Niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar and production method thereof

A technology of microalloying and production methods, which is applied in the manufacture of converters, etc., can solve the problems of low yield, achieve the effects of increasing yield, low niobium and titanium content, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-36

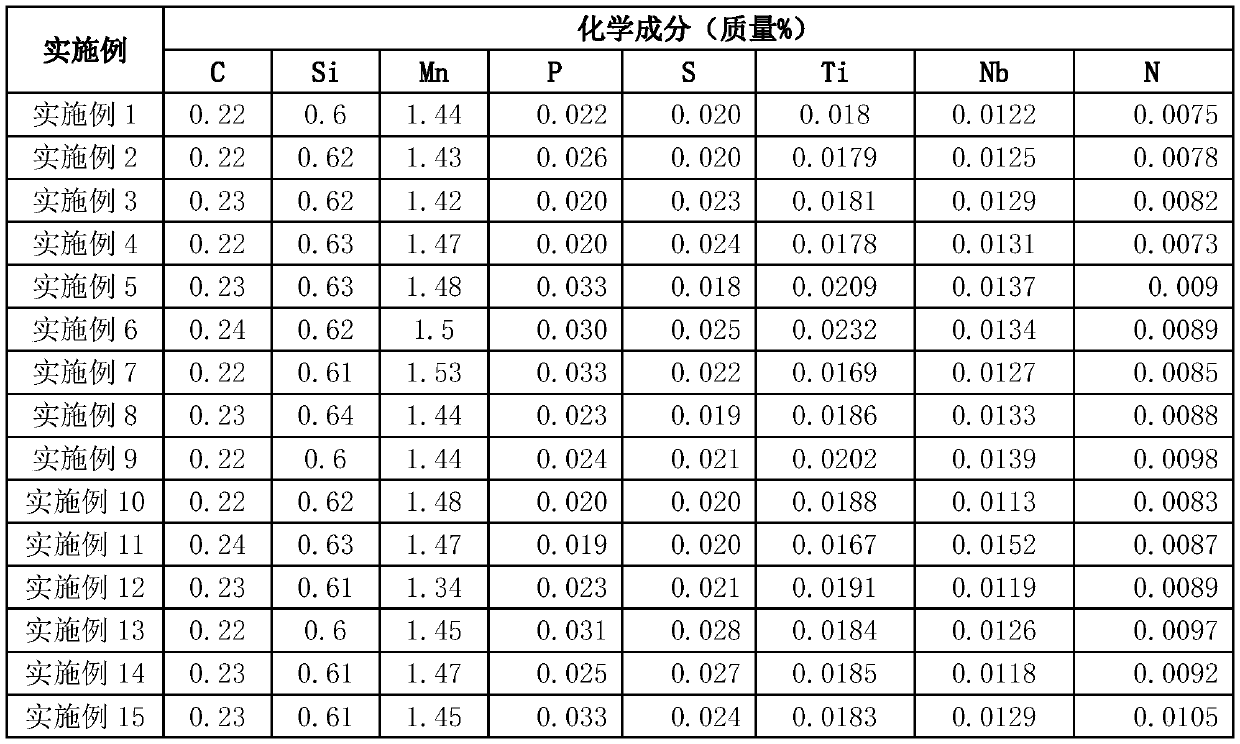

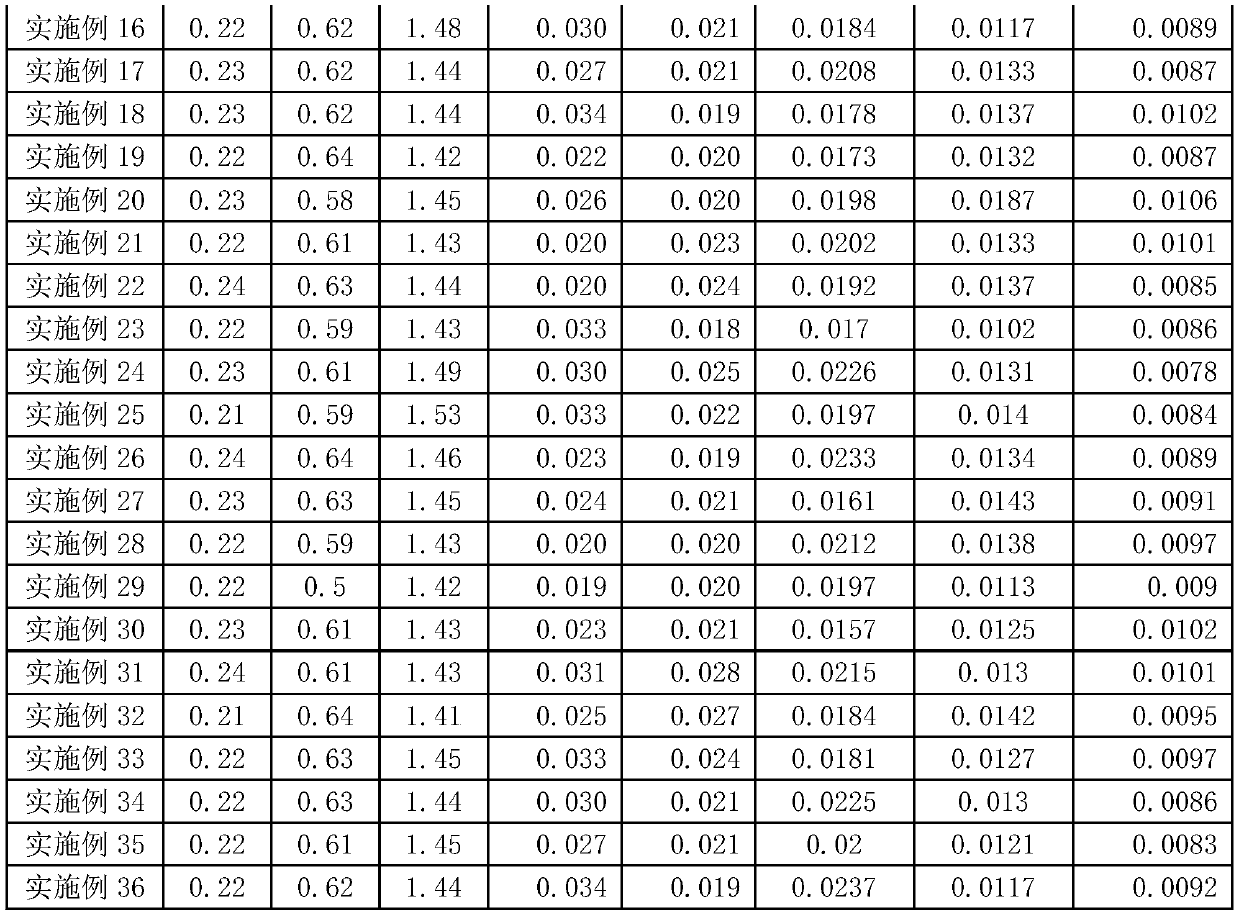

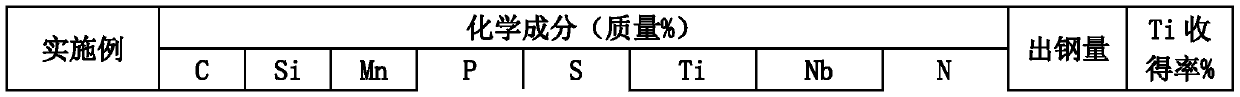

[0032] Example 1-36: A kind of niobium-titanium-nitrogen and titanium-nitrogen composite micro-alloyed HRB400E steel bar, the steel bar with a diameter of 12 mm to 22 mm, calculated by mass percentage, the included chemical components and their percentages are shown in Table 1 below, and the remaining For Fe and other impurities.

[0033] Table 1: Proportion table of chemical composition of steel parts in each embodiment

[0034]

[0035]

[0036] Among them, the niobium-titanium-nitrogen microalloyed HRB400E steel bars of Examples 1 to 9 in the above table 1 are produced according to the following production methods, including converter smelting, argon blowing, continuous casting, heating, rolling and cooling bed cooling processes, specifically Control conditions include:

[0037] (1) During the converter, high-strength carbon is used to increase the end point carbon, and the end point of tapping carbon is controlled at 0.04-0.05%; the molten steel is deoxidized by usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com