Patents

Literature

41results about How to "Reduce defects such as pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth lead alloy for lead-acid storage battery positive grid

ActiveCN103762369AImprove corrosion resistanceReduce grain gapElectrode carriers/collectorsCeriumLanthanum

The invention discloses rare-earth lead alloy for a lead-acid storage battery positive grid. The rare-earth lead alloy is characterized by being prepared by smelting the following component materials by weight percent: 0.01 to 0.12 percent of calcium, 1.2 to 2.0 percent of tin, 0.02 to 0.05 percent of aluminum, 0.01 to 0.12 percent of lanthanum, 0.01 to 0.12 percent of yttrium, 0.02 to 0.15 percent of cerium and the balance being lead. The rare-earth lead alloy is stable in chemical property, good in mobility, excellent in conductivity and strong in corrosion resistance; a lead-acid storage battery which is assembled by the grid is long in cycling life, strong in current discharging capacity and strong in charging acceptance capacity.

Owner:江苏海宝电池科技有限公司

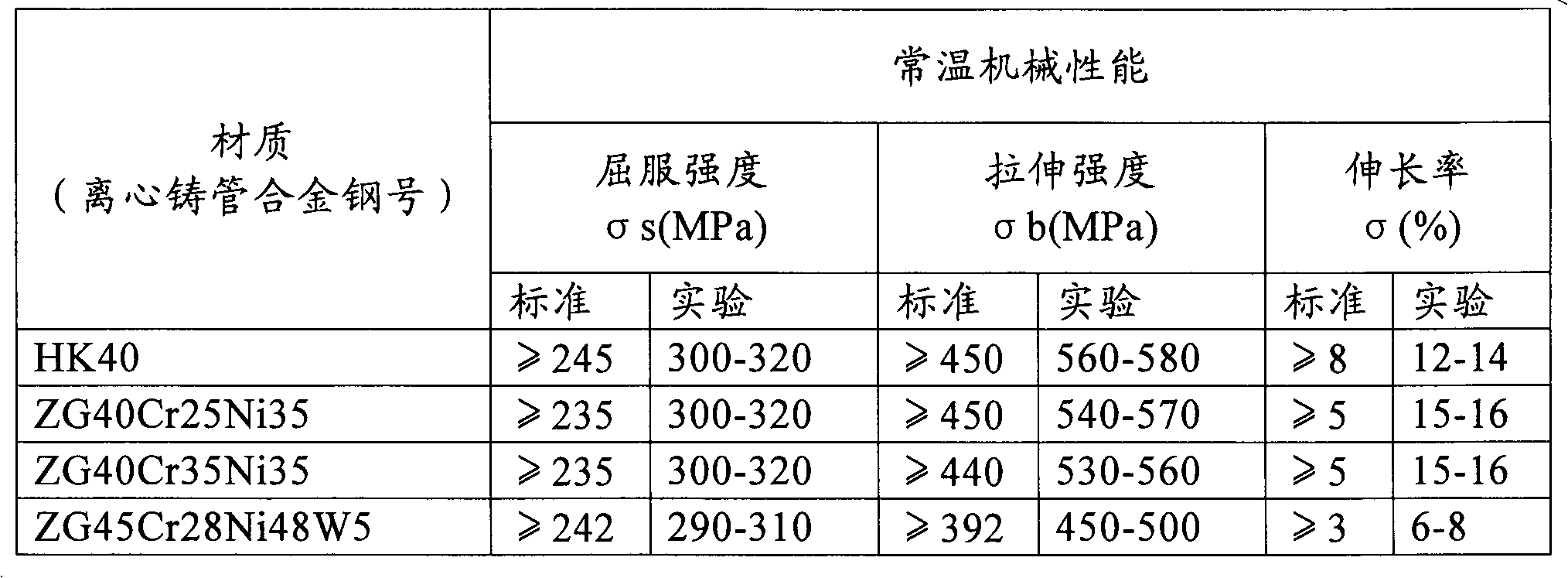

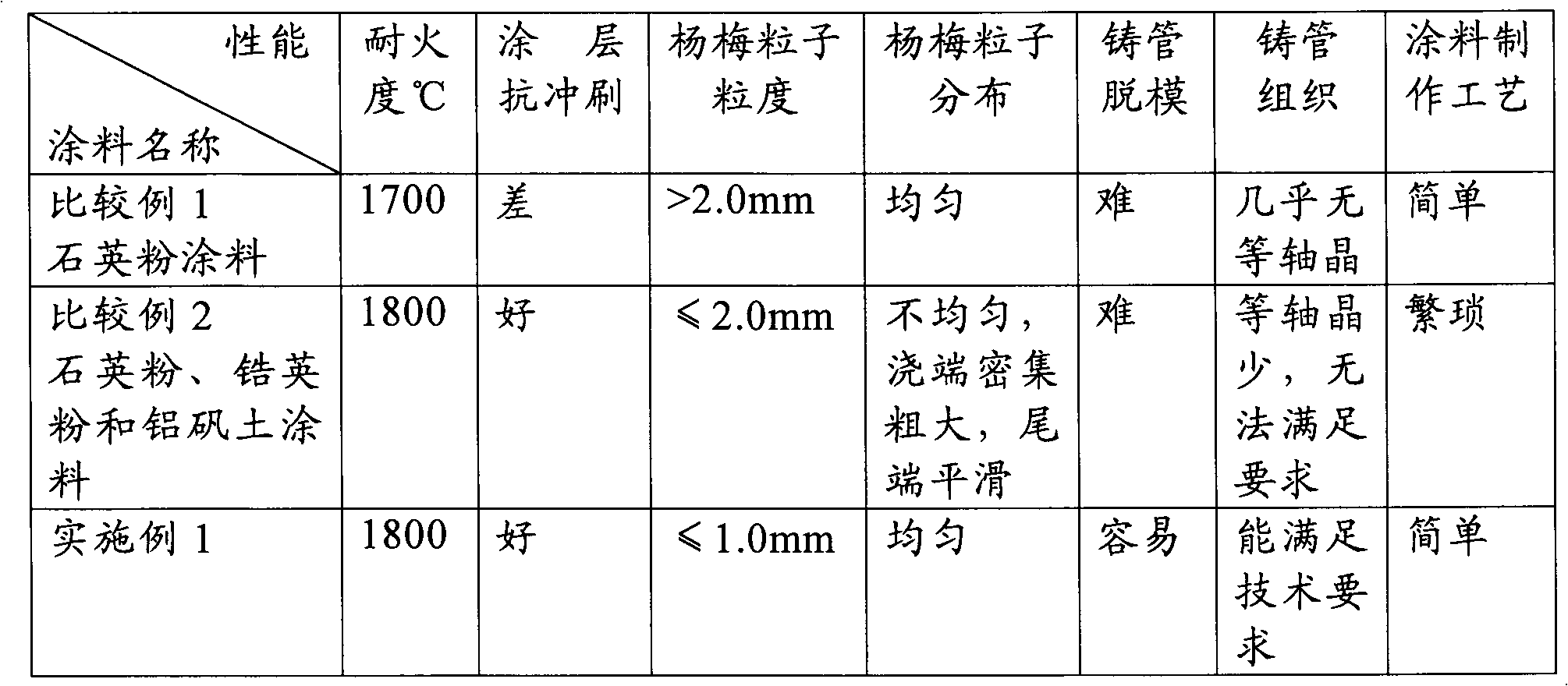

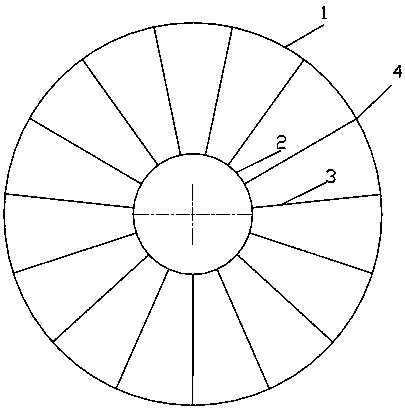

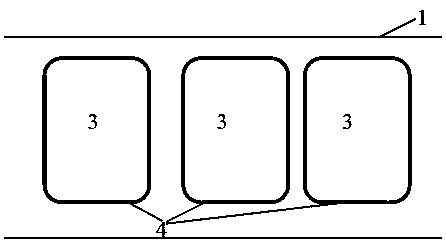

Composite coating for heat-resisting alloy centrifugal casting tube

InactiveCN101648802AStable and uniform use requirementsEasy to operateFoundry mouldsFoundry coresSuspending AgentsAlloy

The invention discloses a composite coating for a heat-resisting alloy centrifugal casting tube, which comprises the following components by weight part: 20-60 parts of quartz powder, 20-70 parts of zircon powder, 0.4-1.5 parts of suspending agent, 0.3-0.8 part of binding agent, 20-40 parts of carrier, 0.1-0.3 part of magnesium oxide and 0.1-0.3 part of activating agent. In the invention, the centrifugal casting tube which has favorable appearance and evenly-distributed waxberry particles is obtained as the composite coating containing quartz powder and zircon powder is adopted; meanwhile, theinherent quality of tube sections is improved, the heat transferring effect of furnace tubes while in use is enhanced; and the composite coating is mainly used in coating processes of reformer tubesand ethylene cracking furnaces in petrochemistry.

Owner:浦杰

Electron beam welding method for dense rectangular ring welding lines of outer ring face

ActiveCN109202254ASuitable for mass productionGuarantee welding quality requirementsElectron beam welding apparatusButt jointLap joint

The invention relates to an electron beam welding method for dense rectangular ring welding lines of an outer ring face. According to the electron beam welding method for the dense rectangular ring welding lines of the outer ring face, a thickness-unequal butt joint form increasing the local thickness of the welding part head portion is designed, and a beam flow guiding welding along long edges and lap-joint and step-attenuating beam flow closing welding method is adopted, so that the amount of molten metal is increased, the welding line molding quality is improved, and the process stability and margin are improved; misplaced and lapped U-shaped protective structures are designed inside an outer ring, and injuries by burning on a shaft rod and an inner ring structure are avoided; and a symmetrical welding method is adopted, the welding sequence is designed, a grouped multiple welding manner is adopted, the accumulation effect of dense welding-line welding heat input and stress deformation is reduced, influence of the dense welding-line stress deformation on welding gaps, order difference and the like is reduced, the welding quantity is improved, control of welding deformation and structural size accuracy is facilitated, and the welding finished product rate is increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

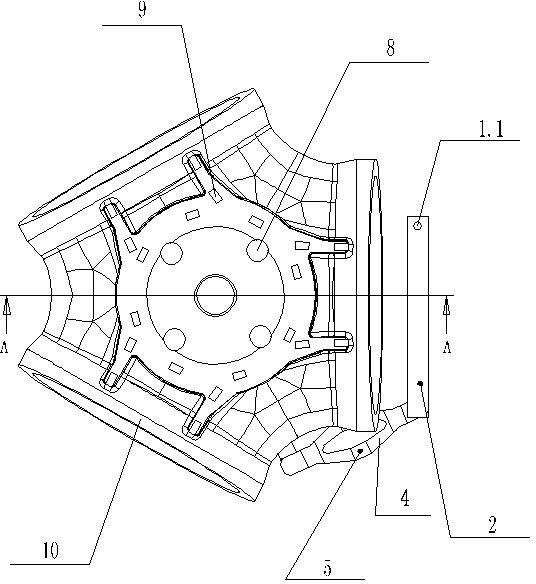

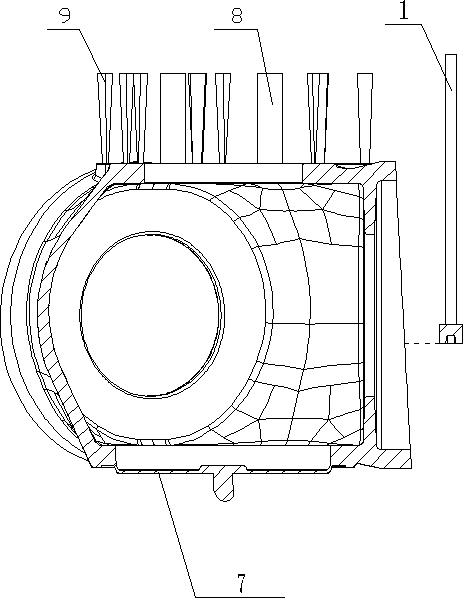

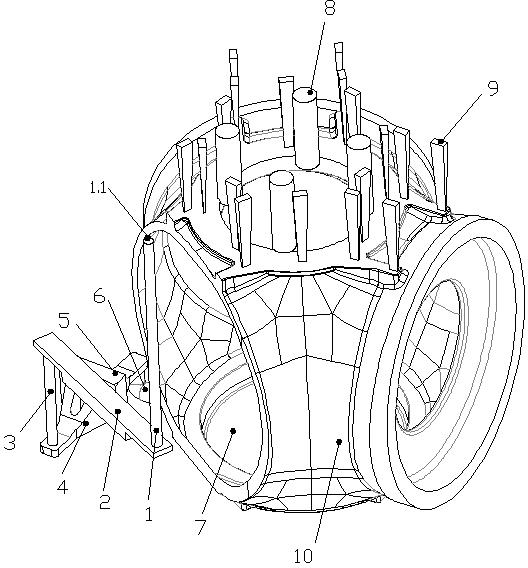

Chill-free processing method of wind-driven generator hub

The invention discloses a chill-free processing method of a wind-driven generator hub, and the method comprises the following steps: manufacture of a mould, manufacture of a sand mould and moulding by casting, wherein in the manufacture of the sand mould, a completely opened bottom gating system is utilized; an ingate is designed to be disc-shaped; a downgate on an upper sprue is a quantitative ladle stopper sprue gate; the ratio of the components is F(straight):F(transverse):F(internal)=1:(1.5-2):(25-28); a rectangular vent hole is arranged at the highest point at the top face of a casting; the total section area of the rectangular vent hole is greater than that of the ingate; a casting head is arranged on the top face of the casting; the height of the single casting head is greater than 400 mm; no chills are discharged during the manufacture procedure; in the moulding by casting, the casting speed of melted iron entering into a casting cavity is controlled within 0.5-1.0 m / s; the casting time is controlled within 150-210 seconds; and the casting temperature is between 1300 and 1310 DEG C. The chill-free processing method of the wind-driven generator hub disclosed by the invention has the advantages that the method adapts to the large scale production of low-temperature ductile iron castings for large wind-driven generator with quite high requirements, the process is simple, and the production cost is low.

