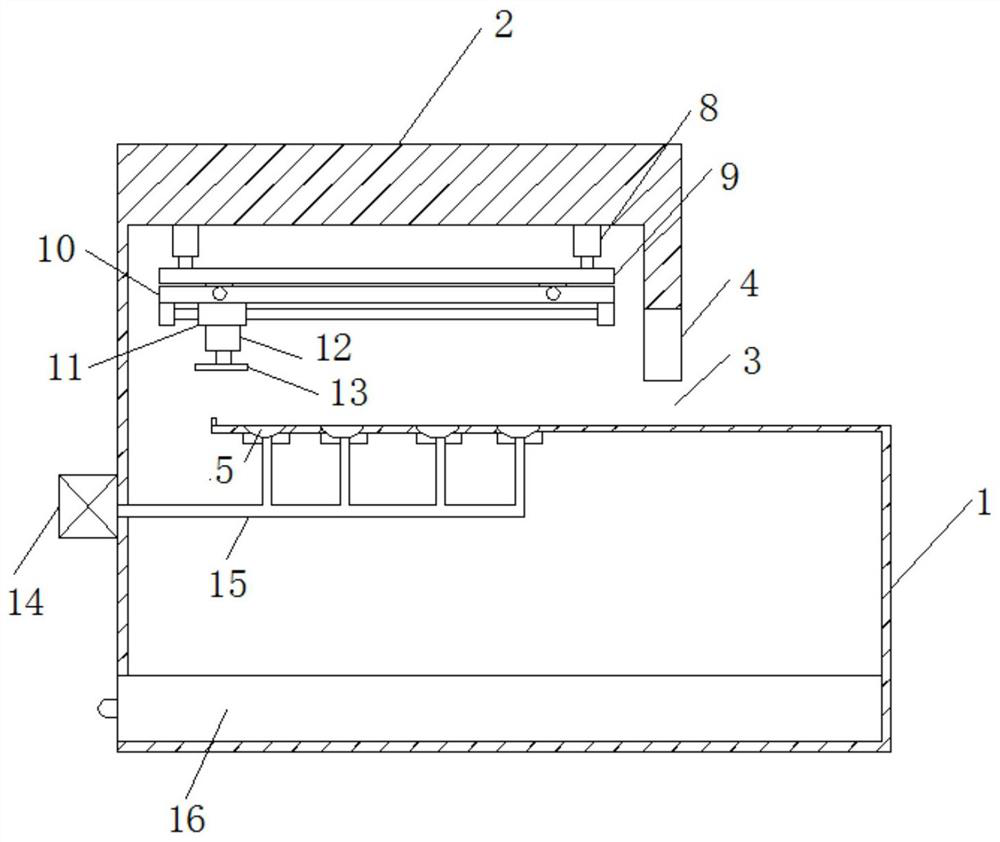

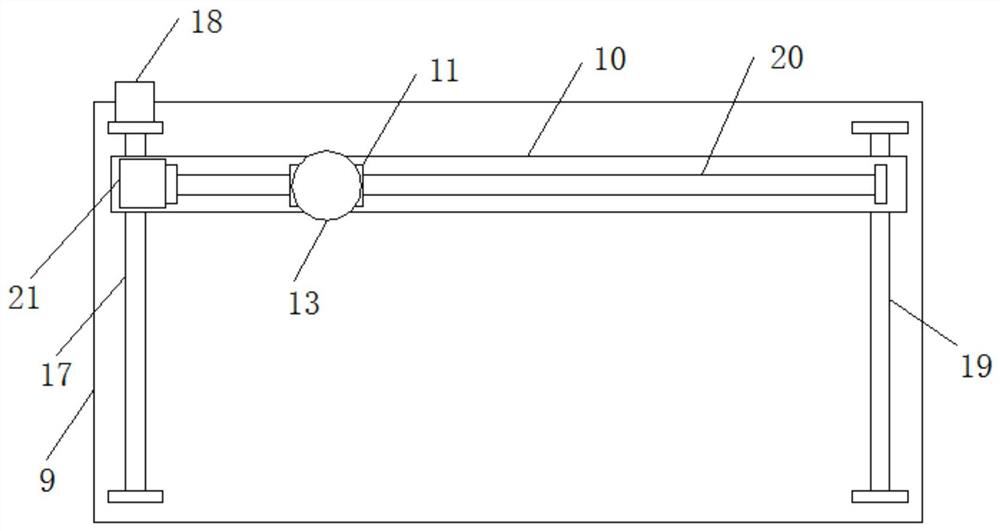

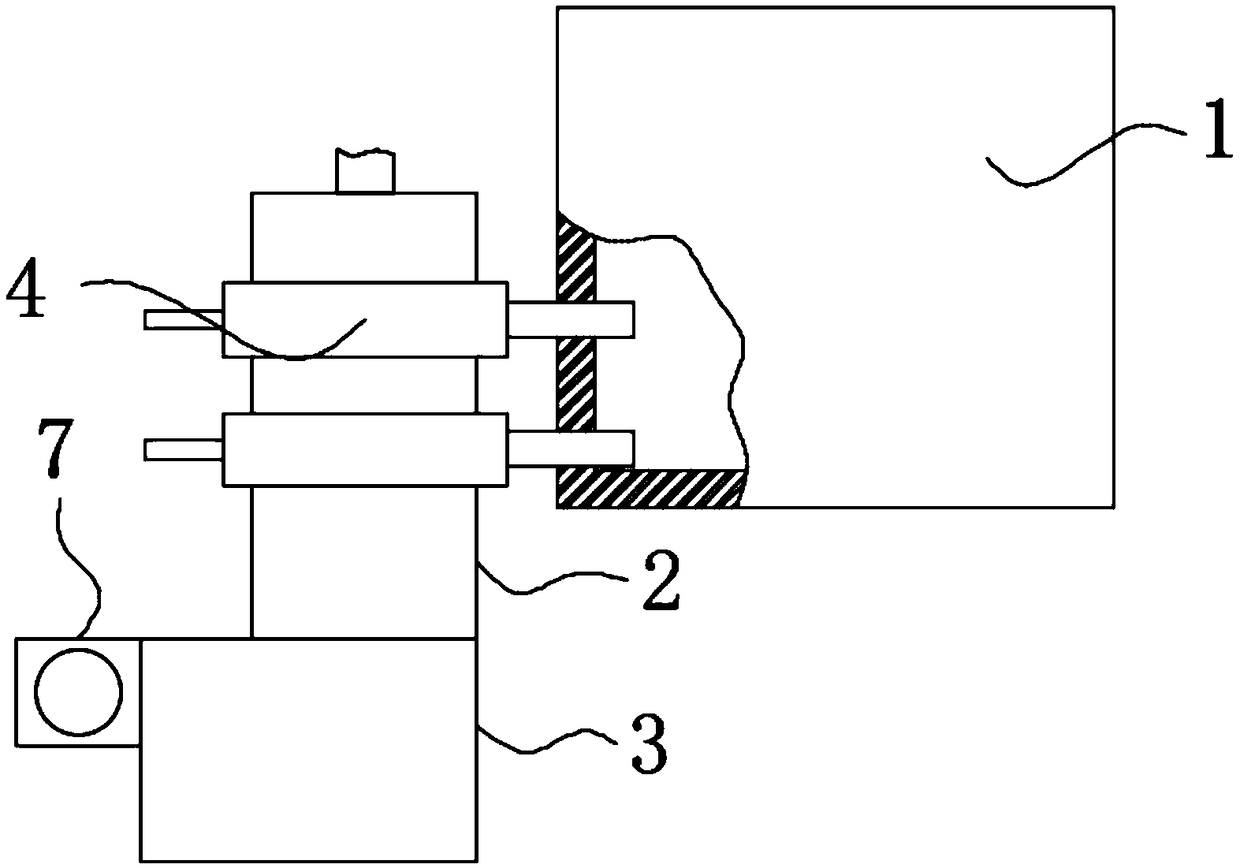

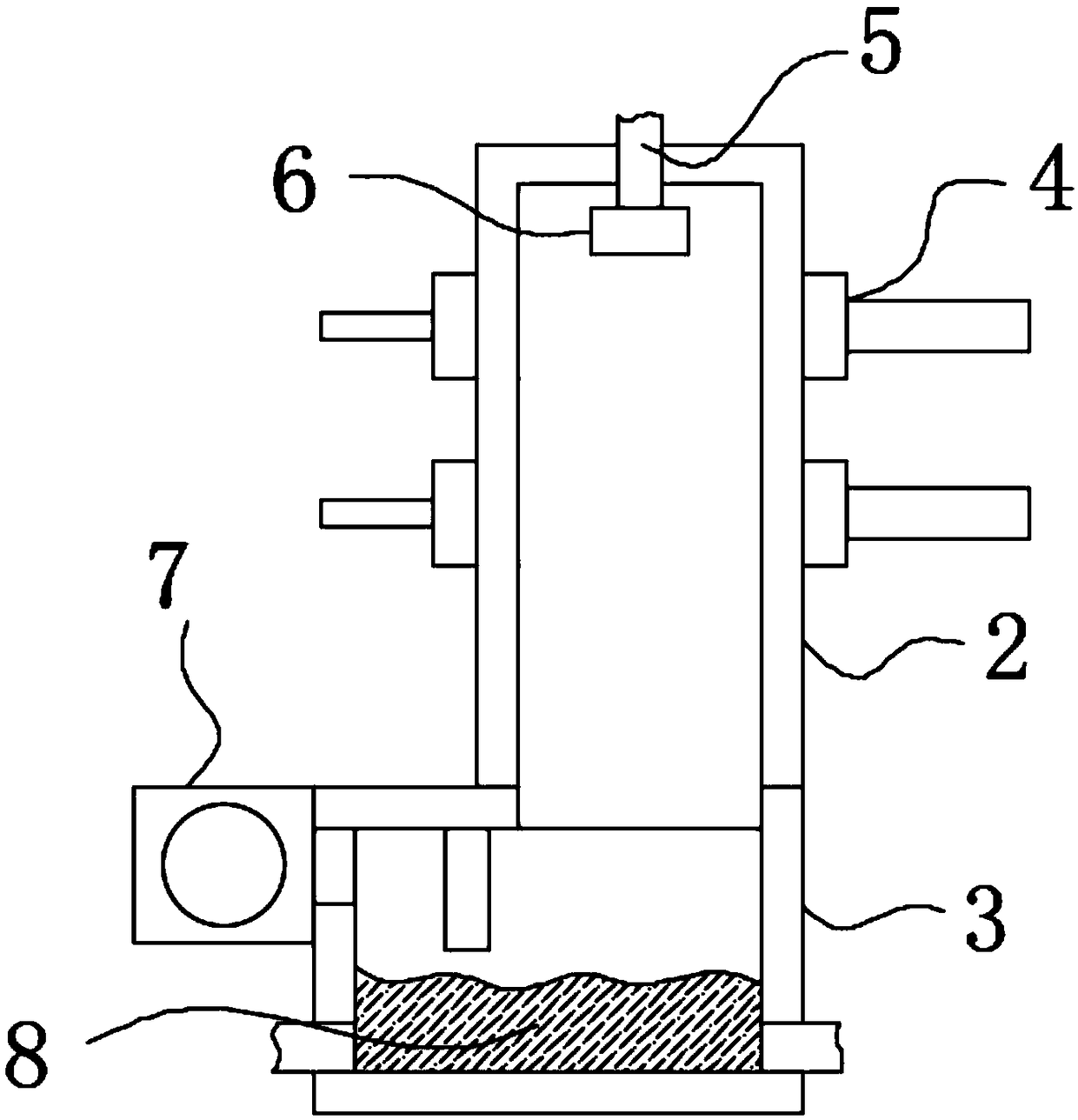

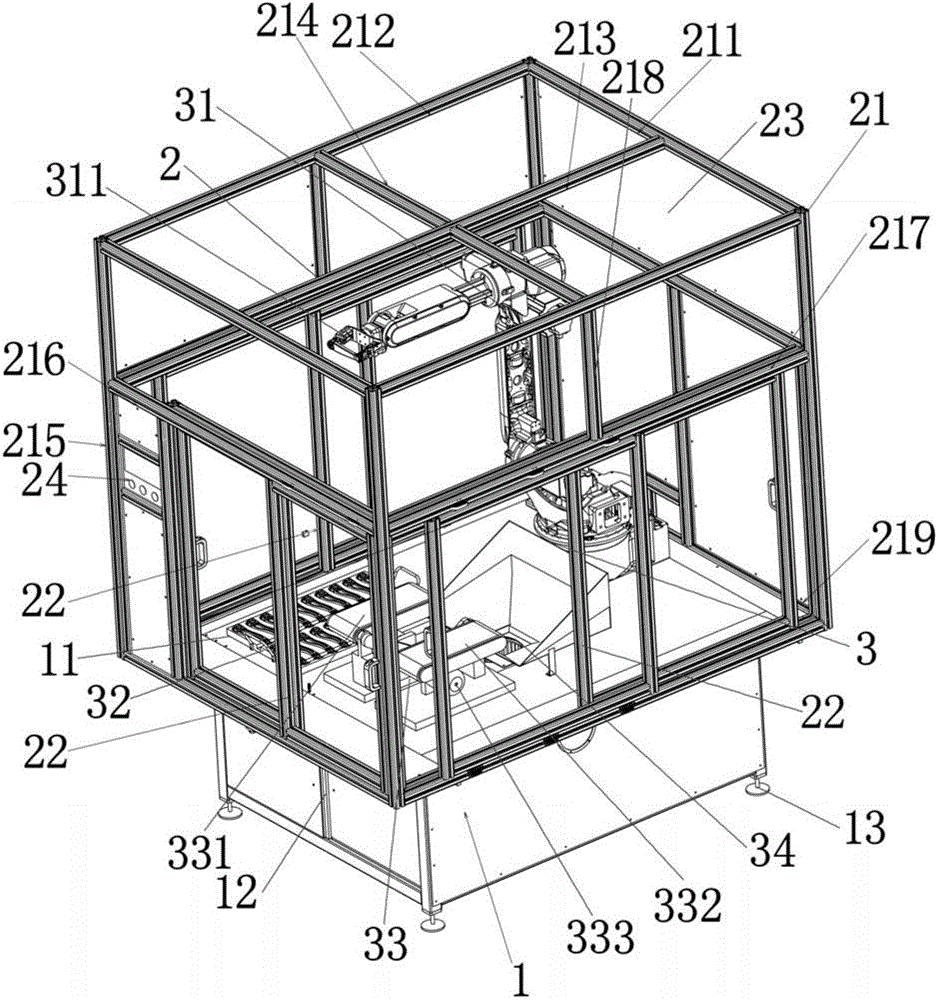

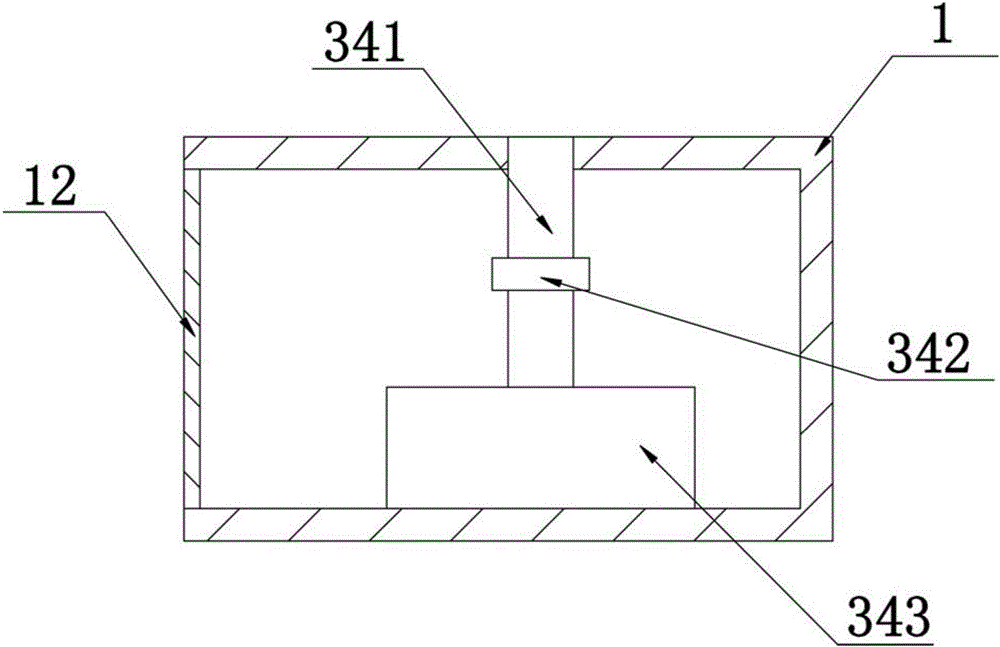

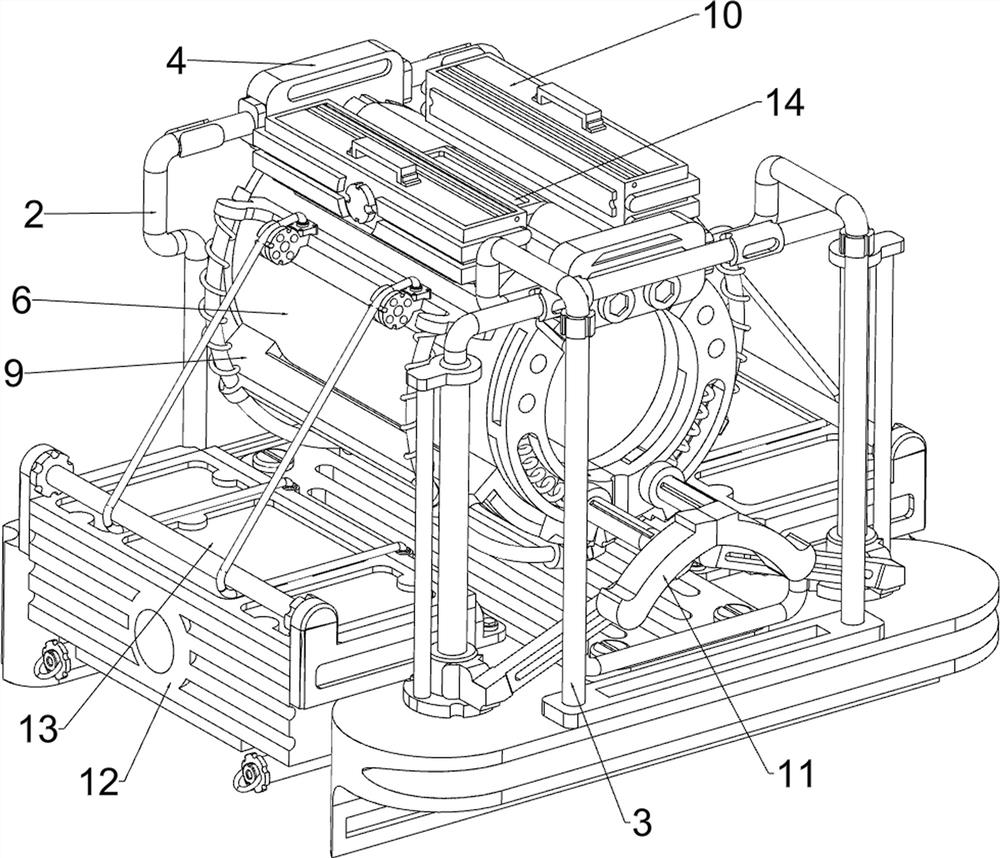

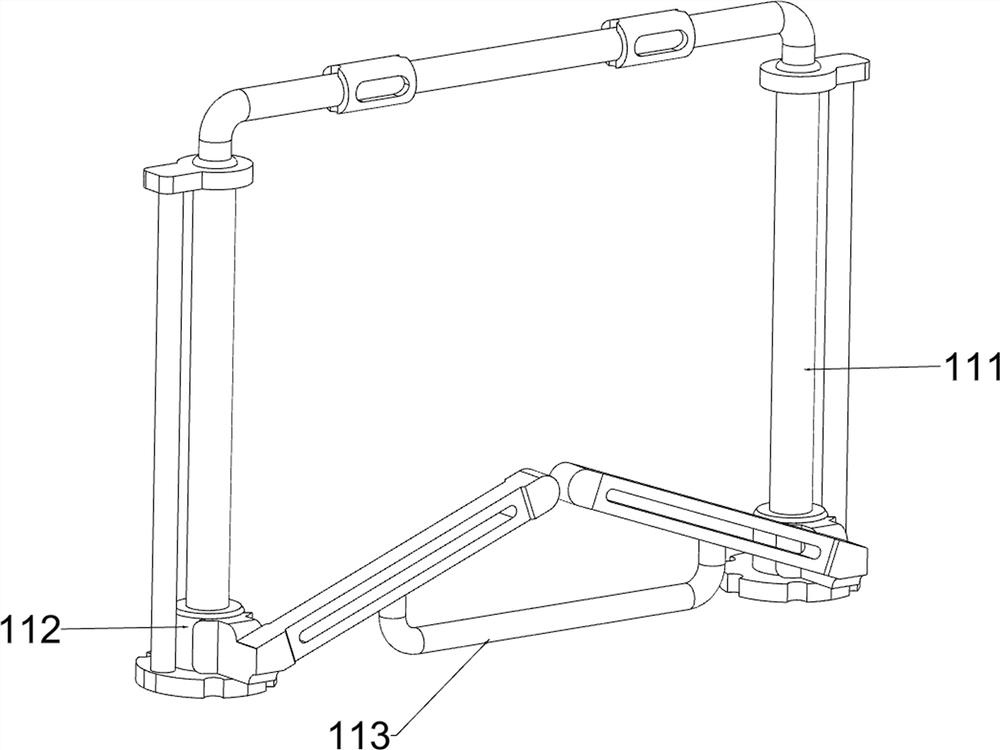

