Casting process of a truck sideframe, casting model, railway car truck sideframe, railway car truck and railway car

A technology for casting models and rail cars, applied in bogies, casting equipment, casting molds, etc., can solve the problems of reducing cores, failing to develop casting methods, and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

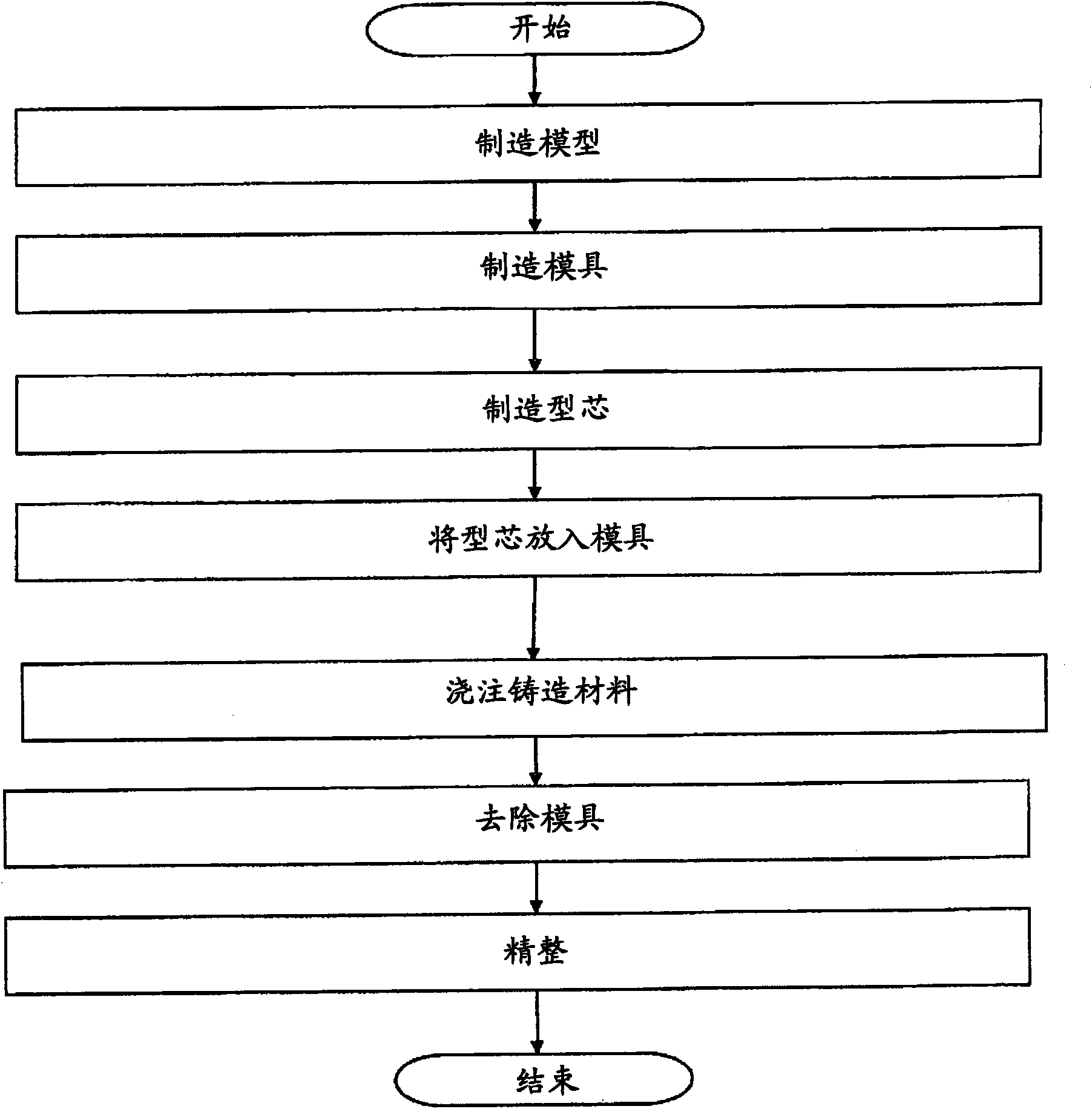

[0053] 1) Casting method

[0054] First of all, it is important to note that the casting method of the present invention includes the same stages as the prior art method, which is advantageous as will be demonstrated. This is because the benefits provided by the method of the present invention can be obtained without changing the main characteristics of the method.