Owner:宁波日星铸业有限公司

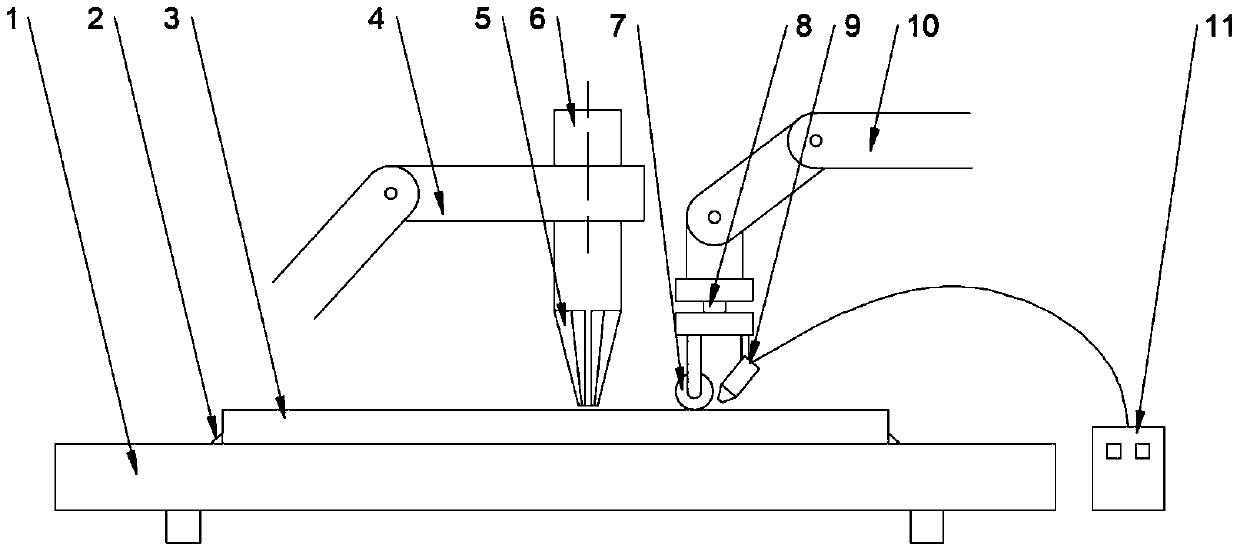

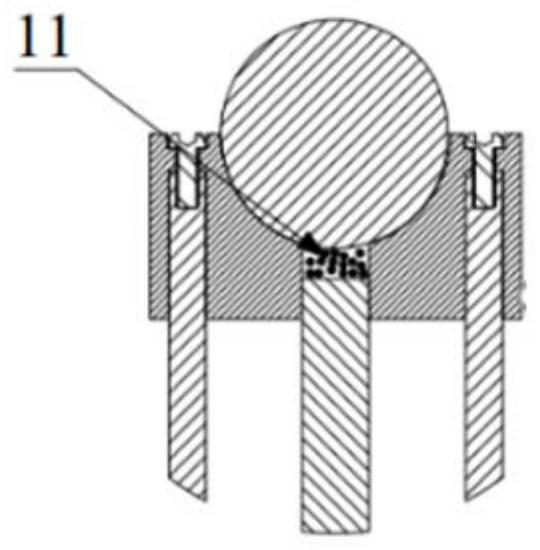

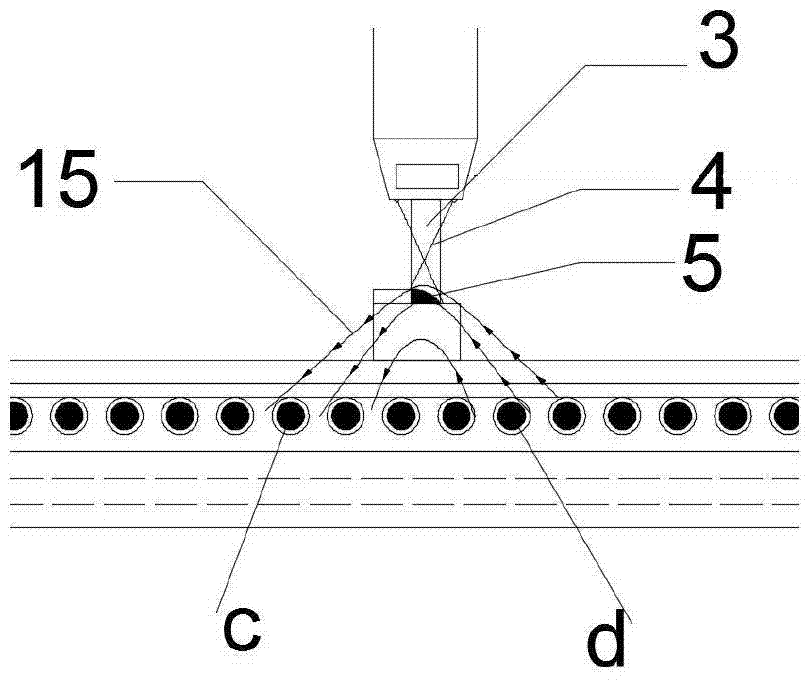

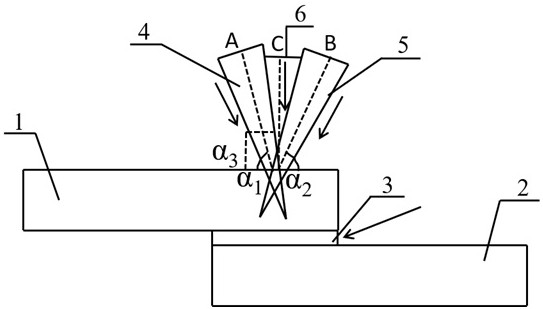

Micro rolling and ultrasonic-assisted laser cladding device

PendingCN110643996AEliminate residual tensile stressReduce residual tensile stressMetallic material coating processesLaser scanningEngineering

The invention relates to a micro rolling and ultrasonic-assisted laser cladding device, in particular to strengthening to the surface of a cladding layer. The device comprises a workbench, a fixed check block, a workpiece, a first mechanical arm, a synchronous powder feeder, a laser device, a micro roller, a rotating device, an amplitude-change pole, a second mechanical arm and an ultrasonic generator. During laser cladding, the micro rolling technology and the ultrasonic technology are used for assistance, and adverse effects left during pure laser scanning can be eliminated to the largest degree by means of the combination. By means of micro rolling, dendritic crystalline lenses generated during cooling of the cladding layer are ground through the micro roller, the crystal structure is refined, and air pores are effectively suppressed. By means of the ultrasonic technology, residual tension generated during temperature decrease of the cladding layer is eliminated, and cracks are effectively reduced. The micro rolling technology and the ultrasonic technology are applied to the laser cladding layer, and compactness, isotropy and other properties of the cladding layer are further improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

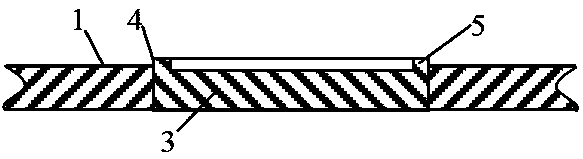

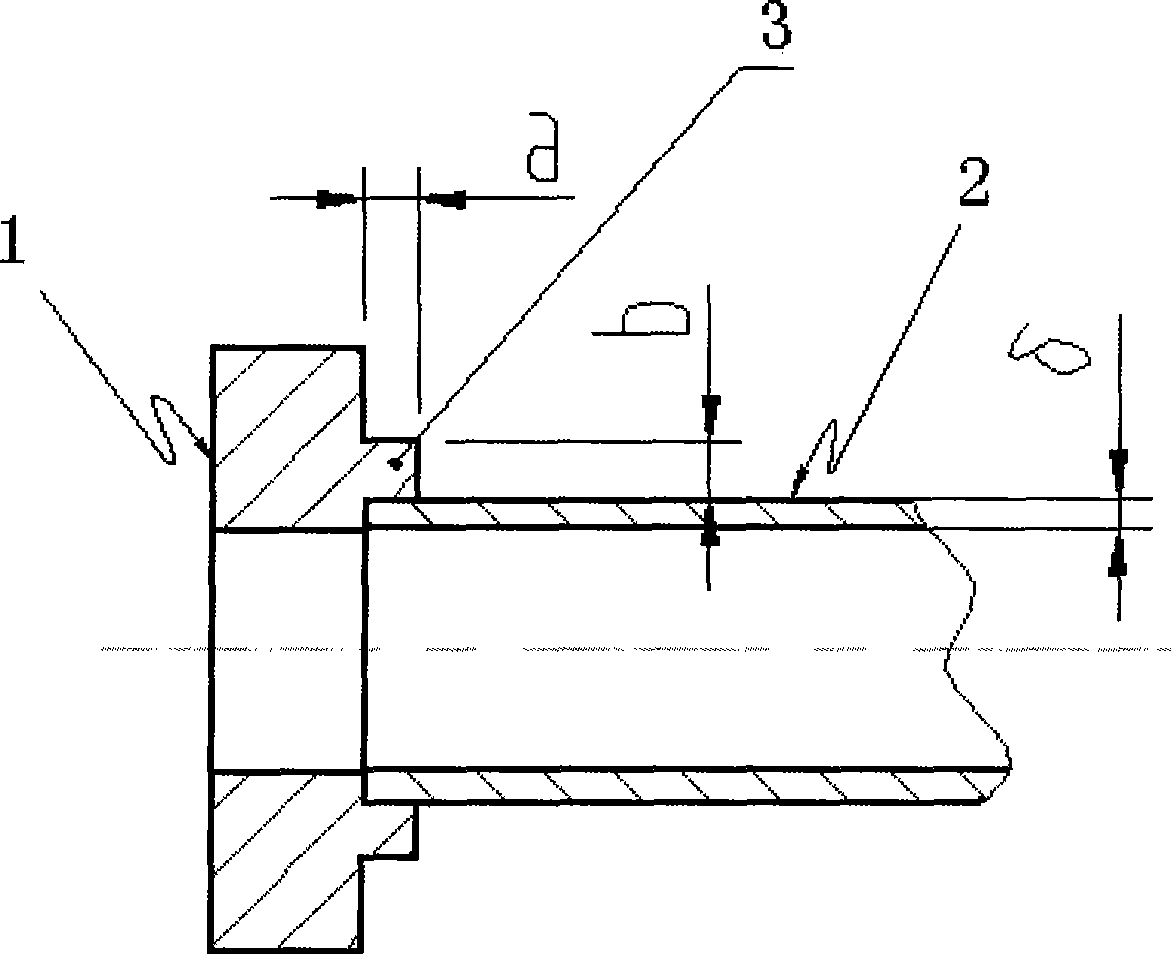

Self-melting and welding method for hydraulic oil tube

InactiveCN101367152AImprove pass rateLow skill level requiredWelding/cutting auxillary devicesElectrode supporting devicesWorking environmentFusion welding

The invention discloses a self-fusion welding method for a hydraulic oil pipe, which comprises the following steps: 1) a pipe joint of the hydraulic oil pipe is matched with a steel pipe, and 2) welding equipment is adopted to weld the pipe joint of the hydraulic oil pipe and the steel pipe into a whole. The pipe joint of the hydraulic oil pipe consists of a pipe joint body and a self-fusion lug boss axially extending at one end of the pipe joint body; and a circular welding seam can be formed at the joint of the pipe joint and the steel pipe after the welding fusion of the self-fusion lug boss is solidified. With the mode adopted, the self-fusion welding method for the hydraulic oil pipe greatly reduces defects such as air holes during the welding, improves the qualification rate of welding products, reduces the technical class requirement on operating personnel, can guarantee the stability and consistency of the welding quality to middle and small thin-wall hydraulic oil pipes, increases work efficiency, and improves the work environment of welding fields.

Owner:WUHU SHUANGYI HYDRAULIC COMPONENT

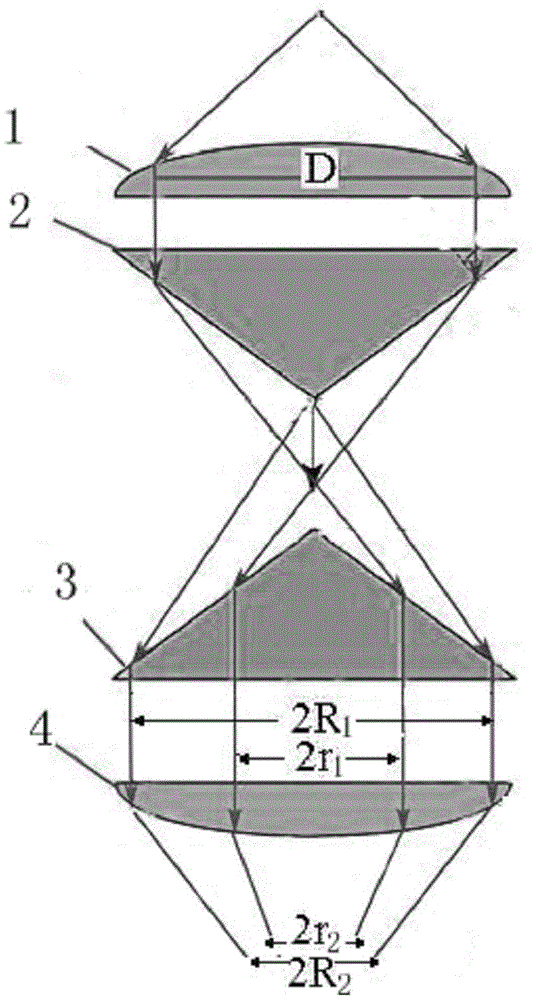

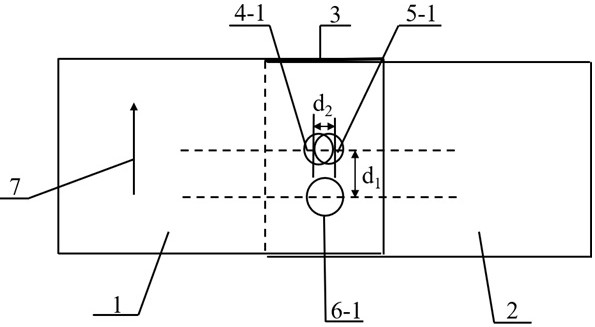

Annular laser welding head and annular laser welding method

InactiveCN105689890AAdapt to welding requirementsReduces susceptibility to ablationLaser beam welding apparatusMetallic materialsCircular cone

The invention relates to an annular laser welding head. The annular laser welding head is characterized in that the welding head is sequentially provided with a collimating mirror, a first circular cone lens, a second circular cone lens and a focusing lens from top to bottom; and the first circular cone lens and the second circular cone lens are placed in a manner that vertex angles are opposite, and the degrees of the vertex angles are equal. When the annular laser welding head conducts welding, laser beam energy density Gaussian distribution can be effectively avoided, the defect that high polymer materials and metal materials are prone to occurring defects such as ablation and air holes in centers of welding lines can be reduced, and the welding quality of the high polymer materials is improved.

