Patents

Literature

31results about How to "Stable pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

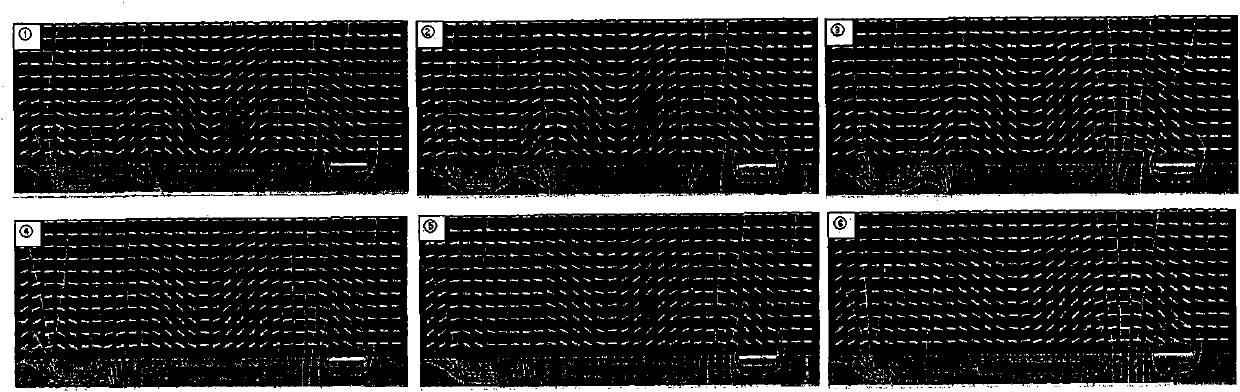

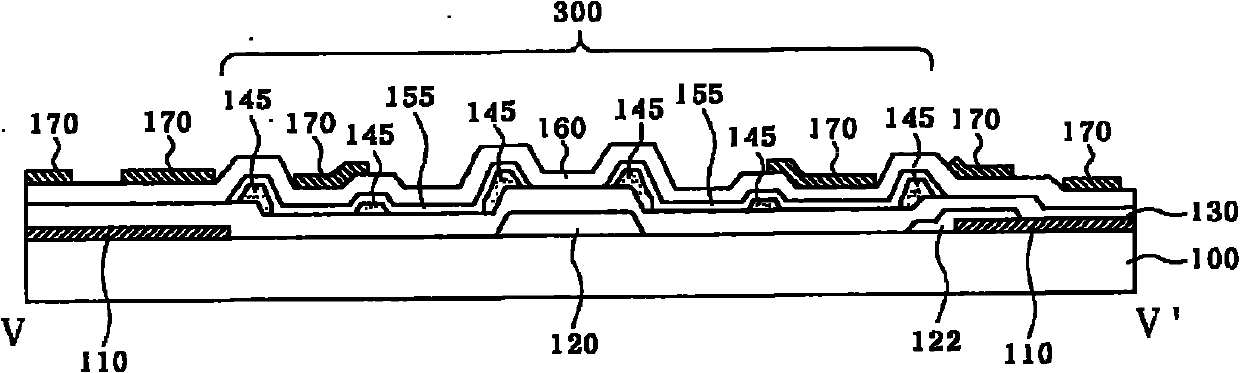

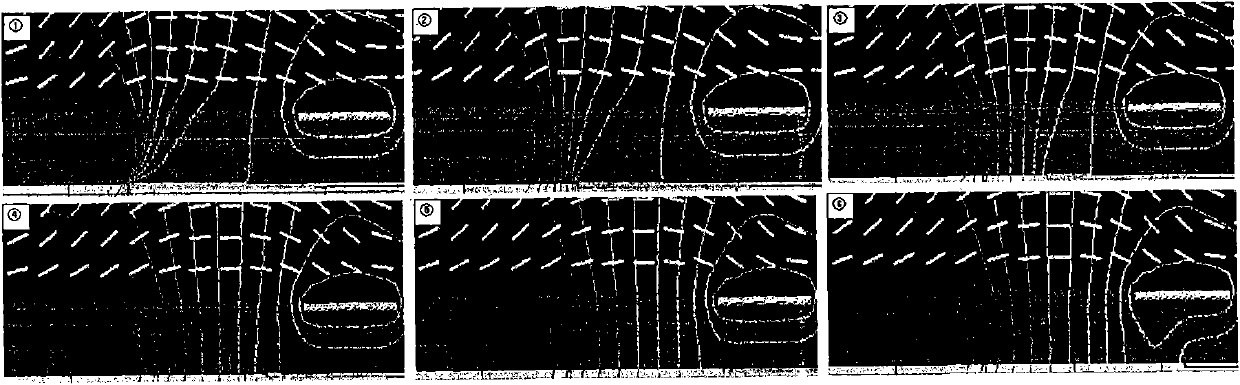

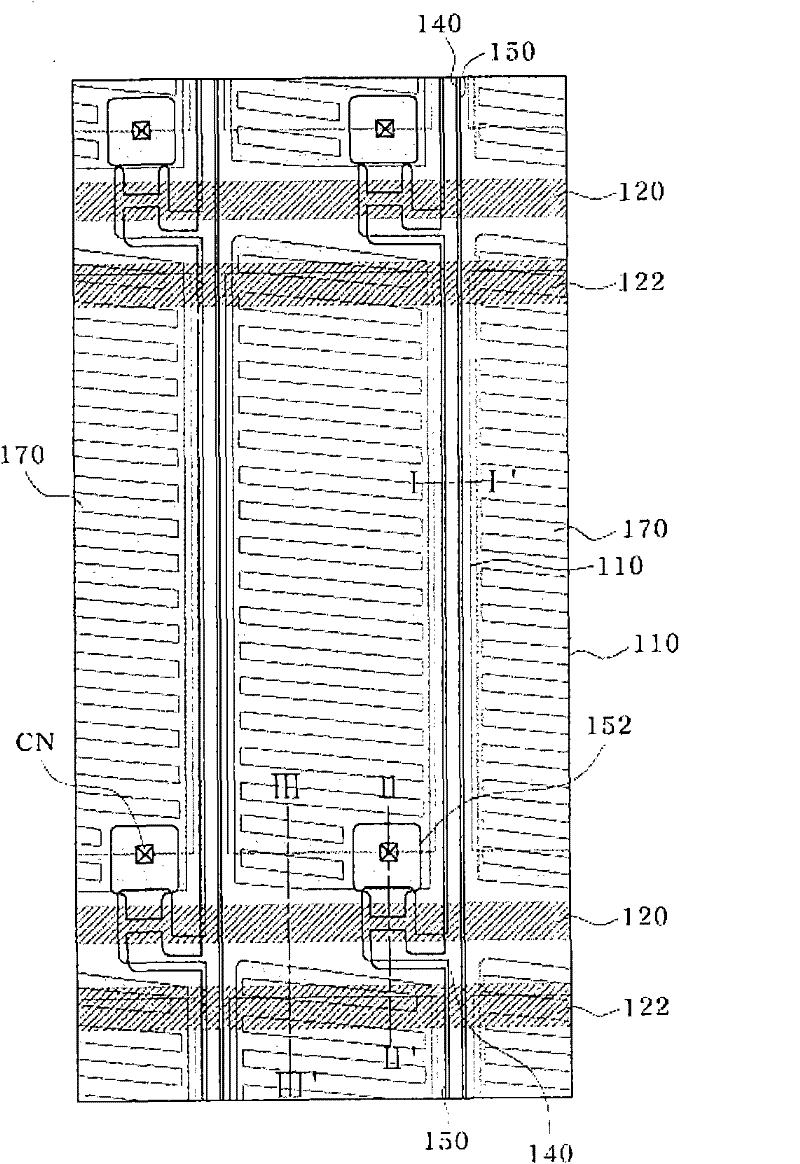

Fringe field switching mode liquid crystal display and manufacturing method thereof

ActiveCN101907802AImprove outdoor clarityIncrease the aperture ratioNon-linear opticsLiquid-crystal displayTransmittance

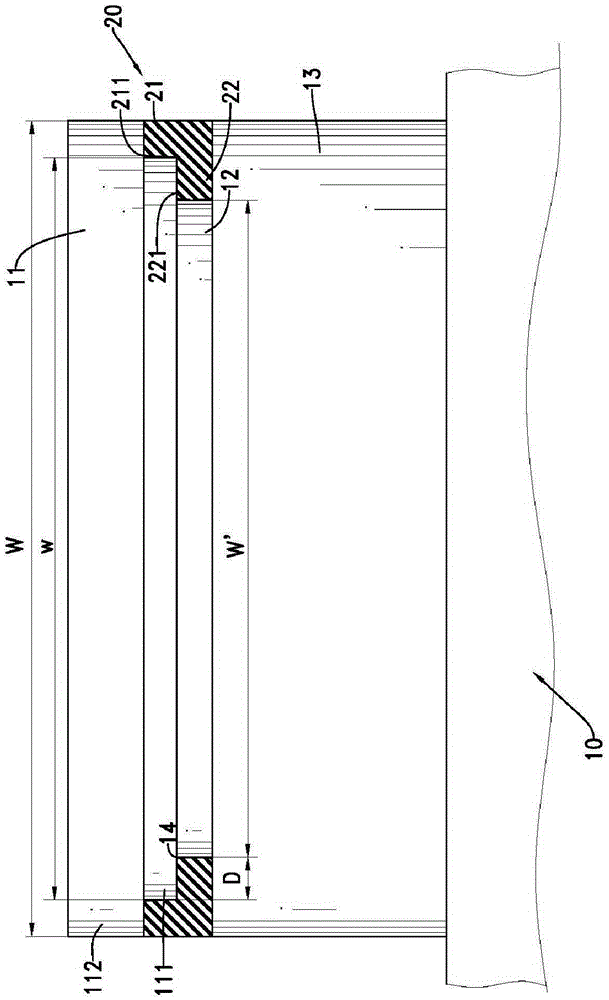

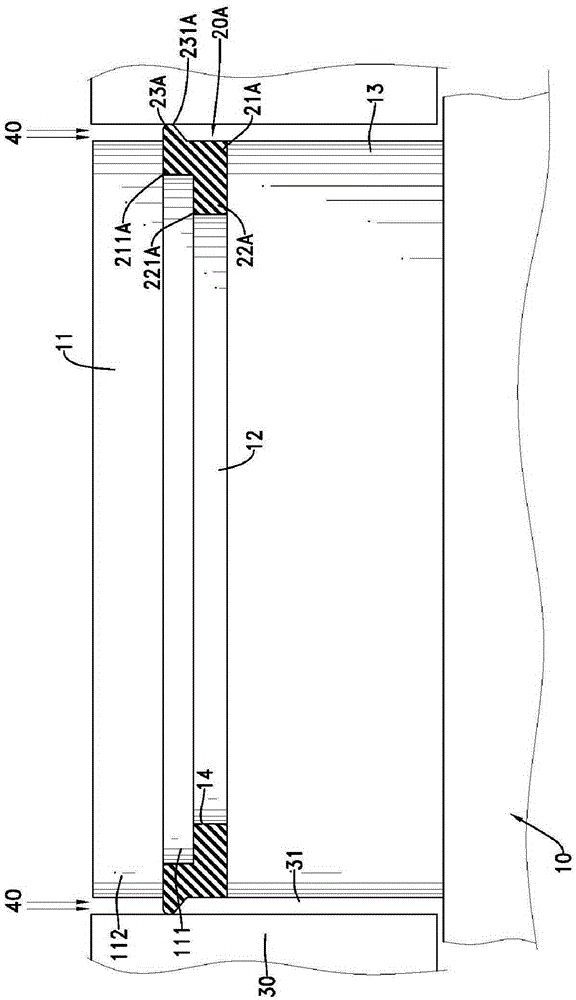

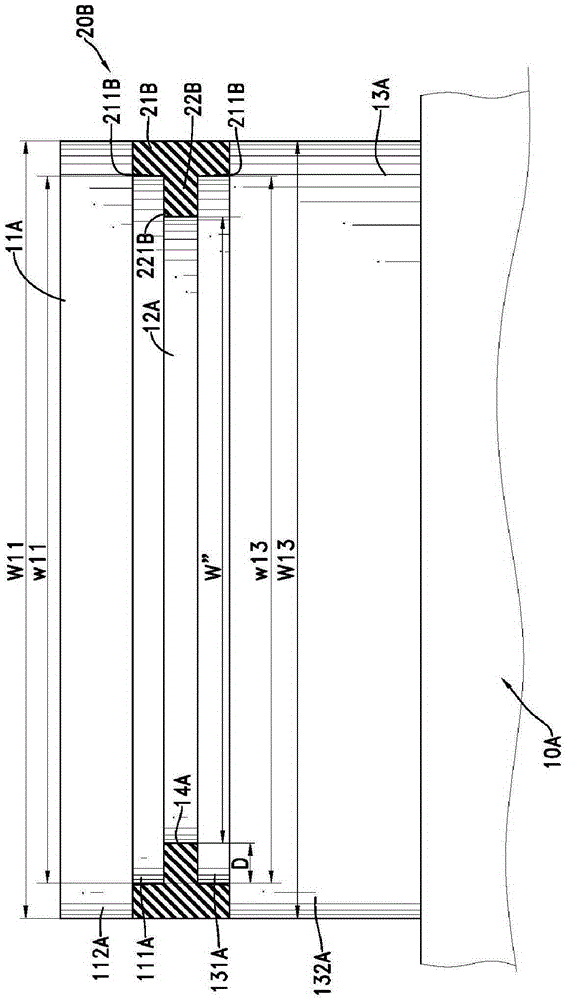

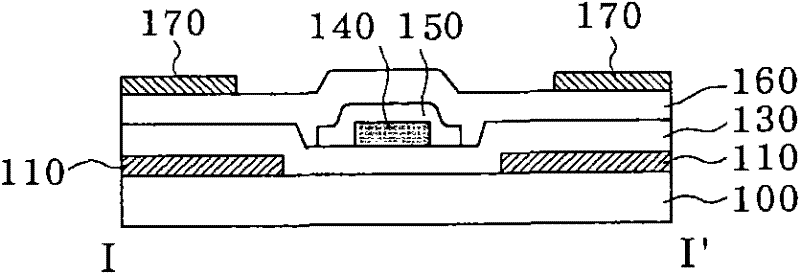

Provided is a fringe field switching mode liquid crystal display and manufacturing method thereof. The fringe field switching mode liquid crystal display device includes a lower substrate, an upper substrate, and a liquid crystal layer inserted between the lower substrate and the upper substrate, wherein the select line and the data line are mutually intersected, a pixel region is limited on the lower substrate, a switching device is provided at the intersecting part between the select line and the data line. The fringing field switching mode liquid crystal display device includes a transparent common electrode having a predetermined shape and formed within the pixel area to adjust light transmittance by applying a voltage to the liquid crystal layer, and a transparent pixel electrode having a plurality of slits and formed above the transparent common electrode with an insulating layer interposed between the transparent common electrode and the transparent pixel electrode. A rubbing direction for aligning the liquid crystal layer is within 5 DEG with respect to a direction of the gate line to remove a light shielding region above the data line, one end of the transparent common electrode is arranged between the data line and the transparent pixel electrode. A reflector is manufactured in an electrically independent type by using the material identical to that of the data line.

