Cleaning machine with dual-face brushing function

A cleaning machine and functional technology, applied in the field of cleaning machines, can solve problems such as low efficiency, single flushing or brushing, and insufficient cleaning, and achieve efficient and clean cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

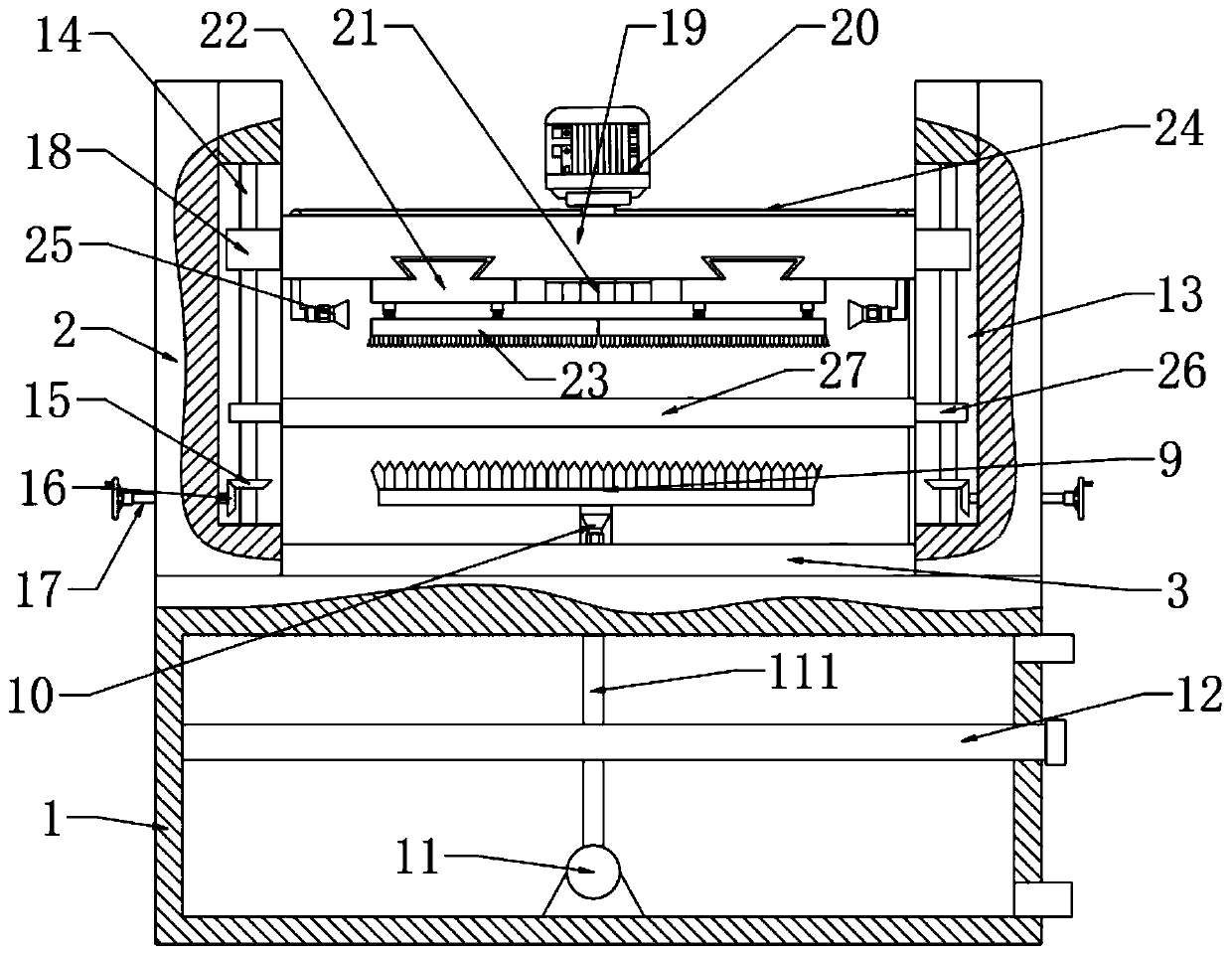

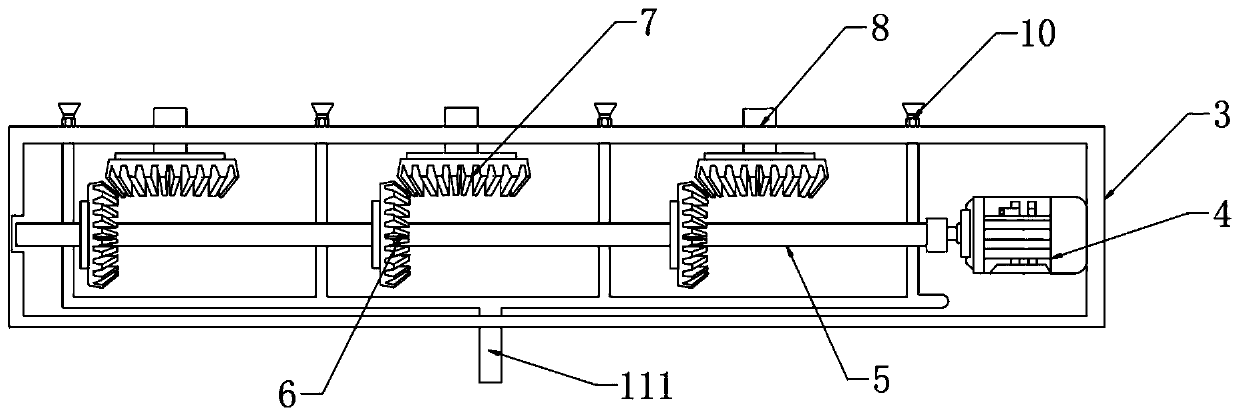

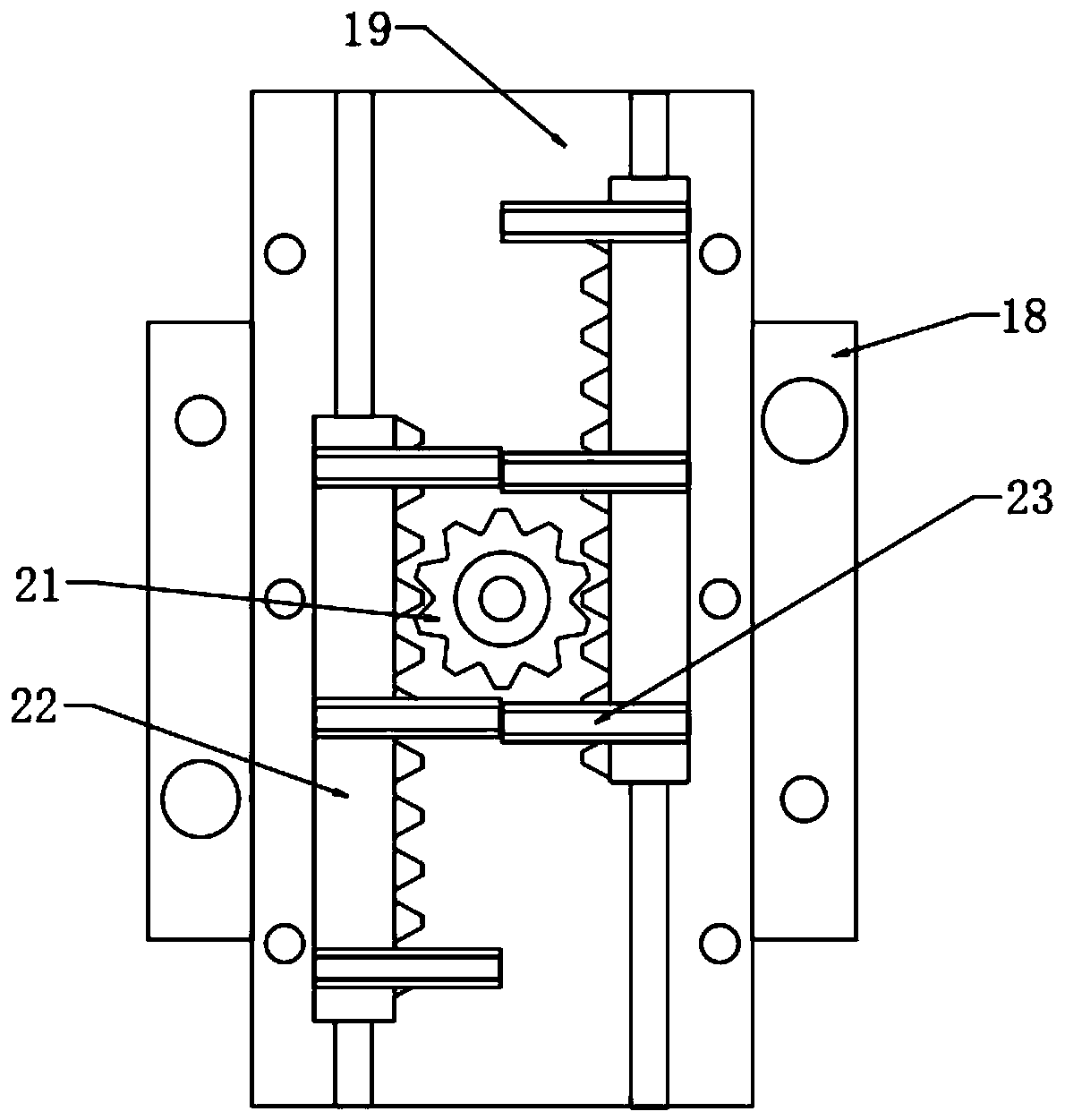

[0025]Embodiment: When working, the workpiece is placed on the workpiece placement frame 27 and fixed and clamped with the V-shaped block 29, and the workpiece placement frame 27 and the lifting mounting plate 19 are adjusted up and down according to the thickness of the workpiece, and the right manual wheel is rotated to drive Bevel gear 16 meshes with transmission bevel gear 15 to drive the right screw mandrel 14 to rotate, and the right screw mandrel 14 drives the workpiece placement frame 27 to lift up and down, so that the bottom of the workpiece is in contact with the bottom cleaning brush 9, and then rotates the left manual wheel to drive the bevel gear 16 meshes with the transmission bevel gear 15 to drive the left screw 14 to rotate, and the left screw 14 drives the lifting mounting plate 19 to descend, so that the upper cleaning brush 23 is in contact with the upper surface of the workpiece, and the upper nozzle 25 is tilted upward by 30 to 60 degrees to start Circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com