Owner:SHENYANG POLYTECHNIC UNIV

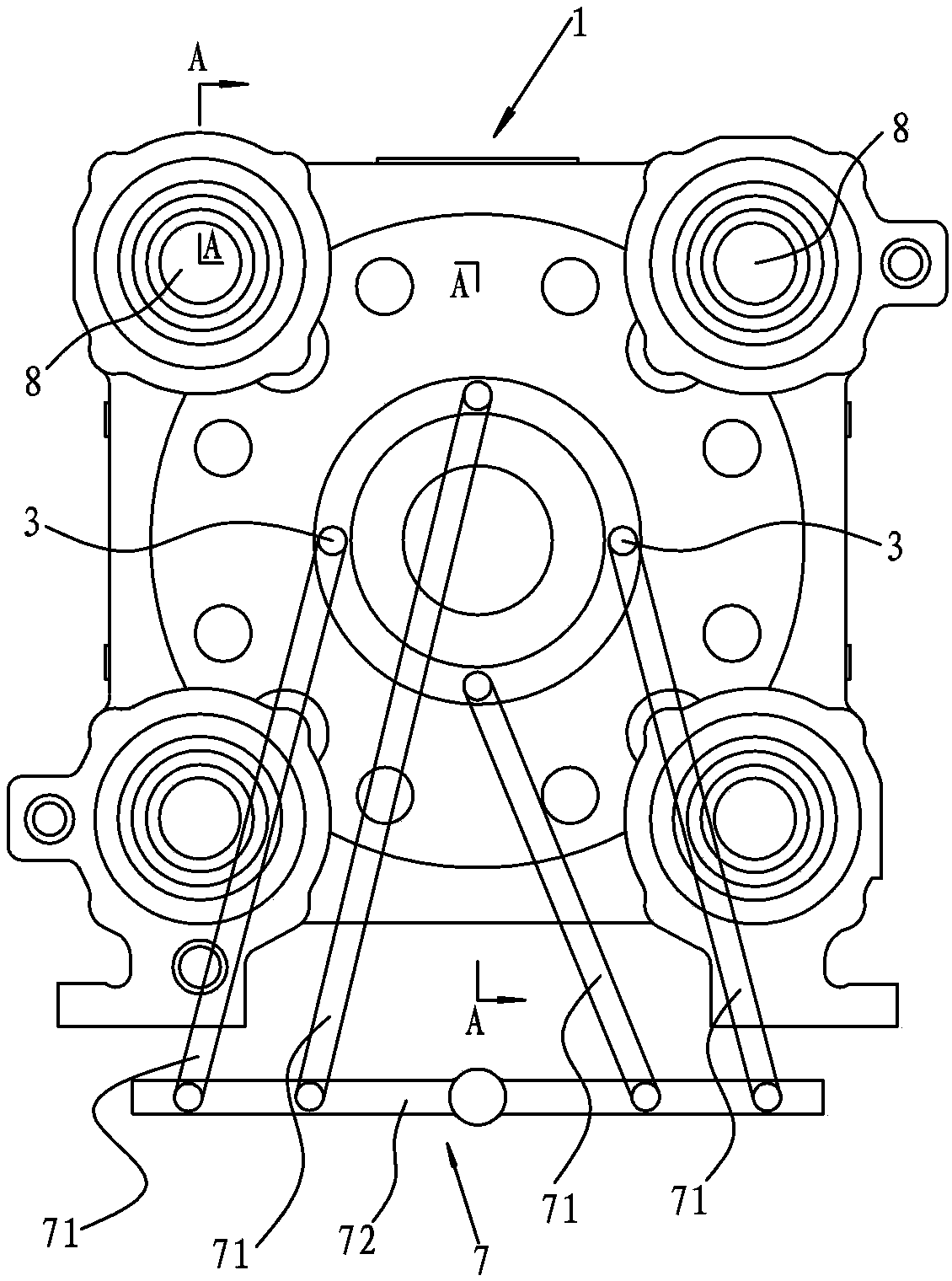

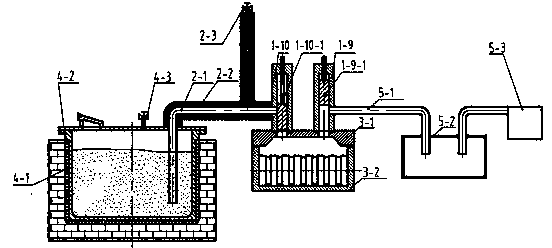

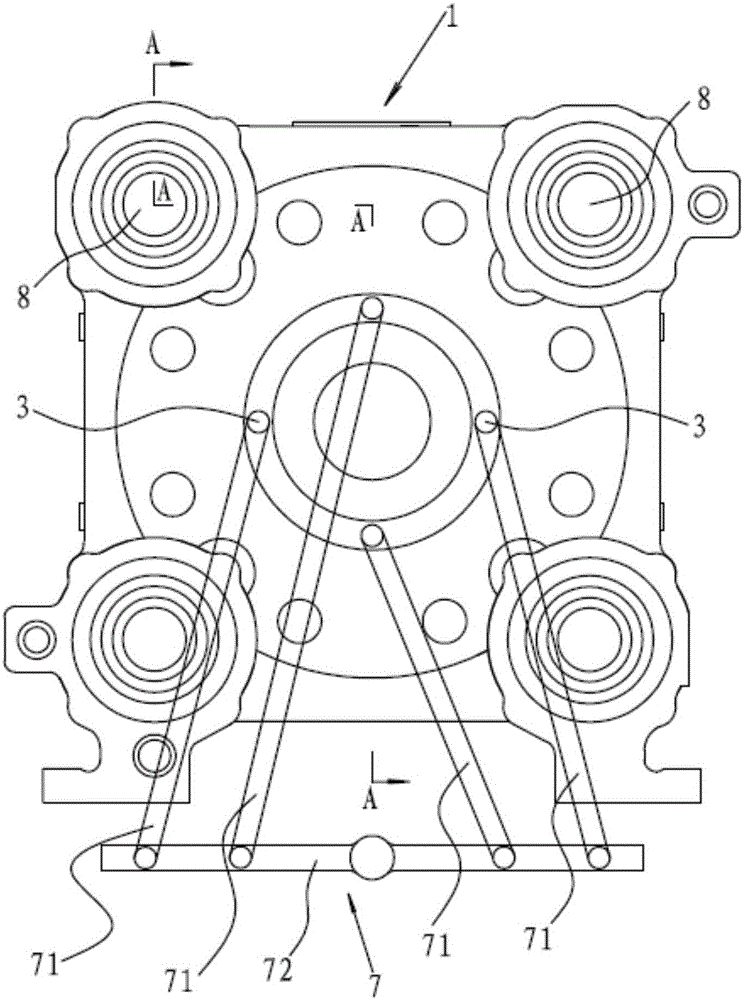

Hydraulic oil inner circulation type fixed mold plate casting technology of injection molding machine

ActiveCN104338898AEasy dischargeQuality improvementFoundry mouldsFoundry coresTissue densityInjection molding machine

The invention discloses a hydraulic oil inner circulation type fixed mold plate casting technology of an injection molding machine. The technology comprises the following steps that a mold of a fixed mold plate is manufactured, upper, middle and lower three-part molding is adopted and comprises an upper box, a middle box and a lower box, and a mold joint of the upper box and the middle box serves as a mold mounting face of the fixed mold plate; b, a steel pipe is buried in the middle box, and the steel pipe corresponds to a hydraulic oil path in the fixed mold plate; c, sprue positions are arranged on the lower box in the step b, sprues are formed in the bottom face of the fixed mold plate, exhaust dead heads and an exhaust path are formed, the exhaust dead heads are formed in the upper box, and the exhaust path is communicated with the upper box and the middle box; d, casting forming is carried out, the upper box in the step c is arranged upwards and the lower box in the step c is arranged downwards to be casted, and the casting temperature ranges from 1320 DEG C to 1350 DEG C. The hydraulic oil inner circulation type fixed mold plate casting technology of the injection molding machine has the advantages of being good in material uniformity, high in tissue density, good in surface quality and high in casting yield.

Owner:GUANGDONG BLOOMACHINE

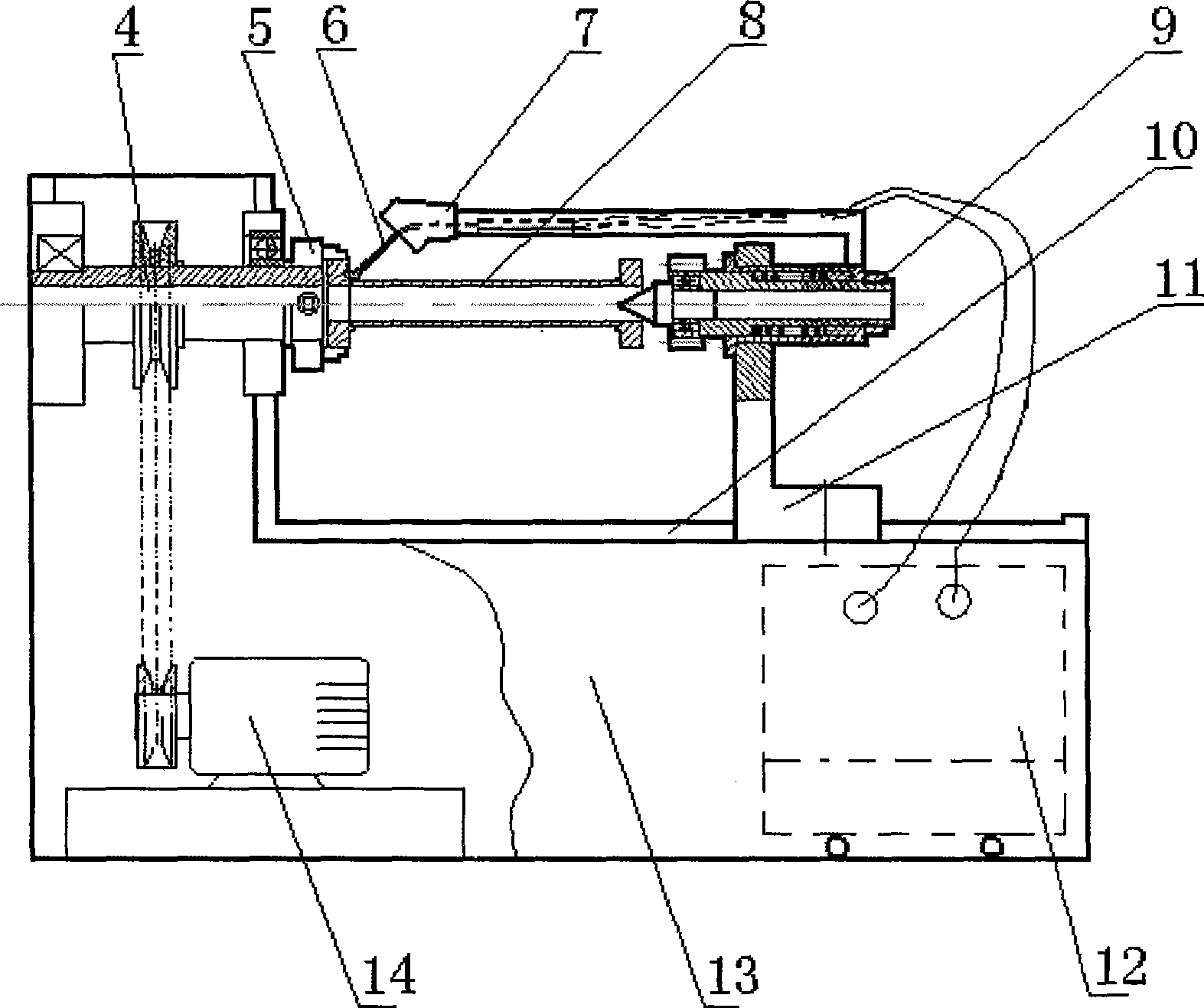

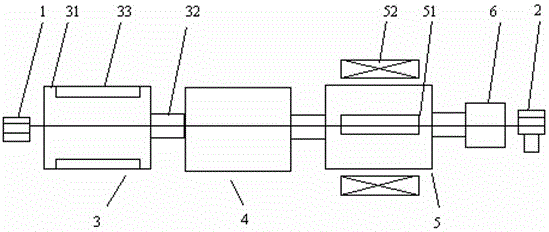

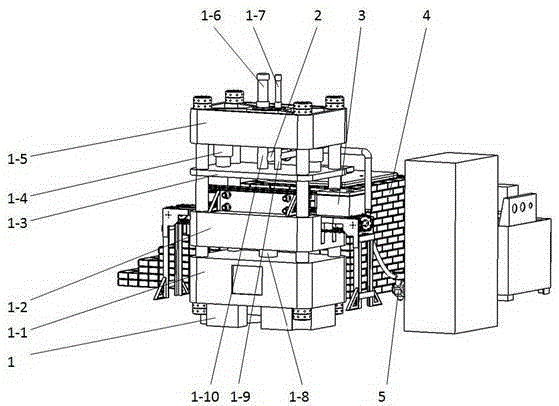

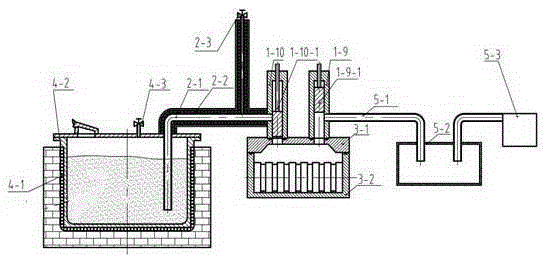

Metal and alloy vacuum die casting forming device and method

Disclosed is a metal and alloy vacuum die casting forming device and method. The metal and alloy vacuum die casting forming device comprises an extrusion casting system, a conveying system, a die and a melting furnace; the melting furnace is connected with the conveying system; the conveying system is connected with the extrusion casting system; the extrusion casting system is connected with the die; the metal and alloy vacuum die casting forming device is provided with a vacuum pumping system which is connected with the extrusion casting system; the extrusion casting system comprises a lower beam, a die supporting beam, a die clamping beam and an upper beam which are arranged from bottom to top in turn; a lower cylinder is arranged between the lower beam and the die supporting beam; the lower cylinder is located in the center of the lower beam; the front end of a piston of the lower cylinder is connected with the die supporting beam. According to the metal and alloy vacuum die casting forming device and method, the composite effect is good and an air hole, shrinkage porosity and shrinkage cavity can be avoided.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

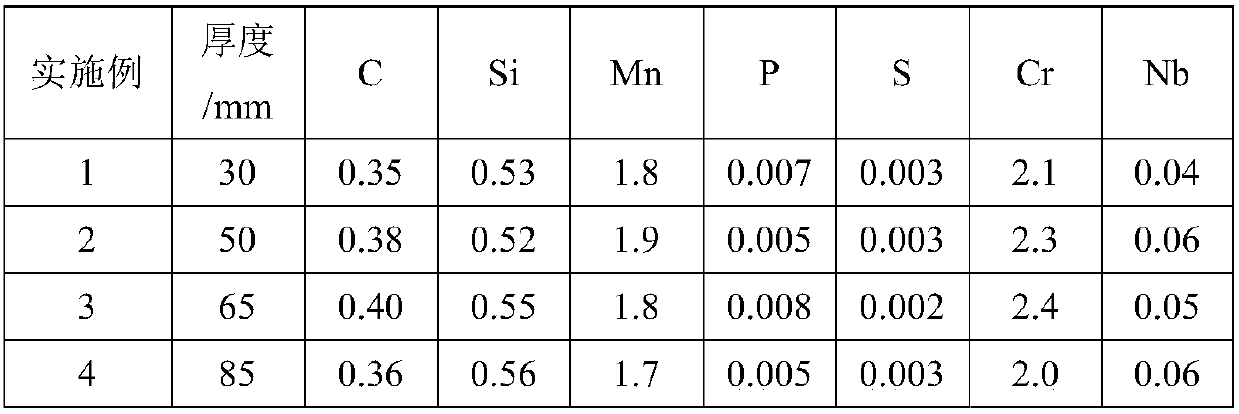

Novel non-quenched-and-tempered plastic die steel plate and preparation method thereof

The invention provides novel non-quenched-and-tempered plastic die steel plate and a preparation method thereof. The steel plate is prepared from the following components in percentage by weight: 0.35to 0.40 percent of C, 0.52 to 0.56 percent of Si, 1.7 to 1.9 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 2.0 to 2.3 percent of Cr, 0.04 to 0.06percent of Nb and the balance of Fe and unavoidable impurities. The preparation method comprises the following steps: heating a plate blank at temperature of 1,200 to 1,220 DEG C; carrying out open rolling at open rolling temperature of 1,100 DEG C, and carrying out final rolling at final rolling temperature of 890 to 930 DEG C; after rolling, carrying out air cooling to 200 to 300 DEG C, and carrying out tempering at 550 to 580 DEG C; and carrying out net heat preservation for 1.5 to 2.0 min / mm. By optimal component design and cooperation with hot rolling and tempering processes, the shortcoming of high quenching crack sensitivity of plastic die steel is overcome; and meanwhile, a prehardening effect is achieved, and the energy consumption is reduced.

