Method for predicting freckle morphology defects in directional solidification peritectic alloy paste area

A directional solidification, mushy zone technology, applied in chemical property prediction, instrumentation, computational theoretical chemistry, etc., can solve problems such as low accuracy and insufficient dendritic mushy zone analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

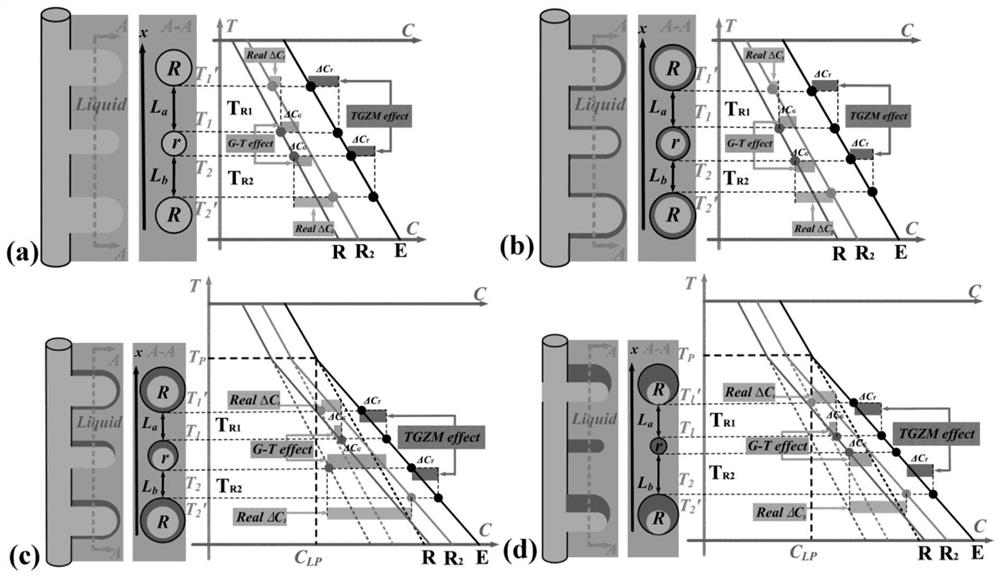

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0031] The present invention needs to carry out directional solidification experiment first to prepare sample rod, comprises the following steps:

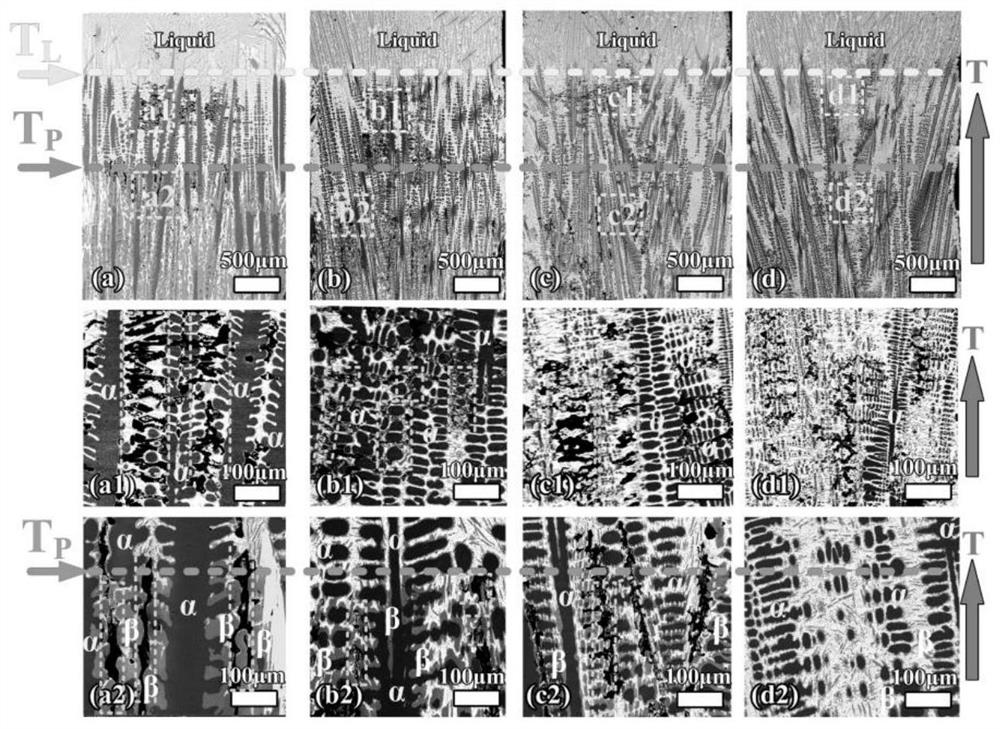

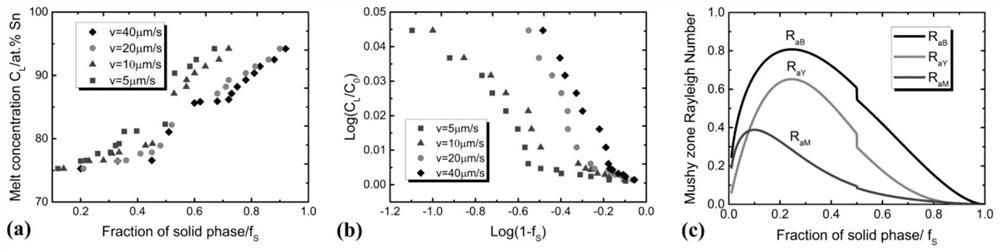

[0032] A Sn-36at.%Ni alloy was first cast in an induction melting furnace using nickel and tin with a purity of 99.9%. Rods with a diameter of 3 mm and a length of 110 mm were then cut from the ingot. The rod is subsequently placed in the Al 2 o 3tube and placed in a Bridgman type furnace. Next, the temperature of the rod was raised to 1250°C to melt it, after which the sample was left to stand in a Bridgman type furnace for 30 minutes. Subsequent directional growth was performed under a constant temperature gradient at different growth rates: 5 μm / s, 10 μm / s, 20 μm / s and 40 μm / s. The tube was then rapidly quenched when the growth distance re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com