Dedusting device for crusher

A technology of dust removal device and crusher, which is applied in the direction of dust removal, combination device, cleaning method and utensils, etc., can solve the problems of waste of resources, pollution of the environment, no separation and collection of debris, etc., and achieve easy maintenance and replacement, easy cleaning and recycling, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

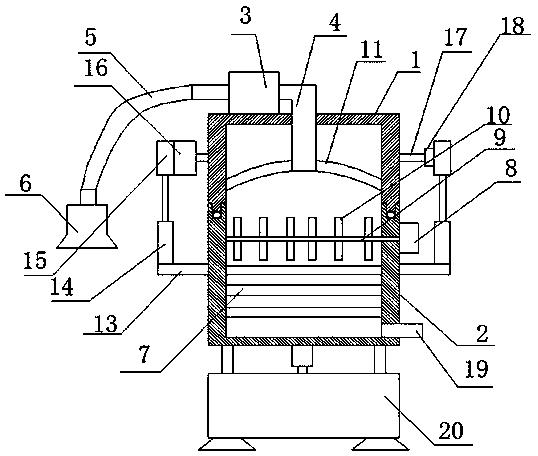

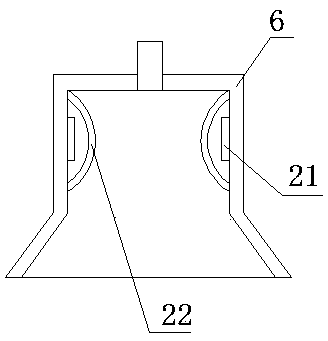

[0024] see Figure 1-4 , in an embodiment of the present invention, a dust removal device for a crusher includes a box body and a base 20, the box body includes an upper box body 1 and a lower box body 2, the upper end of the upper box body 1 is provided with a fan 3, the The fan 3 is provided with a blowing pipe 4 extending into the box, the fan 3 is connected with a dust suction pipe 5, the dust suction pipe 5 is connected with a dust collection cover 6, and the inside of the upper box 1 is provided with a magnet plate 11, The inside of the lower box 2 is provided with a multi-stage dust filter screen 7, and the lower end of the right side of the lower box 2 is provided with an exhaust pipe 19, and the left and right sides of the lower box 2 are provided with a support plate 13, and the support plate 13 The upper side is provided with a first electric telescopic mechanism 14, and the upper end of the first electric telescopic mechanism 14 is provided with a mounting seat 15,...

Embodiment 2

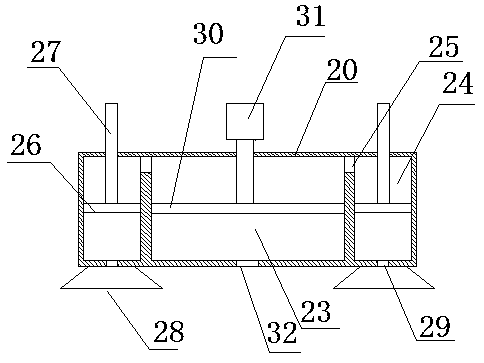

[0029] The inside of the base 20 is provided with a first sliding chamber 23, and the left and right sides of the first sliding chamber 23 are provided with a second sliding chamber 24, and the first sliding chamber 23 and the upper part of the second sliding chamber 24 pass through a first communication channel. The air hole 25 is connected, and the inside of the first sliding chamber 23 is provided with a first piston plate 30, and the upper side of the first piston plate 30 is provided with a second electric telescopic mechanism 31, and the upper end of the second electric telescopic mechanism 31 is installed on At the lower end of the box body, the lower end of the first slide chamber 23 is provided with a second vent hole 32, the inside of the second slide chamber 24 is provided with a second piston plate 26, and the upper side of the second piston plate 26 is provided with a slide rod 27, The upper end of the sliding rod 27 is connected to the lower end of the box body, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com