Owner:ANGANG STEEL CO LTD

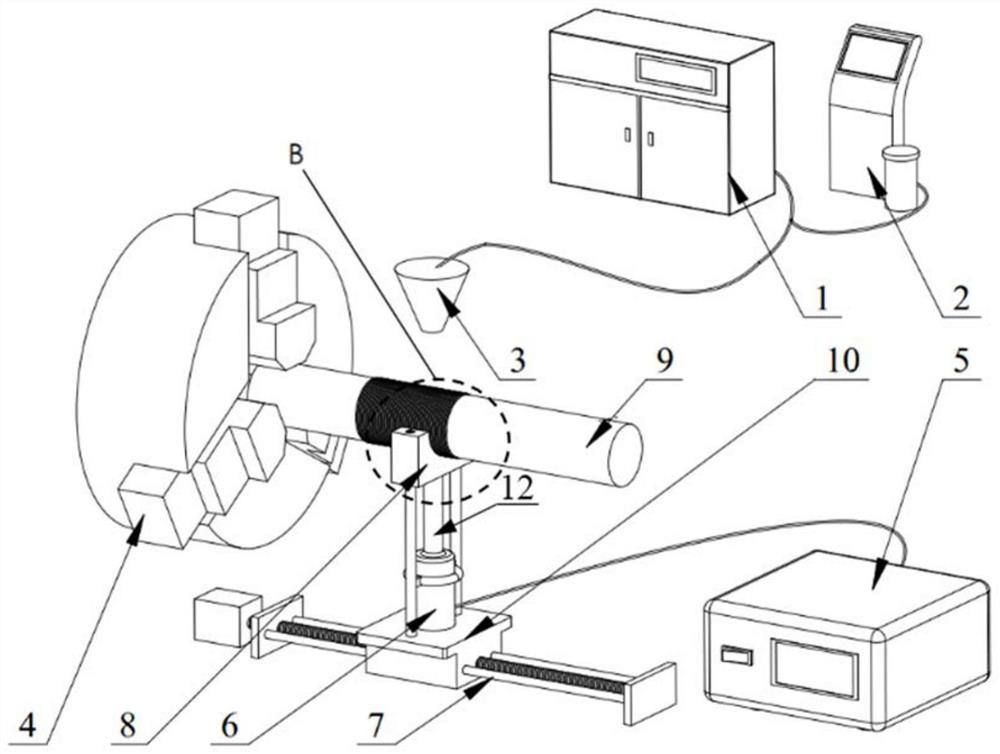

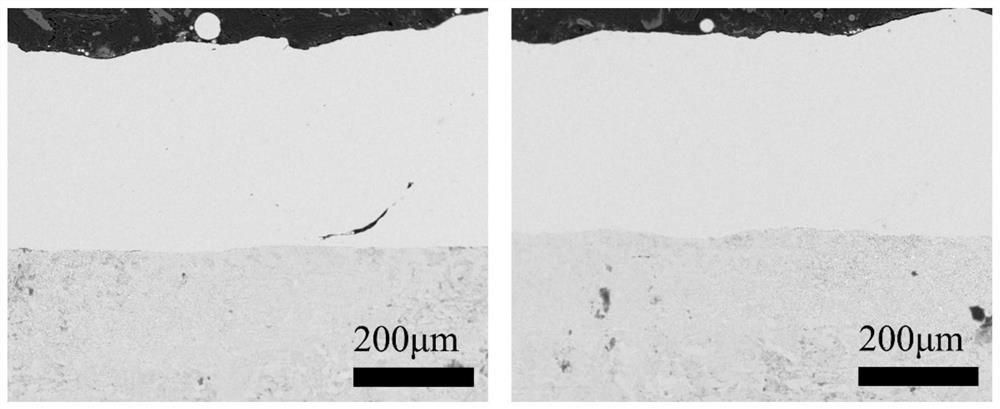

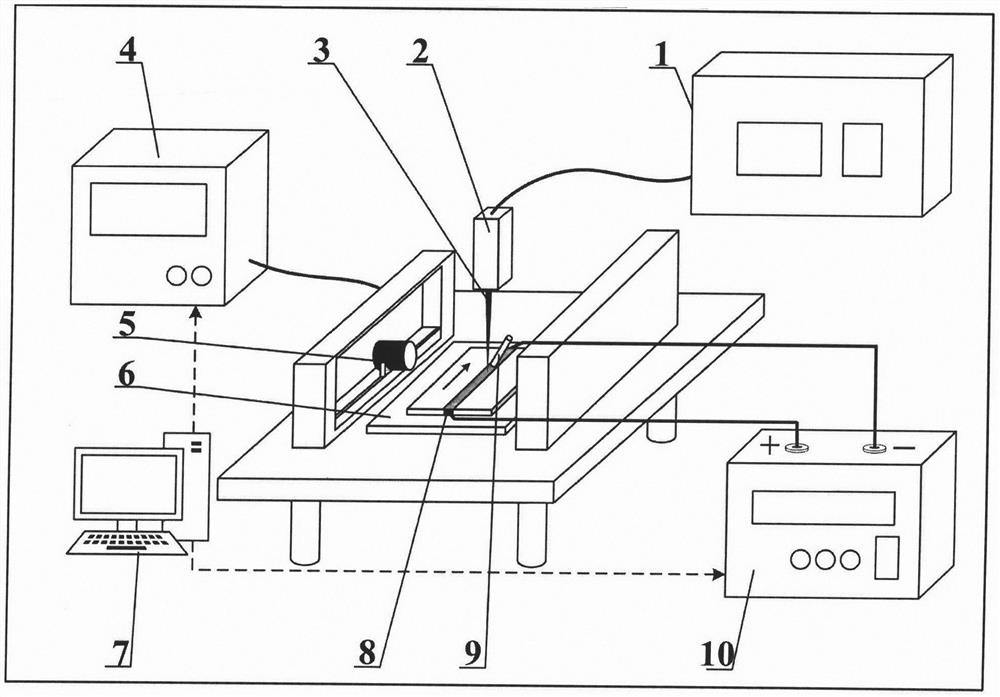

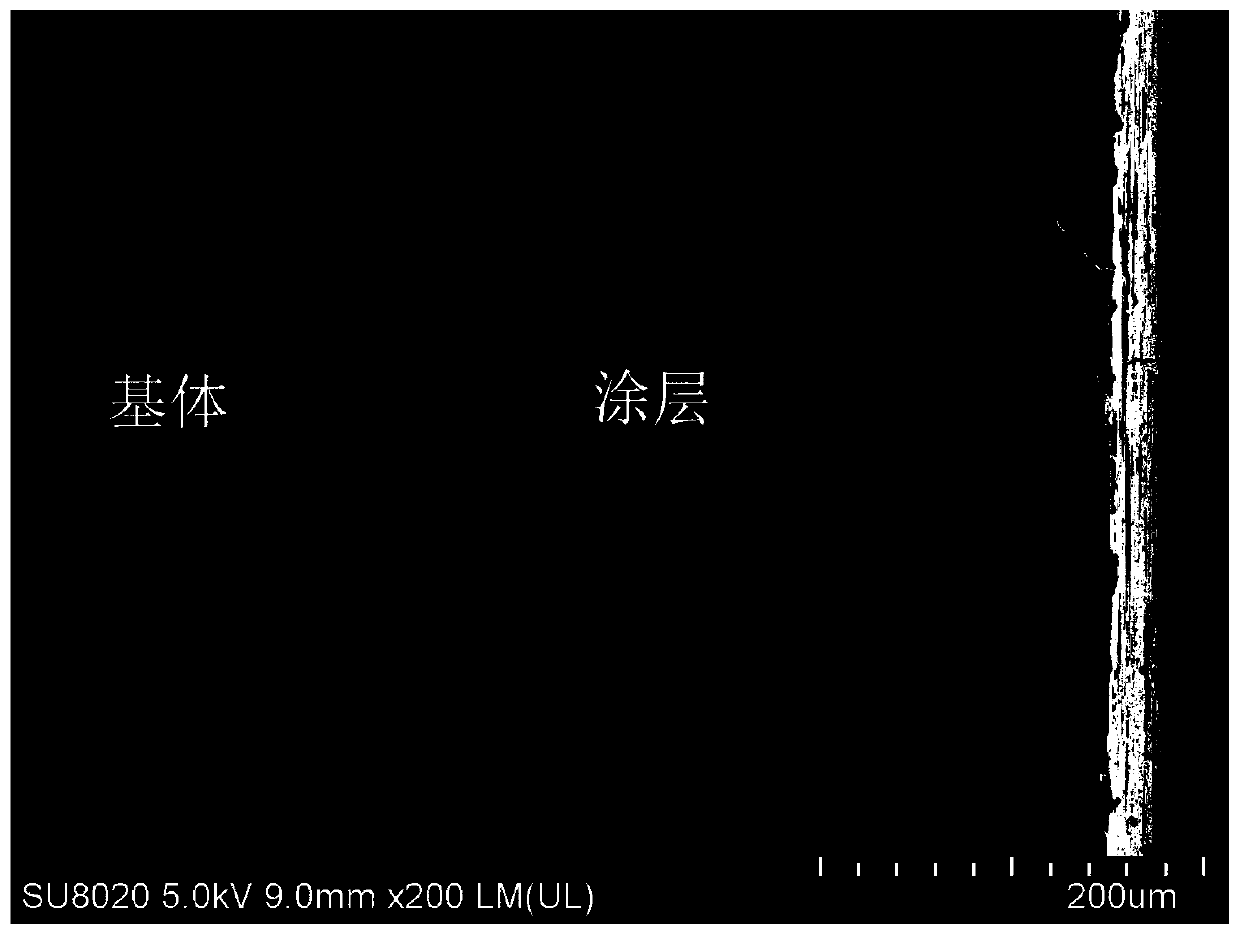

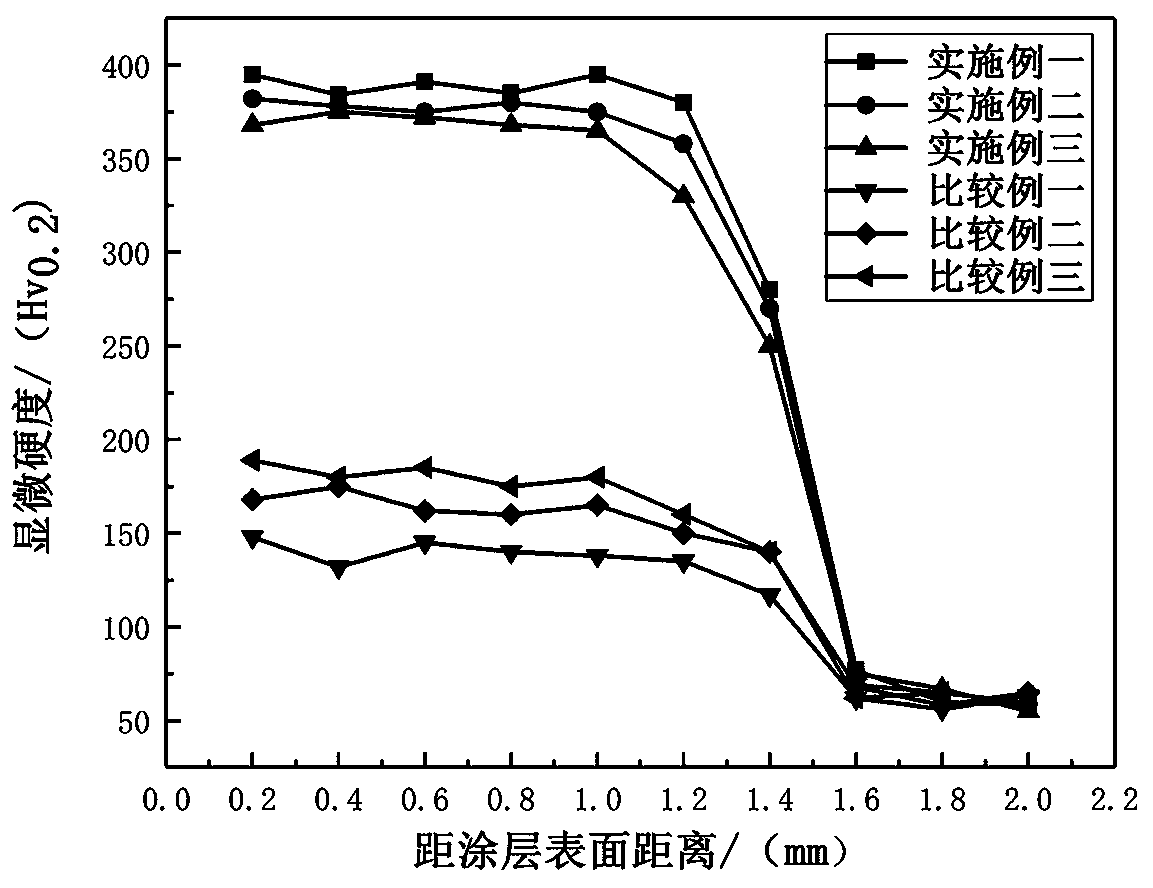

Method for preparing defect-free abrasion-resistant coating with assistance of synchronous ultrasonic shot blasting

PendingCN113774373AReduce crackingReduce defects such as poresMetallic material coating processesSurface cleaningPeening

The invention discloses a method for preparing a defect-free abrasion-resistant coating with the assistance of synchronous ultrasonic shot blasting. The method specifically comprises the following steps that a to-be-machined shaft sample is fixed to an integrated machining platform, and surface cleaning and rust removal treatment are conducted; powder to be used for cladding is baked and dehumidified and is loaded into a synchronous powder feeder; high-speed laser cladding parameters and the translation rate of a cladding head are set; a moving controller in the synchronous ultrasonic shot blasting system is adjusted and moved, so that a shot blasting cavity is just located under the cladding head and located on the same horizontal plane with the cladding head, and the synchronous ultrasonic shot blasting system and the cladding head are identical in translation rate and move in the same direction; and the high-speed laser cladding system and the ultrasonic shot blasting auxiliary system are started at the same time until the cladding process is finished, and the defect-free abrasion-resistant coating is obtained. The method for preparing the defect-free abrasion-resistant coating with the assistance of synchronous ultrasonic shot blasting has the beneficial effects that the interior and the interface of the prepared high-speed laser cladding abrasion-resistant coating have no obvious macro-micro defects, crystal grains of the coating are obviously refined, the hardness of the coating is improved, the abrasion resistance of the coating is obviously improved, and the service life of the coating is obviously prolonged.

Owner:华能汕头海门发电有限责任公司

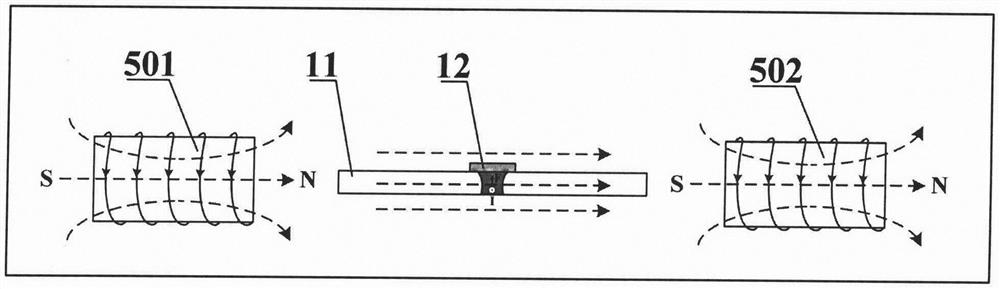

Electromagnetic auxiliary laser welding method for pre-arranged powder on surface of aluminum alloy

PendingCN112719594AIncrease profitReduce lossesIncreasing energy efficiencyWelding/soldering/cutting articlesMagnetohydrodynamicsTransverse magnetic field

The invention relates to the technical field of aluminum alloy laser welding, and discloses an electromagnetic auxiliary laser welding method for pre-arranged powder on the surface of an aluminum alloy. According to the method, alloy powder is pre-arranged at the butt joint of an aluminum alloy flat plate, meanwhile, an electromagnetic field is additionally arranged to assist laser welding, and the method aims to improve the laser welding quality of the aluminum alloy. Compared with the prior art, the method has the advantages that the problem that the pore defect is prone to being generated due to the fact that powder is pre-arranged through a chemical bonding method is solved; meanwhile, based on the magnetohydrodynamic principle, the electromagnetic field is additionally arranged to change the flow of a molten pool, the magnetic stirring effect is generated on liquid metal, crystal grains are refined, and the weld joint structure is improved; and in the laser welding process, a transverse magnetic field generation device can generate a steady-state magnetic field at the molten pool, the steady-state magnetic field is coupled with an electric field generated by a direct-current power supply, the molten pool is subjected to stable electromagnetic force, so that the weld joint is effectively prevented from collapsing, the mechanical property of a joint is improved, and therefore the reliability of an aluminum alloy welding structural part for aviation is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

