Cross wedge rolling type strain-induced semi-solid die forging process for high-pressure common rail pipe for internal combustion engine

A semi-solid die forging and high-pressure common rail technology, which is applied in the field of high-pressure common rail pipe manufacturing for internal combustion engines, can solve the problems of poor mechanical properties of the high-pressure common rail pipe, coarse grains, and uneven structure distribution of the high-pressure common rail pipe, and saves energy. Raw materials, microstructure with fine grains and good metal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

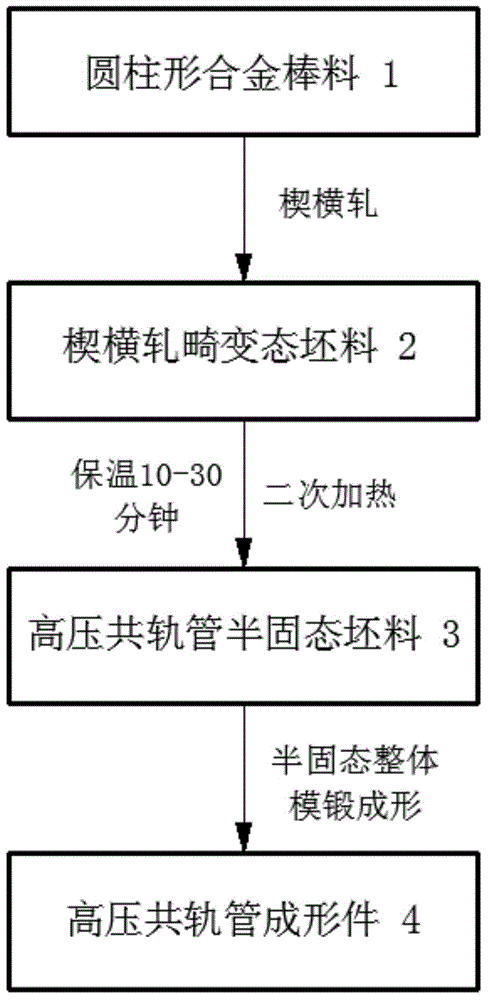

[0025] refer to figure 1 , a cross-wedge rolling strain-induced semi-solid die forging process for high-pressure common rail pipes for internal combustion engines, including the following steps:

