A device for electromagnetic field-assisted laser additive manufacturing

An auxiliary laser and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, and process efficiency improvement, to achieve the effects of ensuring manufacturing quality, improving performance, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

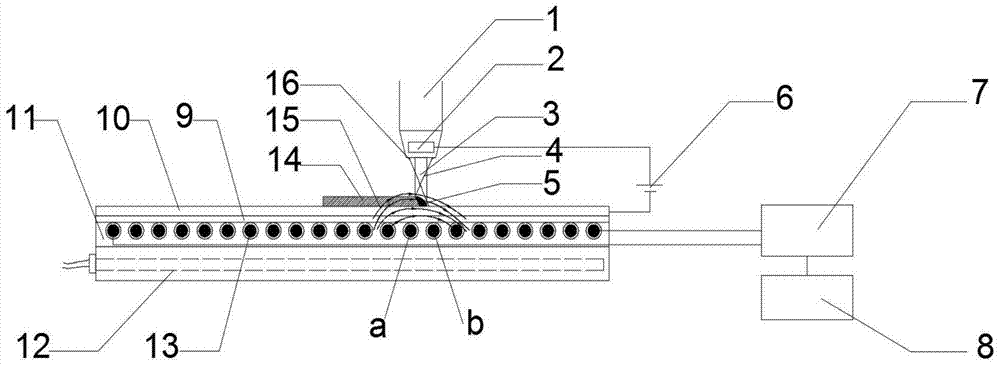

[0029] The powder mixing chamber 2 is connected to the positive pole of the DC power supply 6 , and the base 10 is connected to the negative pole of the DC power supply 6 . An electric field perpendicular to the substrate 10 is formed from top to bottom.

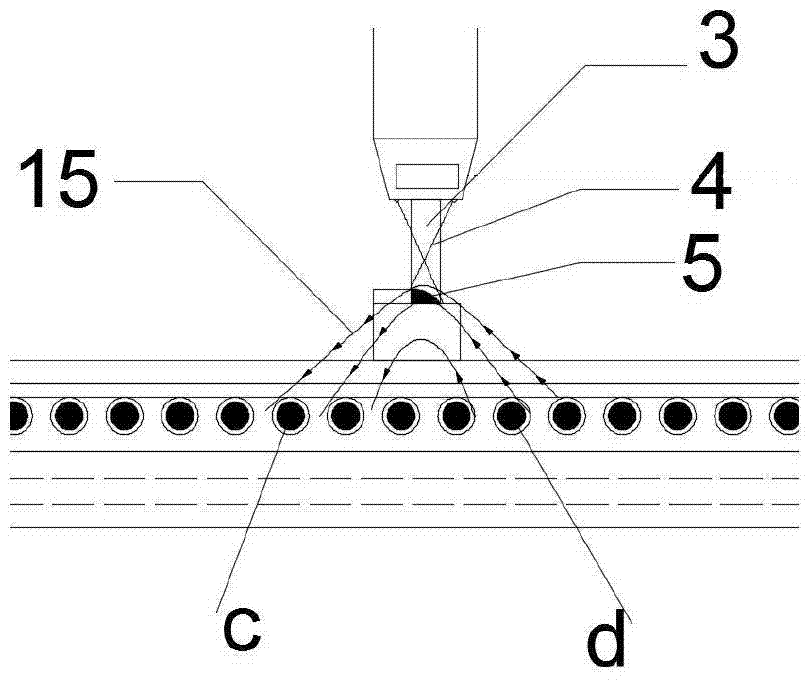

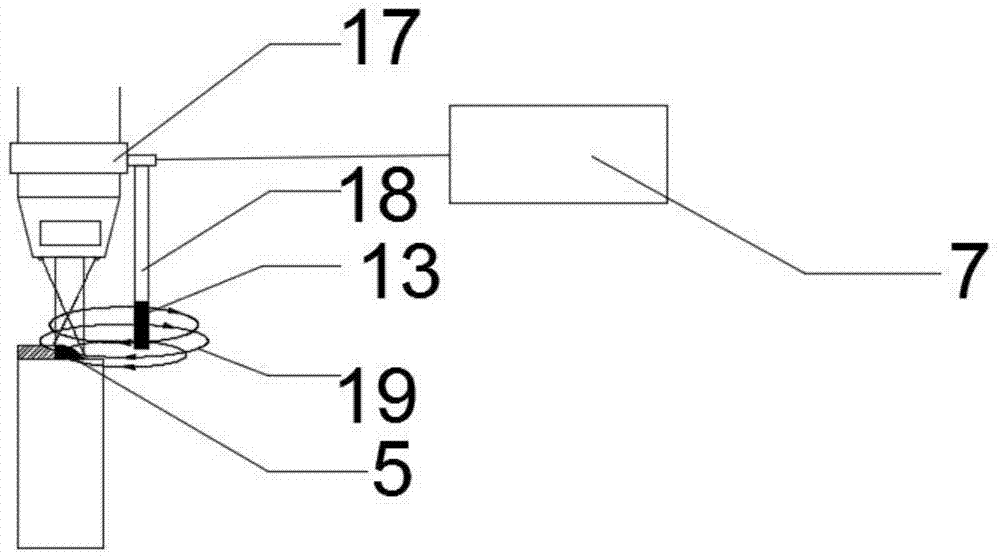

[0030] Input the laser additive manufacturing parameters into the controller, the controller 7 controls the raw magnetic rods 13 at different positions in the magnetic field generator 11 according to the laser additive manufacturing parameters, and the controller 7 constantly changes the direction of the current in the raw magnetic rods to generate the direction Changing high-frequency magnetic fields15. Taking the raw magnet bar a and the raw magnet bar b as an example, the controller 7 regulates the current in the raw magnet bar a and the raw magnet bar b to form an alternating magnetic field with a lower height, such as figure 1 As shown, the controller 7 regulates the current in the raw magnetic rod c and the raw magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com