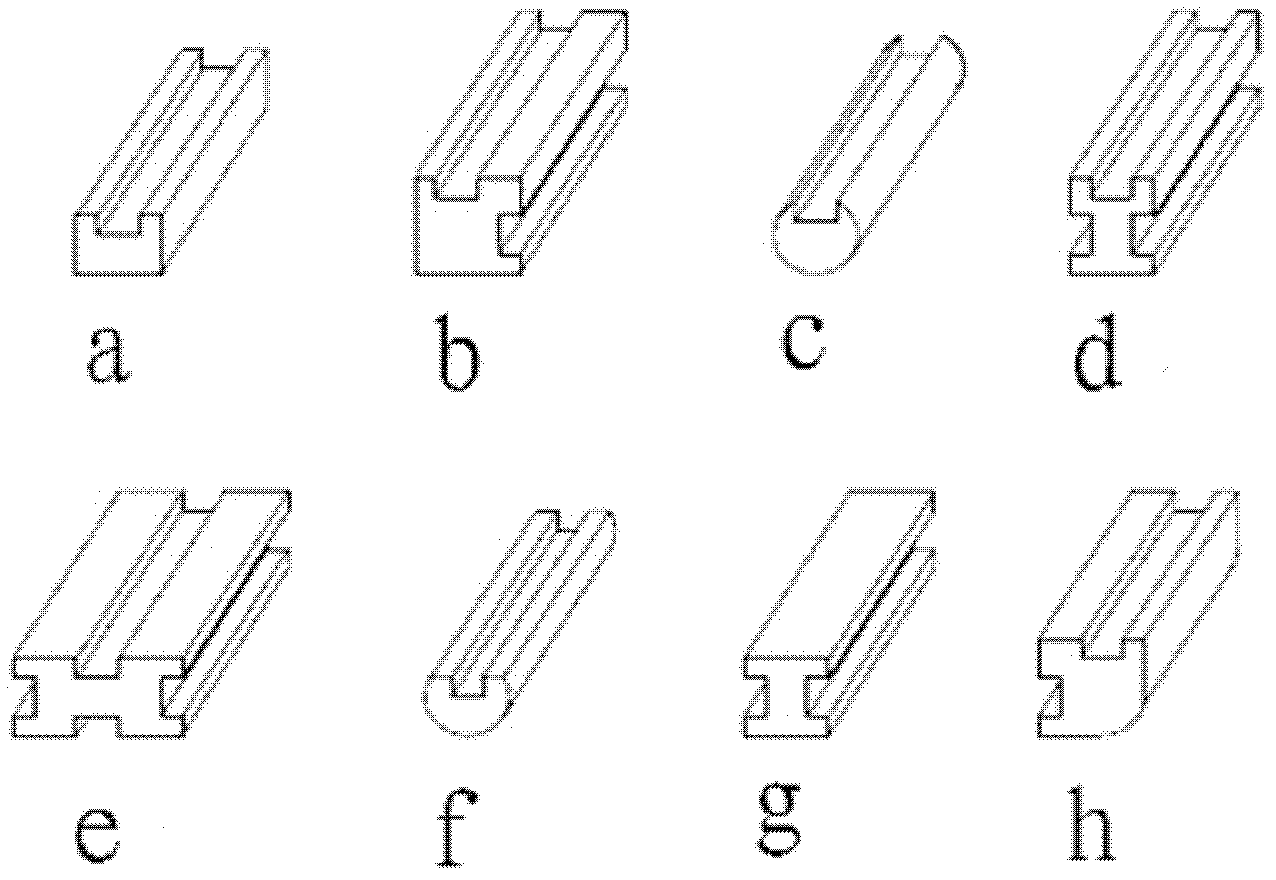

Partition plate connection member and preparation method

InactiveCN103319136AHigh strengthReduce moisture contentCeramic shaping apparatusBattenHigh pressure

The invention discloses a high-performance concrete extrusion partition plate connection member and a preparation method, comprising the following raw materials: cement, gesso, fly ash, quartz sand, mekralon, water reducer, water-retaining agent and water. The raw materials of the connection member, after mixing and stirring, are orderly extruded by a high pressure and vacuum extruder. The partition plate connection member prepared through forming treatment and twice maintenance treatment has high intensity, and an ultimate flexural capacity and compressive strength exceeds a government standard. The connection member has advantages of small drying shrinkage, low expansion and contraction ratio, high distortion-resistant performance, aging resistance, water proof, fire proof and sound insulation. After the connection member is connected with the partition plate, no crack and no shedding are generated between the connection member and the partition plate, and the connection member accords with installation requirement, and reaches requirement of a government standard of lightweight batten for construction (GB / T 23451-2009).

Owner:福建朗创建科新材料有限公司

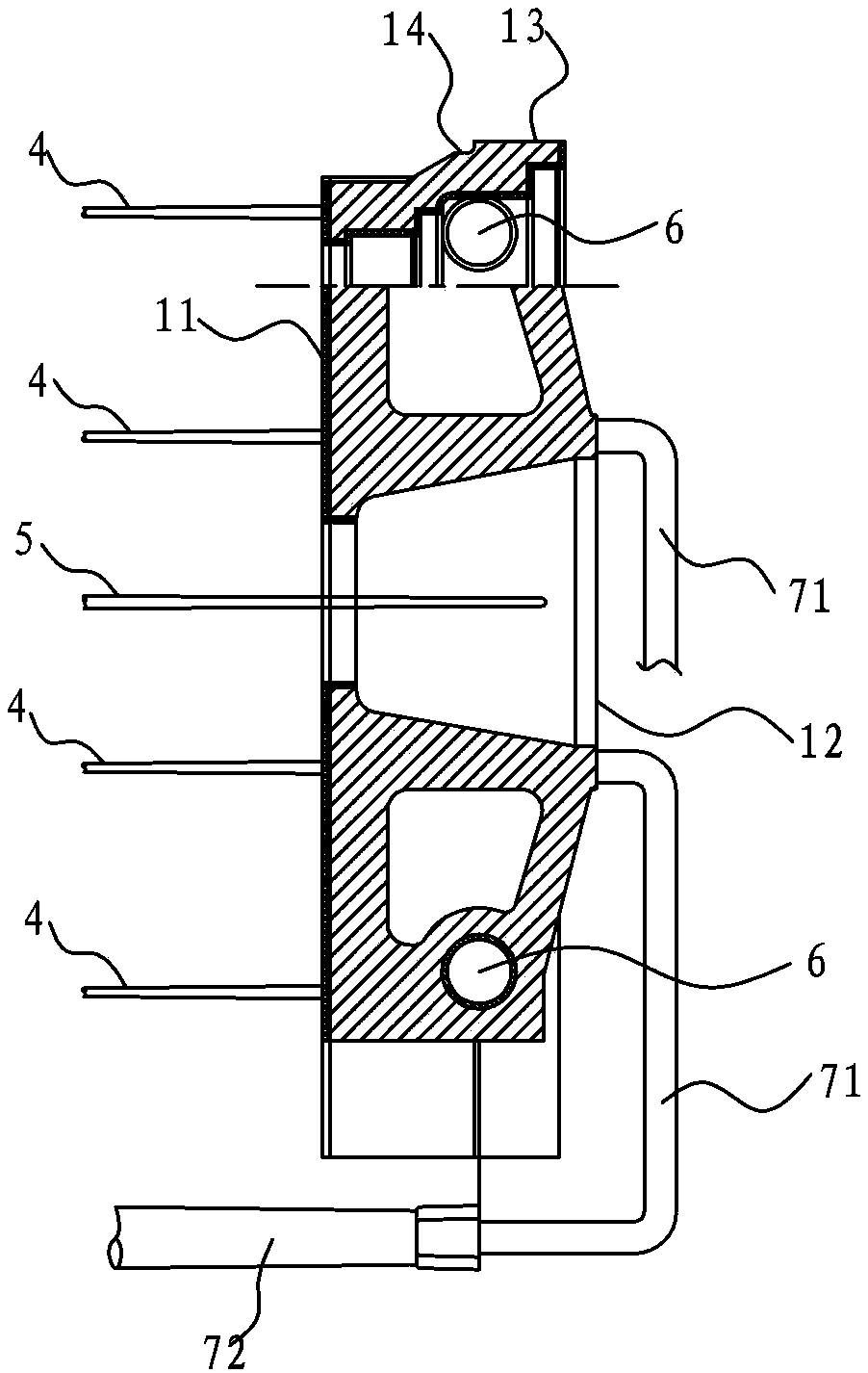

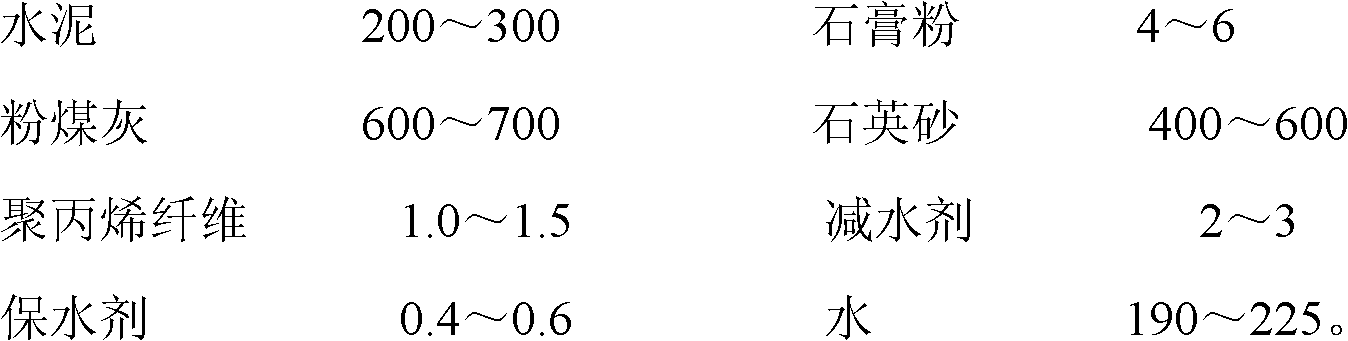

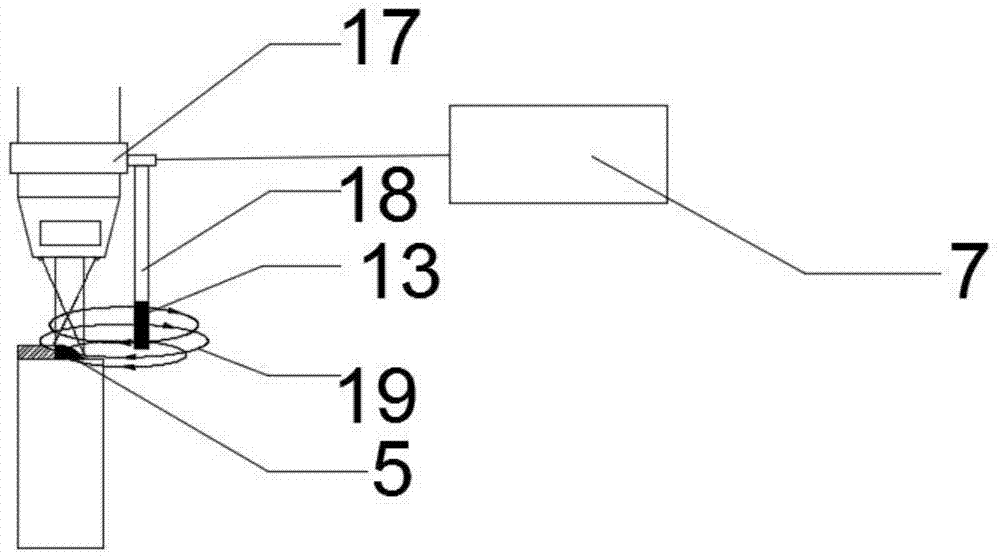

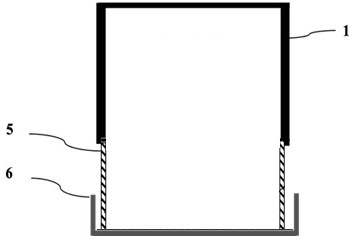

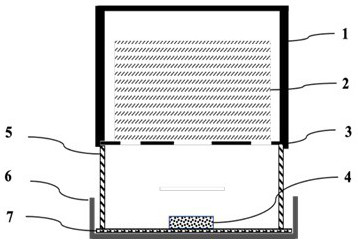

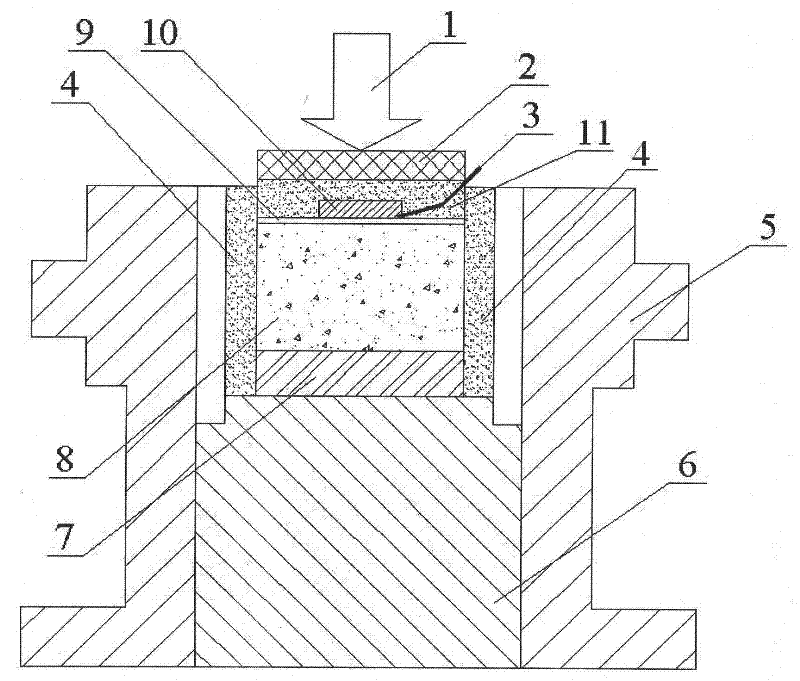

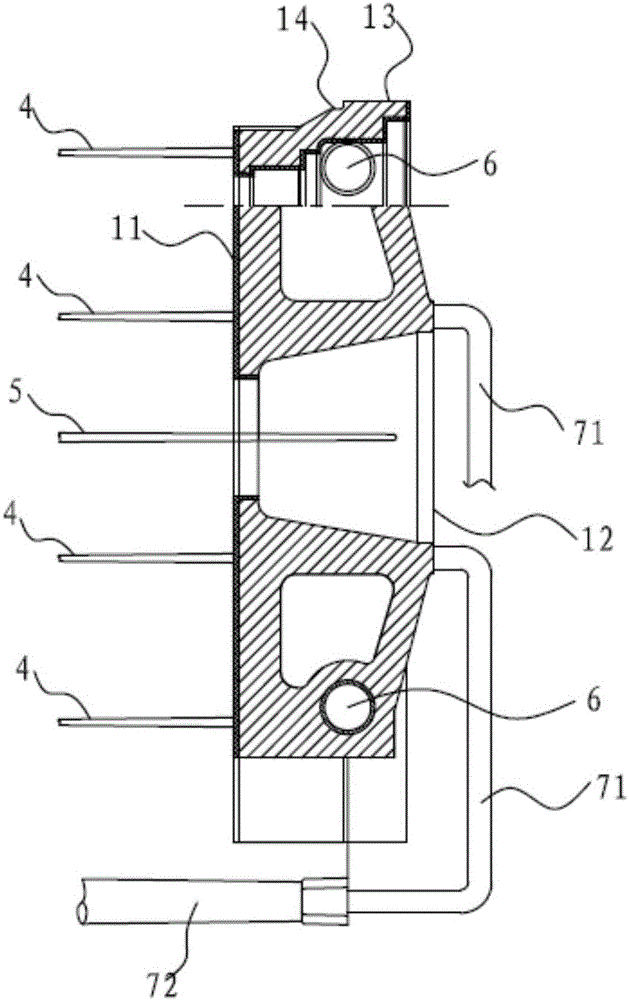

A device for electromagnetic field-assisted laser additive manufacturing

ActiveCN105522153BGuaranteed uniformityFine grainAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLaser additive manufacturing

The invention is a device for electromagnetic field-assisted laser additive manufacturing, which includes a laser head (1), which is composed of a base (10), an insulating heat dissipation layer (9), a magnetic field generating device (11), and a water cooling device (12). Manufacturing base, AC power supply (8), longitudinal magnetic field generator, DC power supply (6), controller (7); wherein, the manufacturing base is divided into 4 layers from top to bottom, the uppermost layer is the base, and the bottom of the base is The insulating heat dissipation layer is used to control the temperature of the substrate and prevent the substrate from communicating with the magnetic field generating device. The magnetic field generating device is located below the insulating heat dissipation layer (9); the magnetic field generating device is connected with the controller and is controlled by the controller, and the controller communicates with the AC The power supply is connected, and the AC power supply supplies power to the controller; a plurality of raw magnetic rods (13) are arranged in the magnetic field generating device, and a water cooling device (12) is arranged below the magnetic field generating device to keep the manufacturing substrate in an appropriate temperature range.