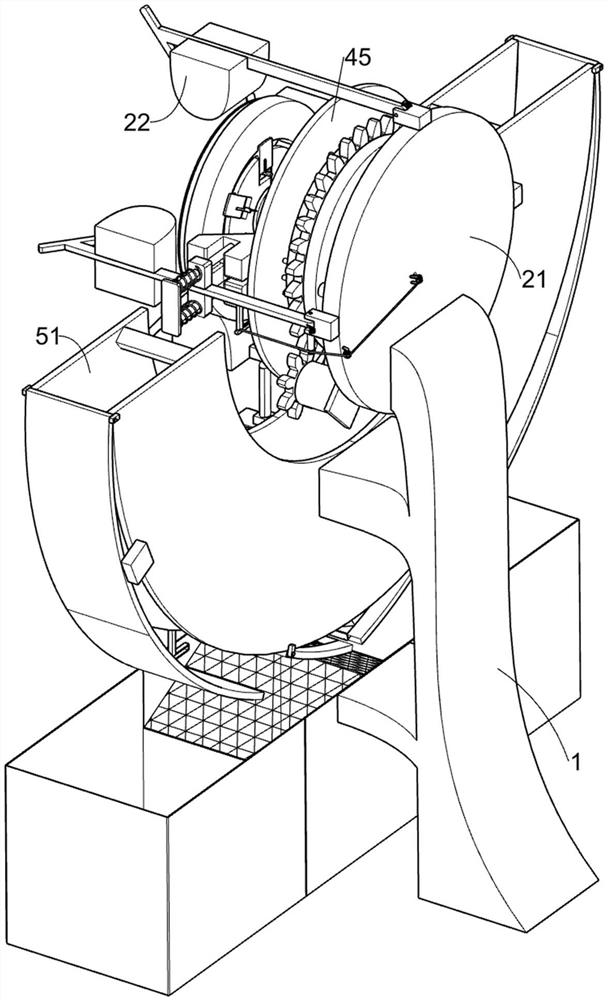

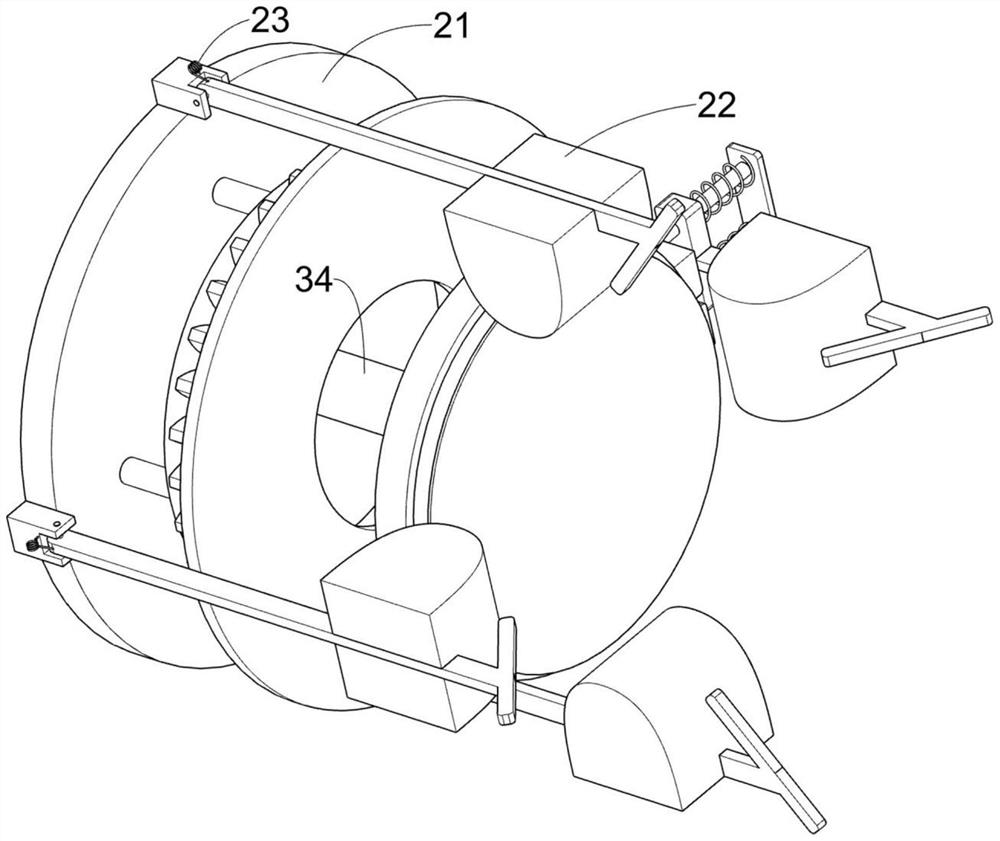

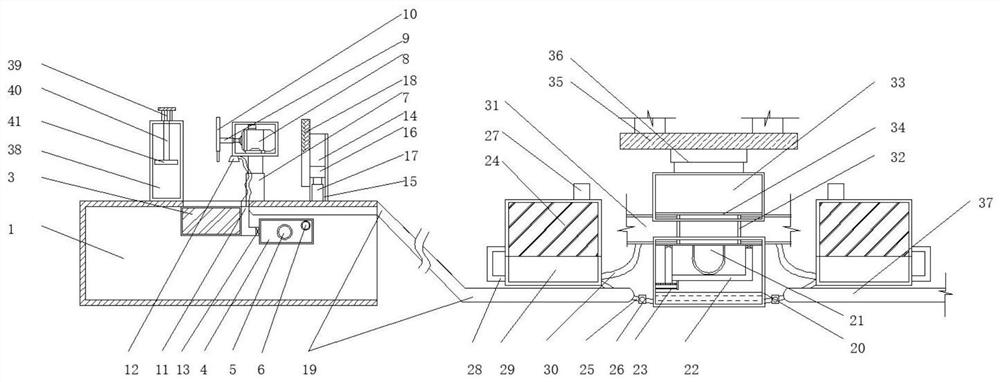

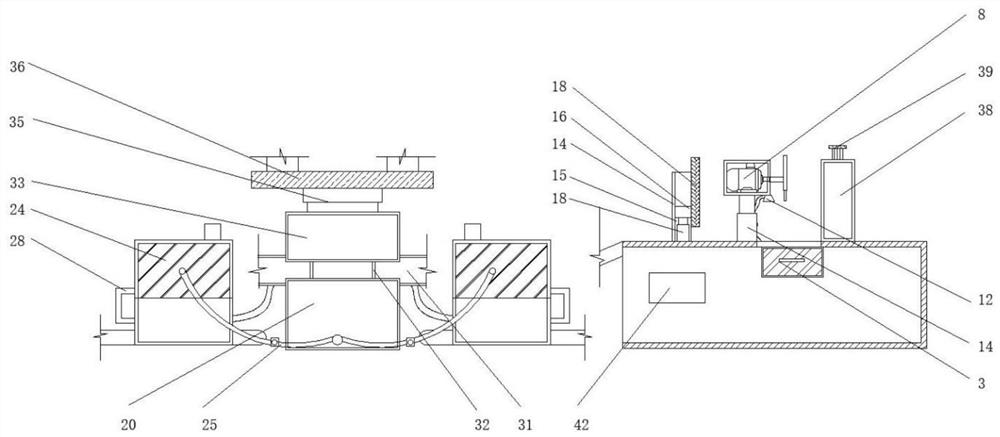

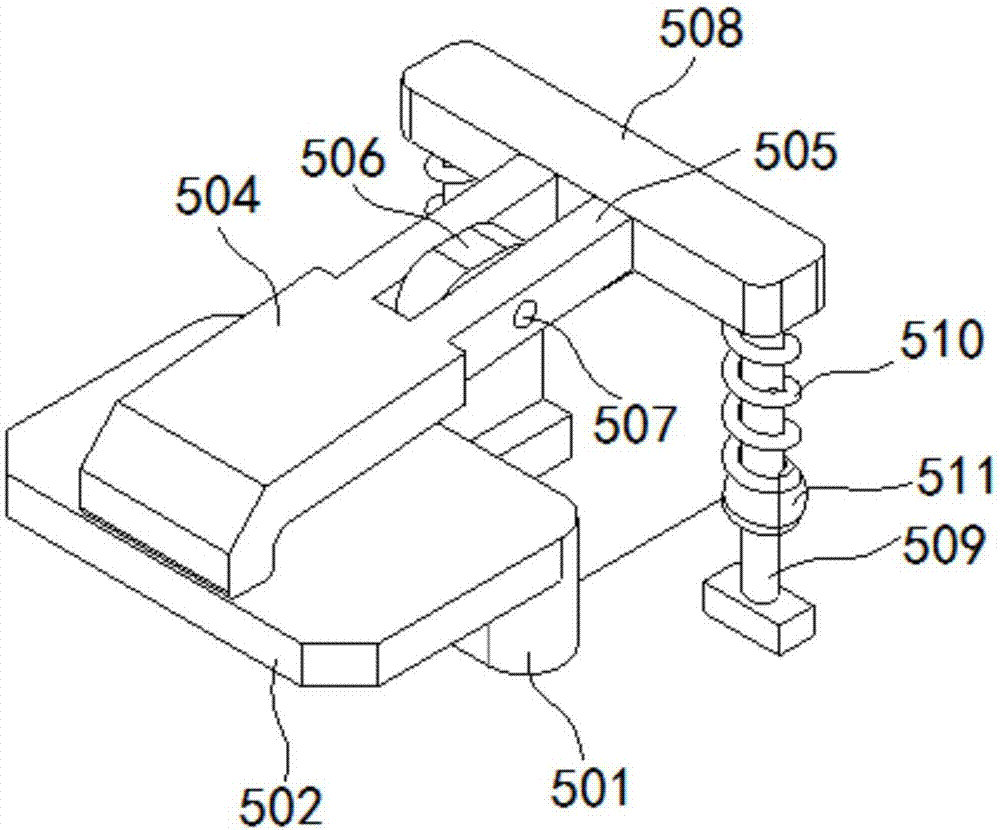

Automatic grinding machine

InactiveCN105127856AStable pass rateEffective cleaning and recyclingEdge grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention discloses an automatic grinding machine. The automatic grinding machine comprises a base (1), a work room (2) and an automatic grinding system (3), wherein the work room (2) is fixed to the upper plane of the base (1); the automatic grinding system (3) is arranged inside the work room (2); the worm room (2) comprises a support frame (21), movable doors (22) and baffles (23); the automatic grinding system (3) comprises a six-shaft machine arm (31), a tray (32), a polishing and grinding system (33) and a dust collection system (34); the six-shaft machine arm (31), the polishing and grinding system (33) and the dust collection system (34) are fixed to the base (1); the top end of the six-shaft machine arm (31) is provided with a clamping jaw (311); the base (1) is provided with a tray fixing groove (11) matched with the tray (32). By the adoption of the structure, burrs of workpieces can be automatically removed, working efficiency is improved effectively, the cost is reduced, and stability of the percent of pass of the workpieces is ensured.

