Electromagnetism attached copper-aluminum composite wire production device

A copper-aluminum composite and preparation device technology, which is applied in the direction of cable/conductor manufacturing, superimposed layer plating, circuit, etc., can solve problems such as insufficient bonding fastness, limited stirring strength, and polluted solution, and achieves improvement of electroplating quality, stirring Ease of strength, effect of strengthening bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

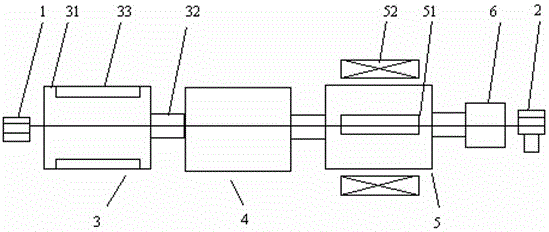

[0015] As shown in the figure, the electromagnetically attached copper-aluminum composite wire preparation device includes a pay-off mechanism 1 and a take-up mechanism 2 for releasing the wire and winding the wire, on the wire transmission channel between the pay-off mechanism and the take-up mechanism A chemical cleaning device 3 , a pre-plating device 4 and a main plating device 5 are arranged in sequence. The main plating device includes a main plating tank 51, and an electromagnetic device 52 capable of generating a stirring electromagnetic field in the main plating tank is arranged on the periphery of the main plating tank. The chemical cleaning device 3 includes a chemical cleaning tank 31 and a clean water tank 32 arranged in sequence, and an ultrasonic generator 33 is arranged in the chemical cleaning tank. The frequency range of the ultrasonic generator is 20-50 kHz. A drying device 6 is arranged between the main plating device 5 and the wire take-up mechanism 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com