Work fixture on laser cutting device

A technology of laser cutting and tooling fixtures, applied in the field of tooling fixtures, can solve the problems of inability to guarantee the flatness and stability of metal sheets, inconvenient manual cleaning of waste materials, low cutting quality, etc., and achieves simple structure, convenient cutting, and high cutting quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

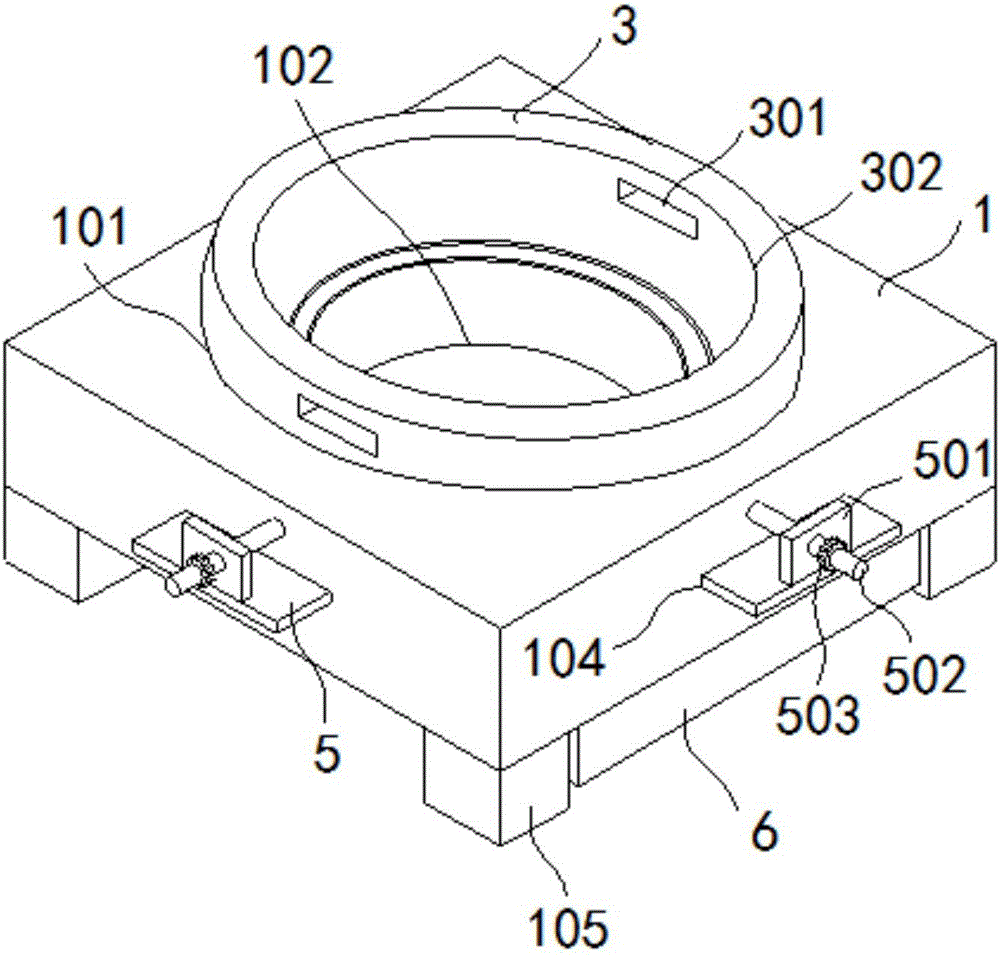

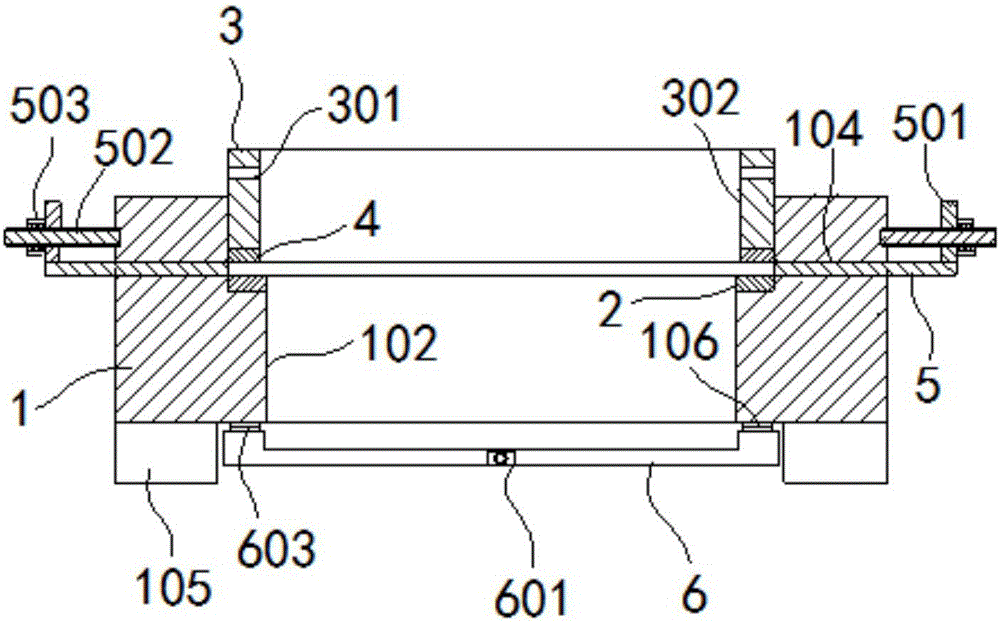

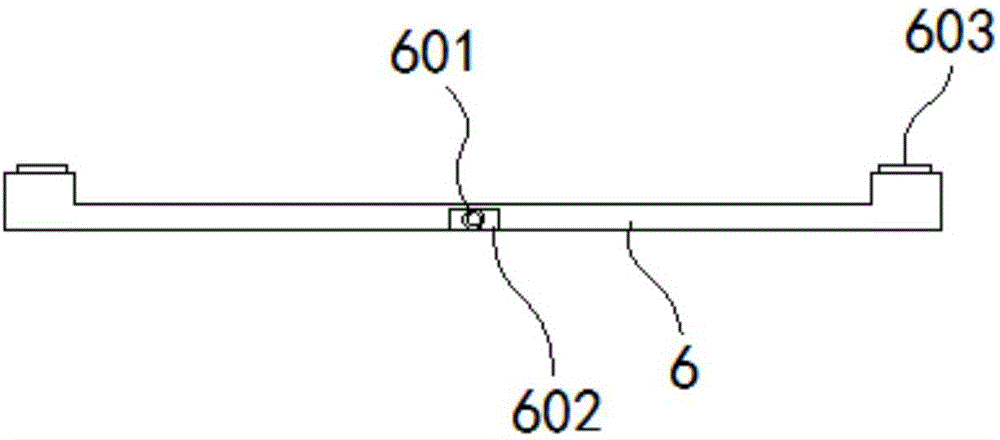

[0030] Such as figure 1 , figure 2 As shown, the fixture of the laser cutting equipment of the present invention includes:

[0031] Base 1, a circular sunken platform 101 is formed on the base 1, a through hole 102 penetrating the bottom surface of the base 1 is formed in the center of the sunken platform 101, and a through hole 102 is formed on the side wall of the sunken platform 101 through the base. 1 short groove 104 in the outer wall. Four corners of the lower end surface of the base 1 are respectively provided with fixing blocks 105 , and the base 1 is fixed on the machine platform or the ground through the fixing blocks 105 .

[0032] The first magnetic chuck 2 is fixedly arranged on the upper surface of the countertop 101 . The lower end surface of the short slot 104 is flush with the upper end surface of the first magnetic chuck 2 .

[0033] The fixed seat 3, the fixed seat 3 is a circular fixed seat, the fixed seat 3 is inserted into the sinking platform 101 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com