Owner:NINGBO ASIAWAY AUTOMOTIVE COMPONENTS CO LTD

Cold compress nursing equipment for outer epidermis of leg burn patient

PendingCN114392039AFacilitates cold therapyAvoid risk of injuryTherapeutic coolingTherapeutic heatingCold compressesCold pack treatment

The invention relates to nursing equipment, in particular to cold compress nursing equipment for the outer skin of a leg burn patient. According to the cold compress nursing equipment for the outer skin of the leg burn patient, ice blocks are convenient to clean, and errors caused by manual operation can be avoided through automatic operation. A cold compress nursing device for the outer skin of a leg burn patient comprises a base, a first mounting frame, a second mounting frame and the like, the first mounting frame is arranged on the front side of the top of the base, and the second mounting frame is arranged on the rear side of the top of the base. Through operation of the electric sliding rails, the two shells can be automatically rotated and opened, cold compress treatment of a patient is facilitated, when cold compress of the patient is completed and the shells are opened, the sliding plates are rotated and opened through the connecting frames, ice cubes in the shells can automatically fall off, people can conveniently clean and recycle the ice cubes, the convenience of overall operation is effectively improved, and the practicability is high. And the risk that the patient is injured due to manual operation is avoided.

Owner:付德为

A control system based on intelligent agricultural greenhouse

ActiveCN113079891BPromote growthMeet growth needsClimate change adaptationPressurised distribution of liquid fertiliserAgricultural scienceEnvironmental regulation

The invention relates to an intelligent agricultural greenhouse control system and its planting frame, including environmental parameter detection modules arranged inside the greenhouse, soil parameter detection modules arranged inside the soil, a central processing unit, a management database, and a water resource irrigation module , a nutrient component adjustment module and a nutrient component watering module. Beneficial effects of the present invention: the environmental regulation inside the greenhouse is conducive to the growth of crops, meets the growth needs of crops, provides a good growth environment for crops, reduces the stability of roots, and facilitates the cleaning and recycling of plants. During the adjustment and supplementation of nutrients, the liquid is filled into the drain pipe through the connection port, so that the liquid fills the entire drain pipe, thereby generating pressure on the baffle, so that the baffle starts to move to one side, so that in the same time period , so that the liquid flows out evenly, so that the soil moisture and the distribution of nutrients can be more uniform.