Owner:HYDIS TECH

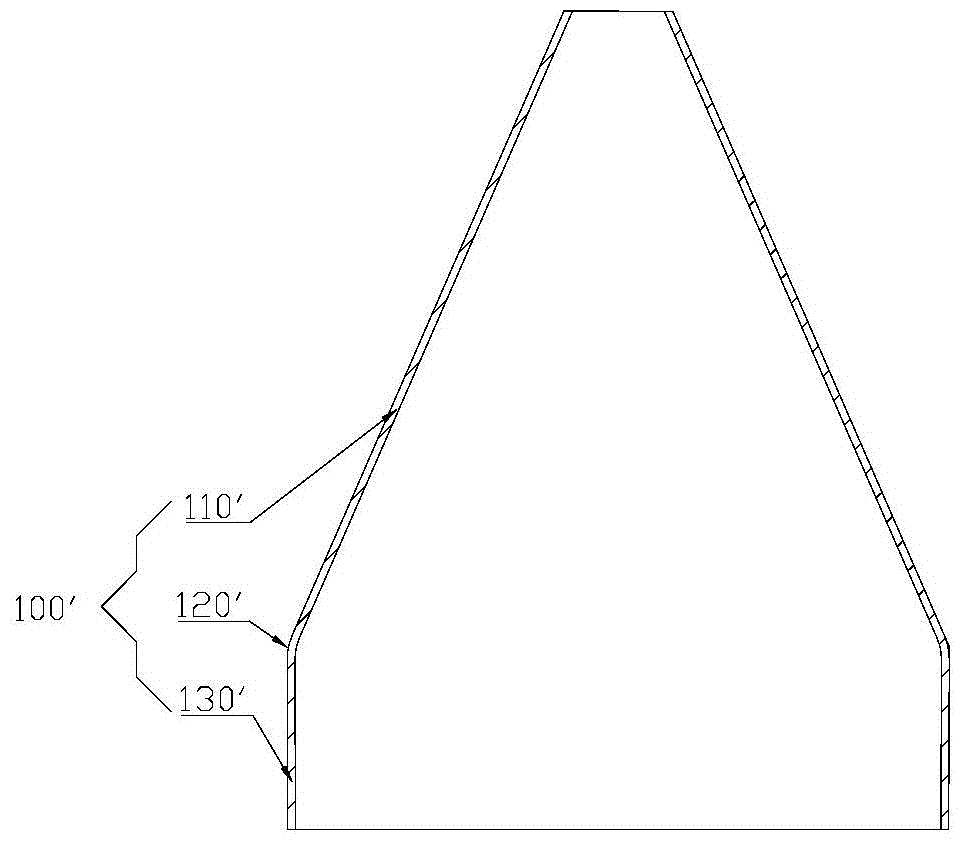

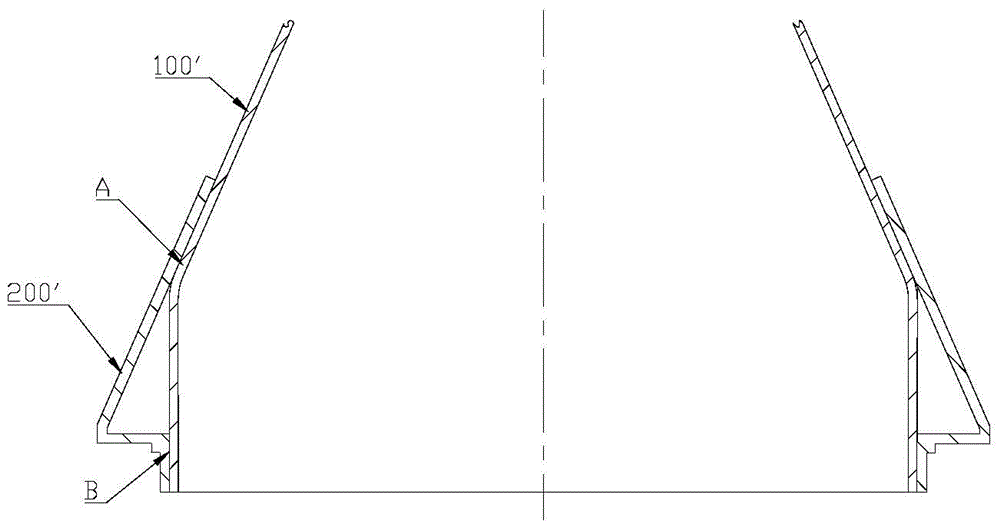

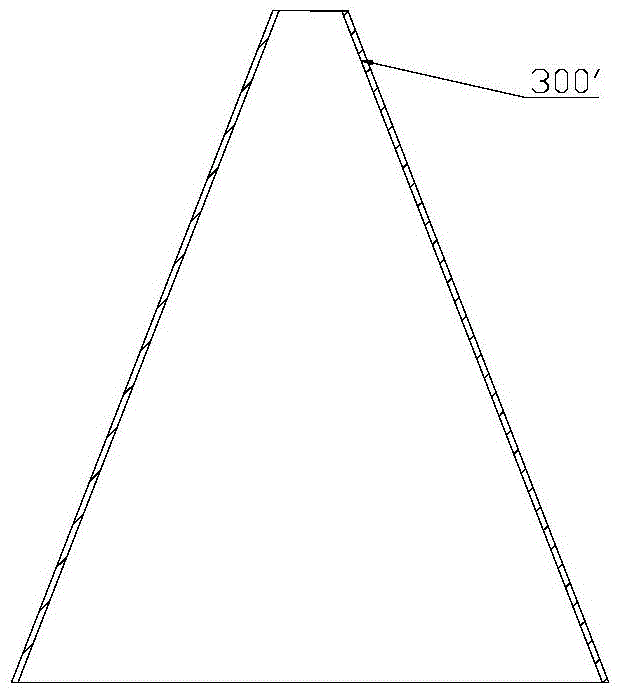

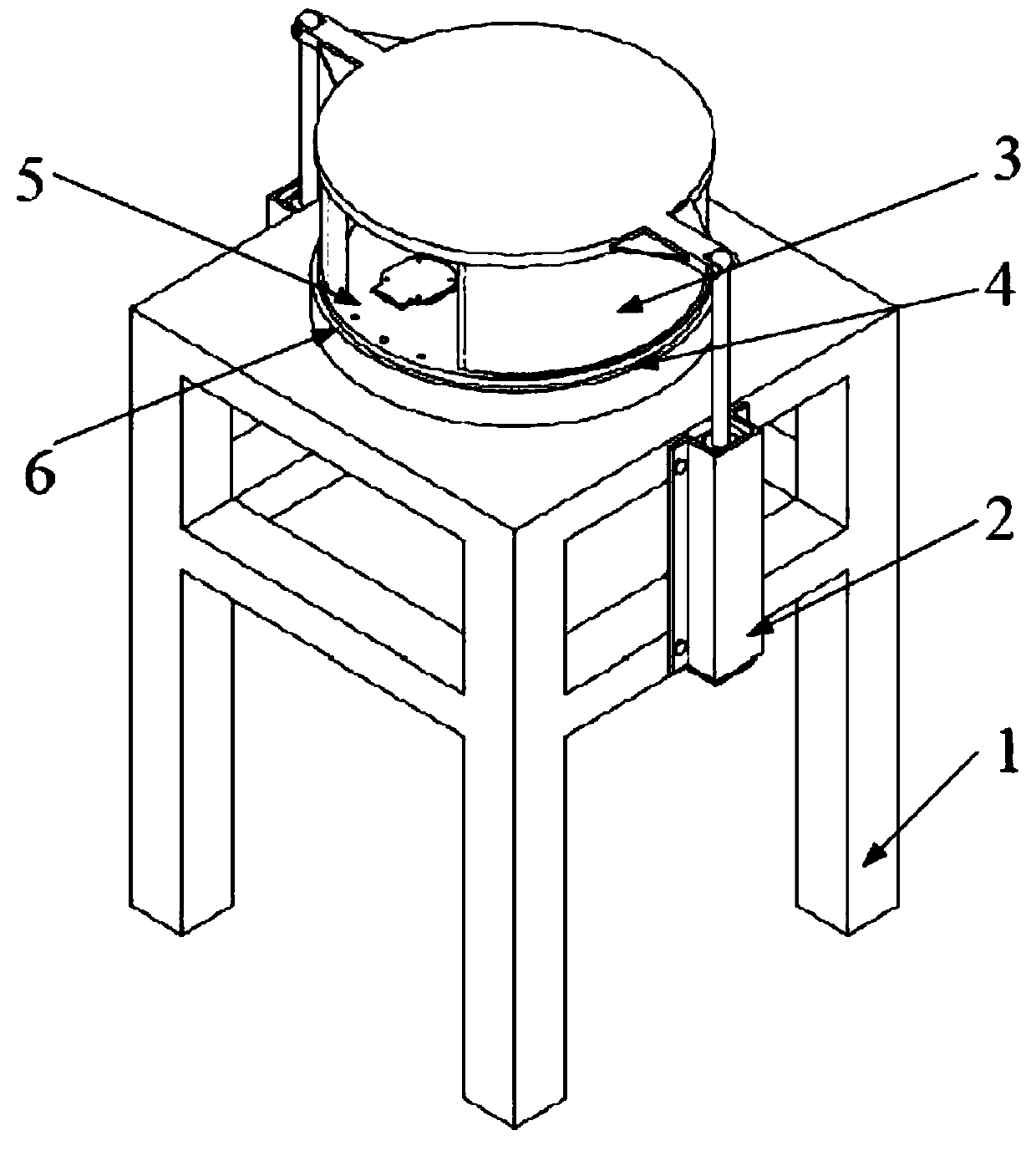

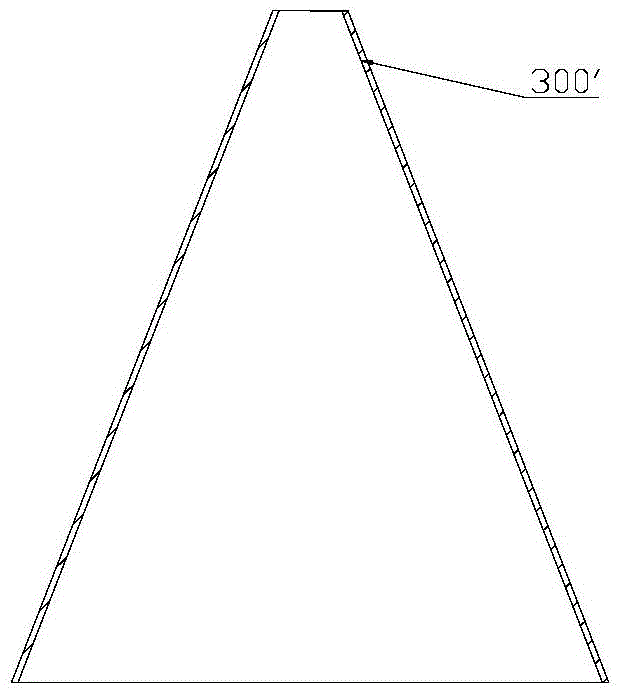

Tailcone forming mould and forming method of tailcone forming mould

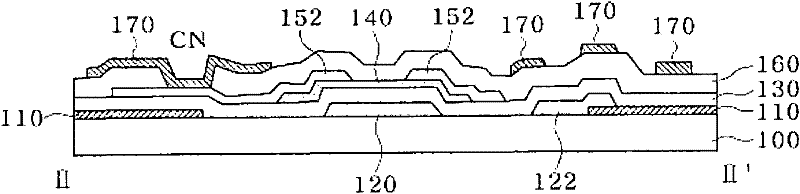

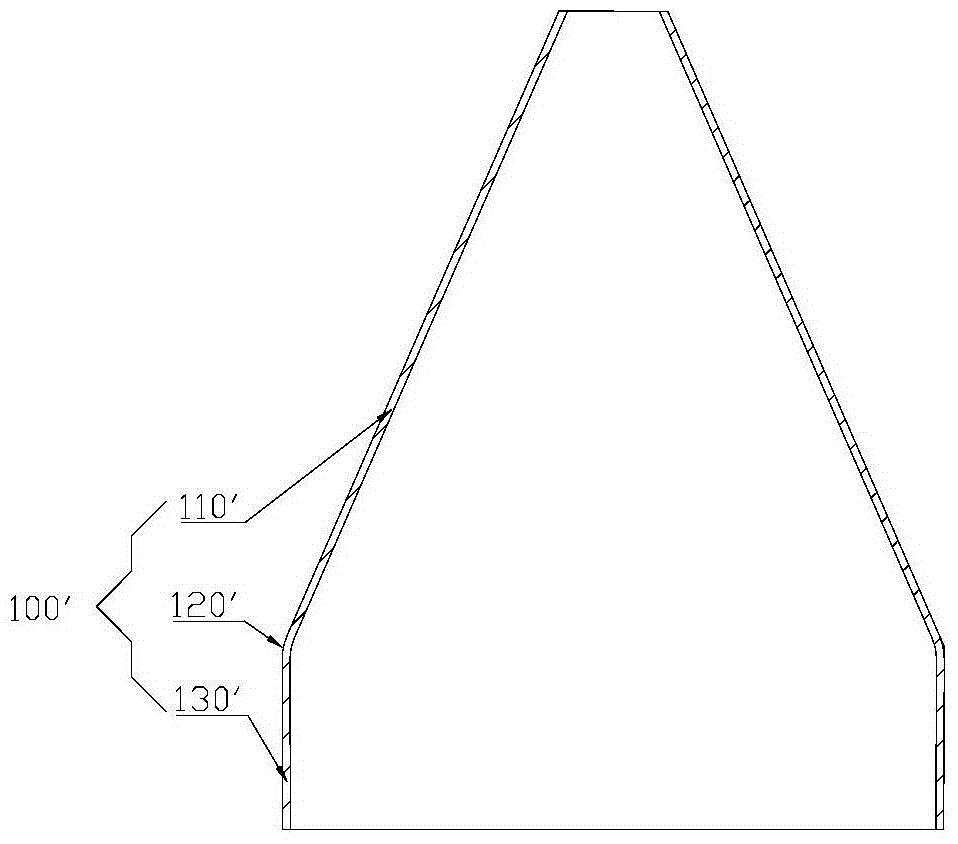

The invention provides a tailcone forming mould which comprises a lower mould plate, an upper mould plate, a concave mould body and a convex mould body. The central lines of the lower mould plate, the upper mould plate, the concave mould body and the convex mould body are coincided with each other, a forming groove is formed in the center of the concave mould body, the convex mould body is fixedly arranged on the top surface of the lower mould plate, and the concave mould body is arranged under the bottom surface of the upper mould plate. The tailcone forming mould further comprises limiting columns for controlling the downward moving distance of the concave mould body, an edge pressing ring in contact with the inner lateral wall of the forming groove and a plurality of ejector rods which can enable the edge pressing ring and the forming groove to clamp a formed workblank; the ejector rods are respectively arranged on the lower mould plate and evenly distributed around the convex mould body in the peripheral direction; the ejector rods abut against the bottom edge of the edge pressing ring and can drive the edge pressing ring and the formed workblank; the at least two limiting columns are evenly distributed between the edge pressing ring and the lower mould plate; the height difference between the top surfaces of the limiting columns and the bottom surface of the edge pressing ring can be determined by the distance between the top end of the formed worblank and a conical face of the convex mould body in the vertical direction. According to the tailcone mould, the rate of finished products of tailcones can be improved to 100% from 50%, the percent of pass is verified repeatedly, and the effect is stable.

Owner:CHINA HANGFA SOUTH IND CO LTD

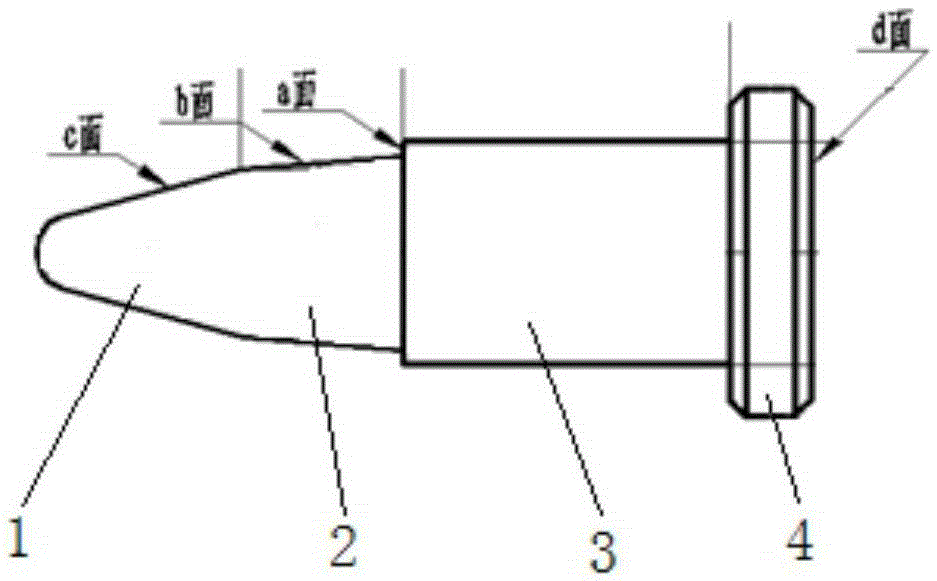

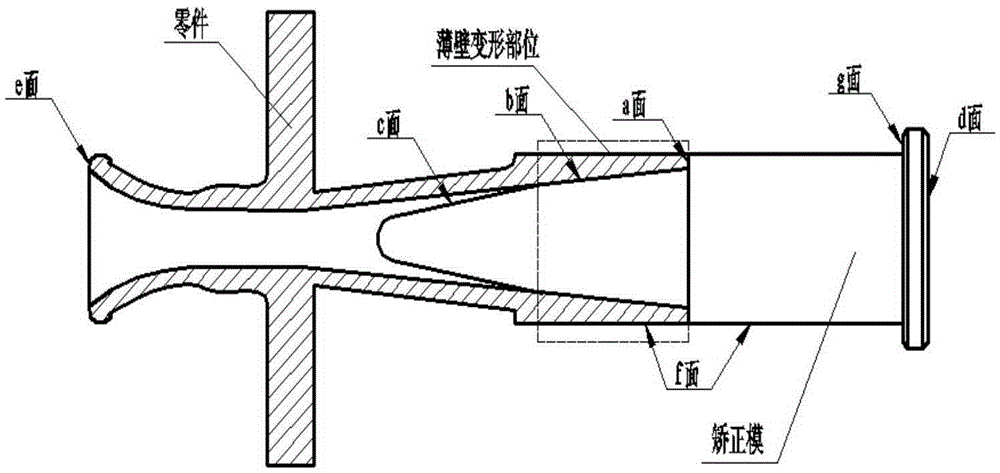

Device and method for rectifying hollow thin-walled castings

The invention discloses a device and method for rectifying hollow thin-walled castings. The device comprises a lead-in part, an inner cavity rectifying part, an outline rectifying and a receding part, wherein the lead-in part is of a conical structure, and the size of the conical structure is smaller than that of the conical hollow part of a casting to be rectified; the outline rectifying part is of a cylindrical structure and is in transitional connection with the lead-in part through the inner cavity rectifying part which is of a conical surface structure, and the diameter value of the outline rectifying part is larger than the maximum diameter value of the inner cavity rectifying part; the receding part for bearing applied stress is installed at the tail end of the outline rectifying part. A deformed thin wall can be rectified by being knocked with a tool, deformation of the thin wall is thoroughly eliminated through combined rectifying of a rectifying mold and the knocking tool, and the qualified rate is close to 100%; the annular thin wall has an orderly outline, excellent surface state and small surface stress; the rectifying period is short, and the batch rectifying consistency is quite excellent.

Owner:AECC AVIATION POWER CO LTD

Edible starch with ultra-low moisture and ultra-low microorganism, and manufacturing method thereof

The invention discloses an edible starch with ultra-low moisture and ultra-low microorganism, and a manufacturing method thereof, belonging to the starch manufacturing technology. The invention is characterized in that the loss on drying is less than or equal to 5.0; the fineness is more than or equal to 99.5% (sieved by a 100-mesh sieve); the number of bacteria is not more than 100 per gram; and the number of moulds and saccharomycetes is not more than 10 per gram. The manufacturing method comprises the following steps of: selecting materials; roasting for sterilization: heating till the temperature of the materials is more than or equal to 110 DEG C but less than or equal to 160 DEG C with the stirring speed being 25+ / -5 times / minute and the stirring time being more than or equal to 120minutes; cooling: leading the temperature of the material to be less than 70 DEG C in 40 minutes; sieving, detecting, metering and packaging; and the cleanliness of the ambient air in roasting for sterilization, cooling, sieving, metering and packaging reaches 30,0000 level. Through implementation, the produced water is 35.7% of the standard in the common edible starch, the index of microorganisms is 10% of the standard of the common edible starch, and the higher and higher food production need for sanitary requirement is met; and in the manufacturing method, the potential safety hazards of the drying and sterilization process are fewest and the safe production is reliably realized.