Owner:SOUTHEAST UNIV

Welding method for gas shielded welding of aluminium-alloy vehicle body

InactiveCN103447664AHigh strengthSmall splashArc welding apparatusWelding/cutting media/materialsSurface oxidationEngineering

The invention discloses a welding method for gas shielded welding of an aluminium-alloy vehicle body. The welding method comprises the following specific steps of: in welding, spraying a layer of pasty welding agent on an assembled welding seam base material in advance, wherein the pasty welding agent is 10-15mm in width and 50-200mum in thickness; when the welding agent entering a low-temperature area at the periphery of the temperature field of the arc reaches the melting temperature (560 DEG C) along with the movement of welding arc along the direction of a welding seam, immediately melting the welding agent into a liquid film, quickly wetting the surface of the base material, removing an oxidation film on the surface of the base material, and then covering the surface of the base material and the surface of metal in a molten pool. The welding method disclosed by the invention has the advantages that the welding process can be finished only by using the heat inputted in arc welding to melt the base material with the melting point of being 570-640 DEG C and welding wires as electrodes; aluminium-alloy MIG gas shielded welding connection of the high-strength vehicle body can be realized only by inputting low heat, the process is excellent, and the performance of joints is stable and good.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

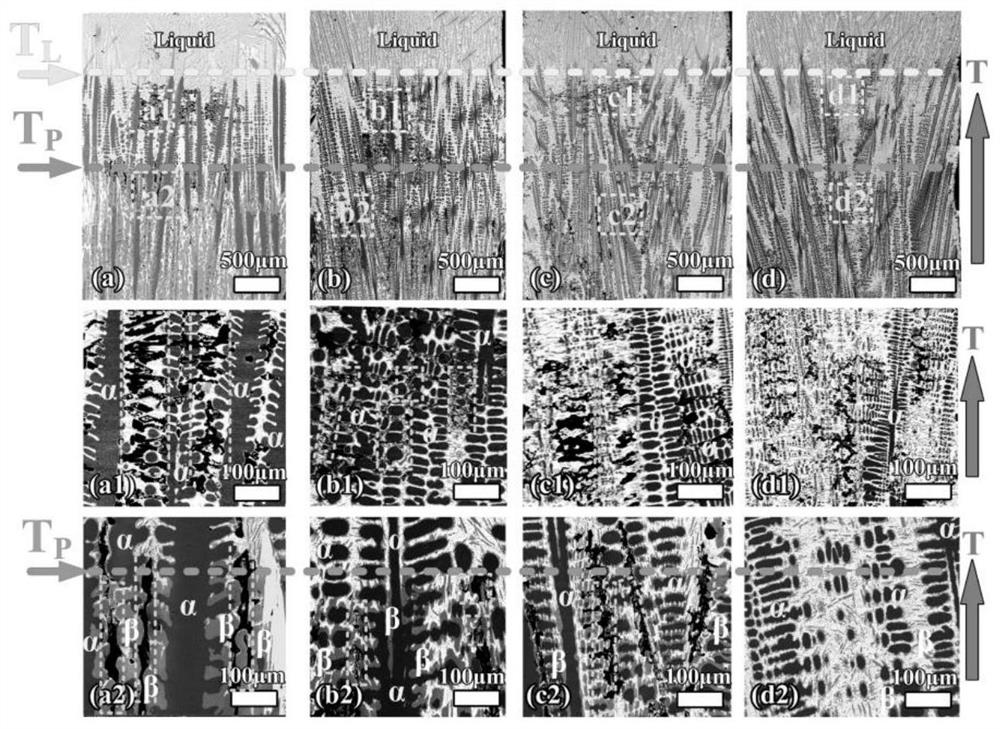

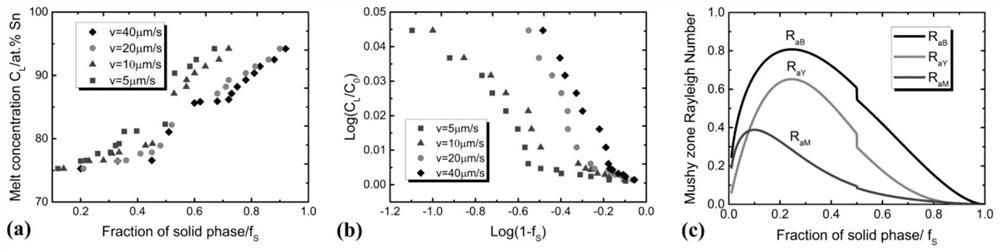

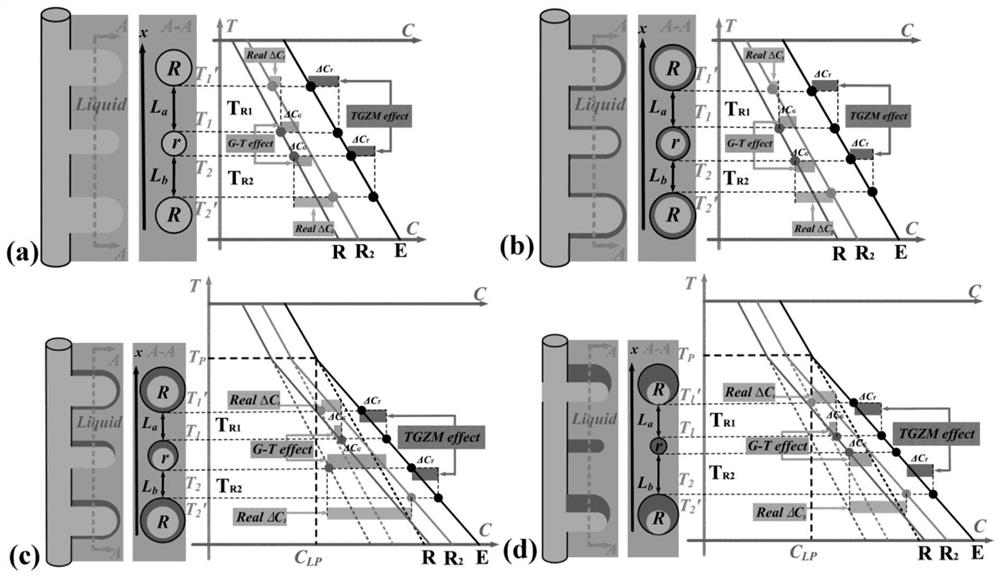

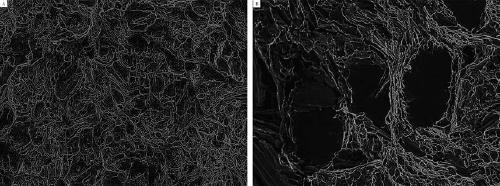

Method for predicting freckle morphology defects in directional solidification peritectic alloy paste area

ActiveCN112185472AImprove reliabilityImprove other performanceChemical property predictionComputational theoretical chemistryDirectional solidificationMaterials science

The invention provides a method for predicting freckle morphology defects in a directional solidification peritectic alloy paste area. The method comprises the steps: firstly, obtaining the relation between the Reynolds number and the permeability K; and establishing a model in which a fine secondary dendrite is located between two thick secondary dendrites, and obtaining the relationship betweenthe permeability K and the solid-phase volume fraction fS in the paste area by combining the influence of the TGZM effect and the G-T effect on the secondary dendrites. According to the relations, therelation between the Reynolds number and the solid phase volume fraction fS is obtained, and defect formation is predicted through the maximum value when the Reynolds number changes along with the solid phase volume fraction fS. In the peritectic solidification process, the formation of the freckle morphology in the dendritic paste area can be more accurately predicted.

Owner:LANZHOU UNIVERSITY

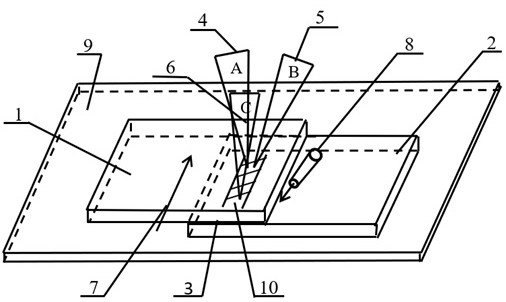

Steel-aluminum alloy laser welding method adopting nickel-based high-entropy alloy intermediate layer

PendingCN114406469AReduce thicknessReduce interdiffusionWelding/soldering/cutting articlesLaser beam welding apparatusMolten stateMetal foil

The invention relates to a steel-aluminum alloy laser welding method adopting a nickel-based high-entropy alloy intermediate layer, and belongs to the technical field of dissimilar material welding. And a nickel-based high-entropy alloy metal foil is used as a middle layer material. The high entropy effect and the high thermal resistance effect of the nickel-based high-entropy alloy metal foil control that no intermetallic compound is generated in a weld fusion area, and the intermetallic compound is only generated at the interface of the fusion area and the aluminum alloy. And by adding the nickel element and the silicon element, generation of Fe-Al intermetallic compounds at the interface is reduced, a Ni-Al-Si phase with better toughness is generated, the metallurgical reaction at the interface is improved, and then the mechanical property of the joint is improved. Laser beams A, B and C are adopted for simultaneous welding, the connecting area of the interface of the steel plate and the aluminum alloy plate is increased, and it is ensured that aluminum in the molten state fully wets and spreads the interface. The anti-shearing strength of a lap joint is improved; and meanwhile, the defects such as cracks and air holes are avoided.

Owner:JILIN UNIV

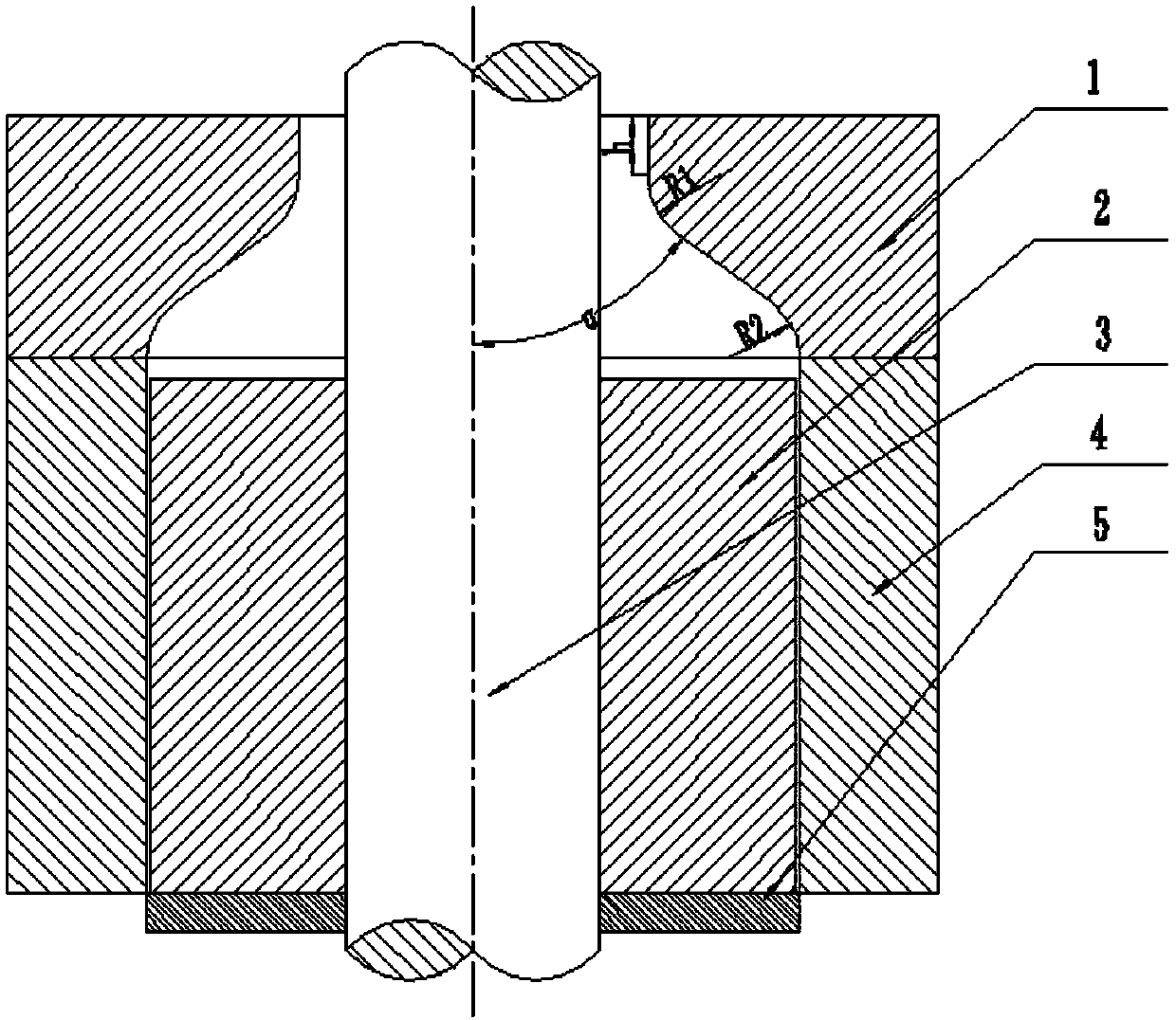

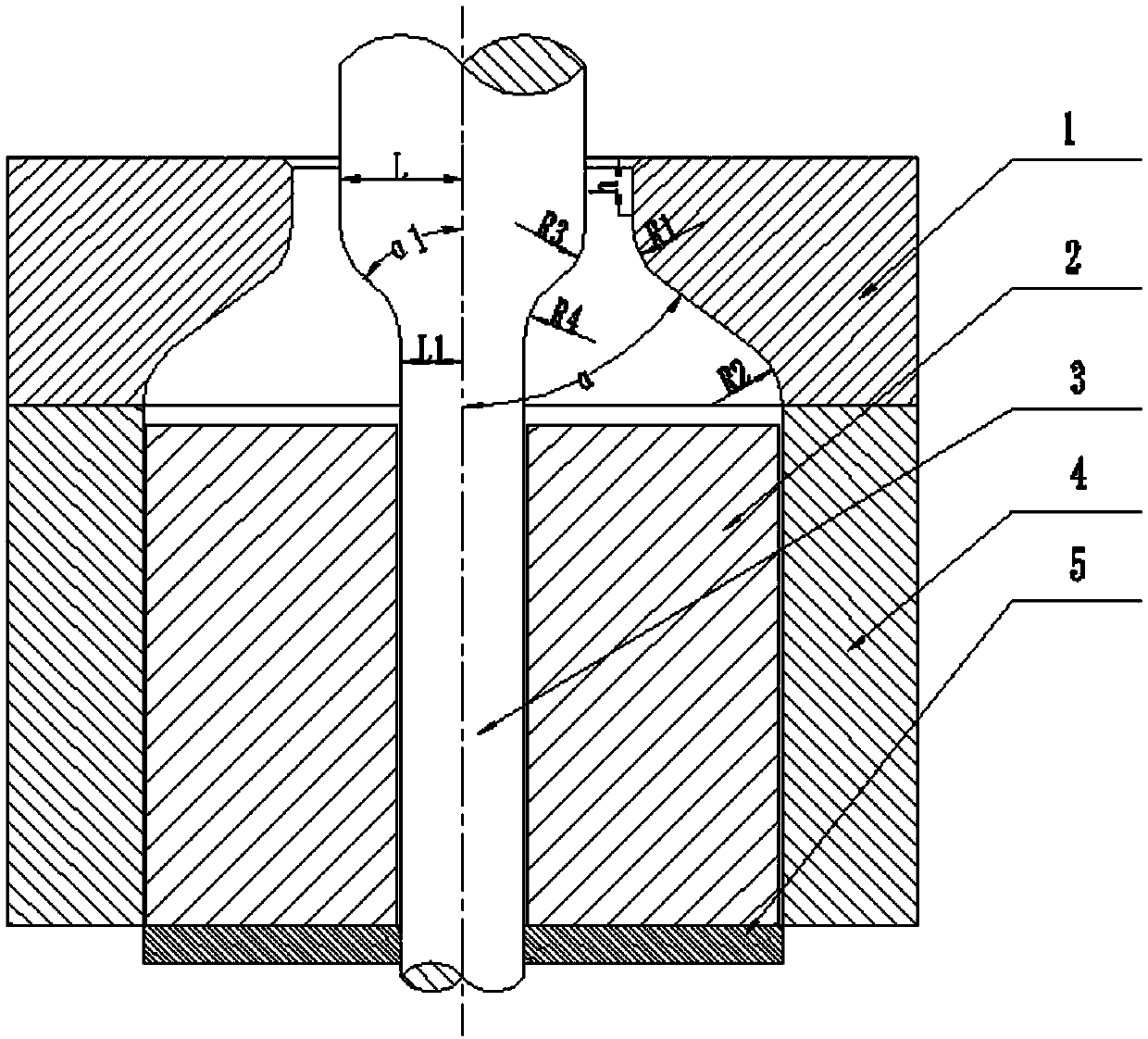

Design method of large-diameter thick-walled tube casting and extrusion compound forming mold cavity

