Magnesium alloy hub manufacture

A manufacturing method, magnesium alloy technology, applied in the direction of the wheel hub, transportation and packaging, vehicle parts, etc., can solve the problems that the magnesium alloy hub is difficult to meet the mechanical performance requirements, the quality of the casting is very sensitive, and the metal mold is airtight, etc. , to achieve the effect of good fuel saving, wide applicability and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Magnesium alloy wheel products are used in MT2.5×10 front and rear wheels on Lingying motorcycle produced by Huaying Company.

[0049] A: On the basis of AZ81 magnesium alloy material, 1.9% of the total weight of rare earth mixed elements containing 50% of cerium is added.

[0050] B: Using a MgCl at 38% by weight 2 , 4% by weight of CaF 2 , 47% by weight of KCl, 8% by weight of BaCl 2 , 3% by weight of MgO is the magnesium alloy covering agent of raw material (addition is 2% of the smelting amount of magnesium alloy material), and a magnesium alloy refining agent ( The addition amount is 0.6% of the smelting amount of the magnesium alloy material), and 0.4% of the total amount of zirconium chloride is added to refine the grains of the magnesium alloy melt.

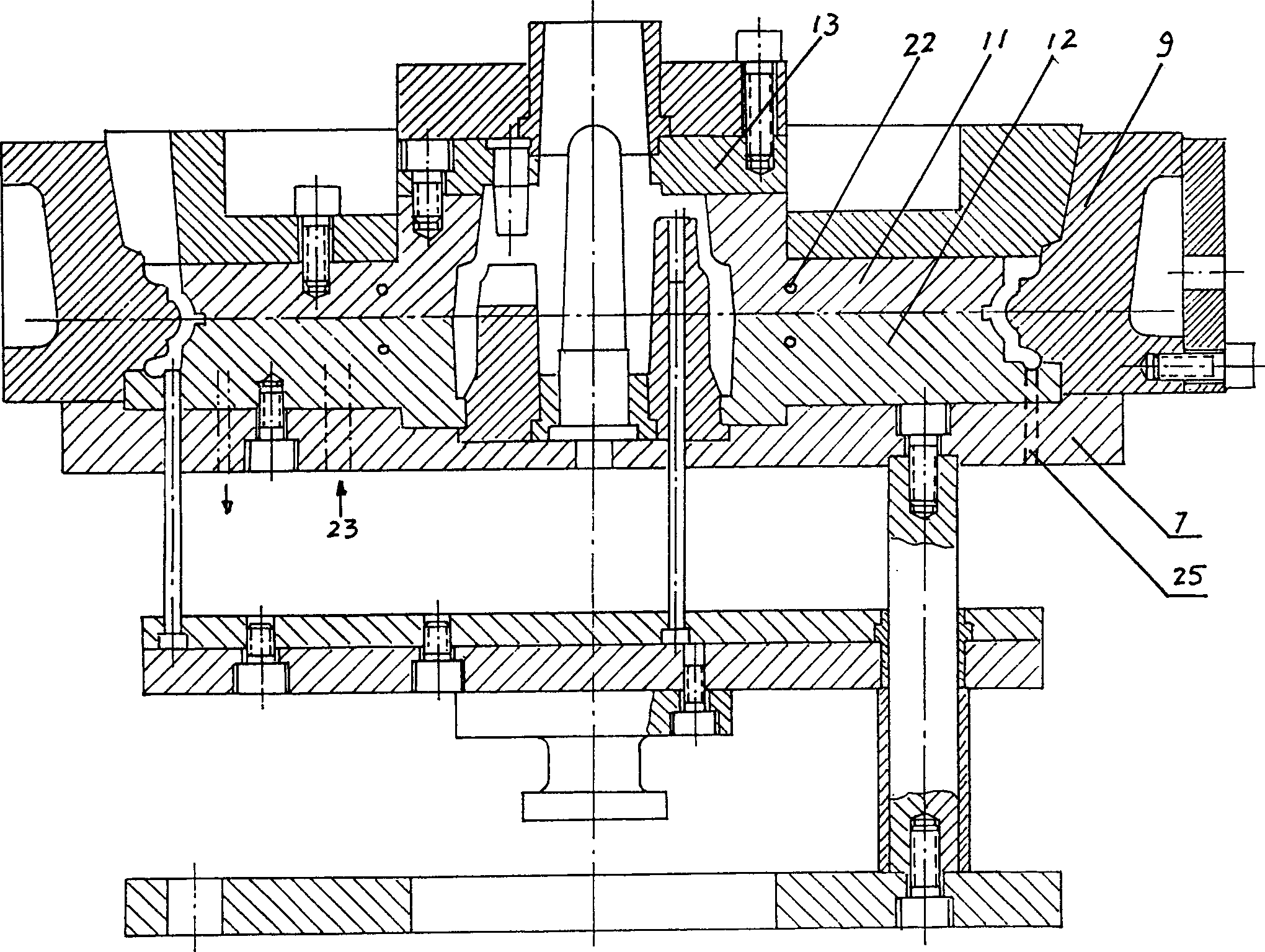

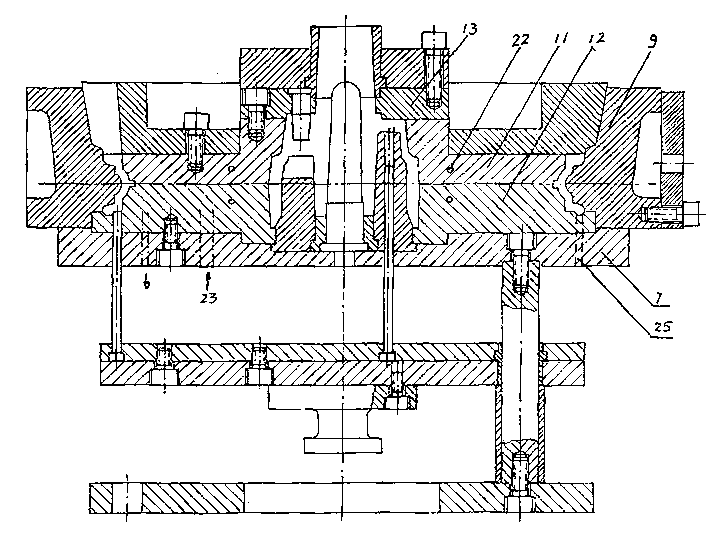

[0051] C. to use figure 1 The hub mold shown, and the mold cavity is sprayed and poured. The pouring speed should be slow first, then fast, and then slow. During the pouring process, the liquid flow should be...

Embodiment 2

[0064] Magnesium alloy wheels are used for 18-inch front and rear wheels on power bicycles produced by Chongqing Longding Power Machinery Co., Ltd.

[0065] A. On the basis of AM50A magnesium alloy material, 1.2% of the total weight of rare earth mixed elements containing 85% of neodymium is added.

[0066] B, adopt a kind of MgCl of 37% by weight 2 , 5% CaF by weight 2 , 45% by weight of KCl, 9% by weight of BaCl 2 , MgO of 4% by weight is a magnesium alloy covering agent (the addition amount is 4% of the smelting amount of the magnesium alloy material), a magnesium alloy refining agent with 74% by weight of NaCl and 26% by weight of KCl as raw materials (adding The amount is 0.8% of the smelting amount of the magnesium alloy material), and 1.2% calcium chloride is added to refine the grain of the magnesium alloy melt.

[0067] C. Same as step C of Example 1.

[0068] D. The as-cast quenching method is adopted for the heat treatment of the wheel hub: when the casting is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com