Study article recycling and processing device

A technology for processing equipment and school supplies, applied in plastic recycling, metal processing, recycling technology, etc., can solve problems such as pollution of the environment and pollution, and achieve the effect of avoiding pollution and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

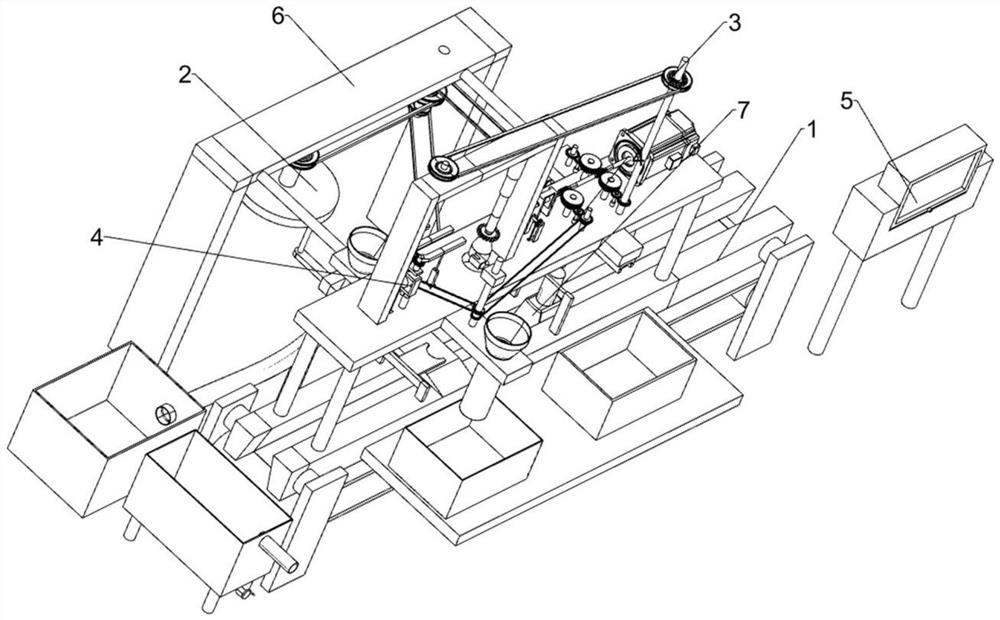

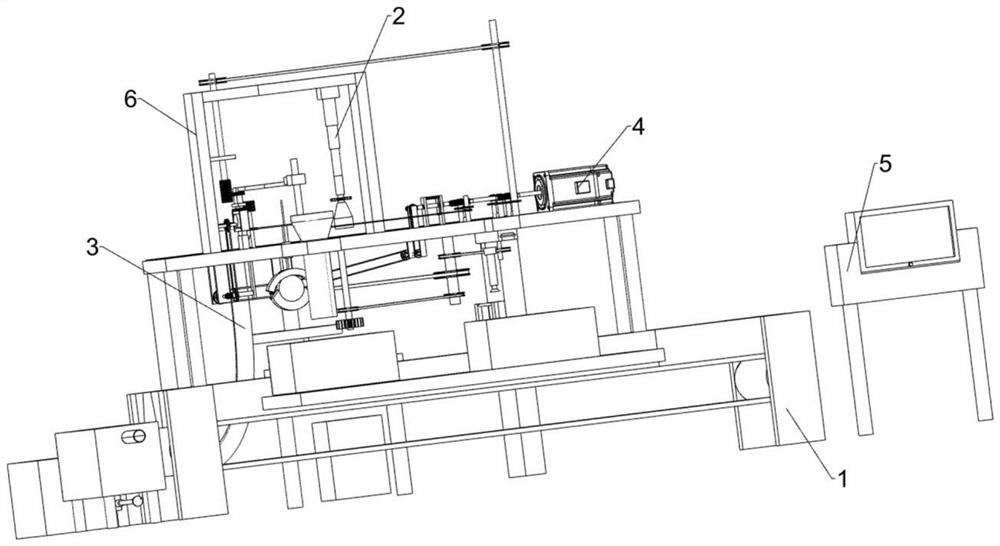

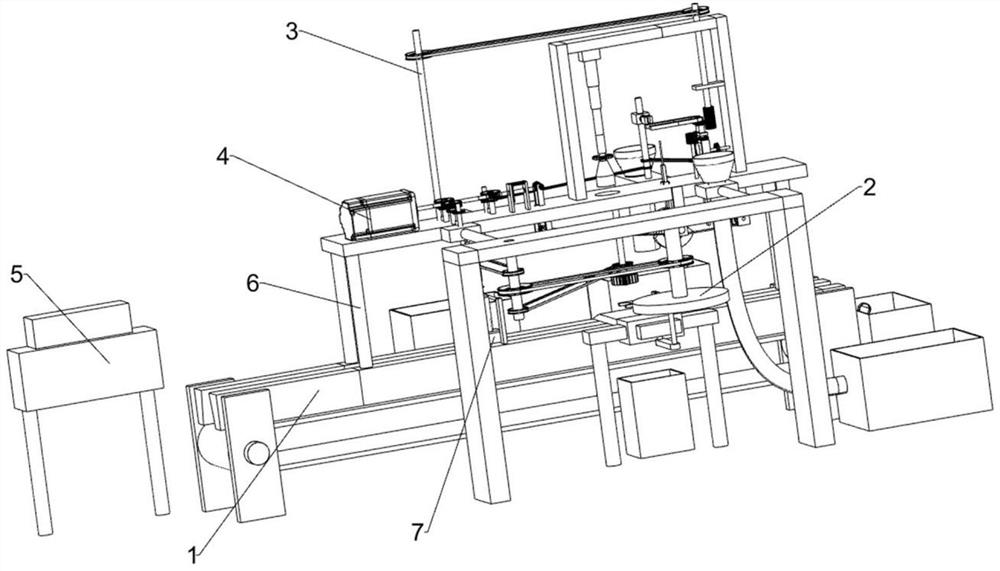

[0027] A kind of school supplies recycling processing device, such as Figure 1-7 As shown in the figure, it includes transportation limit and cap removal mechanism 1, cutting and separation fastening mechanism 2, clamping and rotating mechanism 3, ejection mechanism 4, control display screen 5, workbench 6 and correction fluid 7; transportation limit and cap removal mechanism 1 is connected with the cutting and separating fastening mechanism 2; the transport limit cap removal mechanism 1 is connected with the clamping and rotating mechanism 3; the transport limit cap removal mechanism 1 is connected with the workbench 6; the transport limit cap removal mechanism 1 is connected with the modification The liquid 7 is connected; the control display 5 is set beside the transport limit and cover removal mechanism 1; the cutting and separating fastening mechanism 2 is connected with the workbench 6; the cutting and separating fastening mechanism 2 is connected with the ejection mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com