Owner:江苏昕宇药业有限公司

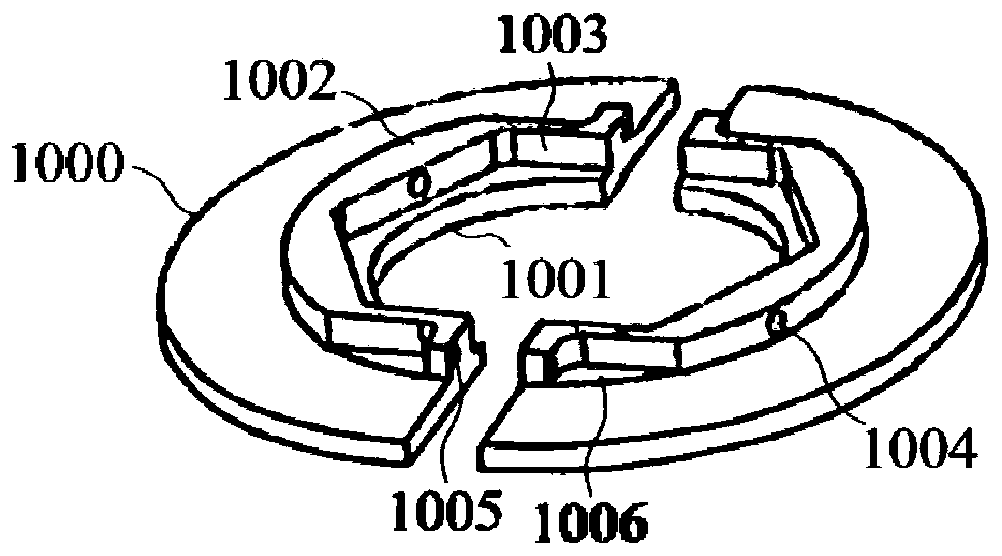

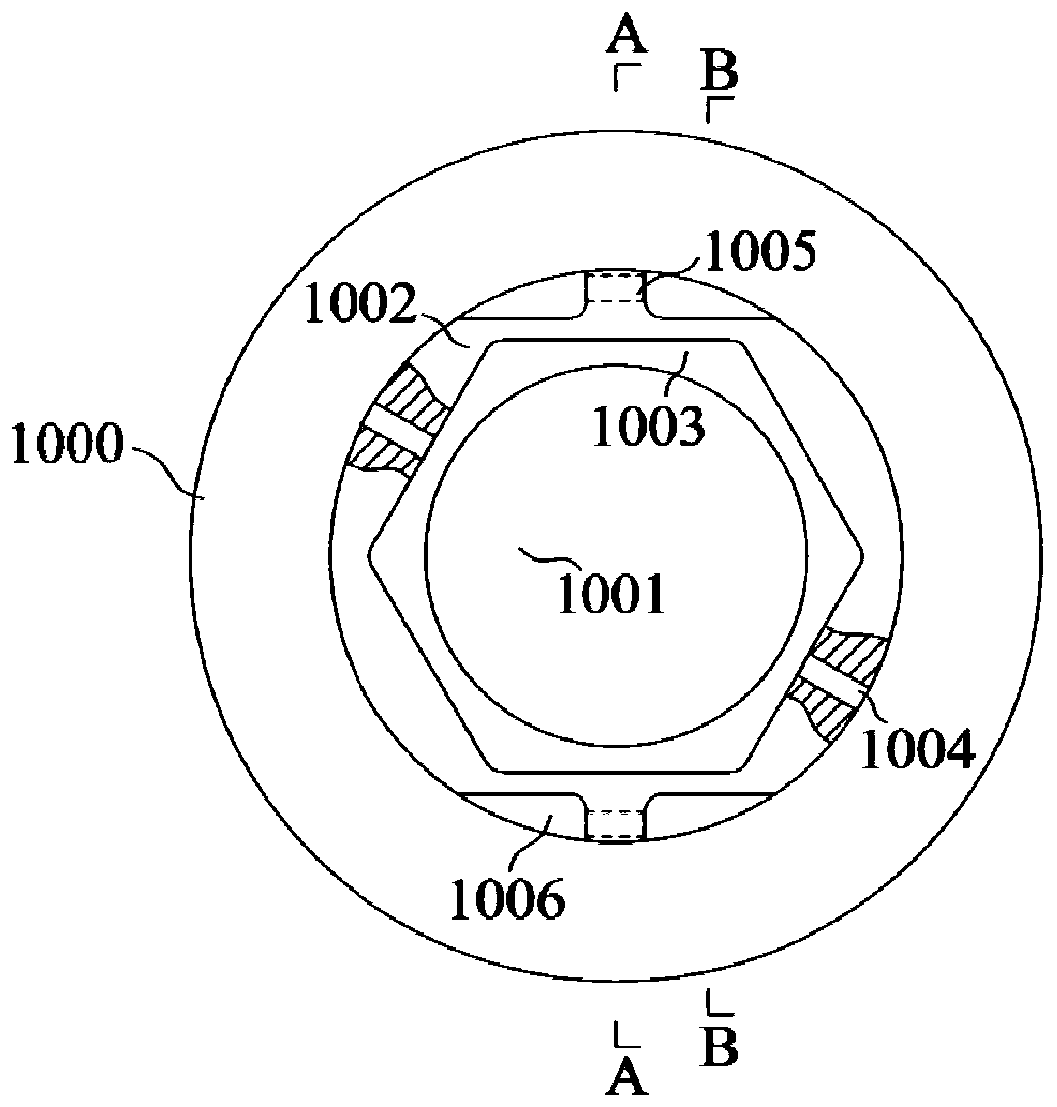

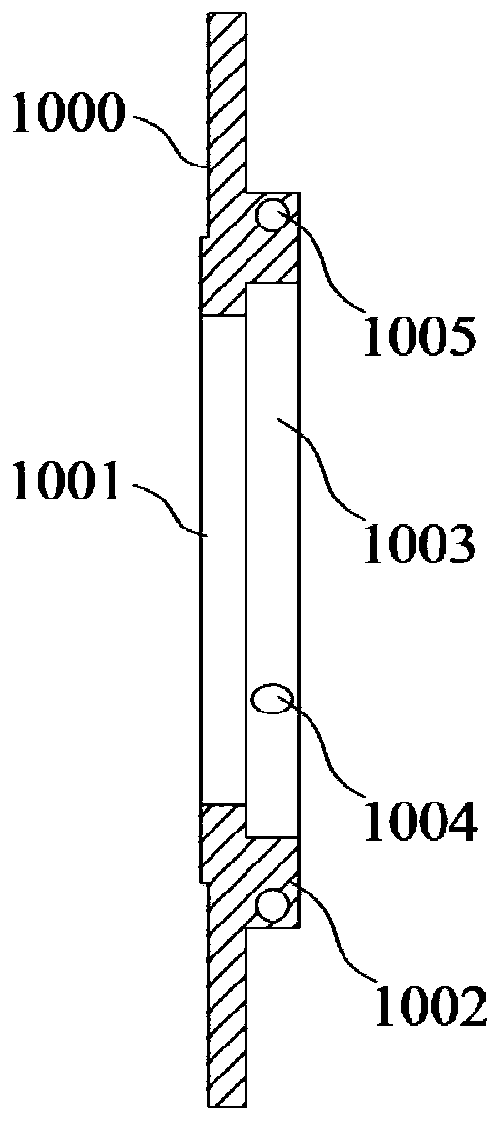

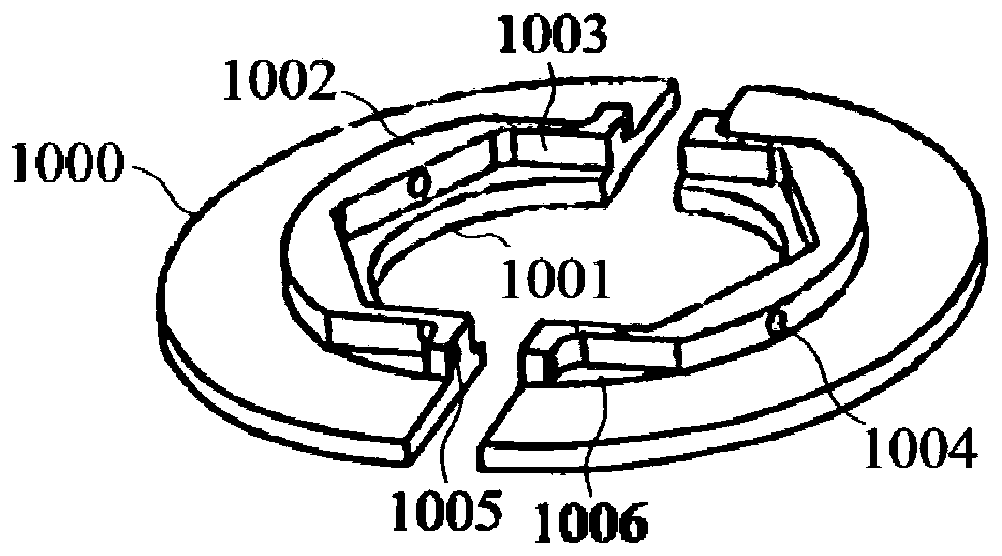

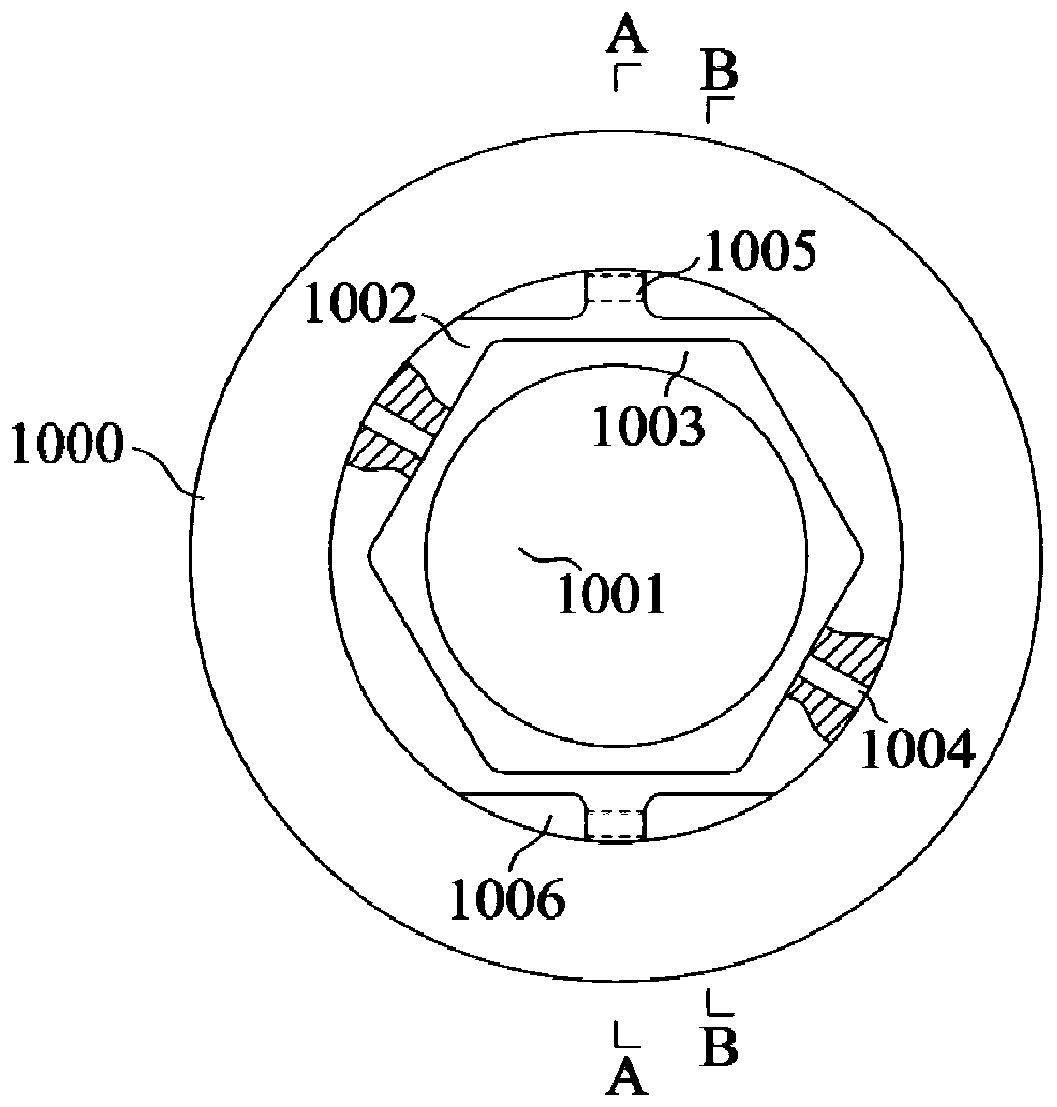

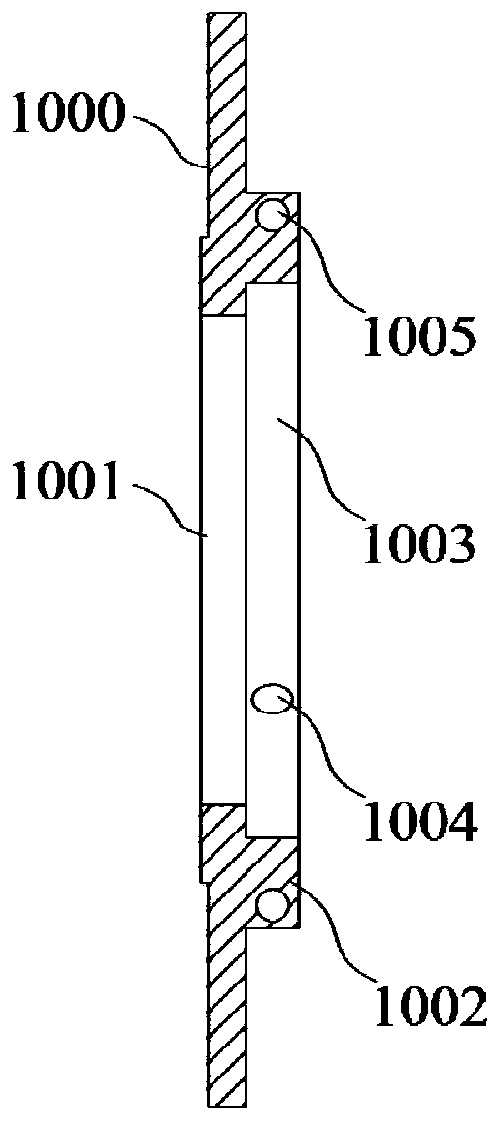

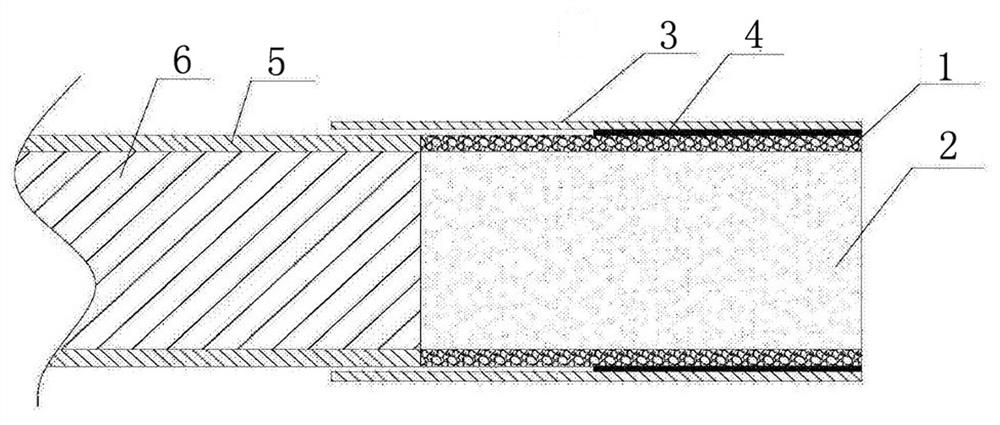

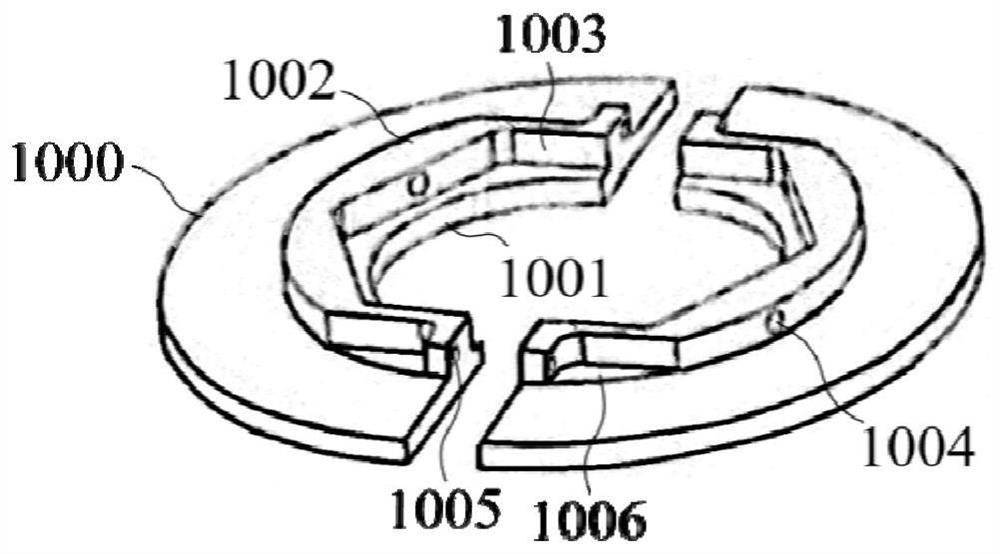

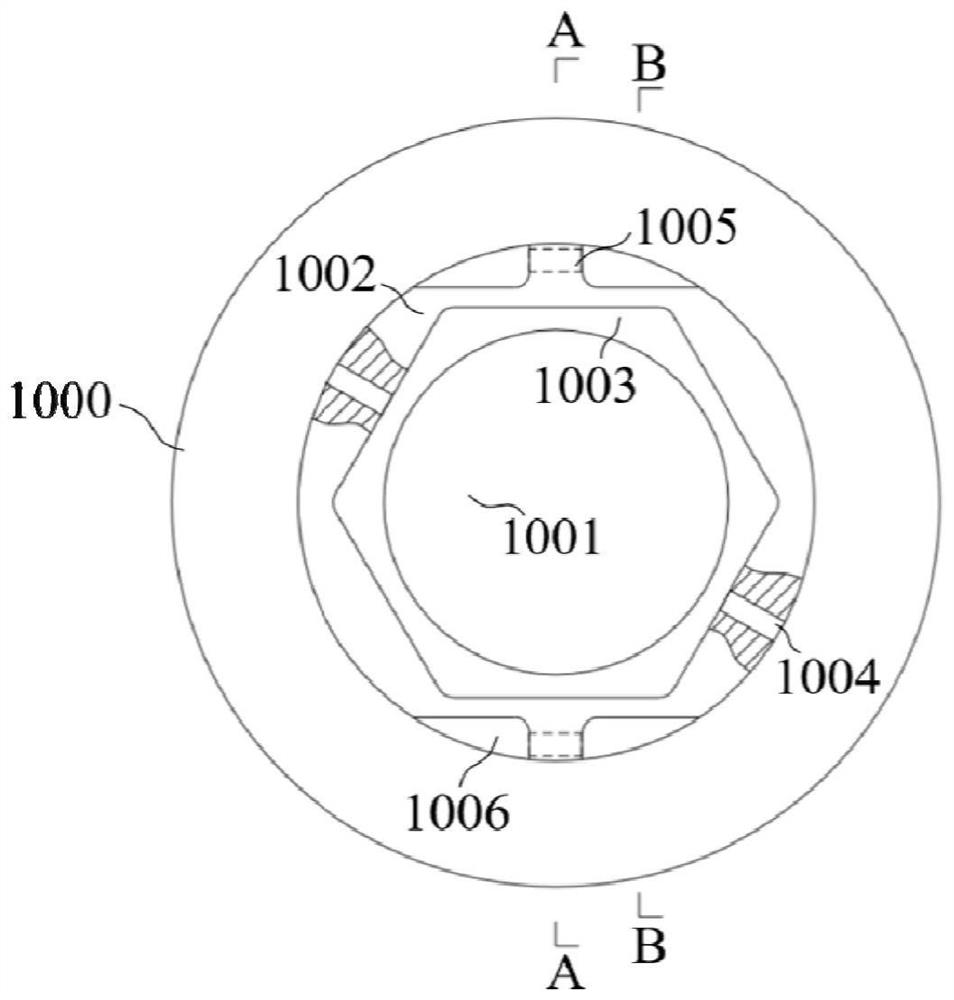

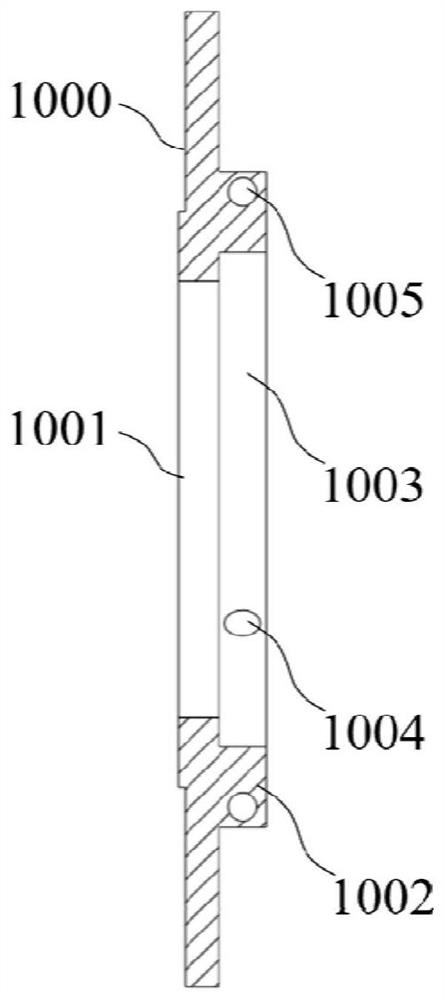

Improved seal for side walls of electrostatic chuck

ActiveCN105895570AAvoid damagePrevent leakageEngine sealsElectric discharge tubesPlasma GasesMechanical engineering

Provided is an improved seal for side walls of electrostatic chuck which enables multiple portions to form between the improved seal and the electrostatic chuck through utilization of arrangement of a plurality of sealing portions. The groove of the electrostatic chuck may be completely filled by the improved seal. Even one of the multiple sealing portions is destroyed in the plasma etching process by the plasma gas, the seal still prevents leaking of the electrostatic chuck effectively. The seal provides a buffer period for engineers to replace the improved seal before the leaking occurs. Danger of leaking caused by abrupt breaking of the barrier seal is reduced. Furthermore, the seal facilitates stability and safety of the plasma etching process. The yield of products manufactured by the electrostatic chuck may be improved.

