Self-melting and welding method for hydraulic oil tube

A technology of hydraulic oil pipe and welding method, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that welding reliability cannot be kept stable, products are prone to blow holes, undercuts, and operators have high technical level requirements. The effect of reducing technical level requirements, reducing air holes, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

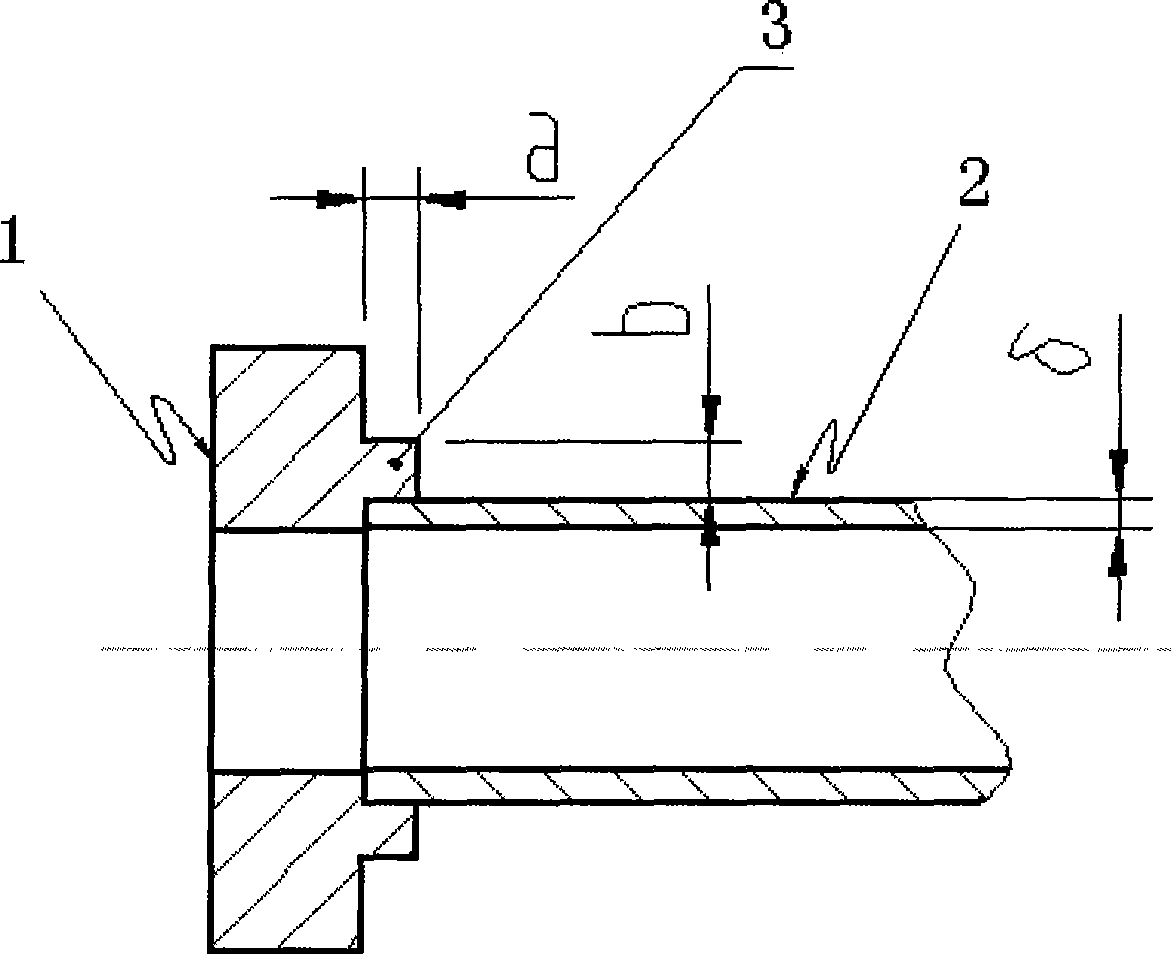

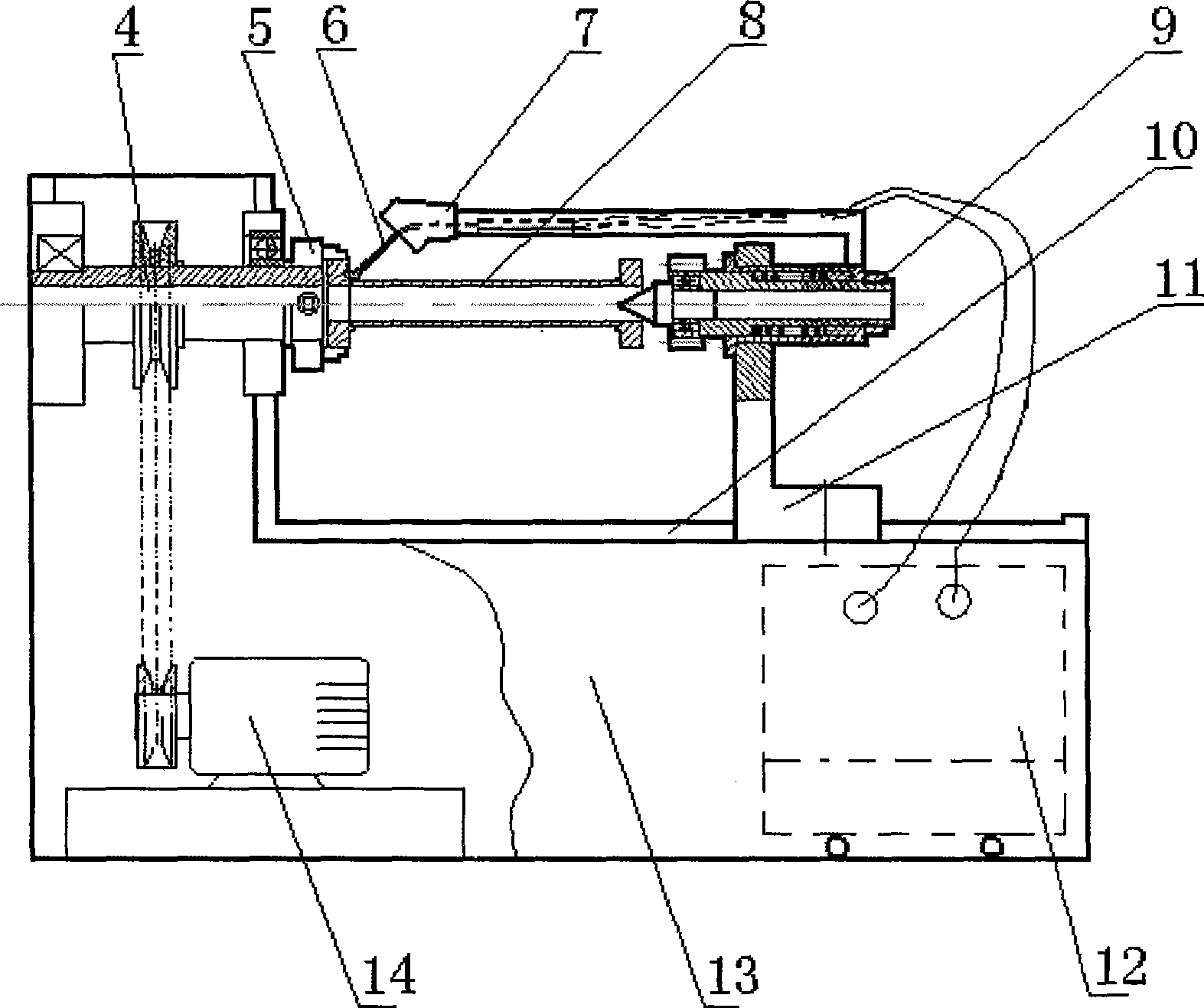

[0016] Such as figure 1 As shown, a hydraulic oil pipe argon tungsten arc welding self-fluxing welding equipment includes a body 2, argon tungsten arc welding welding machine 1, a motor 3, a transmission mechanism 4, a clamping mechanism 5, a welding torch fixing frame 7, a welding torch 6, and a thimble Tailstock 9 and control mechanism (not shown in the figure), argon tungsten arc welding machine 1, motor 3 and transmission mechanism 4 are placed in the cavity of body 2, and body 2 side upper part has horizontal rail 10, and thimble tail The tailstock base 11 at the bottom of the frame 9 can reciprocate along the horizontal rail 10. One end of the welding torch holder 7 is affixed to the upper part of the outer side of the thimble tailstock 9. The welding torch 6 is installed on the welding torch holder 7. The upper part of the body 2 has a positioning The clamping mechanism 5 of the pipe joint of the hydraulic oil pipe workpiece 8. When welding, the pipe joint of the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com