Owner:中科海拓(无锡)科技有限公司

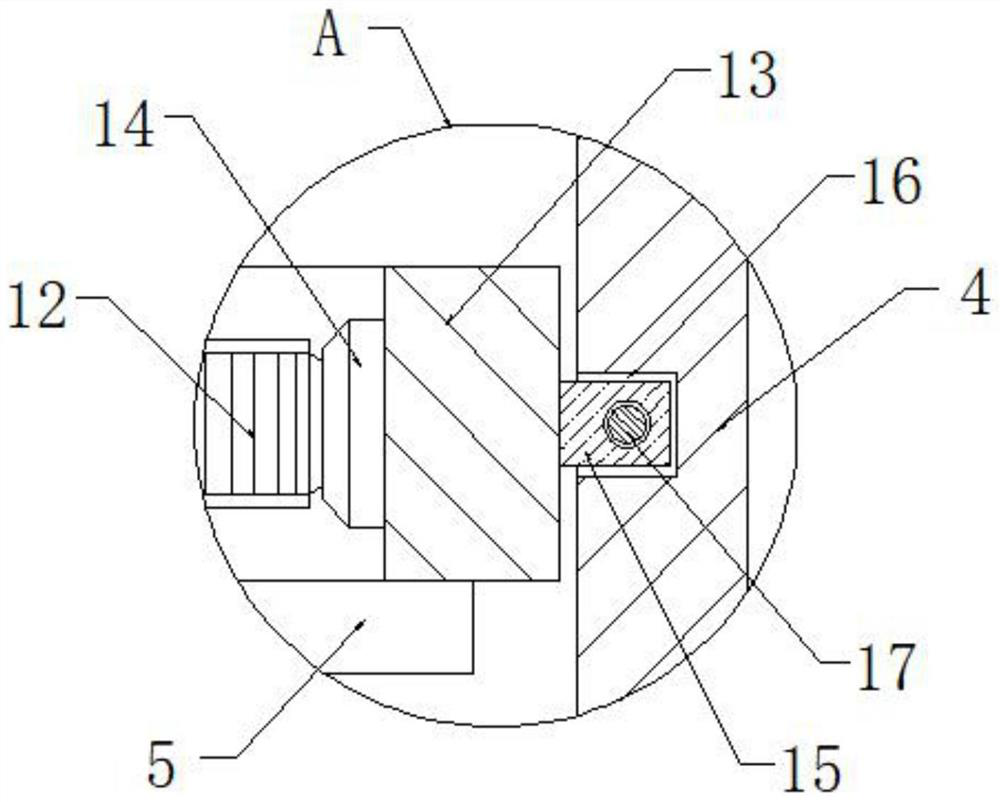

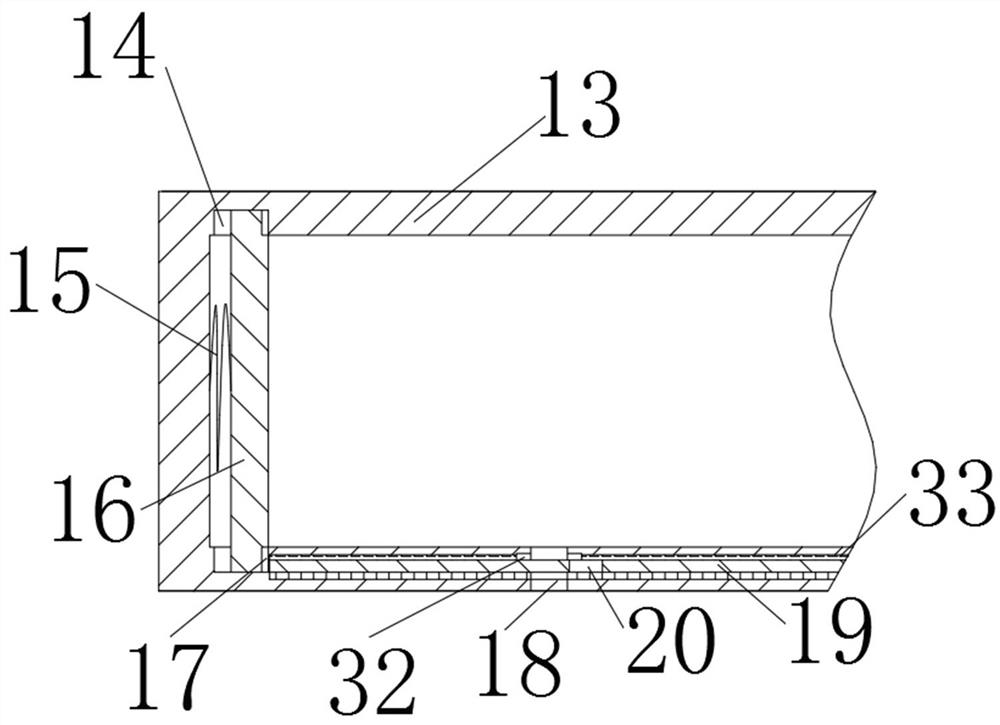

Polishing device easy to clean and capable of adapting to pipeline openings of different sizes

ActiveCN113070760AAvoid offsetAvoid enteringEdge grinding machinesGrinding work supportsTorsion springIndustrial engineering

The invention relates to the technical field of pipeline machining, in particular to a polishing device easy to clean and capable of adapting to pipeline openings of different sizes. The device comprises a first support frame, an anti-deviation assembly, a sealing assembly and the like; and an anti-deviation assembly is arranged on the first support frame, and the sealing assembly is arranged on the anti-deviation assembly. A pipeline is pushed in the direction close to a supporting disc through external pushing traction equipment, the pipeline can push a clamping frame to swing, a first torsion spring is compressed, then the outer wall of the pipeline is clamped by the clamping frame through the reset effect of the compressed first torsion spring, the pipeline is prevented from deviating when the pipeline is polished in the later period, and through the function of the clamping frame, the device can be suitable for pipelines with different sizes and specifications.

Owner:WEGS SHANGHAI FLUID TECH

A smokeless cutting steelmaking and casting slag steel rotary workbench which is convenient for loading and unloading steel slag

ActiveCN113061671BEasy to cleanEasy to useRecycling and recovery technologiesProcess efficiency improvementSteelmakingStructural engineering

The invention discloses a smokeless cutting steelmaking and casting slag steel rotary workbench which is convenient for loading and unloading steel slag, and relates to the technical field of steel slag treatment. Aiming at the problem of poor working performance of the existing workbench, the following scheme is proposed, which includes a base , the top of the base is provided with a loading platform, the middle part of the loading platform is provided with a loading tank, the inside of the loading tank is provided with a workbench, the workbench is provided with a connecting mechanism, and the workbench passes through the connecting mechanism Rotationally connected to the inside of the loading tank, a bearing platform is provided between the base and the loading platform, the four corners of the top of the bearing platform are fixed with connecting columns, and the ends of the connecting columns away from the loading platform are fixed at the bottom of the loading platform . The invention has a reasonable structure, can effectively carry steel slag, and can flexibly adjust the corresponding angle of the workbench, and can simply and conveniently clean and recycle the steel slag residue on the top of the workbench, with high flexibility and convenient use. High performance.

Owner:新疆互力佳源环保科技有限公司

A three-way elbow forming and processing integrated equipment

ActiveCN110732881BGood for cleaning and recyclingReduce entryOther manufacturing equipments/toolsMetal working apparatusScrew threadIndustrial engineering

The invention discloses three-way elbow forming and processing integration equipment which comprises a base, a second water delivery pipe, a third water delivery pipe and a fourth water delivery pipe,wherein a first slideway is arranged in the base; a bellows is arranged on the right side of a withdrawal box; a waste gas treatment tank cover is connected on the front side of a waste gas treatmenttank by screw threads; a first electric expansion link is fixed on the upper side of the base; a material suction port is formed at one end of the bellows in a penetrating manner; a fixing plate is arranged on the right side of the first electric expansion link; a second slideway is arranged in the fixing plate; a second electric expansion link is fixed on the lower side of a sliding block; a first conveying belt is inserted at the upper end of the base; a three-way elbow die groove is formed on the upper side in a lower die block; and a filter screen is arranged at the lower end of the leftside of a first water delivery pipe. The three-way elbow forming and processing integration equipment is provided with the withdrawal box, so that scraps generated during pipeline cutting fall into the withdrawal box by a hole in the base to be stored.