Owner:MFC SEALING TECH

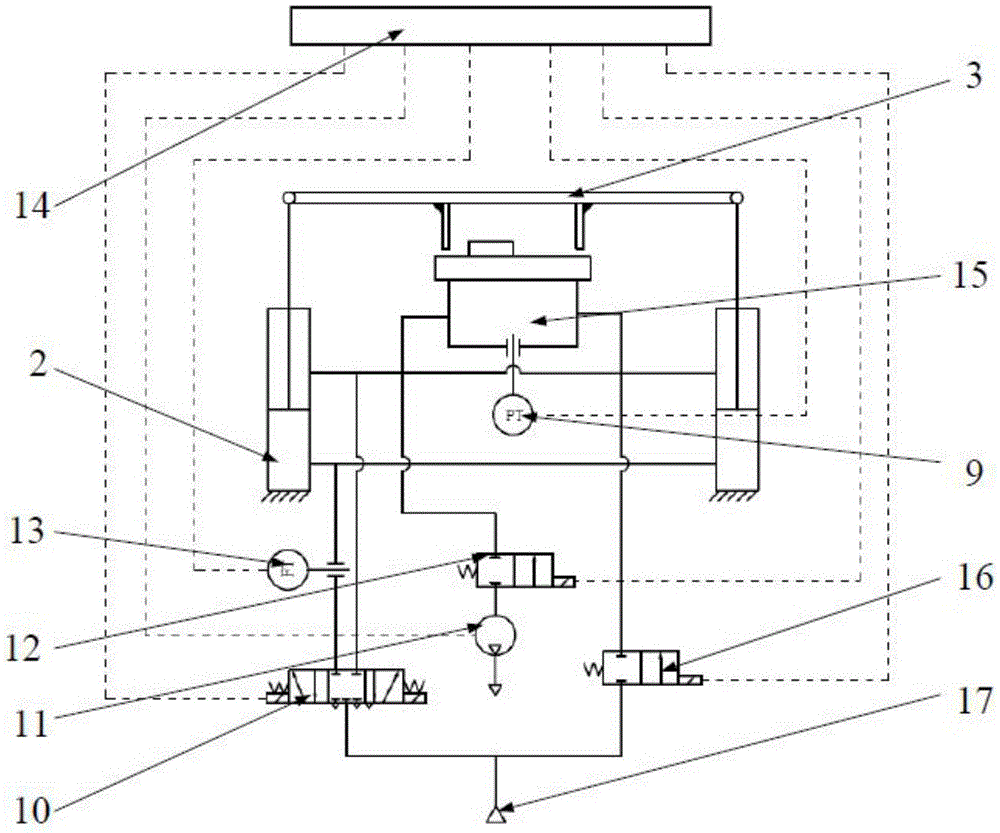

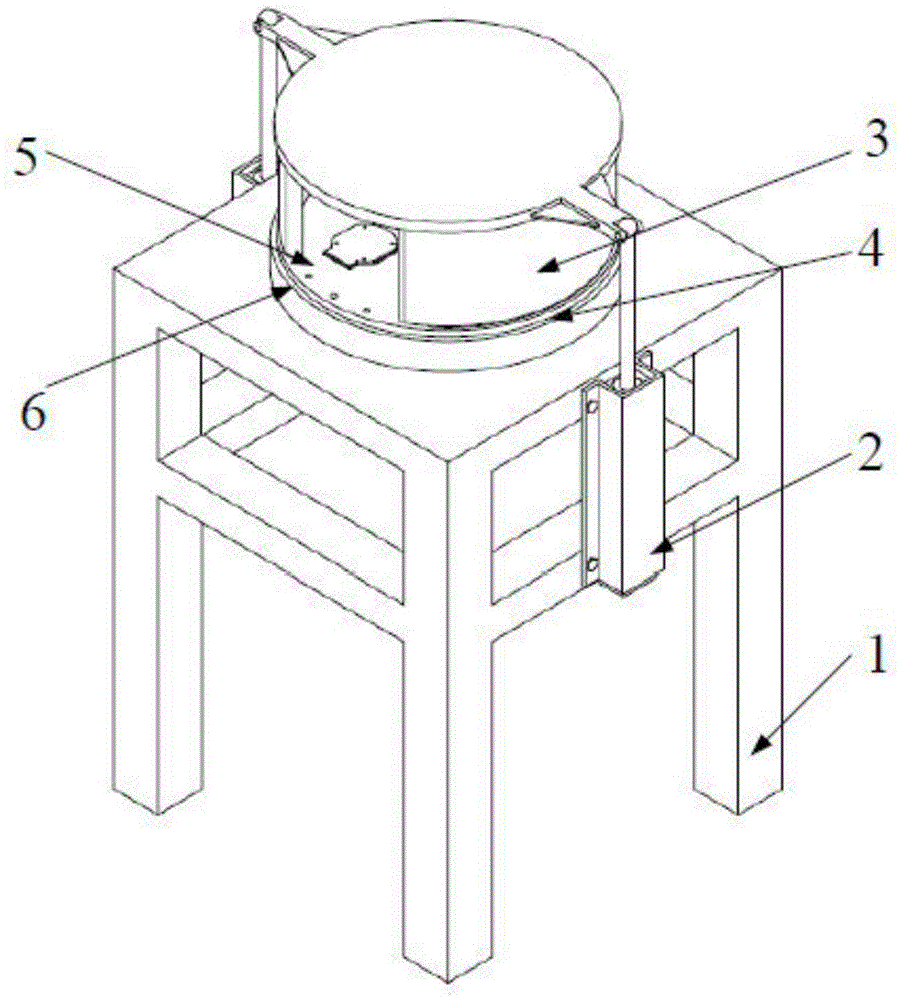

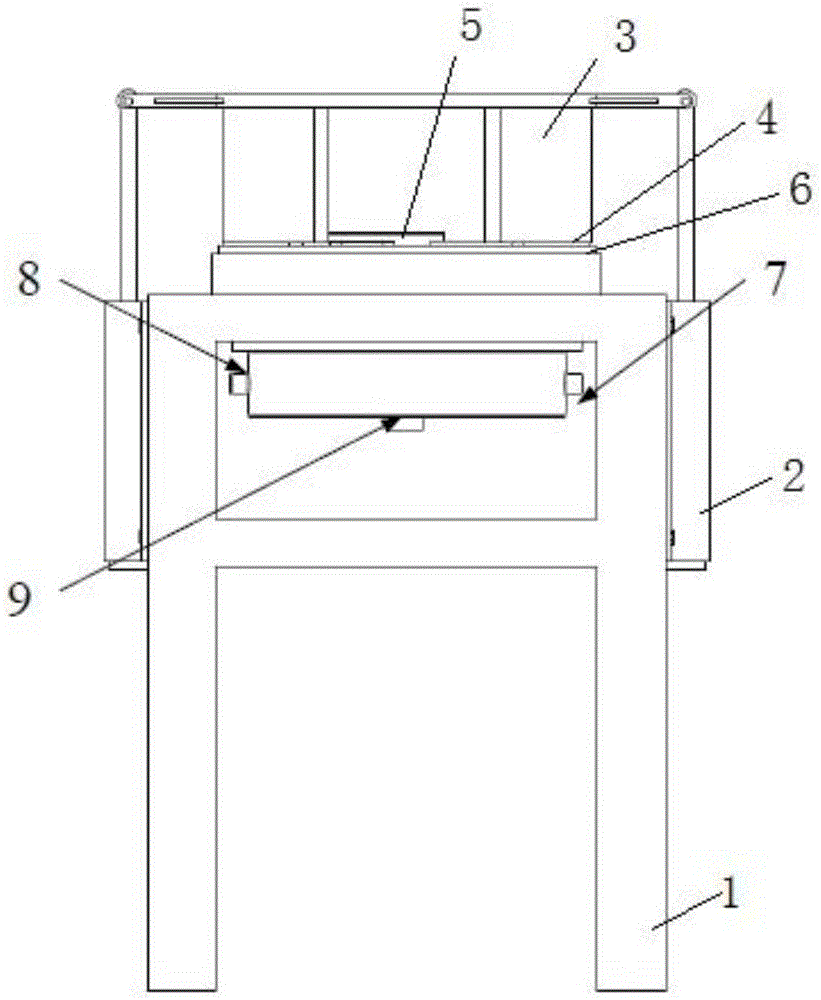

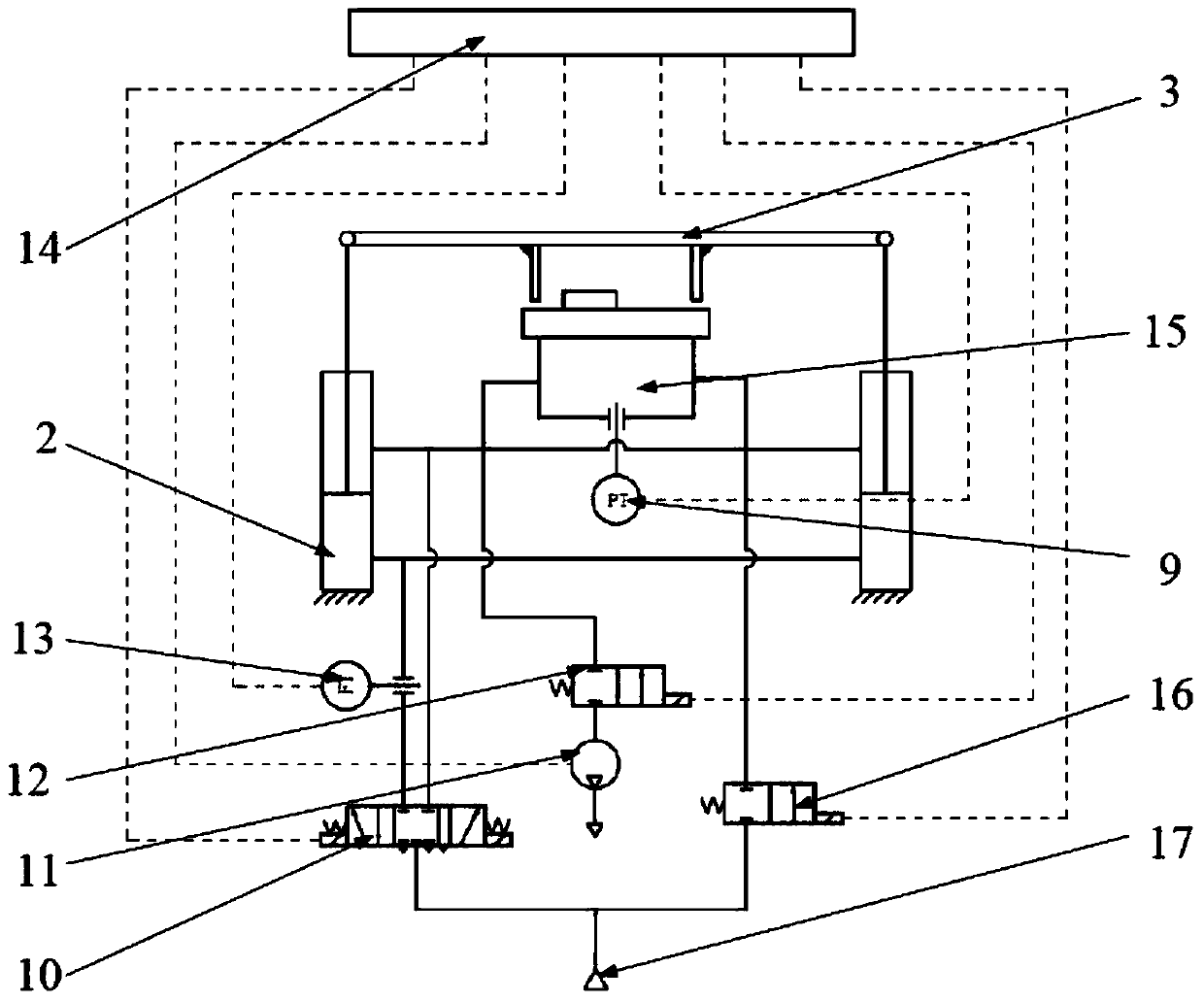

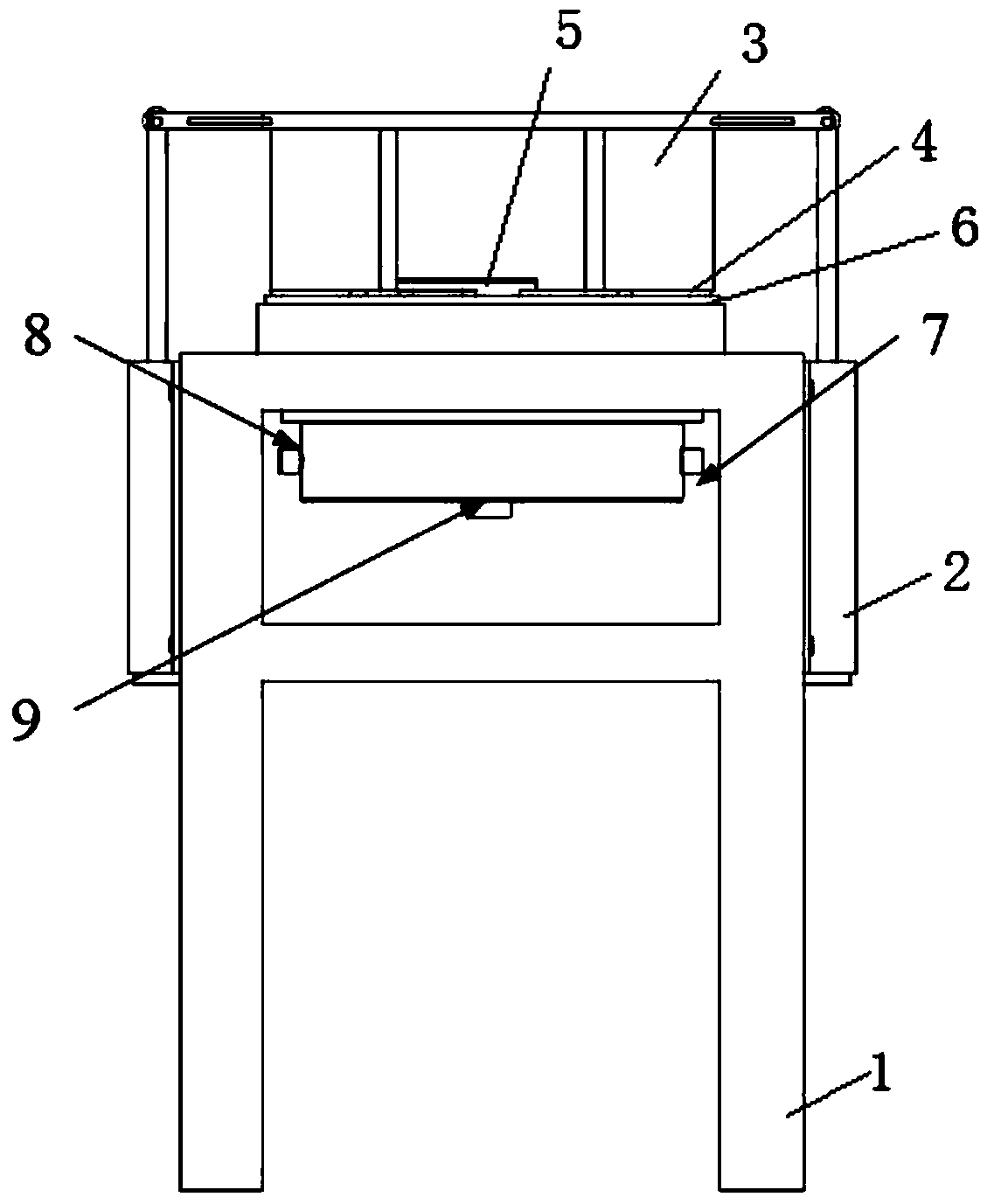

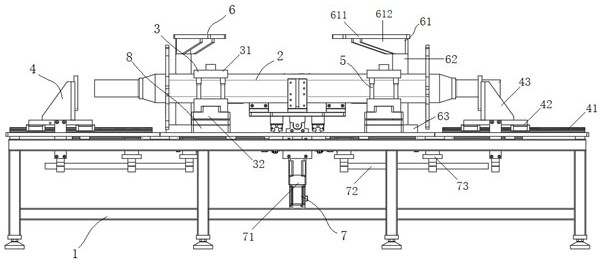

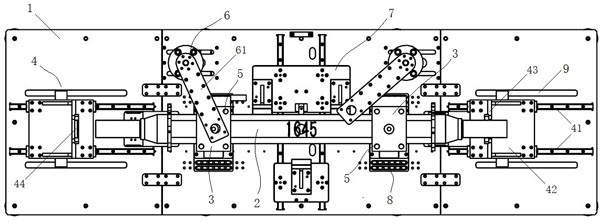

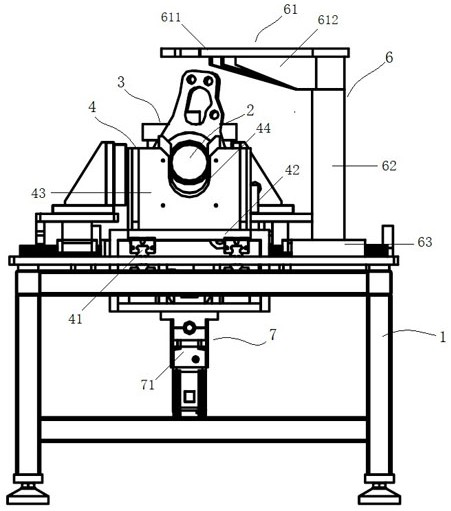

Manhole cover positive and negative pressure performance test bench and manhole cover positive and negative pressure performance test method

InactiveCN105547666AImplement automated testingGuaranteed uptimeMachine part testingTest chamberEngineering

The invention discloses a manhole cover positive and negative pressure performance test bench and a manhole cover positive and negative pressure performance test method. The test bench comprises a frame, the center of the frame is provided with a test chamber, and the upper part of the test chamber is provided with a manhole cover. A semi-circular symmetric pressing plate is arranged above the manhole cover. Two cylinders are symmetrically arranged on the two sides of the frame, and the piston rods of the cylinders are connected with the semi-circular symmetric pressing plate. The lower part of the test chamber is provided with an air inlet, an air intake port and a pressure sensor. The air inlet is connected with an air source through a two-position two-way electromagnetic directional valve I. The air intake port is connected with a vacuum pump through a two-position two-way electromagnetic directional valve II. Rodless cavities and rod-containing cavities of the cylinders are connected with the air source through a three-position four-way electromagnetic directional valve. The test method comprises four steps: manhole cover mounting and compressing, test chamber air inflation detecting, test chamber air intake detecting, and manhole cover unloading and disassembling. The test bench and the test method make up for the shortcomings of the existing manhole cover detection device and test method. Integration of the automatic compressing, testing and unloading and disassembling steps in the process of manhole cover positive and negative pressure performance test is realized.