InactiveCN109092922ALow costHigh strengthExtrusion diesExtrusion mandrelsPipe fittingUltimate tensile strength

The invention relates to a design method of a large-diameter thick-walled tube casting and extrusion compound forming mold cavity, and belongs to the technical field of large-diameter thick-walled tube casting and extrusion compound forming. The design method solves the technical problem that a microstructure of a formed part exists in the process of casting and extrusion compound forming of a large-diameter thick-walled tube is not uniform. According to the technical scheme, the design method for the large-diameter thick-walled tube casting and extrusion compound forming mold cavity comprisesthe following steps that (1) the parameters of an extrusion model cavity are determined; (2) the transition position of a core rod section is determined to ensure that the inner and outer walls of apipe fitting finish plastic deformation at the same time; and (3) the size parameter of the transition part of a core rod is determined. The design method has the advantages of low cost, high strength, good plastic toughness, high production efficiency and excellent inner wall of the pipe fitting and overall performance.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

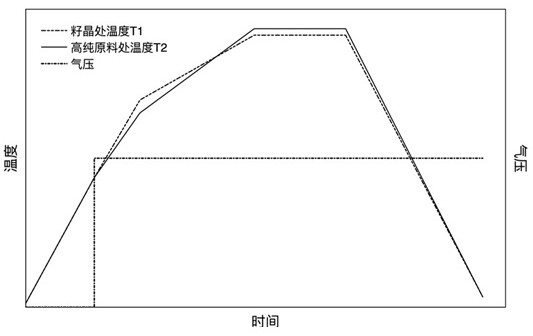

High-temperature bonding method for aluminum nitride seed crystals

ActiveCN113668065AEfficient removalQuality improvementPolycrystalline material growthAfter-treatment detailsCrystallographyCrucible

The invention discloses a high-temperature bonding method for aluminum nitride seed crystals. The aluminum nitride seed crystal, a seed crystal supporting piece and a high-purity aluminum nitride raw material are placed in a crucible of a closed structure, the seed crystal supporting piece and the seed crystal are placed at the bottom of the crucible, and the aluminum nitride raw material is fixed to the position above the seed crystal; and bonding is completed in a high-temperature furnace. The bonding method mainly comprises the following steps that (1) vacuumizing a high-temperature furnace, introducing high-purity nitrogen, and increasing the temperature to a certain temperature, wherein the seed crystal temperature in the process is higher than the raw material temperature; (2) continuously raising the temperature while the temperature raising speed of the raw material is greater than that of the seed crystal to form a gradient that the temperature of the seed crystal is less than that of the raw material, keeping the temperature after raising the temperature to a set high temperature, thermally bonding the seed crystal and the seed crystal support during the temperature keeping period, and depositing aluminum nitride on the surface of the seed crystal; and (3) finally cooling to room temperature. The high-temperature bonding method provided by the invention solves the technical problems that the seed crystal is easy to fall off, holes are formed, the seed crystal is polluted by impurities, the growth surface is damaged and the like in the chemical bonding and mechanical fixing methods of the seed crystal.

Owner:ULTRATREND TECH INC

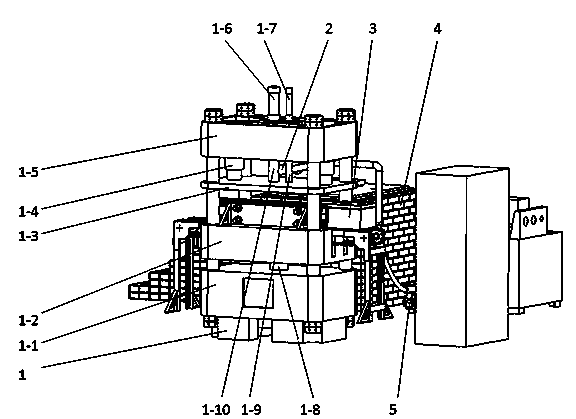

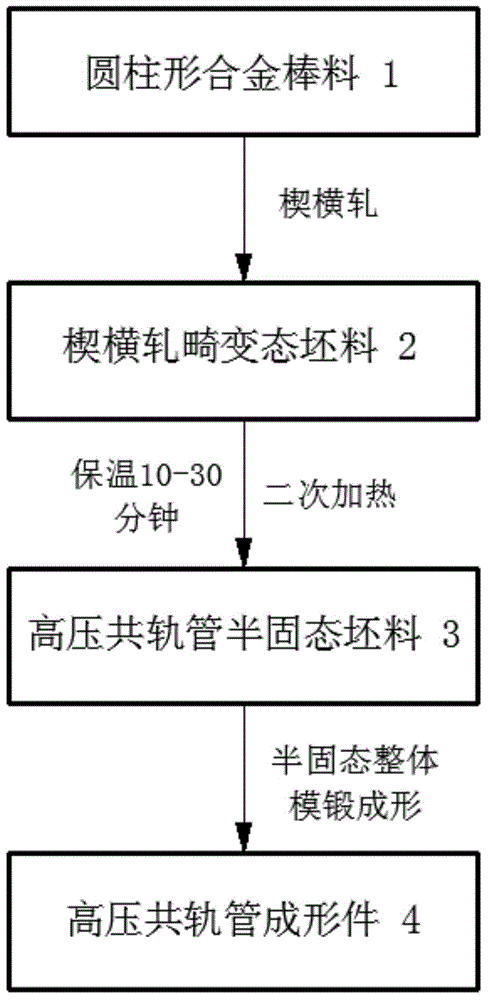

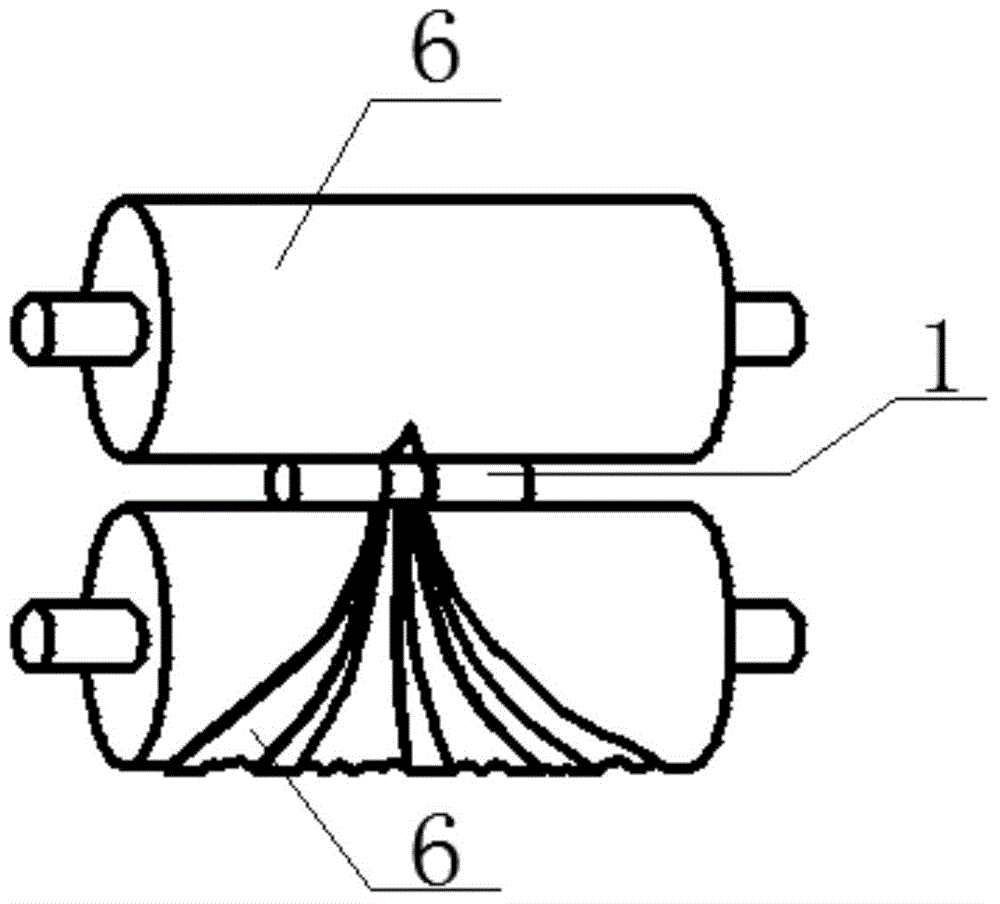

Cross wedge rolling type strain-induced semi-solid die forging process for high-pressure common rail pipe for internal combustion engine

The invention provides a cross wedge rolling type strain-induced semi-solid die forging process for a high-pressure common rail pipe for an internal combustion engine. An alloy bar made of a 0Cr18Ni9 stainless steel material and used for forming the high-pressure common rail pipe is preheated and then subjected to cross edge rolling, and a cross wedge rolling distorted state blank is obtained; then the cross wedge rolling distorted state blank is subjected to secondary heating, and then a high-pressure common rail pipe semi-solid blank with certain solid phase components is obtained; and finally the high-pressure common rail pipe semi-solid blank is subjected to semi-solid die forming, and then a high-pressure common rail pipe formed part is obtained. The low forming pressure is obtained, the product quality is good, and the material utilization rate is high.

Owner:XI AN JIAOTONG UNIV

Electromagnetism attached copper-aluminum composite wire production device

InactiveCN106637325AClean upImprove bindingSingle bars/rods/wires/strips conductorsSuperimposed coating processCopperElectromagnetic field

The invention related to cable production equipment, and in particular relates to an electromagnetism attached copper-aluminum composite wire production device. The electromagnetism attached copper-aluminum composite wire production device comprises a paying off mechanism and a taking up mechanism used for releasing and rolling a wire, wherein a chemical cleaning device, a pre-plating device and a main plating device are sequentially arranged on a wire transferring passage between the paying off mechanism and the taking up mechanism; the main plating device comprises a main plating tank around which an electromagnetic device capable of generating a stirring electromagnetic field in the main plating tank is arranged. Compared with existing production equipment, the production device provided by the invention can improve composite compactness, and is small in pollution, easy to control stirring strength, and improved in plating quality.

Owner:镇江鑫中宝电子有限公司

Method for preparing metal ceramic coating material with plasma/combustion synthesis/quasistatic pressing process

InactiveCN101869985BMeet the use requirementsHas a wetting effectMolten spray coatingSelf-propagating high-temperature synthesisPorosity

The present invention relates to a method for preparing a metal ceramic coating material with a plasma / self-propagation high temperature synthesis / pseudo hot isostatic pressing process, relating to a method for preparing a metal-matrix ceramic coating. The invention solves the problems of low fatigue resistance, poor bonding strength, short service life and the like existing in ceramic coating prepared on the surface of metal in the prior art. The method comprises the following steps of: dry or wet mixing titanium powder, iron powder and carbon powder and pressing a preset blank; carrying out ultrasonic cleaning on a metal substrate, carrying out sand blasting and coarsening and spraying NiCrBSi with plasma; and obtaining the metal ceramic coating material with a self-propagating high-temperature synthesis combined quasi-thermal isostatic pressing method. The method has easy operation and low cost; the obtained coating and substrate achieve metallurgical bonding, has high fatigue resistance, large thickness of the coat and low porosity, improves the wear resistance of the metal surface, can be widely applied to surface treatment and remanufacture of structural steel products, tool steel products, mould steel products and the like, and prolongs the service life of the products.