Owner:江苏新泰隆管件有限公司

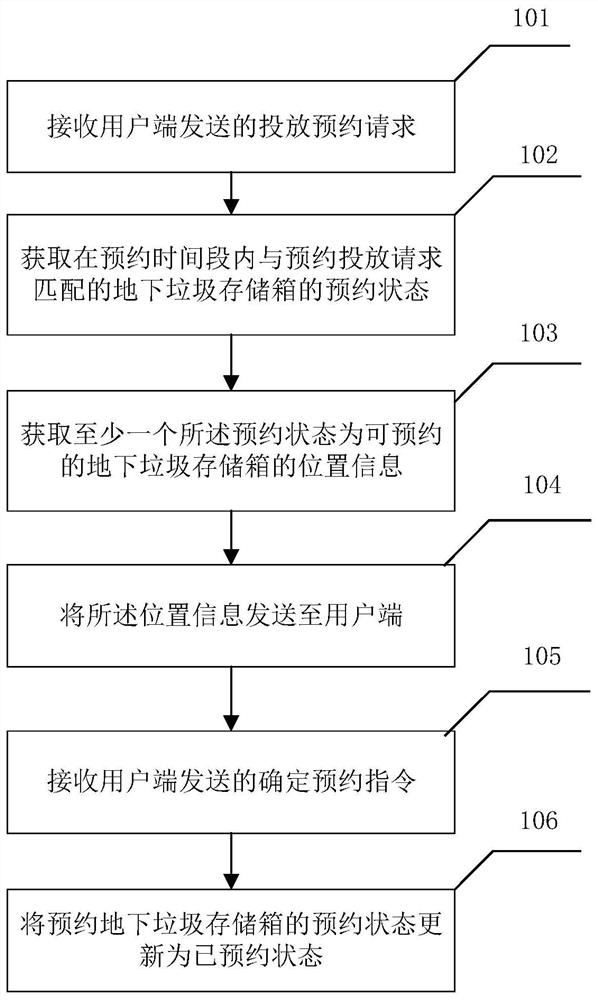

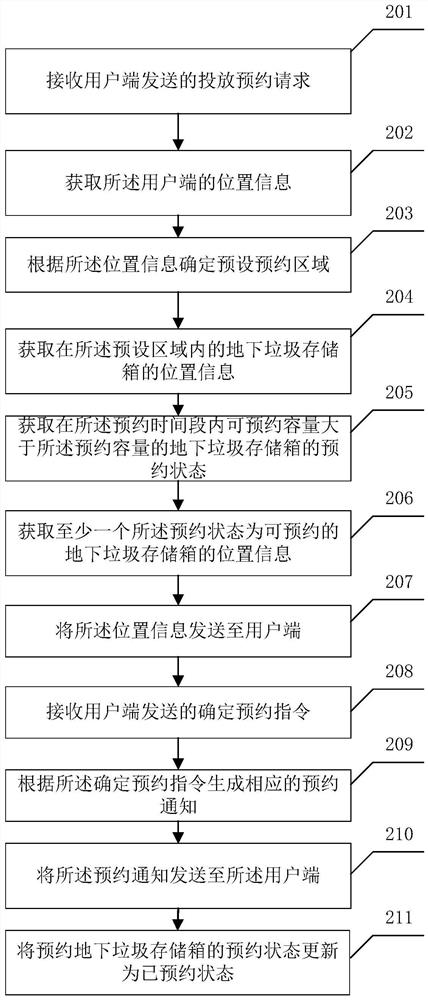

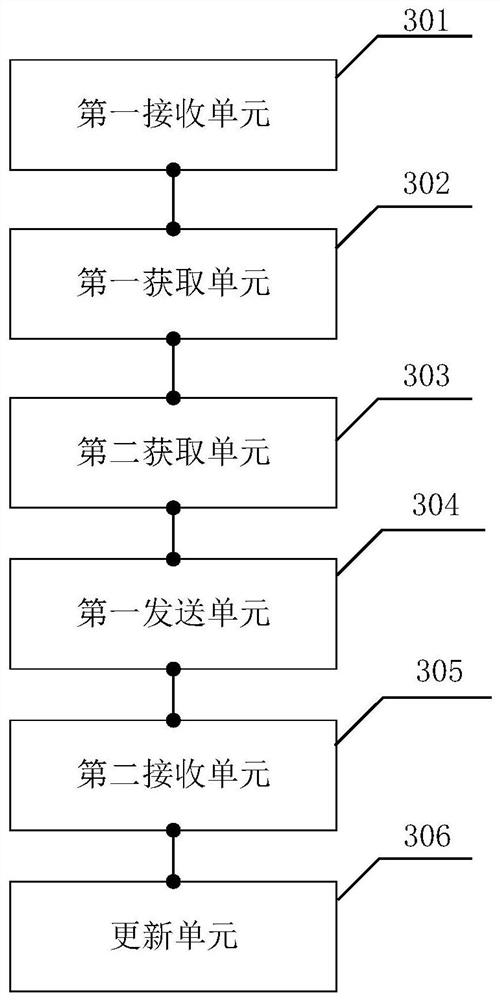

Garbage throwing reservation method and system

InactiveCN112722651AGood for cleaning and recyclingEasy constructionRefuse receptaclesRefuse transferringUser identifierOperations research

The invention discloses a garbage throwing reservation method and system which are used for enabling a user to reserve a garbage throwing box by himself / herself according to own requirements and providing convenience for sanitation workers to clean and recycle special types of garbage. The garbage throwing reservation method provided by the embodiments comprises the following steps that a throwing reservation request sent by a user side is received, wherein the throwing reservation request comprises a user identifier, reservation weight and a reservation time period; a reservation state of an underground garbage storage box matched with the reservation throwing request in the reservation time period is obtained; position information of at least one underground garbage storage box with the reservation state being an appointable state is obtained; the position information is sent to the user side so that the user can determine a target underground garbage storage box capable of being reserved according to the position information; a reservation determining instruction sent by the user side is received, wherein the reservation determining instruction comprises position information of the target underground garbage storage box; and the reservation state of the target underground garbage storage box is updated into a reserved state.

Owner:江苏地风环卫有限公司

A sheet clamping device for laser cutting equipment

InactiveCN106312340BEasy to installEasy to disassembleWelding/cutting auxillary devicesAuxillary welding devicesBiochemical engineeringLaser cutting

The invention discloses a plate clamping device for laser cutting equipment. The device comprises a bottom plate, a discharging box, a processing plate, lifting cylinders, clamping seats and baffles. By means of the clamping seats arranged on the processing plate, a plate can be conveniently mounted and dismounted, the clamping is reliable, and the stability is high; besides, the clamping seats can be moved according to the size of the plate, therefore, the application range is broad. By the arrangement of the discharging box which is equipped with a mounting plate and is detachably arranged on the bottom plate, waste can be cleaned and recycled conveniently. The device is simple in structure, convenient to operate, high in reliability and good in stability.

Owner:重庆聚纵贸易有限公司

Garbage incinerator with flue gas filtration function

The invention relates to the technical field of incinerator flue gas filtration and purification, in particular to a garbage incinerator with a flue gas filtration function. The garbage incinerator comprises an incineration mechanism, a placement mechanism, a collection mechanism, a shaking mechanism, a purification mechanism and a locking mechanism. Under the action of the incineration mechanism, garbage and sundries can be incinerated conveniently, exhausted glue gas can be filtered and purified conveniently, and meanwhile, the garbage and sundries can be placed in the incineration mechanism conveniently under the action of the placement mechanism; under the action of the shaking mechanism, dust and sundries fall into the collection mechanism through the placement mechanism to be stored, subsequent cleaning and recycling are facilitated, and secondary pollution is reduced; under the action of the purification mechanism, flue gas can be sufficiently adsorbed and filtered, external pollution of the flue gas is reduced, and the flue gas can be smoothly discharged; and under the action of the locking mechanism, the purification mechanism and the incineration mechanism can be conveniently disassembled and assembled, and therefore adsorbates in the purification mechanism can be conveniently replaced and cleaned.

Owner:李沁芯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com