Metal material galvanic couple corrosion test fixture apparatus

A technology of galvanic corrosion and metal materials, applied in the field of experimental devices and fixtures, can solve problems such as threats to the overall reliability of structural facilities and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

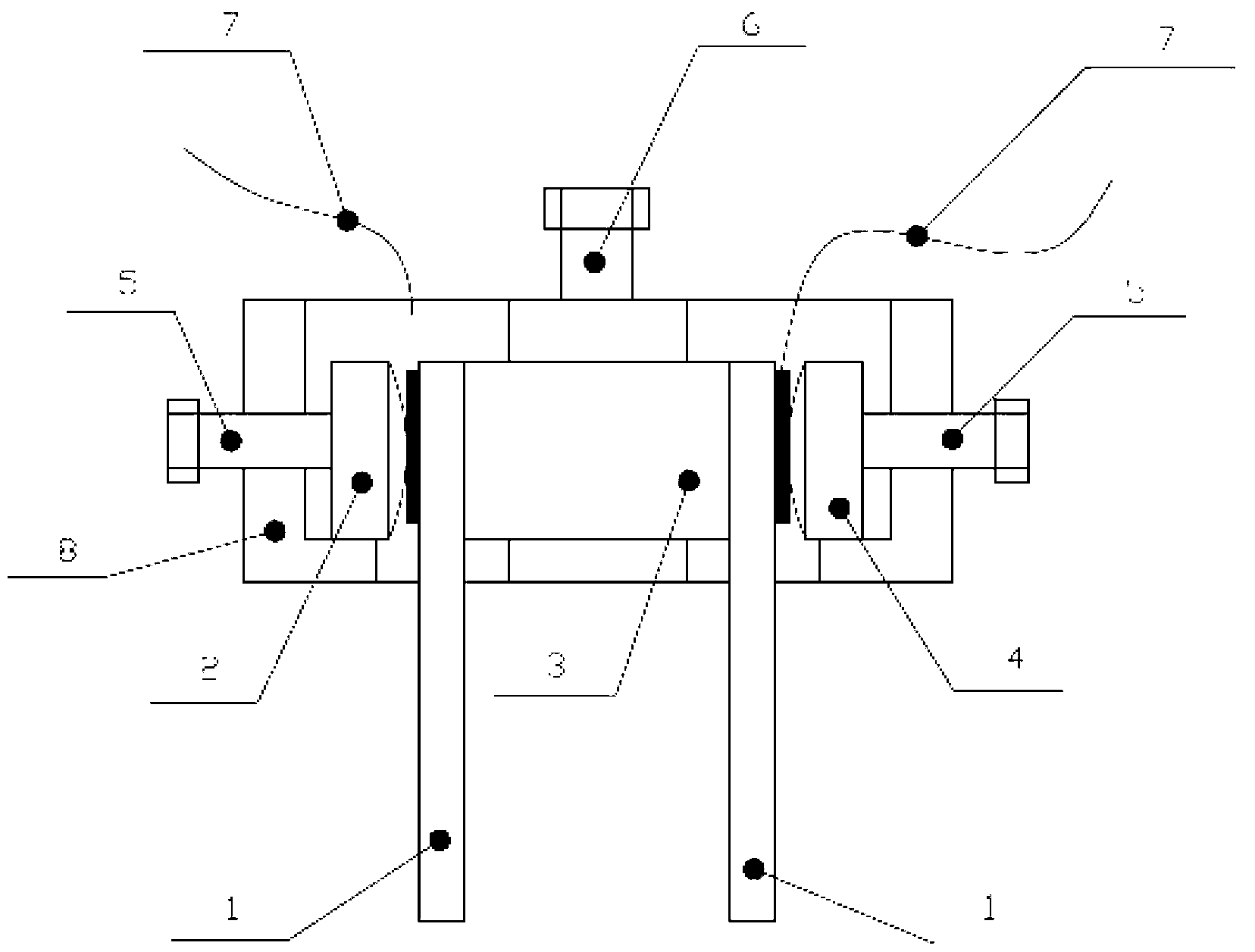

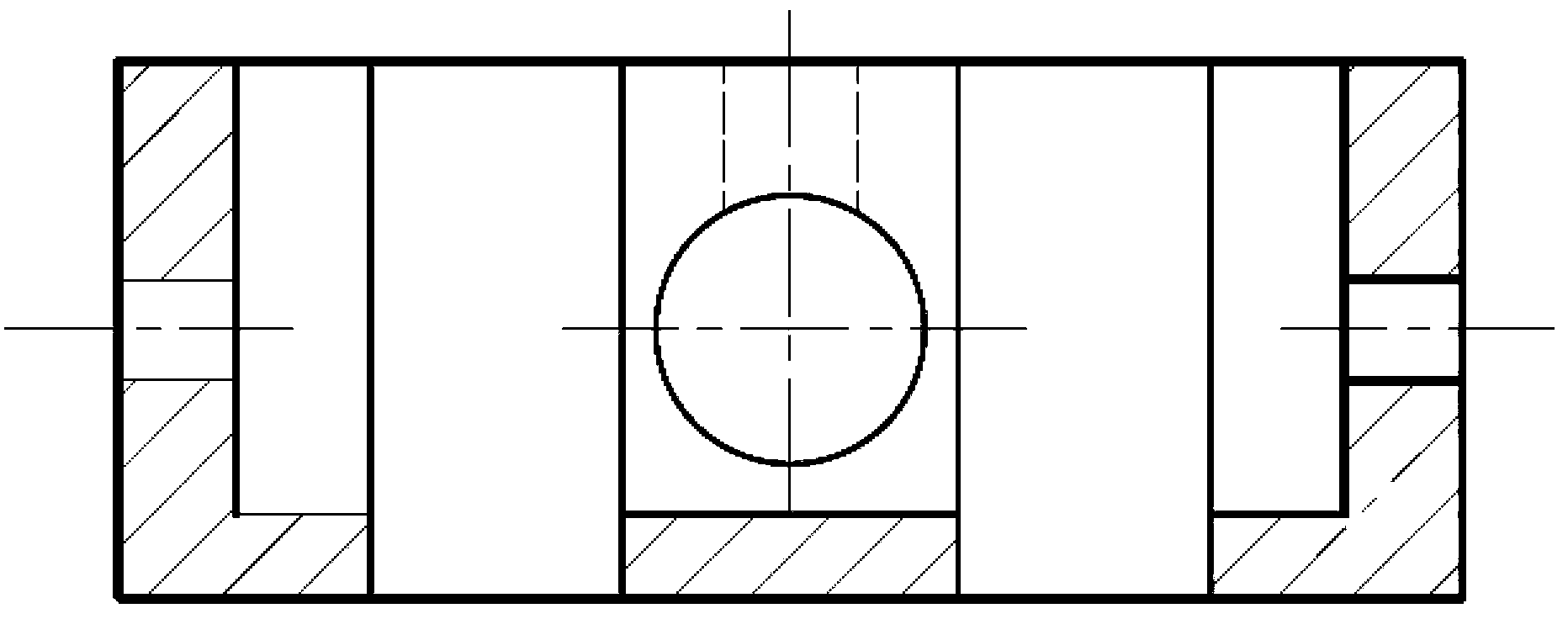

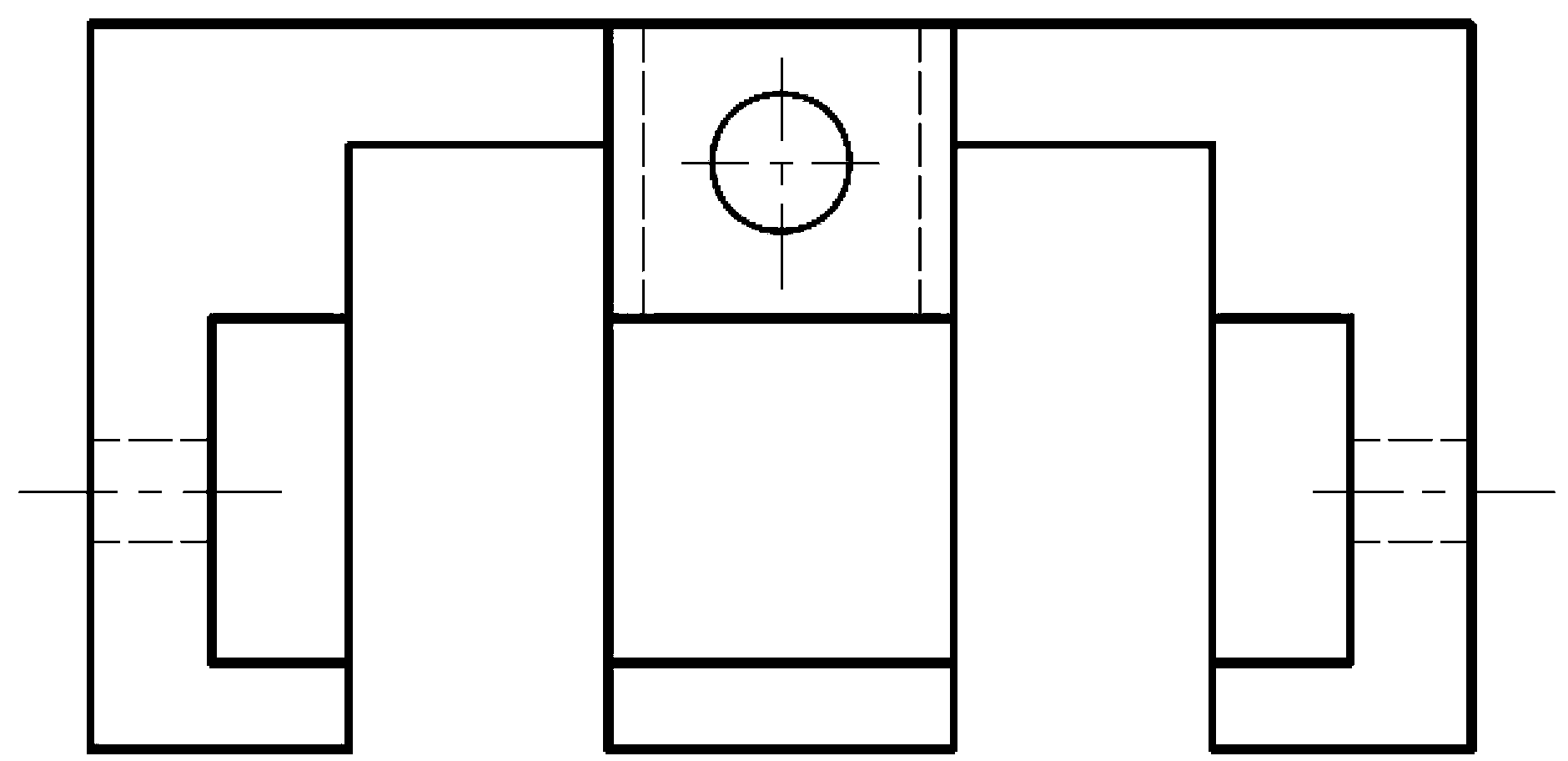

[0031] The fixture for the galvanic corrosion test of the metal material and the method of using the fixture for the galvanic corrosion test of the metal material will be further described in detail below in conjunction with the structural drawings.

[0032] figure 1 Schematic diagram of the work of the fixture device for the galvanic corrosion test of metallic materials. First, cut the length of insulating block 2 3 to the distance between the two samples required by the test, and place insulating block 2 3 in the middle support groove of main clamp body 8 . The two test samples 1 are respectively inserted into the groove of the main clamp body 8 where the insulating block is placed through the two hollow through holes on the bottom surface, and are in smooth contact with the two ends of the insulating block 2 and 3 . Place insulating block 1 2 and insulating block 3 4 on sample 1 and horizontal pressing bolt 5 according to the direction in which the end in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com