Owner:CHINA UNIV OF MINING & TECH

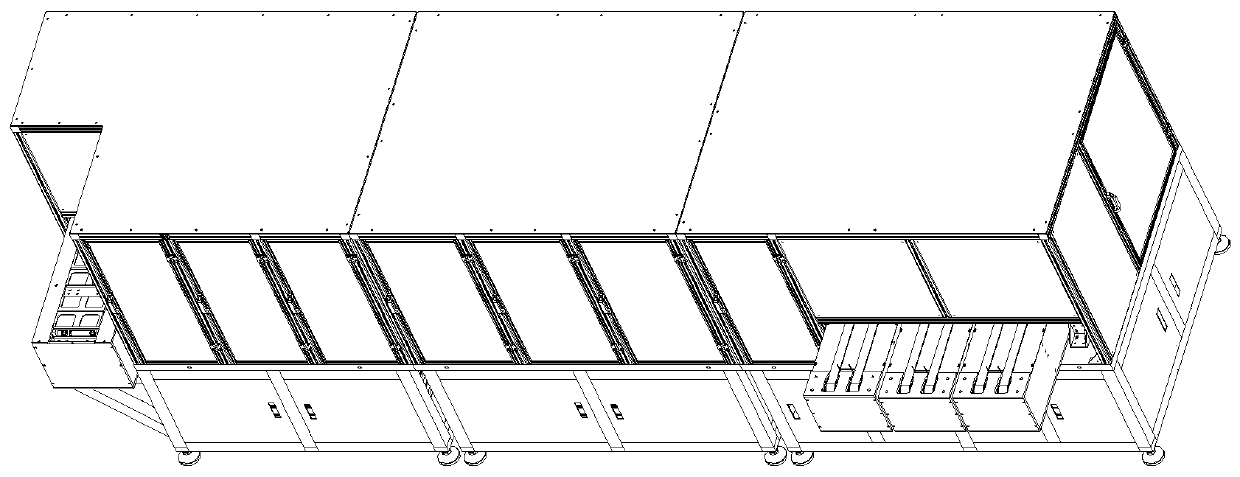

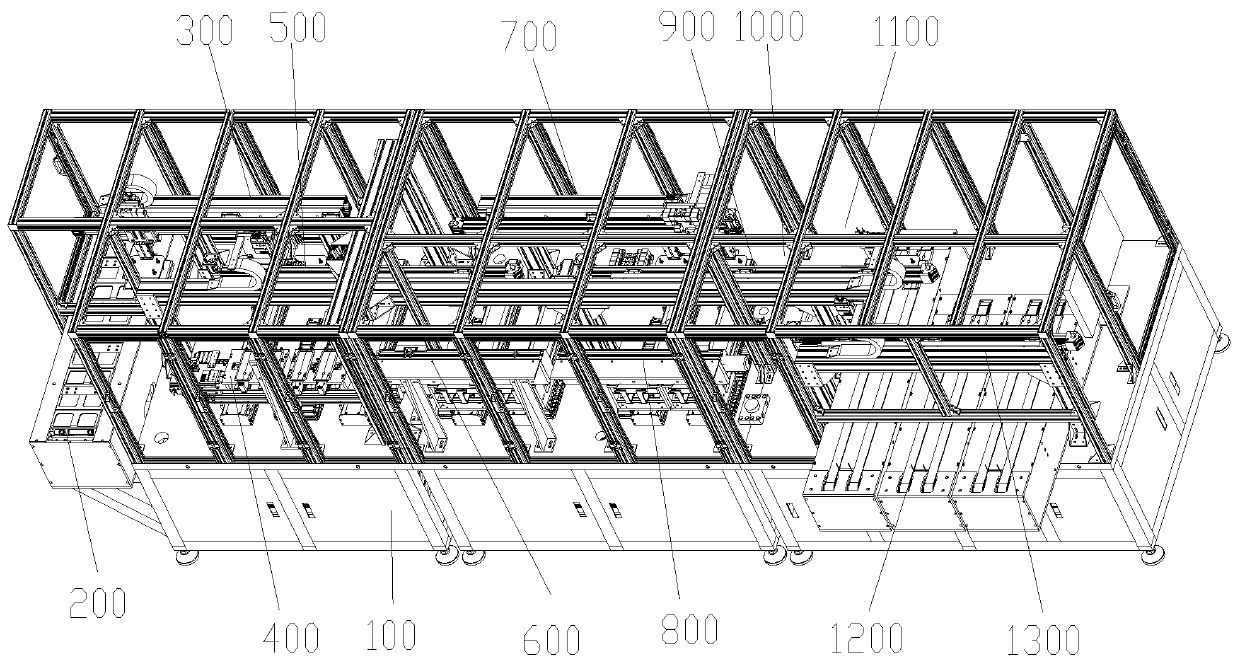

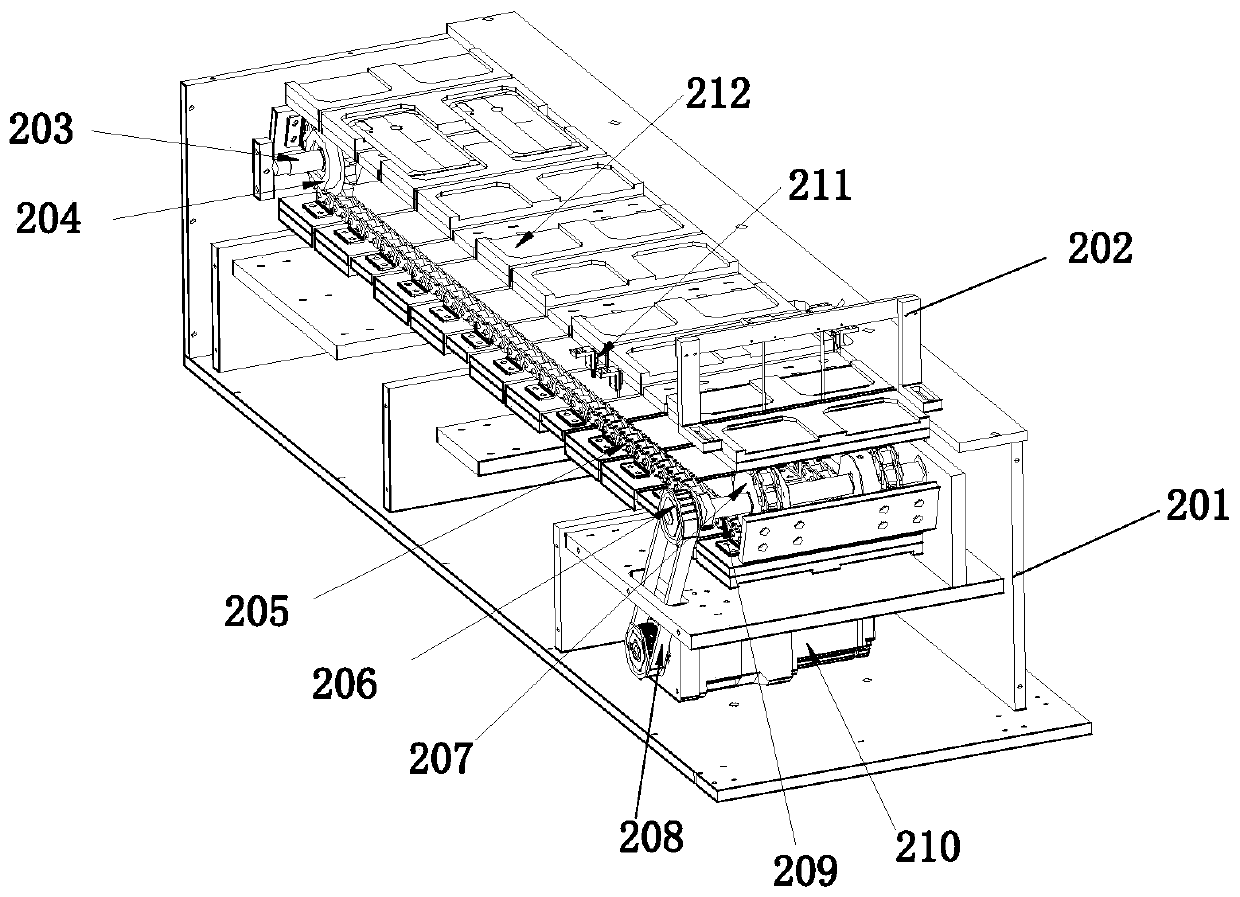

Multi-station automatic measuring device

PendingCN111054644AReduce manual operationsImprove work efficiencySortingComputer hardwareCost Controls

The invention discloses a multi-station automatic measuring device. The device comprises a rack, a profiling base conveying assembly, a first grabbing and conveying assembly, a first detection assembly, a second grabbing and conveying assembly, a second detection assembly, a third grabbing and conveying assembly, a third detection assembly, a fourth grabbing and conveying assembly, a code inkjet printing assembly, a code scanning assembly, a sorting outflow assembly, a grabbing and sorting assembly, a control assembly and a power source. The multi-station automatic measuring device can realizeautomatic circulation and automatic step-by-step measurement, reduces manual operation, improves the working efficiency, is low in operation difficulty, is stable in product qualification rate, and is beneficial to cost control.

Owner:广东天行测量技术有限公司

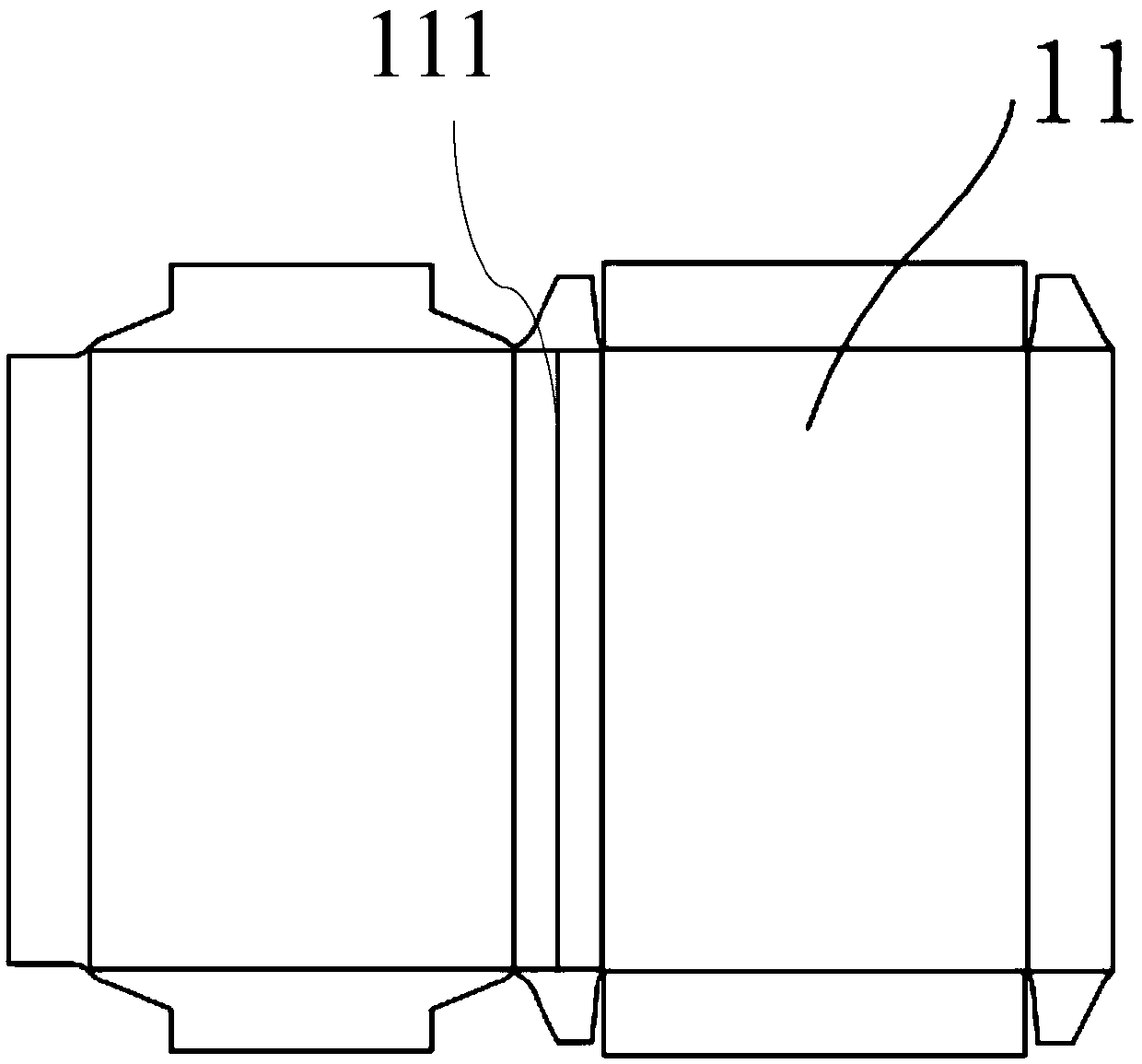

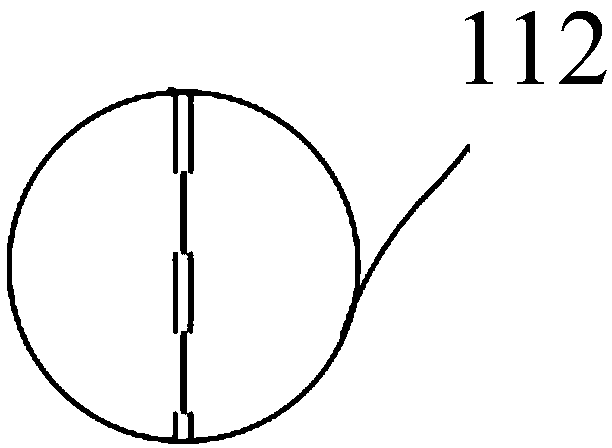

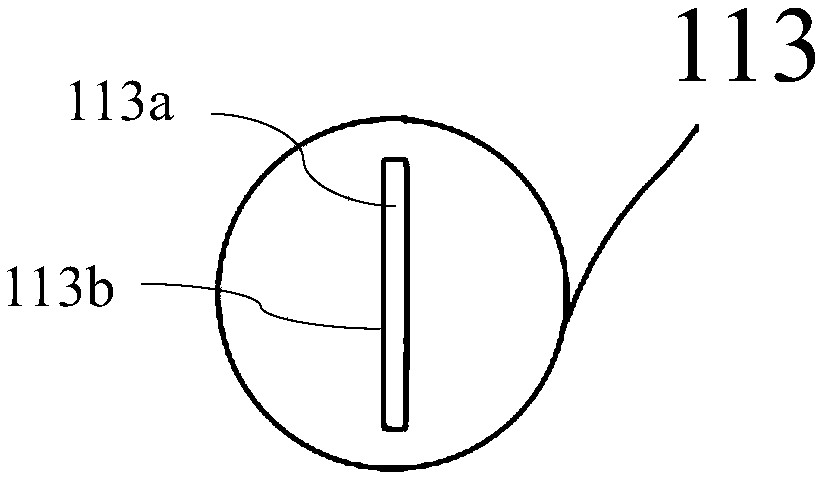

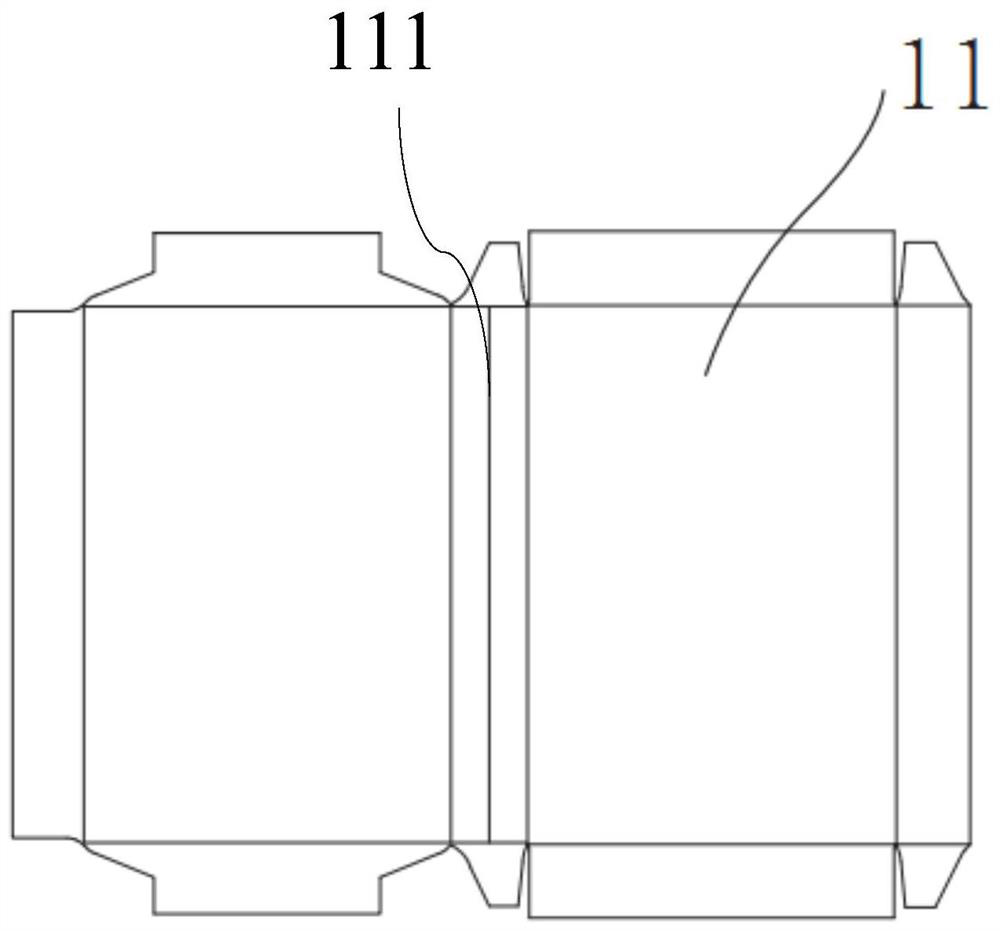

Processing method for manual side flipping hard cigarette box

ActiveCN110861352AEasy to operateEfficient productionEnvelopes/bags making machineryPaper-makingCigarette packManufacturing engineering

Owner:襄阳金飞环彩色包装有限公司

Sliding plate waste material powder, preparation method thereof, sliding plate external layer material, and sliding plate

The invention belongs to the field of sliding nozzle, and more specifically relates to a sliding plate waste material powder, a preparation method thereof, a sliding plate external layer material, anda sliding plate. The preparation method comprises following steps: waste sliding plate mud and collected dust generated in sliding plate treatment process are subjected to aging treatment so as to obtain a pug, and the pug is dried until water content is reduced to be 15% or lower; carbon sealing treatment is carried out, and powder grinding is carried out until particle size ranges from 150 to 200 meshes; and iron is removed so as to obtain the sliding plate waste material powder. According to the preparation method, direct utilization of waste materials is realized, storage space is reducedgreatly, production benefit is excellent, production cost is reduced, and the environment is protected. The obtained sliding plate waste material powder can be used in sliding nozzle external layer materials, the qualified rate and the utilization effect are stable; the qualified rate is equal to that of products containing no waste sliding plate mud and collected dust, and is as high as 95%; theutilization effects in steel mills are the same, the continuous sliding rate is 1.8 times; the cost of each ton of raw materials is reduced by 300 to 400yuan.

Owner:河南新拓耐火材料有限公司

A method of manufacturing 6082t6 aluminum alloy large-scale rods for power equipment

The invention belongs to the technical field of aluminum alloy materials for electric power equipment and particularly relates to a method for manufacturing large-sized aluminum alloy bars with high strength and high electrical conductivity. The large-sized 6082 bars with high strength and high electrical conductivity, especially 6082T6 aluminum alloy bars with diameter from 150mm above to 300mm, are utilized for processing large-sized electrical elements with high strength and high electrical conductivity in the electric power equipment. An aluminum alloy ingot used in the method contains the following elements in percentage by mass: 1.0%-1.05% of Si, no more than 0.12% of Fe, no more than 0.10% of Cu, 0.55%-0.65% of Mn, 0.9%-0.95% of Mg, no more than 0.10% of Cr, no more than 0.10% of Zn, no more than 0.05% of Ti, no more than 0.05% of isolated impurity, no more than 0.15% of total impurities, and the balance being Al. According to the method, mass production and delivery can be achieved, the strength and the electrical conductivity of the large-sized aluminum alloy bars are enhanced, and processing and use are facilitated; the mechanical property and the electrical conductivity of the large-sized aluminum alloy bars obtained by the method are stable; in repeated operation, the bars can satisfy the Chinese standard of bars with diameter smaller than 150mm, the Chinese standard of bars with diameter from 150mm above to 300 mm can be supplemented or perfected and each performance index can be introduced into the Chinese standard.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

A manhole cover positive and negative pressure performance test bench and method

InactiveCN105547666BImplement automated testingGuaranteed uptimeMachine part testingTest chamberEngineering

The invention discloses a manhole cover positive and negative pressure performance testing test bench and method. The test bench includes a frame, a test chamber is arranged in the center of the frame, a manhole cover is arranged on the upper part of the test chamber, and a semi-circular ring is arranged on the top of the manhole cover. Type pressure plate, two cylinders are symmetrically arranged on both sides of the frame, the piston rod of the cylinder is connected with the semi-circular symmetrical pressure plate, the air inlet, suction port and pressure sensor are set at the lower part of the test chamber, and the air inlet is passed through the two-position two-way electromagnetic The reversing valve one is connected to the air source, the suction port is connected to the vacuum pump through the two-position two-way electromagnetic reversing valve two, and the rodless chamber and the rod chamber of the cylinder are connected to the air source through the three-position four-way electromagnetic reversing valve; The method includes four steps of installation and compression of the manhole cover, test cavity inflation test, test cavity suction test, unloading and disassembly of the manhole cover. The invention makes up for many shortcomings of the existing manhole cover detection device and testing method, and realizes the integration of automatic compression, testing, unloading and disassembly steps in the test process of the positive and negative pressure performance of the manhole cover.

