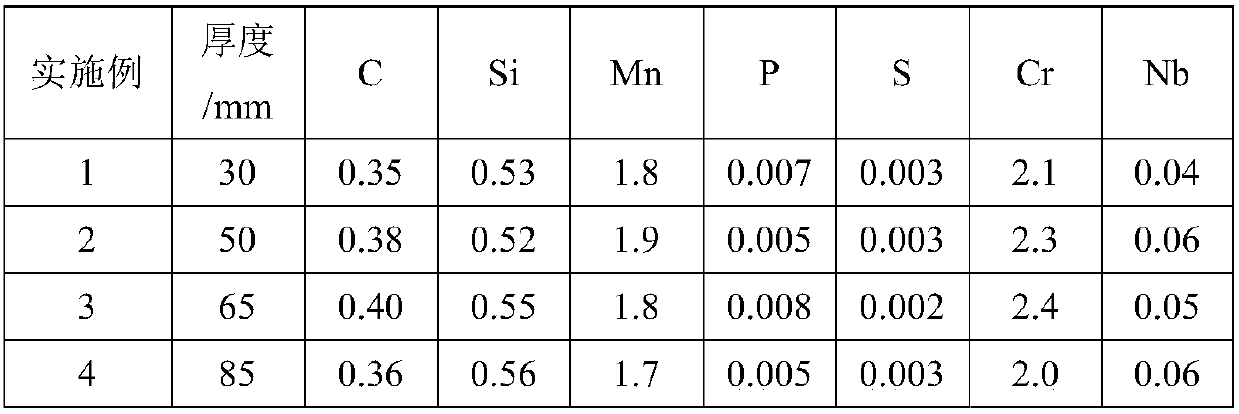

Novel non-quenched-and-tempered plastic die steel plate and preparation method thereof

A plastic mold steel, non-quenched and tempered technology, applied in the field of non-quenched and tempered plastic mold steel plate and its preparation process, can solve the problems of increased quenching cracking tendency, difficult cost control, uneven hardness, etc., achieve uniform hardness and save production Good effect of cost and section hardness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the production method of Example 1, the molten steel is smelted in a converter, refined outside the furnace, cast into a continuous casting slab, and rolled into a finished steel plate with a specification of 30 mm. The main rolling and heat treatment process parameters of steel in Example 1 of the present invention are shown in Table 2. Table 3 shows the hardness test results (HRC) of the steel section in Example 1 of the present invention.

[0039] Table 2 The main rolling and heat treatment process parameters of steel in Example 1 of the present invention

[0040]

[0041] Table 3 Example 1 Steel Section Hardness Test Result (HRC) of the present invention

[0042]

[0043] It can be seen from Table 3 that the hardness of the 30 mm steel plate in Example 1 can meet the P20 hardness requirement in the AISI standard.

Embodiment 2

[0045] In the production method of this embodiment, the molten steel is smelted in a converter, refined outside the furnace, cast into a continuous casting slab, and rolled into a finished steel plate with a specification of 50 mm. The main rolling and heat treatment process parameters of the steel in Example 2 of the present invention are shown in Table 4. Table 5 shows the hardness test results (HRC) of the steel section in Example 2 of the present invention.

[0046] Table 4 The main rolling and heat treatment process parameters of steel in Example 2 of the present invention

[0047]

[0048] Table 5 Example 2 Steel Section Hardness Test Result (HRC) of the present invention)

[0049]

[0050] It can be seen from Table 5 that the hardness of the 50mm steel plate in Example 2 can meet the P20 hardness requirement in the AISI standard.

Embodiment 3

[0052] In the production method of this embodiment, the molten steel is smelted in a converter, refined outside the furnace, cast into a continuous casting slab, and rolled into a finished steel plate with a specification of 65 mm. The main rolling and heat treatment process parameters of the steel in Example 3 of the present invention are shown in Table 6. Table 7 shows the hardness test results (HRC) of the steel section in Example 3 of the present invention.

[0053] Table 6 The main rolling and heat treatment process parameters of steel in Example 3 of the present invention

[0054]

[0055] Table 7 Example 3 Steel Section Hardness Test Result (HRC) of the present invention

[0056]

[0057] It can be seen from Table 7 that the hardness of the 65mm steel plate in Example 3 can meet the P20 hardness requirement in the AISI standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com