[0055] figure 1 The following method stages are shown in .

[0056] (i) Manufacturing model

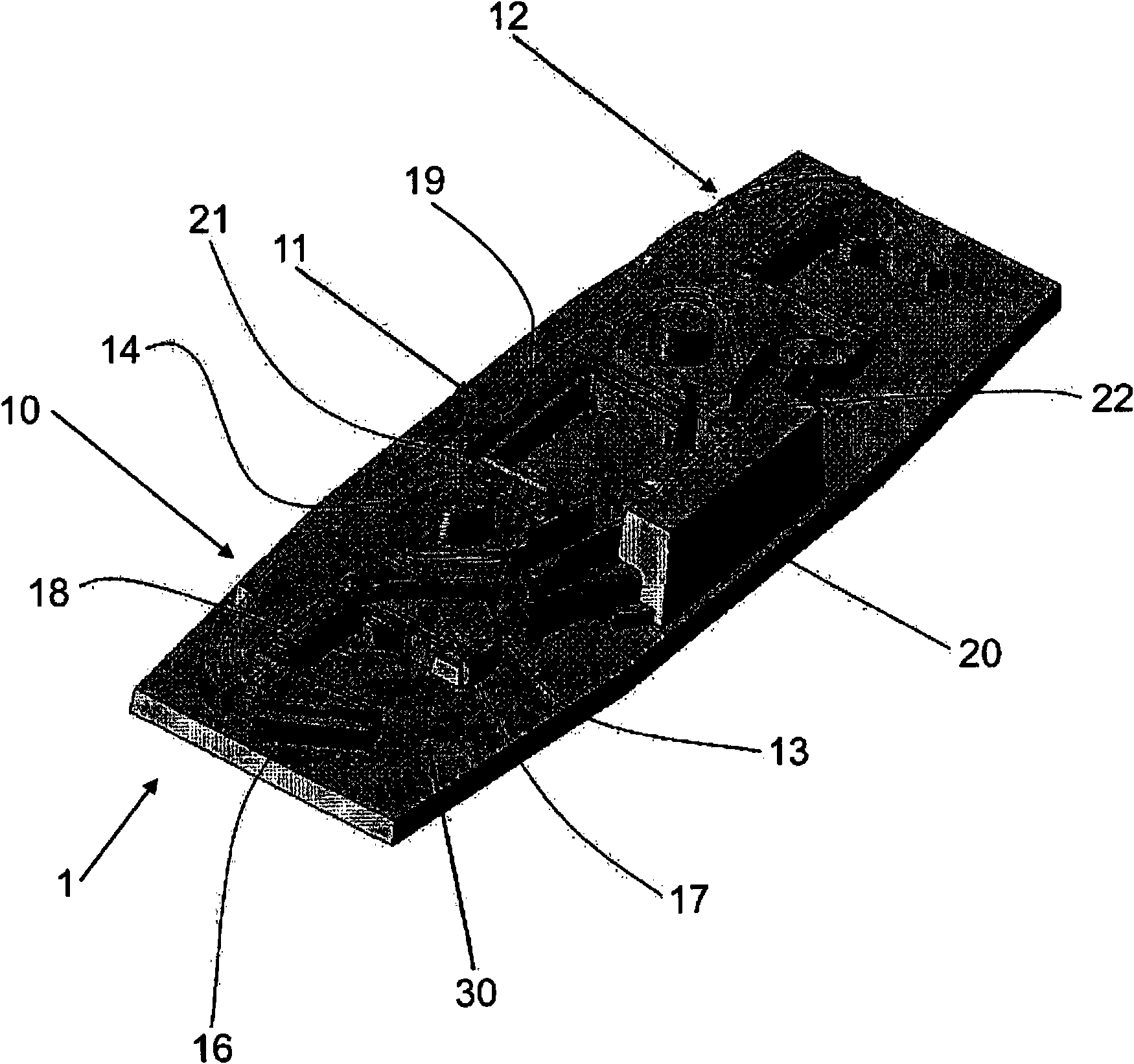

[0057] This stage consists of making the casting model 1 in a form that defines the form of the bogie sideframe to predict material shrinkage after pouring the molten alloy. This casting pattern can be made of any material, such as wood, polymer or preferably metal, or a combination of these materials. It is worth emphasizing that the cast model 1 in any possible form has dimensions slightly larger than when the bogie sideframes are being finished due to the shrinkage of the metal filling the mould, the metal filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com