Owner:CHINA UNIV OF MINING & TECH

A method for detecting lead ion content in separators of power-type lead-acid batteries

ActiveCN107621453BStable pass rateImprove pass rateColor/spectral properties measurementsElectrolytic agentHigh concentration

The invention relates to the technical field of lead acid storage batteries and discloses a method for detecting the content of the lead ion in a separator of the power type lead storage battery. According to the method, the content of the lead ion in the separator of the power type lead storage battery is calculated by detecting the concentration of the lead ion in a free acid solution on the surface of the formed storage battery in an acid extraction charging stage. The method is simple and easy to operate, the experiment result is sable, the structure of the battery is not broken in the measurement, the detection is conducted in the preparation stage of the battery, the thickness of the separator of the battery is regulated according to the data result, or the problem of penetration ofa dendritic crystal of the separator caused by the too high concentration of the ion is reduced by changing the process, the percent of pass of the battery is increased, the production cost of the enterprise is lowered, the method is suitable for the industrial production and the practical application, the problem that the concentration of the Pb<2+> ion in an electrolyte of the lead acid storagebattery cannot be accurately effectively detected is solved, and the technical blank of the detection of the concentration of the Pb<2+> ion in the electrolyte is filled in the preparation process ofthe battery is filled.

Owner:CHAOWEI POWER CO LTD

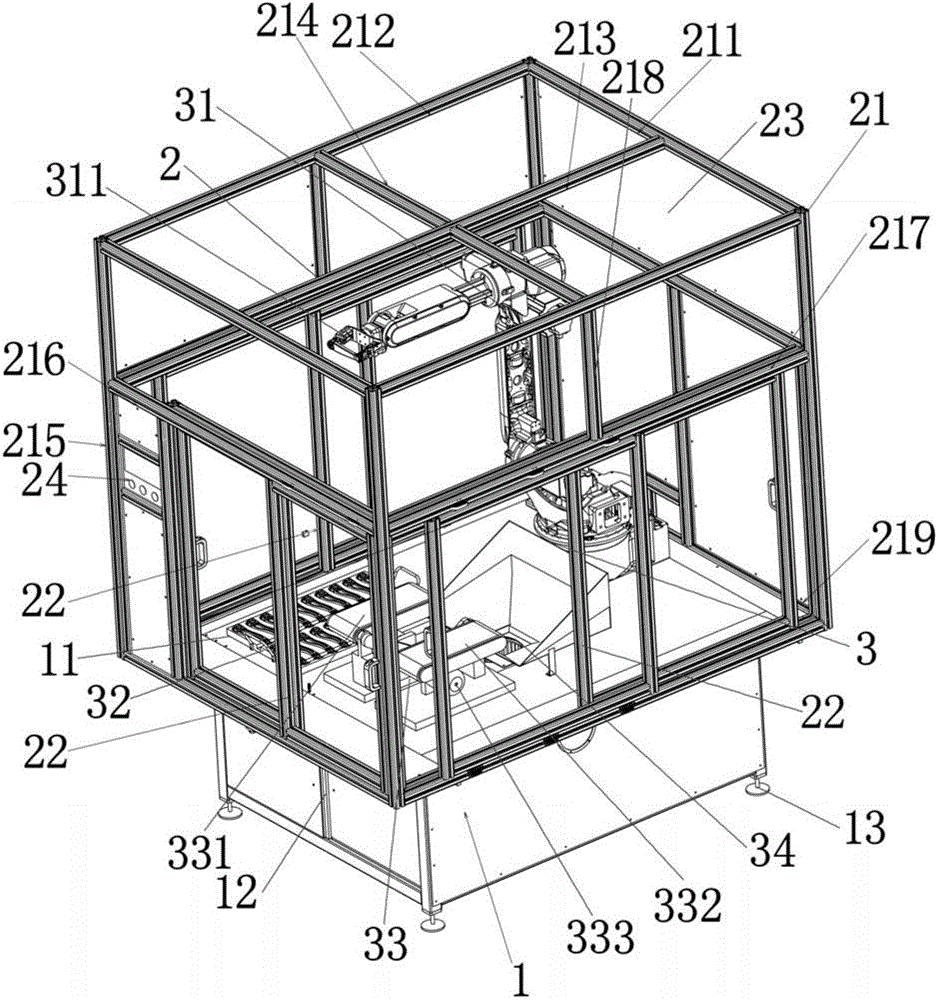

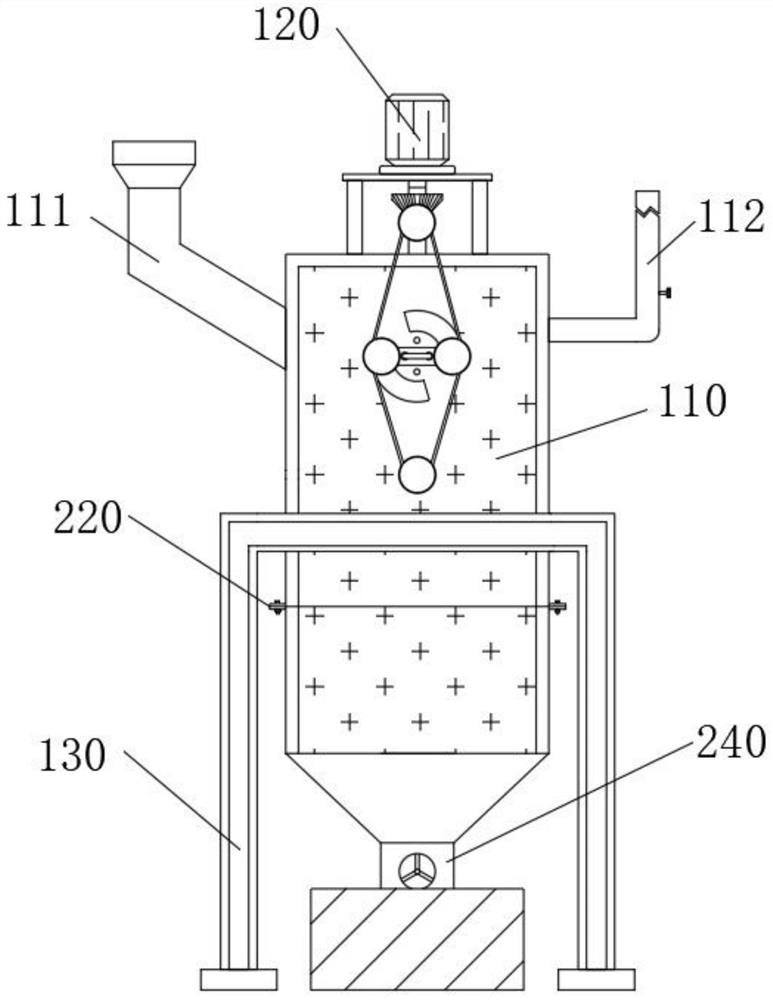

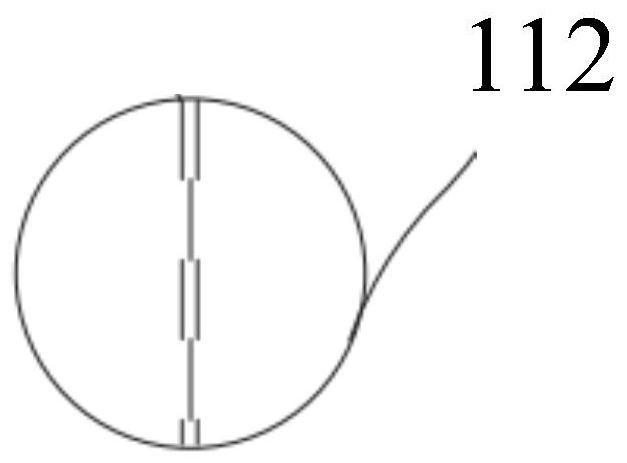

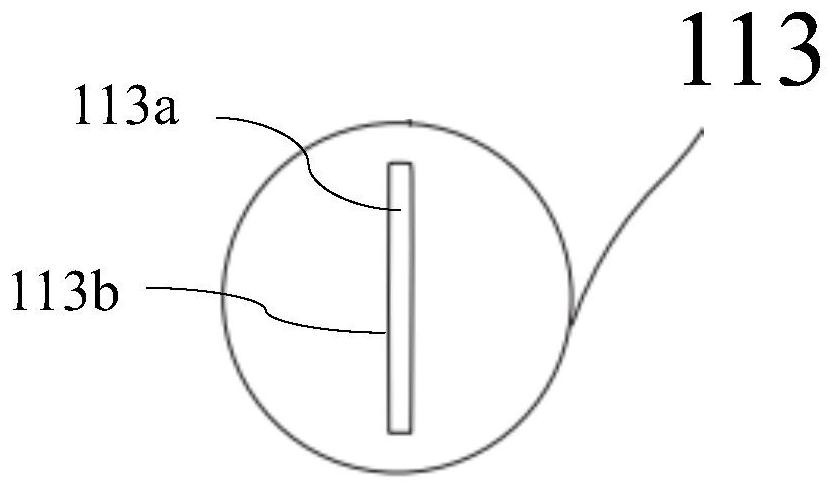

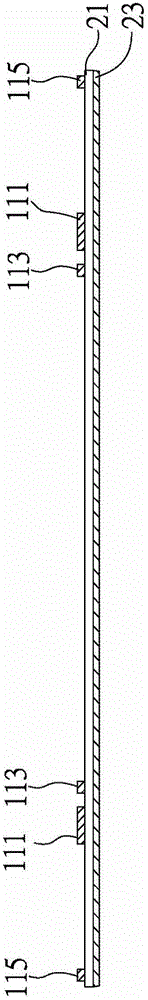

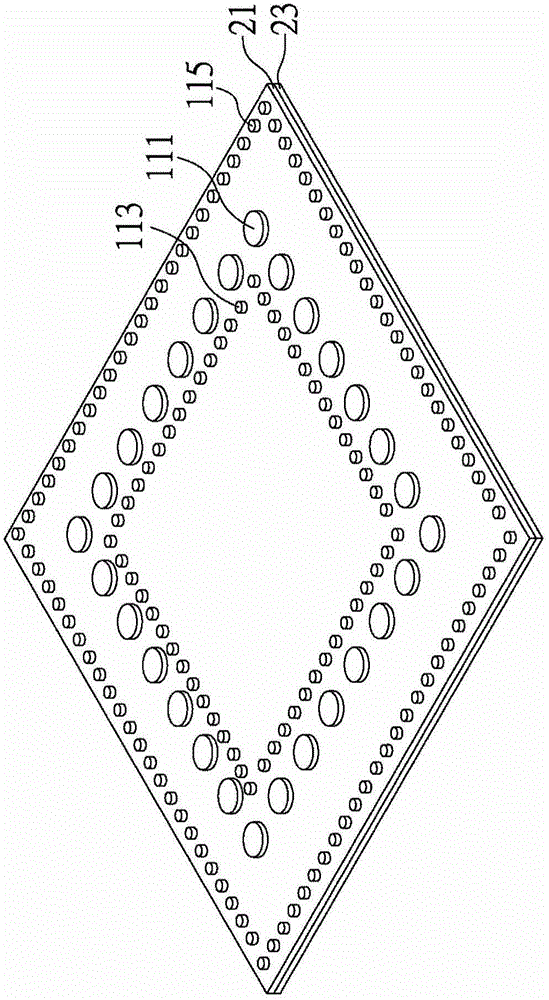

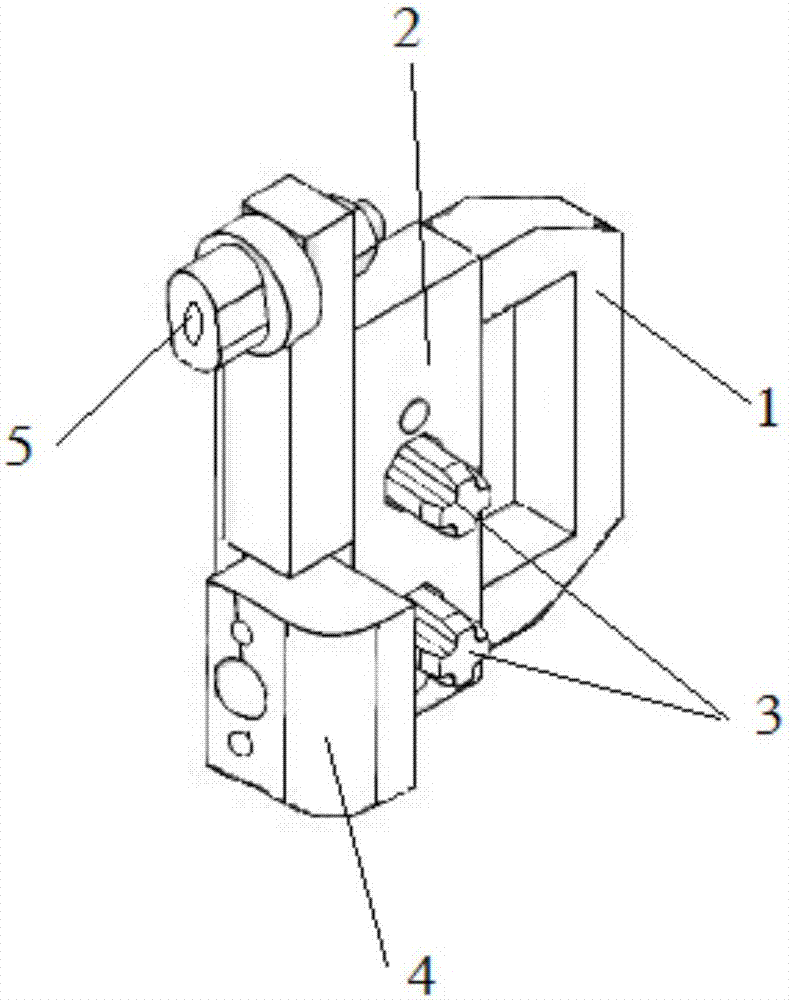

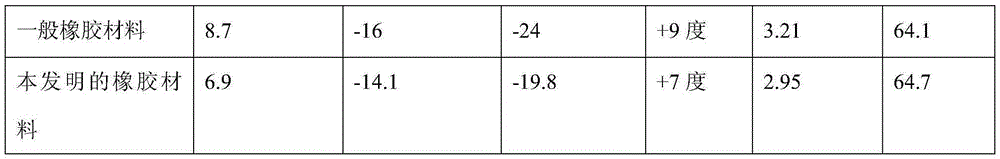

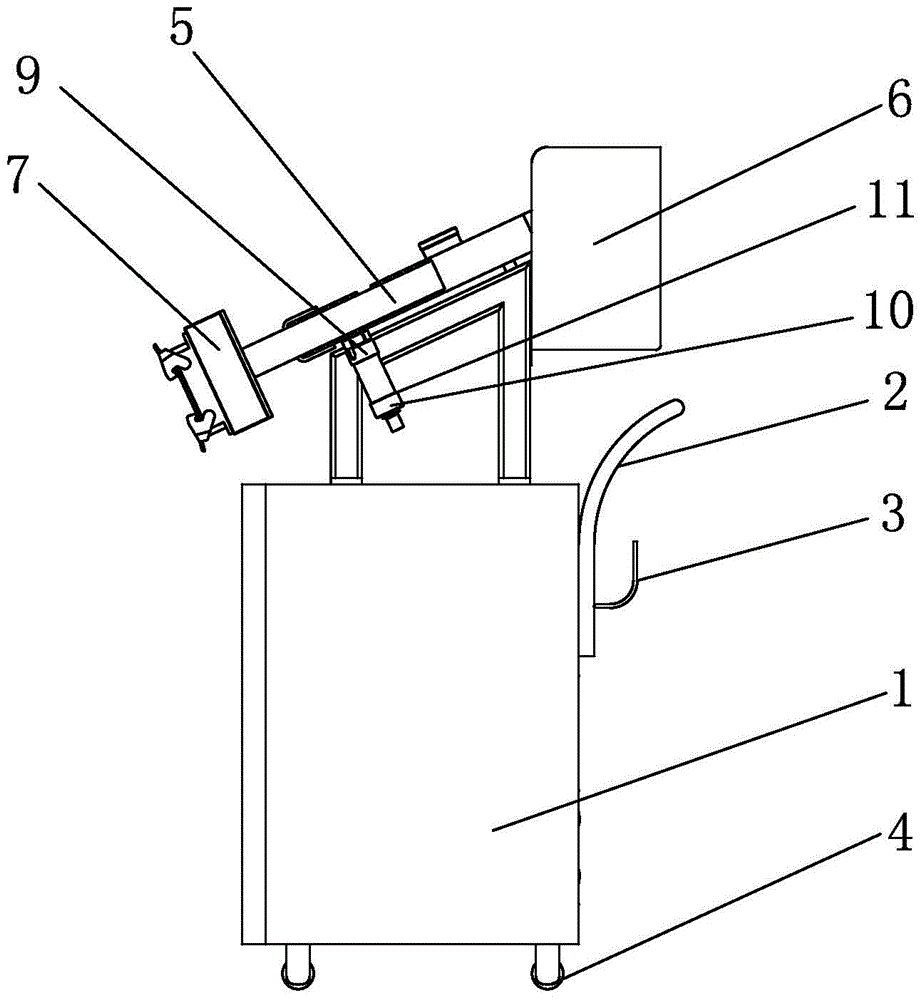

Automatic grinding machine

InactiveCN105127856AStable pass rateEffective cleaning and recyclingEdge grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