Owner:QIQIHAR UNIVERSITY

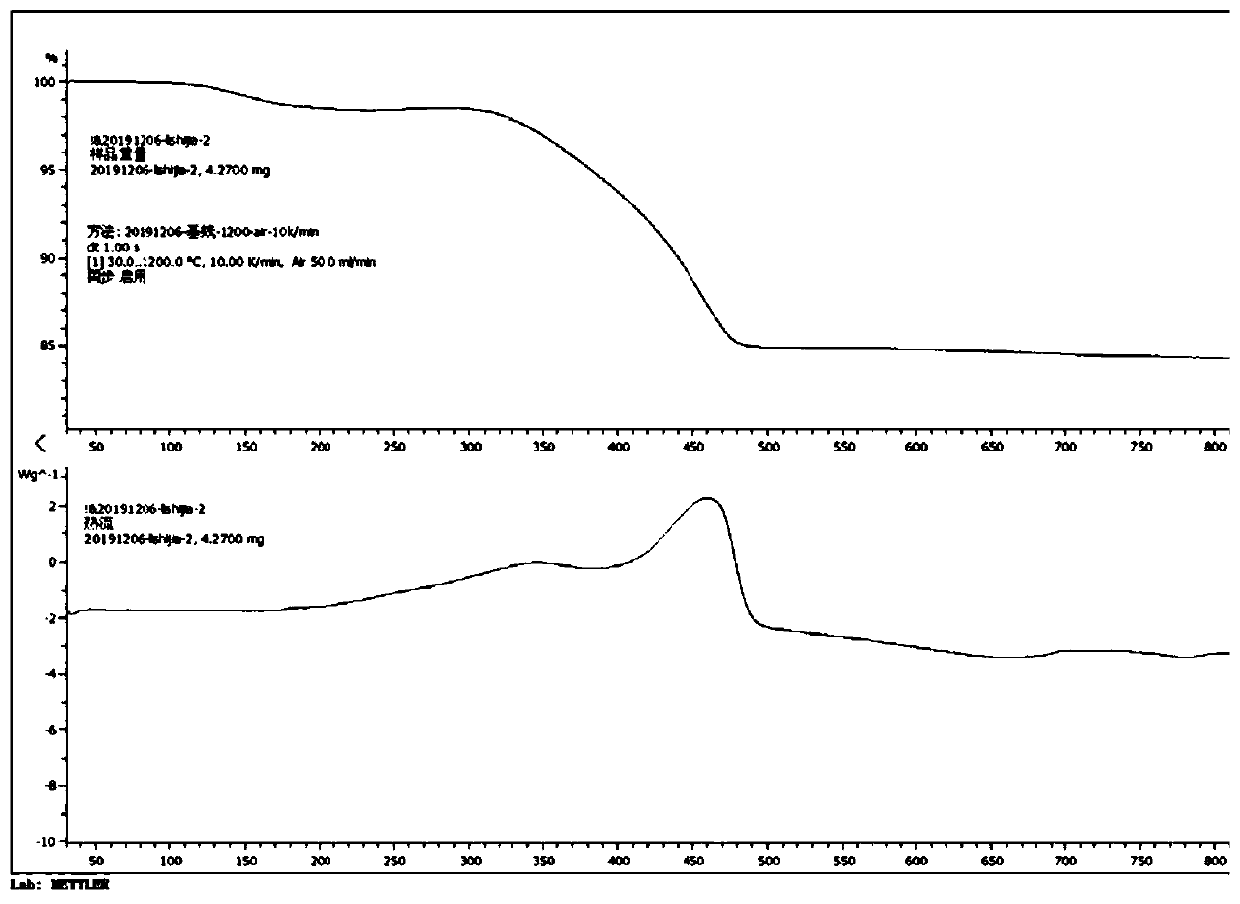

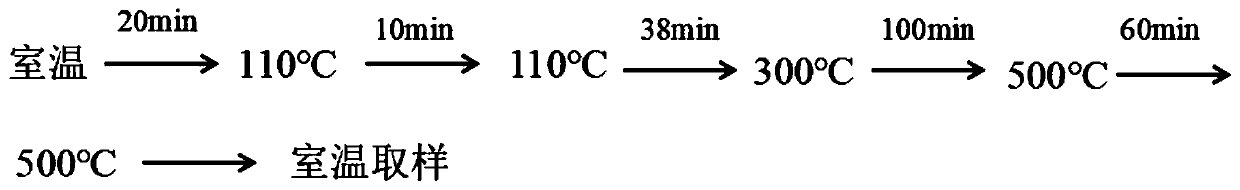

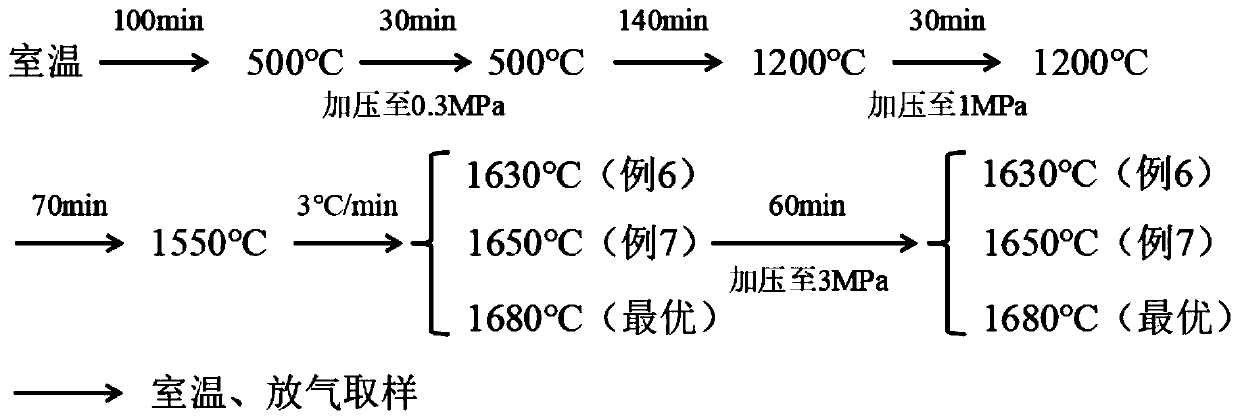

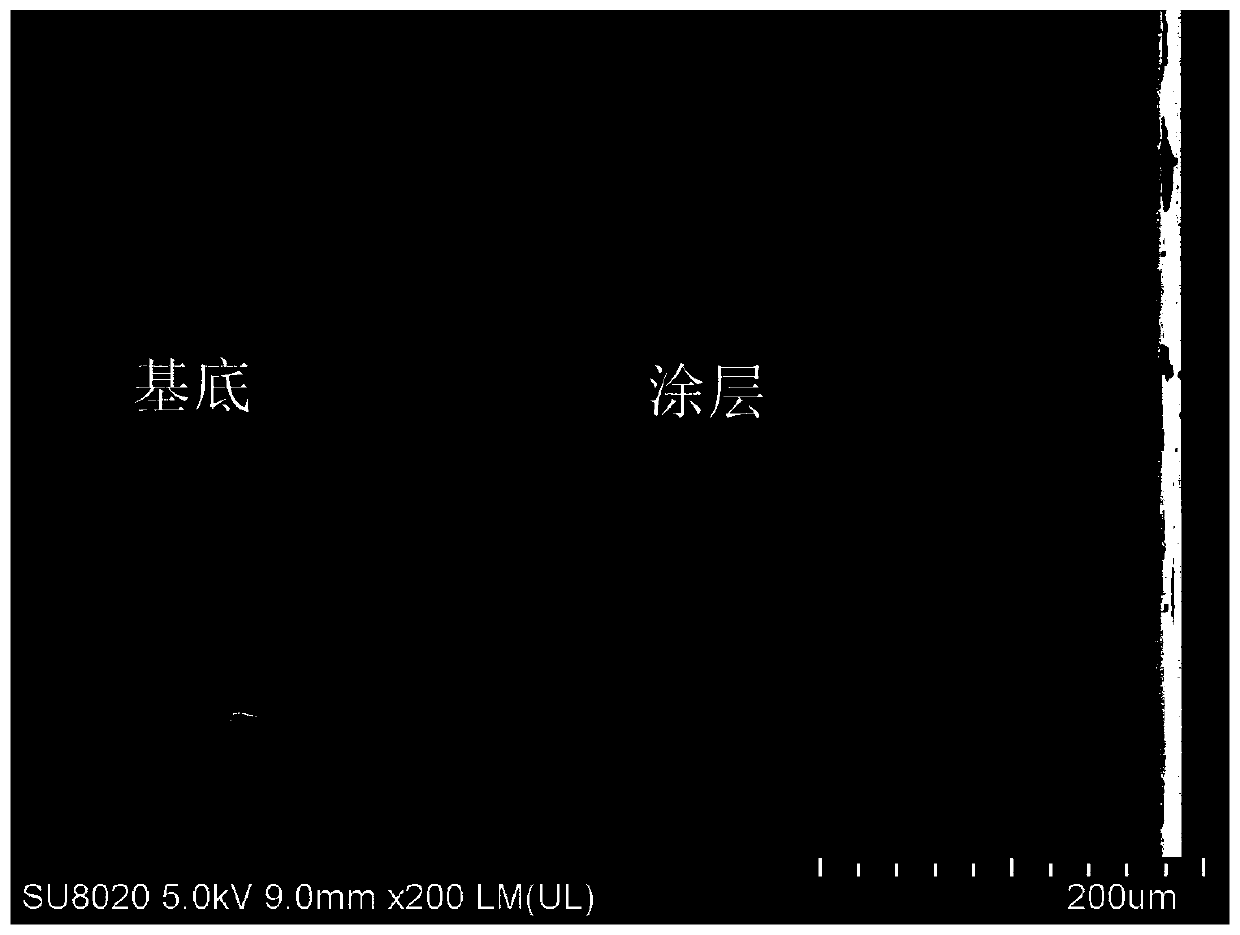

Method for preparing high-density silicon nitride ceramic through multi-factor optimization and prepared silicon nitride ceramic

The invention provides a method for preparing high-density silicon nitride ceramic through multi-factor optimization and the prepared silicon nitride ceramic. According to the invention, by optimizingcold isostatic pressing molding, pre-sintering, hot isostatic pressing sintering process, composition, total content and other test parameters of a binder and a sintering aid, and adopting multi-factor optimization, the density of silicon nitride products is improved, the problem that the existing silicon nitride ceramic products are difficult to obtain parts with high density ( greater than 99.5%) is solved, and the produced silicon nitride product not only has high density ( greater than 99.5%), but also has extremely high strength. The excellent performances determine that the high-densitysilicon nitride ceramic can be more widely applied in the fields of aviation, aerospace, precise high-speed bearings, electronic packaging and the like

Owner:XIAN AOQIN NEW MATERIAL CO LTD +2

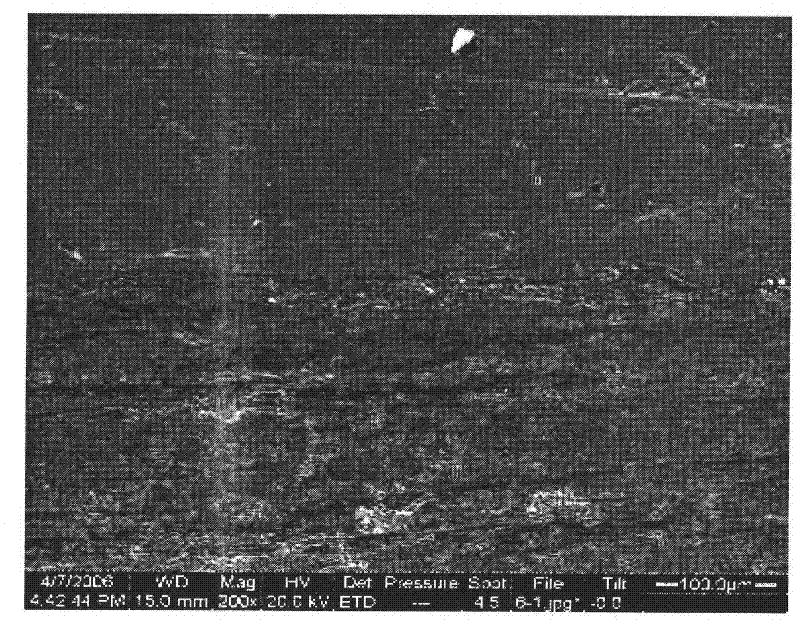

Preparation method of high-temperature wear-resistant oxidation-resistant coating

InactiveCN110527942ATissue structure dense and uniformReduce crackingMolten spray coatingPorosityWear resistant

The invention discloses a preparation method of a high-temperature wear-resistant oxidation-resistant coating. The method comprises the following steps: firstly, carrying out sand blasting treatment on a substrate sample, then carrying out spraying treatment on the sample by adopting a plasma spraying method, fixing the sample on a rotary table while a spray gun moves in the spraying process, enabling the sample to rotate quickly, effectively preventing the coating from being locally overheated, and finally, carrying out high-temperature vacuum heat treatment to prepare the MCrAlY coating. Thecoating is subjected to vacuum heat treatment, so the defects of cracks, pores and the like in the coating are effectively reduced, and the bonding strength of the coating is obviously improved; after heat treatment at 1100 DEG C, the porosity of the coating is reduced to 0.86%, the bonding strength is improved to 62.1 Mpa, and the coating has excellent wear resistance and oxidation resistance atthe high temperature of 900 DEG C and is good in comprehensive performance.

Owner:XI AN JIAOTONG UNIV +1

Rare earth lead alloy for positive electrode grid of lead-acid storage battery

ActiveCN103762369BImprove corrosion resistanceReduce grain gapElectrode carriers/collectorsCeriumLanthanum

Owner:江苏海宝电池科技有限公司

Cast steel coating for vacuum lost foam casting

InactiveCN104550682AReduce carbon increaseReduce defects such as poresFoundry mouldsFoundry coresLost-foam castingMetallurgy

A cast steel coating for vacuum lost foam casting comprises components in percentage by weight as follows: 30-45% of water, 2-5% of sodium bentonite, 1-4% of a suspending agent, 2-4% of an organic binding agent, 50% of emery powder and 0.2-1% of an aid; the performance of the cast steel coating for vacuum lost foam casting depends on composition, a preparation technology, an application technology and a drying technology of the coating. With the adoption of the coating, defects such as recarburization, air holes and the like of cast steel pieces are overcome, the coating is stable in comprehensive coating performance, low in coat and ideal in effect, and the comprehensive product percent of pass of the vacuum lost foam cast steel pieces can be ensured to be higher than 97%.

Owner:ANHUI YONGCHANG CASTING

Metal and its alloy vacuum die casting forming equipment and method

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

Injection molding machine hydraulic oil circulation type fixed template casting process

ActiveCN104338898BEasy dischargeQuality improvementFoundry mouldsFoundry coresTissue densityInjection molding machine

The invention discloses a hydraulic oil inner circulation type fixed mold plate casting technology of an injection molding machine. The technology comprises the following steps that a mold of a fixed mold plate is manufactured, upper, middle and lower three-part molding is adopted and comprises an upper box, a middle box and a lower box, and a mold joint of the upper box and the middle box serves as a mold mounting face of the fixed mold plate; b, a steel pipe is buried in the middle box, and the steel pipe corresponds to a hydraulic oil path in the fixed mold plate; c, sprue positions are arranged on the lower box in the step b, sprues are formed in the bottom face of the fixed mold plate, exhaust dead heads and an exhaust path are formed, the exhaust dead heads are formed in the upper box, and the exhaust path is communicated with the upper box and the middle box; d, casting forming is carried out, the upper box in the step c is arranged upwards and the lower box in the step c is arranged downwards to be casted, and the casting temperature ranges from 1320 DEG C to 1350 DEG C. The hydraulic oil inner circulation type fixed mold plate casting technology of the injection molding machine has the advantages of being good in material uniformity, high in tissue density, good in surface quality and high in casting yield.

Owner:GUANGDONG BLOOMACHINE

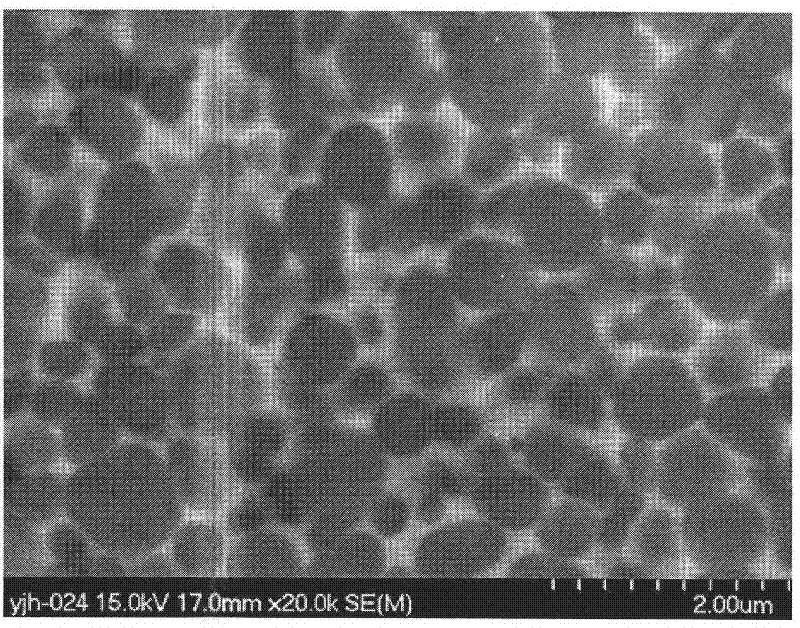

Preparation method of high-performance conductive nano ceramic metal clad coating on pure copper surface

ActiveCN110093604AHigh densityHigh hardnessMetallic material coating processesLaser scanningGraphite

The invention discloses a preparation method of a high-performance conductive nano ceramic metal clad coating on a pure copper surface. The invention relates to a method for preparing Zr(OH) 4 gel byusing a collosol-gel method, 19-24 wt% of Zr (OH) gel, 59-66 wt% of Cu powder, 7-10 wt% of B2O3 powder and 6-8 wt% of graphite are mixed and coat the surface of a pure copper matrix, and laser scanning and cladding is carried out to obtain a nano ZrB2 / Cu ceramic metal cladding coating is achieved. According to the preparation method, the cladding coating is formed by laser irradiation on the basisof in-situ reaction, so that the good compactness of the cladding coating and the uniform distribution of the ZrB2 in the coating are realized, and the nano-ceramic metal cladding coating with high hardness, high tensile strength and good conductivity is obtained.

Owner:ZHONGBEI UNIV

High-chromium acid-resistant cast iron material as well as preparation method and application thereof

PendingCN114769509ASmall mechanical propertiesAccelerated corrosionFoundry mouldsFoundry coresSS - Stainless steelOxidizing acid

The invention relates to a high-chromium acid-resistant cast iron material which comprises the following chemical components in percentage by mass: 1.0-3.0% of C; 35 to 45 parts of Cr; 1.0 to 2.0 parts of Si; mn: < = 1.0; 3.0 to 7.0 parts of Ni; 1.0 to 3.0 parts of Mo; 1.0-3.0% of Cu and the balance of Fe. The invention further relates to a preparation method of the high-chromium acid-resistant cast iron material, and relates to application of smelting, pouring, heat treatment and stable production of slurry pump flow passage components. Compared with austenitic stainless steel 06Cr17Ni12Mo2 (316) and 06Cr19Ni10 (304) materials, the corrosion resistance and the abrasion resistance of the stainless steel material in an oxidizing acid solution containing particulate matter are greatly improved through certain technological treatment.

Owner:SHIJIAZHUANG IND PUMP FACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com