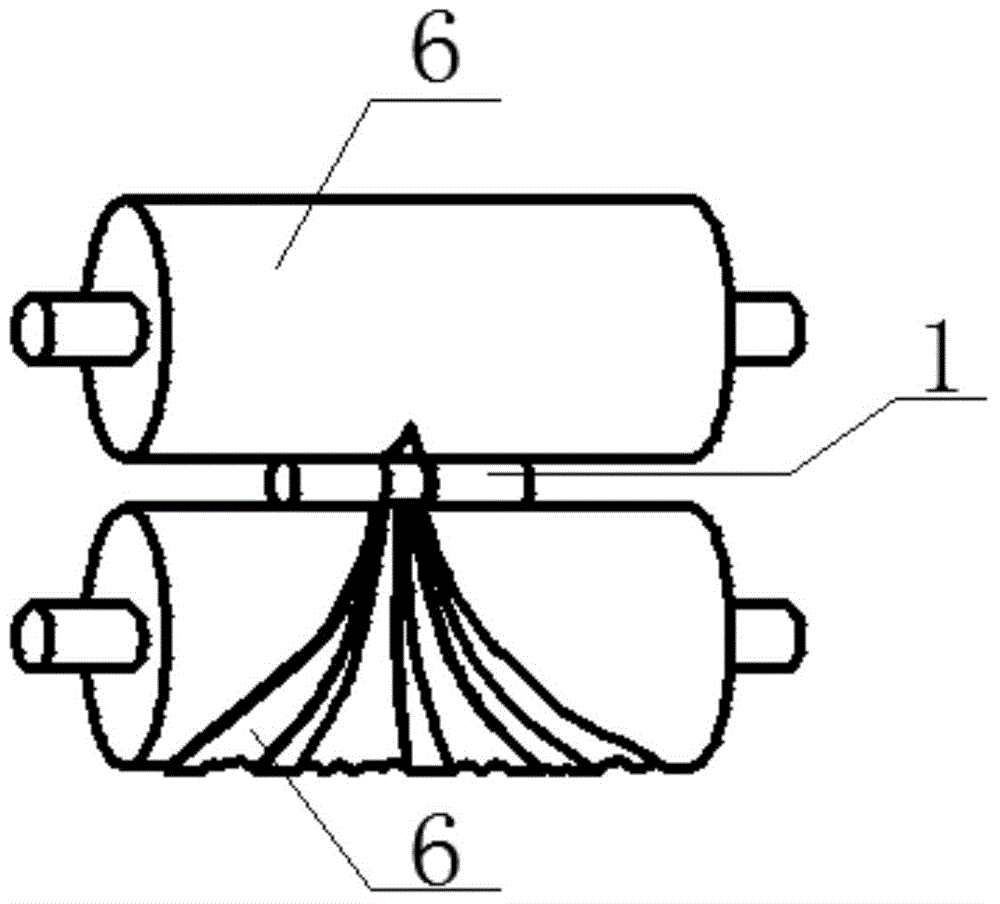

[0026] The first step: bar cross wedge rolling: refer to figure 2 , image 3 Preheat the cylindrical alloy bar 1 made of 0Cr18Ni9 stainless steel to be used for forming the high-pressure common rail pipe, and use the cross wedge rolling process to obtain the cross wedge rolled deformed billet 2, specifically: sawing with a shearing machine The alloy bar 1 is obtained, and then the alloy bar 1 is heated by electric induction at a temperature of 1000° C., and then the heated alloy bar 1 is put into a cross-wedge rolling mill using two rolls 6 with wedge-shaped dies in the same Rotate in the direction of the alloy bar and drive the round rolled piece alloy bar 1 to rotate. The alloy bar 1 undergoes radial compression and axial extension under the action of the wedge. The wedge-shaped...

Embodiment 2

[0031] refer to figure 1 , a cross-wedge rolling strain-induced semi-solid die forging process for high-pressure common rail pipes for internal combustion engines, including the following steps:

[0032] The first step: bar cross wedge rolling: refer to figure 2 , image 3 Preheat the cylindrical alloy bar 1 made of 0Cr18Ni9 stainless steel to be used for forming the high-pressure common rail pipe, and use the cross wedge rolling process to obtain the cross wedge rolled deformed billet 2, specifically: sawing with a shearing machine The alloy bar 1 is obtained, and then the alloy bar 1 is heated by electric induction at a temperature of 1100° C., and then the heated alloy bar 1 is put into a cross-wedge rolling mill using two rolls 6 with wedge-shaped molds in the same Rotate in the direction of the alloy bar and drive the round rolled piece alloy bar 1 to rotate. The alloy bar 1 undergoes radial compression and axial extension under the action of the wedge. The wedge-shape...

Embodiment 3

[0037] refer to figure 1 , a cross-wedge rolling strain-induced semi-solid die forging process for high-pressure common rail pipes for internal combustion engines, including the following steps:

[0038] The first step: bar cross wedge rolling: refer to figure 2 , image 3Preheating the cylindrical alloy bar 1 made of 0Cr18Ni9 stainless steel to be used for forming the high-pressure common rail pipe, and using the cross wedge rolling process to obtain the deformed billet 2 of cross wedge rolling, specifically: sawing with a shearing machine The alloy bar 1 is obtained, and then the alloy bar 1 is heated by electric induction at a temperature of 1200° C., and then the heated alloy bar 1 is put into a cross-wedge rolling mill using two rolls 6 with wedge-shaped molds in the same Rotate in the direction of the alloy bar 1 and drive the round rolling piece to rotate. The alloy bar 1 undergoes radial compression and axial extension under the action of the wedge. The wedge-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com