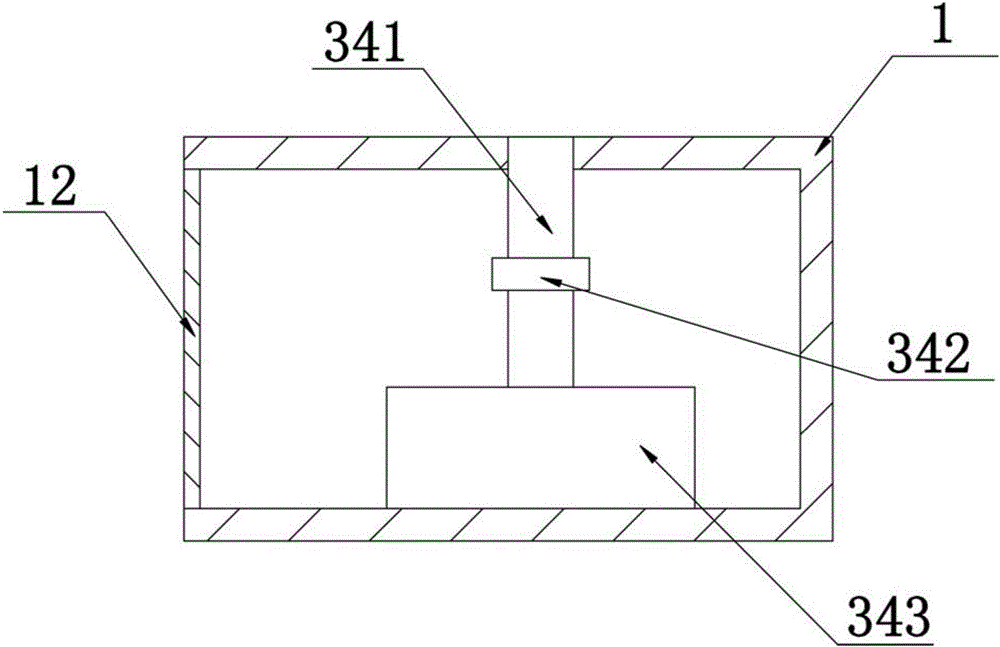

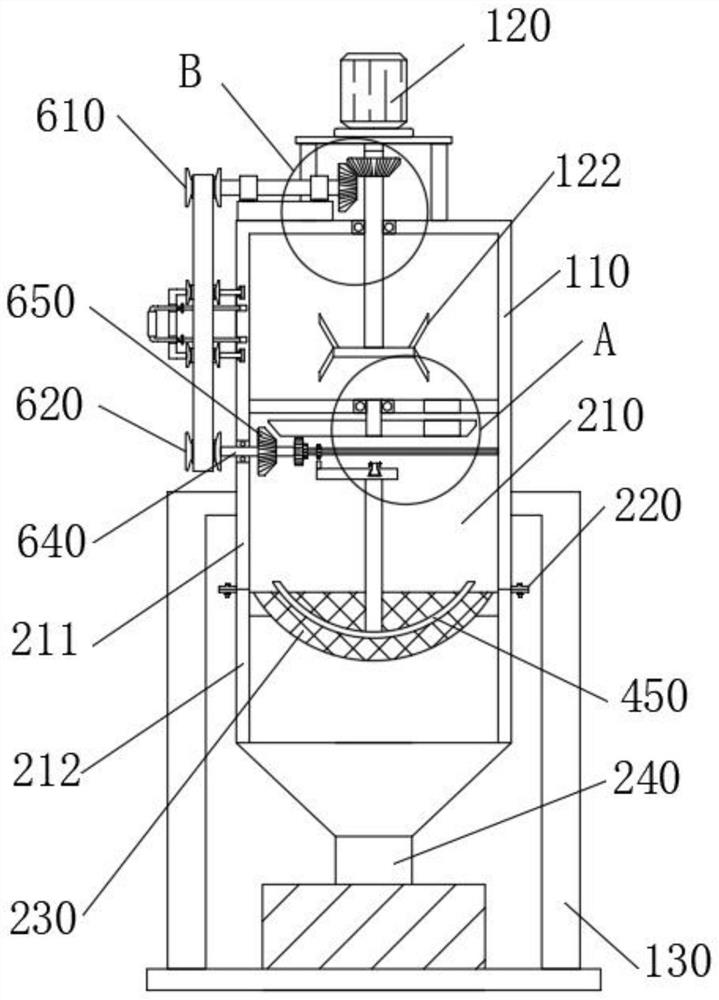

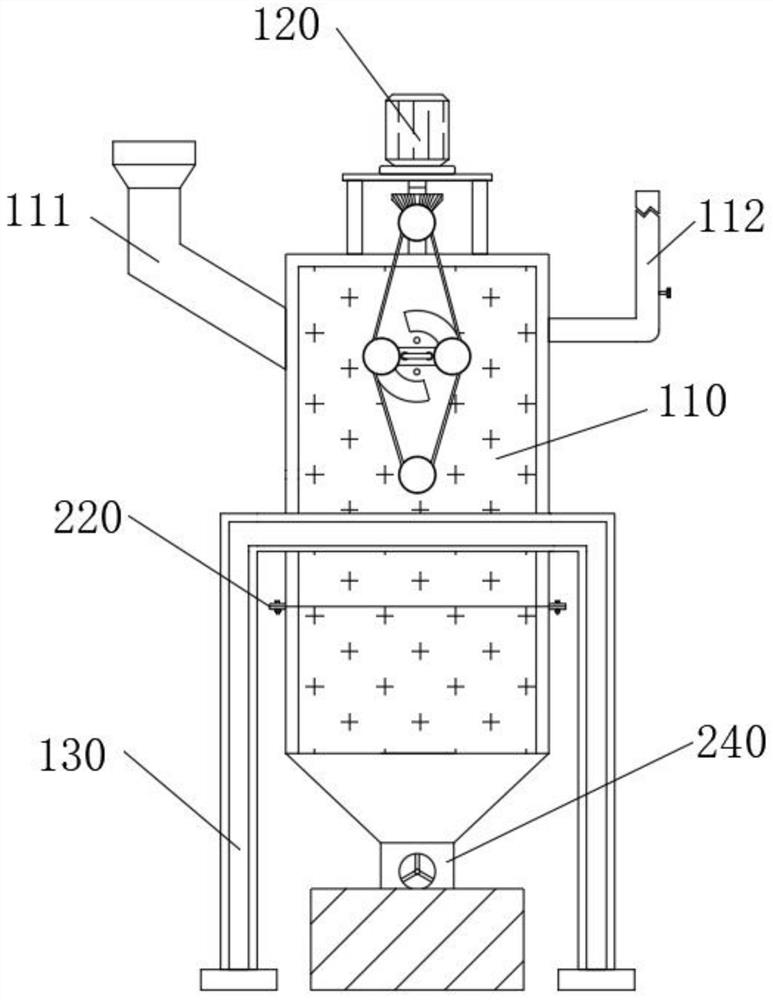

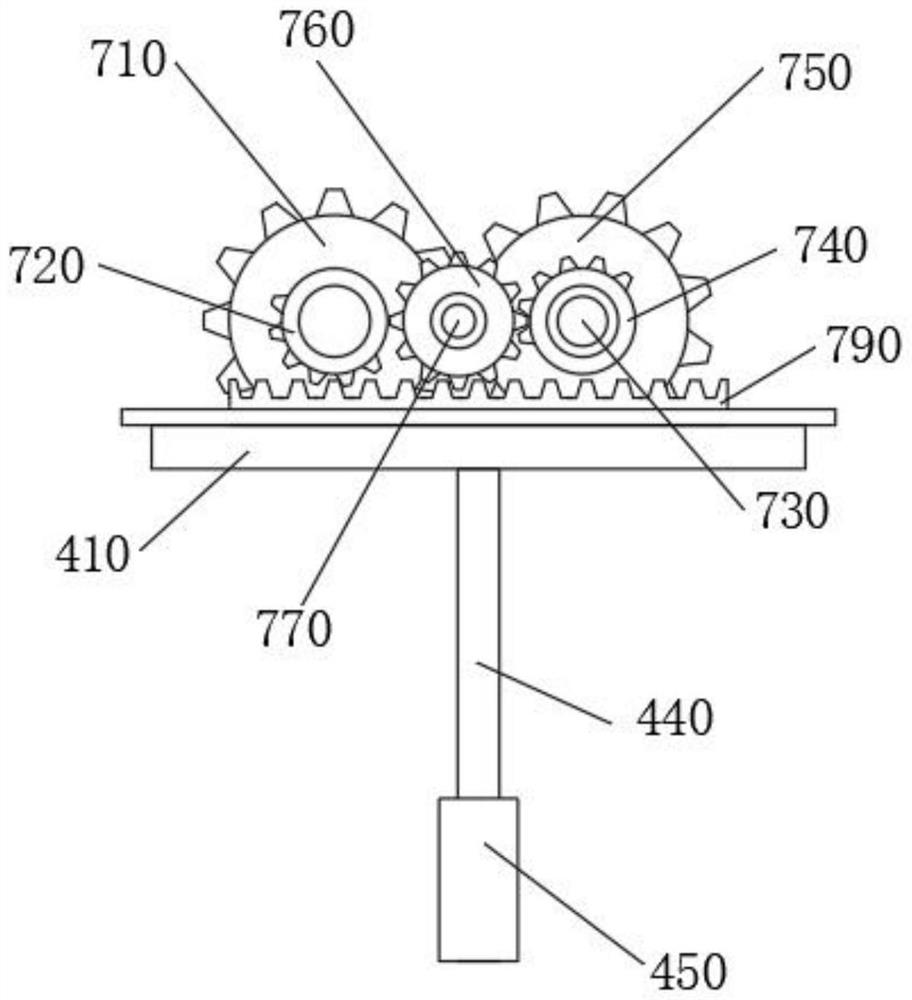

The invention discloses an automatic grinding machine. The automatic grinding machine comprises a base (1), a work room (2) and an automatic grinding system (3), wherein the work room (2) is fixed to the upper plane of the base (1); the automatic grinding system (3) is arranged inside the work room (2); the worm room (2) comprises a support frame (21), movable doors (22) and baffles (23); the automatic grinding system (3) comprises a six-shaft machine arm (31), a tray (32), a polishing and grinding system (33) and a dust collection system (34); the six-shaft machine arm (31), the polishing and grinding system (33) and the dust collection system (34) are fixed to the base (1); the top end of the six-shaft machine arm (31) is provided with a clamping jaw (311); the base (1) is provided with a tray fixing groove (11) matched with the tray (32). By the adoption of the structure, burrs of workpieces can be automatically removed, working efficiency is improved effectively, the cost is reduced, and stability of the percent of pass of the workpieces is ensured.

Owner:NINGBO ASIAWAY AUTOMOTIVE COMPONENTS CO LTD

Wear-resisting nylon PA66 (Polyamide) composite material and preparation method thereof as well as application of composite material in automobile

The invention discloses a wear-resisting nylon PA66 (Polyamide) composite material. The wear-resisting nylon PA66 composite material is prepared by mixing a material A and a material B of modified nylon PA66, and then extruding and granulating. The invention also discloses application of the obtained modified nylon PA66 granules on parts of an automobile; and the application is as follows: the dried modified granules are fed into a heated injection molding machine, the injection pressure, injection speed, injection time and the amount of injected glue of the injection molding machine are adjusted based on different sections, and the final holding pressure and holding speed are adjusted at the same time, thus reaching the optimal injection molding technology, and the qualified product can be obtained by the optimal injection molding technology. An automobile plastic connector prepared by the modified nylon PA66 granules in the injection molding way has the characteristics of high impact strength, excellent toughness and high wear resistance; the injection molding technology is stable; the product is stable in quality and high in percent of pass; the production efficiency is improved; and the producing cost is reduced.

Owner:ANHUI KAIDI ELECTRIC

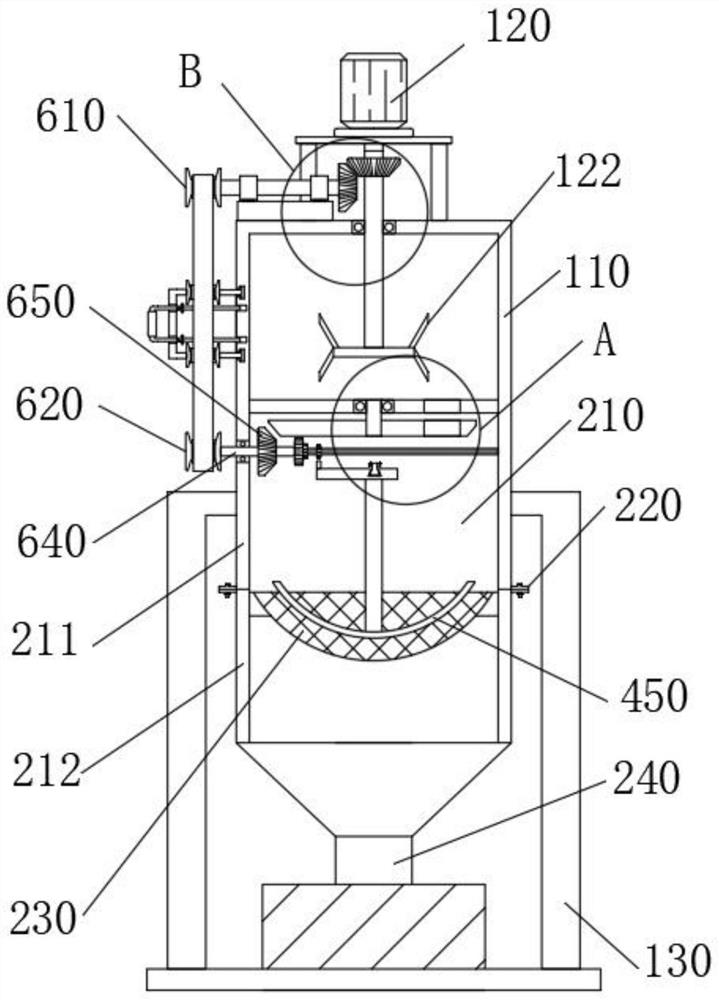

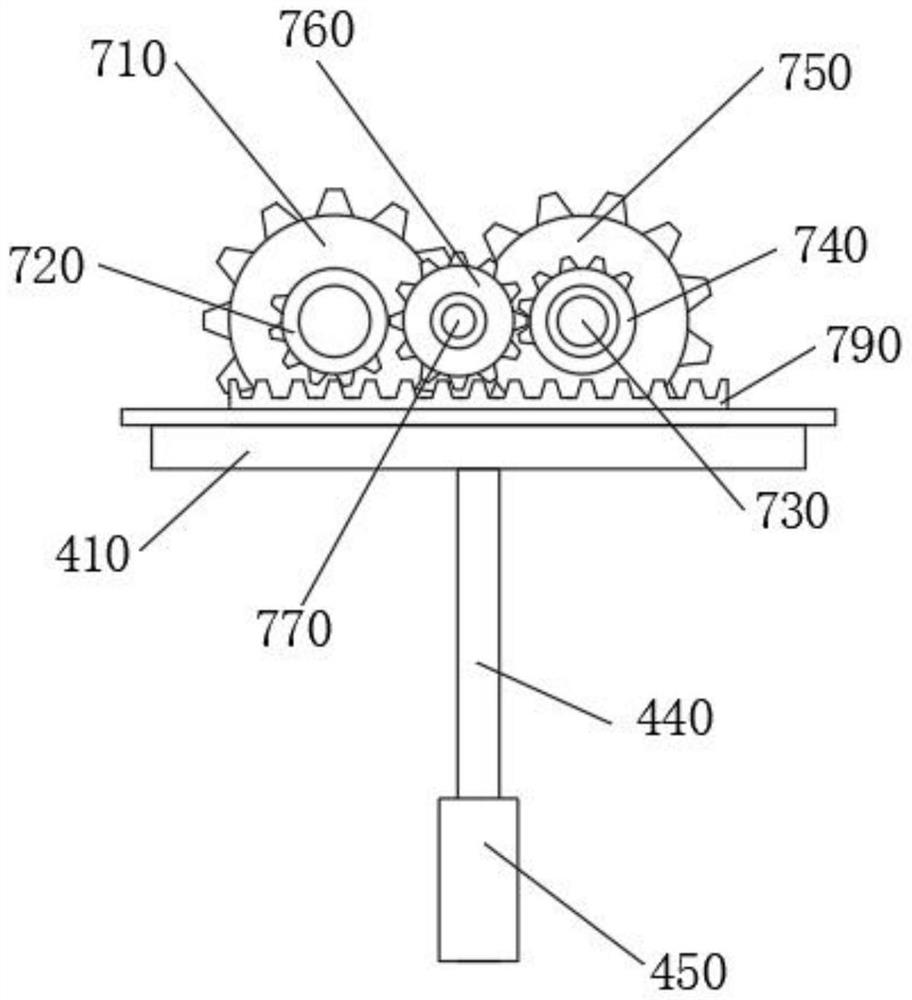

Juicing and hulling mechanism of milled rice with embryo for energy beverage processing

ActiveCN111871486AQuick filterReduce consumptionGrain huskingGrain polishingBiotechnologyElectric machinery

The invention relates to the technical field of juicing and hulling, in particular to a juicing and hulling mechanism of milled rice with embryo for energy beverage processing. The juicing and hullingmechanism comprises a juicing mechanism, wherein the juicing mechanism comprises a juicing cavity main body, a motor and a supporting frame; one end of the juicing cavity main body is fixedly connected with a feed port, and the end, far away from the feed port, of the juicing cavity main body is fixedly connected with a water inlet pipeline; the top end of the juicing cavity main body is fixedlyconnected with the motor through an auxiliary support, an output shaft of the motor is fixedly connected with a first rotating rod, the first rotating rod penetrates through the juicing cavity main body and is rotationally connected with the juicing cavity main body through a bearing, and the end, far away from the motor, of the first rotating rod is fixedly connected with stirring blades; and theside surface of the juicing cavity main body is fixedly connected with the supporting frame, and a filtering mechanism is arranged at the bottom end of the juicing cavity main body. According to thejuicing and hulling mechanism of the milled rice with embryo for energy beverage processing, juicing and hulling of the milled rice with embryo can be completed by using the integrated device, so thatthe product percent of pass is stabler, the electric energy consumption is lower, the production cost is reduced, and the practicability and economy of the device are improved.

Owner:HUNAN UNIV OF ARTS & SCI

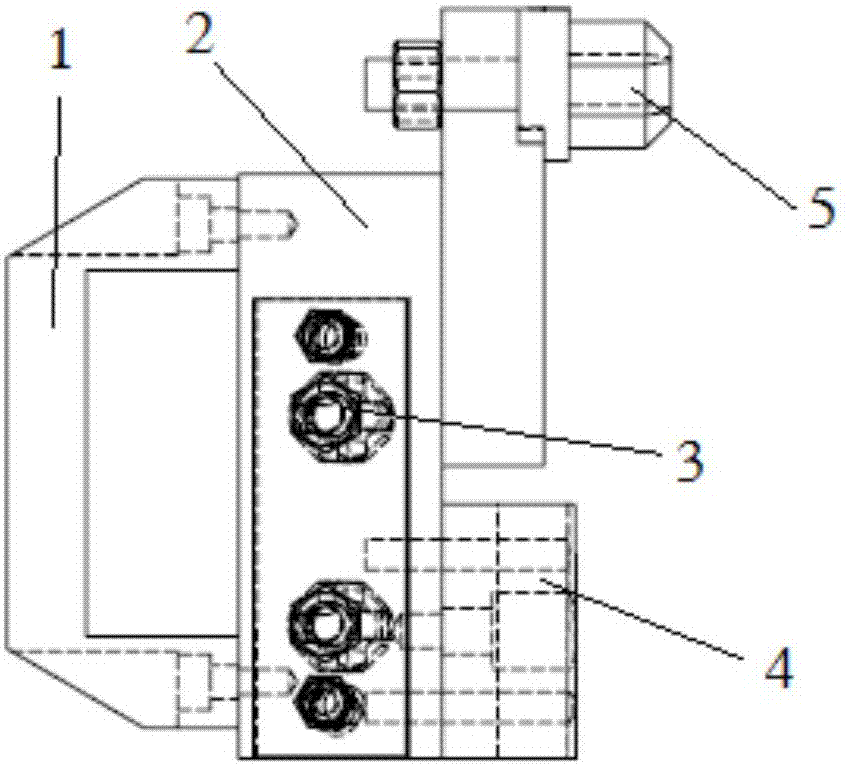

Device and method for fixing shaft tube and plate spring seat before welding

PendingCN113953732ATime outEliminate spot welding fixation timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a device and a method for fixing a shaft tube and a plate spring seat before welding. The fixing device comprises a fixing base and a fixing assembly arranged on the fixing base and used for fixing the shaft tube and the plate spring seat. The fixing assembly comprises a centering mechanism, a manual placing pin and a pressing mechanism. The centering mechanism is used for positioning the corresponding position relation of the shaft tube and the plate spring seat in the axial direction and the radial direction; the plate spring seat comprises an upper plate spring seat and a lower plate spring seat; the manual placing pin is used for limiting the position relation between the upper plate spring seat and the lower plate spring seat; and the pressing mechanism is used for pressing and attaching the upper plate spring seat and the lower plate spring seat to the shaft tube and then welding. Therefore, the scribing time and the spot welding fixing time are saved, and the production efficiency is improved; positioning is carried out according to the position relation of corresponding parts, so that the positioning precision is high; and meanwhile, damage caused by welding operation on the assembled product is avoided, the working efficiency is improved, the product quality consistency is good, and the percent of pass is stable.

Owner:江苏宝京汽车部件有限公司

Juicing and dehulling mechanism of germ rice for energy drink processing

ActiveCN111871486BQuick filterReduce consumptionGrain huskingGrain polishingBiotechnologyElectric machine

The present invention relates to the technical field of extracting juice and shelling, in particular to a mechanism for extracting juice and shelling germ rice for energy drink processing, including a juice extracting mechanism, which includes a juice extracting cavity main body, a motor and a support frame, the One end of the main body of the juicing chamber is fixedly connected with a feed port, and the end of the main body of the juicing chamber away from the feed port is fixedly connected with a water inlet pipe, and the top of the main body of the juicing chamber is fixedly connected with a motor through an auxiliary bracket, and the output The shaft is fixedly connected with the first rotating rod. The first rotating rod runs through the main body of the juice extracting chamber and is rotationally connected with the main body of the juice extracting chamber through a bearing. The end of the first rotating rod far away from the motor is fixedly connected with a stirring blade. The side surface of the main body of the juice chamber is fixedly connected with the support frame, and a filtering mechanism is arranged at the bottom of the main body of the juice extraction chamber. The invention allows the germ rice to be juiced and shelled by using an integrated device to complete the processing, the qualified rate of the product is more stable, the power consumption is less, the production cost is reduced, and the practicability and economical efficiency of the device are improved.

Owner:HUNAN UNIV OF ARTS & SCI

Precise machining method of shaft end piece sealing ring B of stirrer

ActiveCN110355396APrevent movementGuaranteed machining accuracyPositioning apparatusMetal-working holdersDrill bitMachining process

The invention discloses a precise machining method of a shaft end piece sealing ring B of a stirrer, and belongs to the field of shaft end piece machining. According to the method, the to-be-machinedshaft end piece sealing ring B is assembled on a machining tool, a to-be-machined installation hole of the shaft end piece sealing ring B is perpendicular to the horizontal plane, by forming a guide hole, the position of the to-be-machined installation hole can be located fast and accurately, then by fixing the machining tool, the machining tool is prevented from moving in the machining process, and the machining precision is guaranteed. By means of the method, machining of the installation hole can be conducted without line marking, the machining efficiency is improved, in addition, the machining precision is high, and the machining qualification rate is high.

Owner:马鞍山万力重工机械制造有限公司

A kind of processing method of hand-turned hard cigarette box

ActiveCN110861352BEasy to operateShaped squareEnvelopes/bags making machineryPaper-makingPaperboardIndustrial engineering

The invention relates to a processing method of a hand-turned side-turning hard cigarette box, comprising: S1, die-cutting cardboard printed products to obtain semi-finished products of face paper, an upper cover, a skirt and a lower cover; S2, bonding the skirt and the lower cover together Forming an empty box cup and setting the empty box cup on the forming mold; S3, fitting the upper cover on the forming mold, and bonding the facial paper to the upper cover and the empty box cup respectively; S4, pressing and Take out the forming mold after dehumidification and trimming. The processing method of the manual side-turning hard cigarette case of the present invention has the characteristics of simple operation, high production efficiency, and stable product qualification rate. The processing method can make the hand-made side-turning hard cigarette case The shape is square, the opening and closing are smooth, and the box cover will not automatically pop open after the empty box cup is covered; moreover, the processing method can be standardized, and the processing of the manual side flip hard cigarette box with the same structure can be transplanted in batches and standardized production to obtain quality Stable and reliable product.

Owner:襄阳金飞环彩色包装有限公司

Method for machining stirrer shaft end part sealing ring B

The invention discloses a method for machining a stirrer shaft end part sealing ring B, and belongs to the field of shaft end part machining. The method comprises the following steps of 1 first installing hole machining and 2 second installing hole machining. The first installing hole machining step comprises the substeps that 1 assembling is conducted, wherein the position of the to-be-machined first installing hole is perpendicular to a horizontal plane, and a third guide hole is formed to be located over the machining position of the to-be-machined first installing hole; 2 hole machining isconducted; and 3 the to-be-machined shaft end part sealing ring B is rotated by 180 degrees around the center and then reassembled to a machining tool provided with the third guide hole for hole machining. The second installing hole machining step comprises the substeps of 1 assembling, wherein the position of each to-be-machined second installing hole is perpendicular to the horizontal plane, and a first guide hole and a second guide hole are formed to be respectively located over the machining positions of the two to-be-machined second installing holes; and 2 hole machining. According to the method for machining the stirrer shaft end part sealing ring B, the to-be-machined installing holes of the shaft end part sealing ring B can be made to be located perpendicular to the positions of the horizontal plane through assembling, the guide holes are arranged so that a drill bit can rapidly and accurately position the positions of the to-be-machined installing holes, lining marking is notneeded, the machining efficiency is improved, and the machining precision is high.

Owner:马鞍山万力重工机械制造有限公司

Fringe field switching mode liquid crystal display and manufacturing method thereof

ActiveCN101907802BImprove outdoor clarityIncrease the aperture ratioNon-linear opticsLiquid-crystal displayTransmittance

Provided is a fringe field switching mode liquid crystal display and manufacturing method thereof. The fringe field switching mode liquid crystal display device includes a lower substrate, an upper substrate, and a liquid crystal layer inserted between the lower substrate and the upper substrate, wherein the select line and the data line are mutually intersected, a pixel region is limited on the lower substrate, a switching device is provided at the intersecting part between the select line and the data line. The fringing field switching mode liquid crystal display device includes a transparent common electrode having a predetermined shape and formed within the pixel area to adjust light transmittance by applying a voltage to the liquid crystal layer, and a transparent pixel electrode having a plurality of slits and formed above the transparent common electrode with an insulating layer interposed between the transparent common electrode and the transparent pixel electrode. A rubbing direction for aligning the liquid crystal layer is within 5 DEG with respect to a direction of the gate line to remove a light shielding region above the data line, one end of the transparent common electrode is arranged between the data line and the transparent pixel electrode. A reflector is manufactured in an electrically independent type by using the material identical to that of the data line.

Owner:HYDIS TECH CO LTD

Tail cone molding die and molding method thereof

The invention provides a tailcone forming mould which comprises a lower mould plate, an upper mould plate, a concave mould body and a convex mould body. The central lines of the lower mould plate, the upper mould plate, the concave mould body and the convex mould body are coincided with each other, a forming groove is formed in the center of the concave mould body, the convex mould body is fixedly arranged on the top surface of the lower mould plate, and the concave mould body is arranged under the bottom surface of the upper mould plate. The tailcone forming mould further comprises limiting columns for controlling the downward moving distance of the concave mould body, an edge pressing ring in contact with the inner lateral wall of the forming groove and a plurality of ejector rods which can enable the edge pressing ring and the forming groove to clamp a formed workblank; the ejector rods are respectively arranged on the lower mould plate and evenly distributed around the convex mould body in the peripheral direction; the ejector rods abut against the bottom edge of the edge pressing ring and can drive the edge pressing ring and the formed workblank; the at least two limiting columns are evenly distributed between the edge pressing ring and the lower mould plate; the height difference between the top surfaces of the limiting columns and the bottom surface of the edge pressing ring can be determined by the distance between the top end of the formed worblank and a conical face of the convex mould body in the vertical direction. According to the tailcone mould, the rate of finished products of tailcones can be improved to 100% from 50%, the percent of pass is verified repeatedly, and the effect is stable.

Owner:CHINA HANGFA SOUTH IND CO LTD

Edible starch with ultra-low moisture and ultra-low microorganism, and manufacturing method thereof

ActiveCN102432890BStable pass rateImprove sterilization effectManufacturing technologyProduced water

The invention discloses an edible starch with ultra-low moisture and ultra-low microorganism, and a manufacturing method thereof, belonging to the starch manufacturing technology. The invention is characterized in that the loss on drying is less than or equal to 5.0; the fineness is more than or equal to 99.5% (sieved by a 100-mesh sieve); the number of bacteria is not more than 100 per gram; and the number of moulds and saccharomycetes is not more than 10 per gram. The manufacturing method comprises the following steps of: selecting materials; roasting for sterilization: heating till the temperature of the materials is more than or equal to 110 DEG C but less than or equal to 160 DEG C with the stirring speed being 25+ / -5 times / minute and the stirring time being more than or equal to 120 minutes; cooling: leading the temperature of the material to be less than 70 DEG C in 40 minutes; sieving, detecting, metering and packaging; and the cleanliness of the ambient air in roasting for sterilization, cooling, sieving, metering and packaging reaches 30,0000 level. Through implementation, the produced water is 35.7% of the standard in the common edible starch, the index of microorganisms is 10% of the standard of the common edible starch, and the higher and higher food production need for sanitary requirement is met; and in the manufacturing method, the potential safety hazards of the drying and sterilization process are fewest and the safe production is reliably realized.

Owner:江苏昕宇药业有限公司

Semiconductor component with dual connection channels between interposer and coreless substrate

InactiveCN103594444BReduce the number of perforationsSmall sizeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorAdhesive

The invention relates to a semiconductor component with double connection channels between the interposer and the coreless substrate. The semiconductor component includes a semiconductor element, an intermediate layer with a through hole, a coreless substrate, and a strengthening layer. The semiconductor element is flip-chip on the intermediary layer, and the intermediary layer is fixed on the coreless substrate through an adhesive, and extends into a through hole of a reinforcement layer, and the reinforcement layer provides mechanical support for the coreless substrate. The electrical connection between the interposer and the coreless substrate includes wire bonding and conductive microvias, and the coreless substrate can provide a fan-out route from the interposer.

Owner:BRIDGE SEMICON

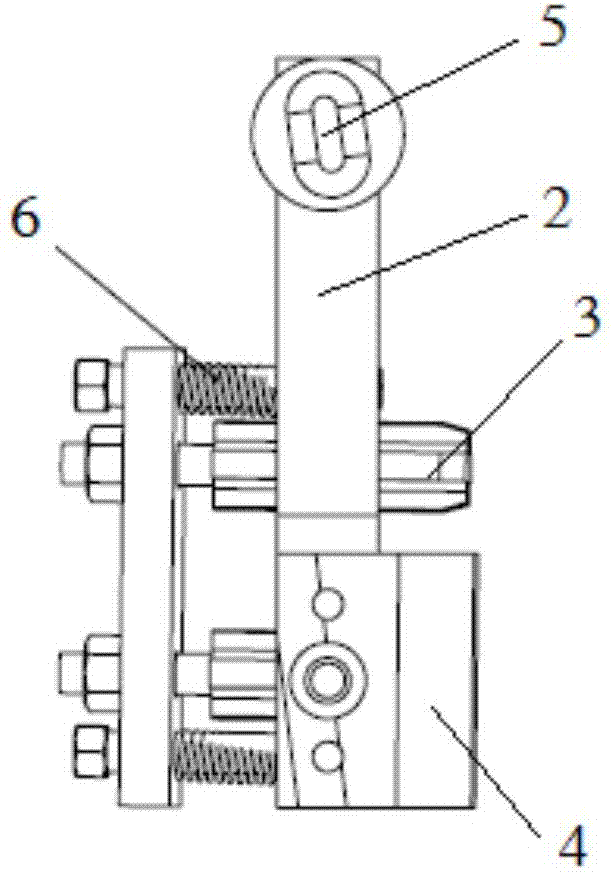

Detection tool for mounting hole of B pillar of vehicle

PendingCN107514951AEffective detection of installation dimensionsEffective detection of installation positionMechanical measuring arrangementsEngineeringMechanical engineering

The invention relates to a detection tool for a mounting hole of a B pillar of a vehicle. The mounting hole comprises a base, a handle, a positioning unit and a measuring unit, wherein the handle is arranged behind the base, the measuring unit is arranged at the right side of the base and comprises two detection pins, the positioning unit comprises a positioning hole and a standard block profile, the positioning hole is arranged in the upper front portion of the base, and the standard block profile is arranged on the lower front part of the f base. The detection tool is fixed by a nylon block profile for better fitting the profile so as to achieve the firmness when the handle is detected, reduce the size deviation and stabilize the qualified rate of the product. The base is a casting piece which ensures the service life of the detection tool. Manual detection means is adopted, and operation is easy. A detection pin is used for manual detection, thereby preventing parts from being damaged during use, and the operation is convenient.

Owner:SHANGHAI ANDELAI AUTO PARTS

Preparation method for casting cast steel paint

InactiveCN106311970AReduce carbon increaseReduce defects such as poresFoundry mouldsFoundry coresSuspending AgentsLost-foam casting

The invention discloses a preparation method for casting cast steel paint. The paint is composed of bauxite, water, sodium bentonite, a suspending agent, an organic binding agent, emery powder and an auxiliary. The paint is prepared from, by weight, 15% of the bauxite, 25% of the water, 5% of the sodium bentonite, 6% of the suspending agent, 13% of the organic binding agent, 33% of the emery powder and 3% of the auxiliary. The performance of the casting cast steel paint is determined by the composition, the preparation process, the smearing process and the drying process of the casting cast steel paint, the defects of recarburization, pores and the like of cast steel pieces are reduced through the paint, the comprehensive paint performance of the paint is stable, cost is low, it can be ensured that the comprehensive qualified rate of products of the vacuum evaporable pattern casting cast steel pieces is stabilized to be 99% or above, and the effect is ideal.

Owner:ANHUI HANSHAN COUNTY ANHUI PROVINCE IN THE SLOWDOWN MACHINERY

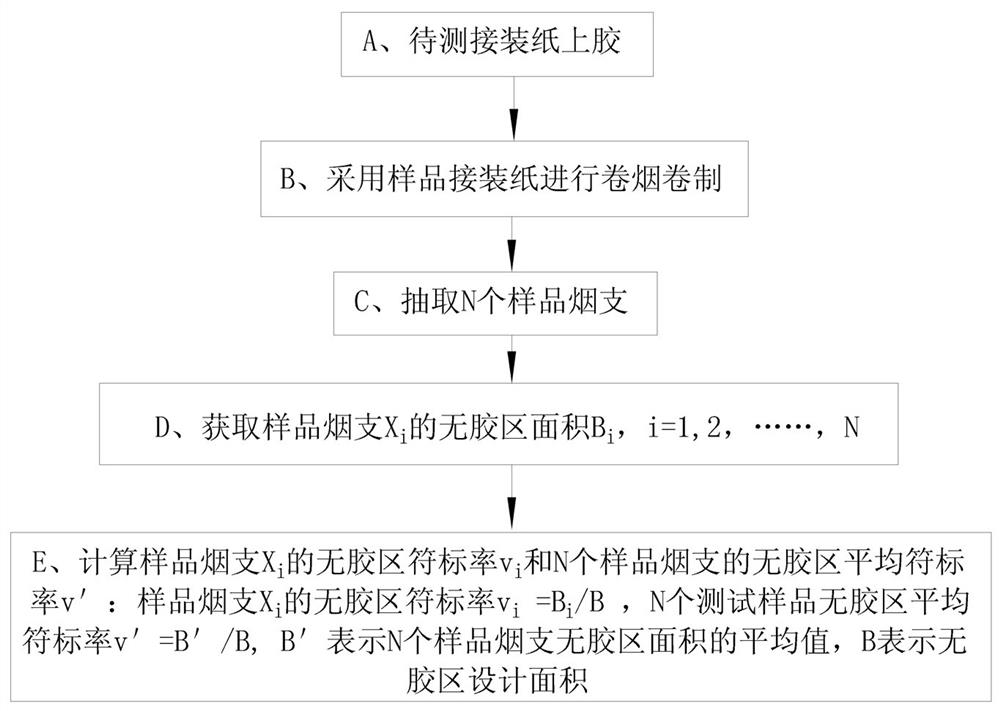

A detection method for conformity rate of cigarette glue-free area based on image detection method

ActiveCN109527648BRealize automatic extractionRealize automatic measurementCigarette manufactureImage detectionProcess engineering

The invention discloses a method for detecting the compliance rate of cigarette glue-free areas based on an image detection method. By selecting a sample tipping paper with a large color difference from the tipping glue, the sample roll is used under the normal production conditions of the cigarette machine and the tipping machine. Load paper for cigarette rolling, and then sequentially undergo sampling and collection of the area of the glue-free area of the sample cigarette, and obtain the shape and area of the glue-free area through image acquisition; the invention can quickly, conveniently and accurately detect the shape of the glue-free area and the area of the glue-free area. area, solve the problem of lack of information on perforated cigarettes, provide accurate data support for the adjustment of equipment parameters, ensure the ventilation effect of finished cigarettes, and improve the qualified rate of finished cigarettes.

Owner:CHINA TOBACCO HENAN IND

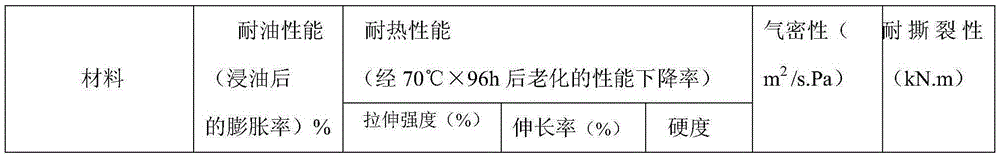

Oil inlet sealing ring for automobile brake master cylinder

The invention discloses an oil inlet seal ring for an automotive brake master cylinder. The oil inlet seal ring comprises the following raw materials in parts by weight: 100-106 parts of ethylene propylene diene monomer rubber K4802, 6-7 parts of calcium silicate, 3-4 parts of polyethylene glycol 400, 3-4 parts of poly(1, 2-propylene glycol adipate), 10-15 parts of sepiolite powder, 6-10 parts of barite powder, 1-2 parts of zinc oxide, 3-4 parts of polyamide wax micro-powder, 1-2 parts of 2-thiol-benzimidazole, 1-2 parts of accelerator TMTD, 0.6-1 part of sulfur, 1-2 parts of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane and 6-8 parts of modifying additives. The oil inlet seal ring disclosed by the invention has the advantages of high strength, tension resistance, tear resistance, corrosion resistance and strong temperature resistance and can overcome the situation that the existing oil inlet seal ring product is very easy to produce a gap during mold stripping, the production efficiency and the product qualification rate are high, the oil inlet seal ring can completely conform to the requirements of using working conditions of the oil inlet seal ring for the automotive brake master cylinder, and the oil inlet seal ring is safe and reliable.

Owner:江苏博盟科技有限公司

A measurement system for detecting temperature control box

The invention discloses a measuring system for detecting temperature control boxes. The measuring system comprises a cart body, and a line pipe frame is arranged on the upper end face of the cart body; an anti-scalding baffle is arranged on one side of the line pipe frame, and a wiring box is arranged on the other side of the line pipe frame; a two-area heating flow dividing plate is arranged at the position, between the anti-scalding baffle and the wiring box, of the line pipe frame; hot nozzles are formed in the lower end of the two-area heating flow dividing plate, and each hot nozzle is provided with a heating temperature sensing line and a measuring temperature sensing line; a heating temperature sensing line socket and a measuring temperature sensing line socket are arranged in the wiring box, and the heating temperature sensing lines are connected with the heating temperature sensing line socket; the measuring temperature sensing lines are connected with the measuring temperature sensing line socket; the interior of the cart body is divided into an upper layer and a lower layer, and the upper layer and the lower layer are each provided with one temperature control box; and the temperature control box on the upper layer is connected with the measuring temperature sensing line socket, and the temperature control box on the lower layer is connected with the heating temperature sensing line socket. Through the manner, the yield of products can be more stable, abnormalities caused by hot flow way temperature control equipment is reduced, the maintenance cost and the raw material cost are reduced, and the profits are large.

Owner:SUZHOU HTS MOLD

A Precise Machining Method for Sealing B Ring of Shaft End Parts of Mixer

ActiveCN110355396BNo shiftGuaranteed service lifePositioning apparatusMetal-working holdersPilot holeMachining process

The invention discloses a precise machining method of a shaft end piece sealing ring B of a stirrer, and belongs to the field of shaft end piece machining. According to the method, the to-be-machinedshaft end piece sealing ring B is assembled on a machining tool, a to-be-machined installation hole of the shaft end piece sealing ring B is perpendicular to the horizontal plane, by forming a guide hole, the position of the to-be-machined installation hole can be located fast and accurately, then by fixing the machining tool, the machining tool is prevented from moving in the machining process, and the machining precision is guaranteed. By means of the method, machining of the installation hole can be conducted without line marking, the machining efficiency is improved, in addition, the machining precision is high, and the machining qualification rate is high.

Owner:马鞍山万力重工机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com