High-temperature bonding method for aluminum nitride seed crystals

A bonding method, aluminum nitride technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of growth surface damage, impurity pollution, formation of holes, etc., to reduce impurities, improve quality, difficult to shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

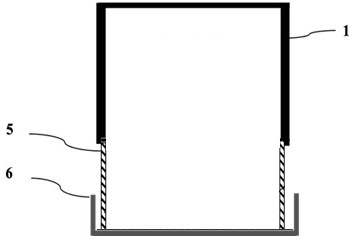

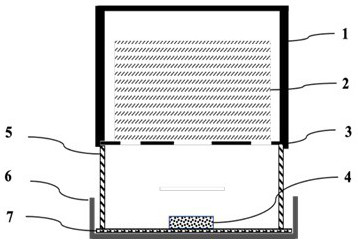

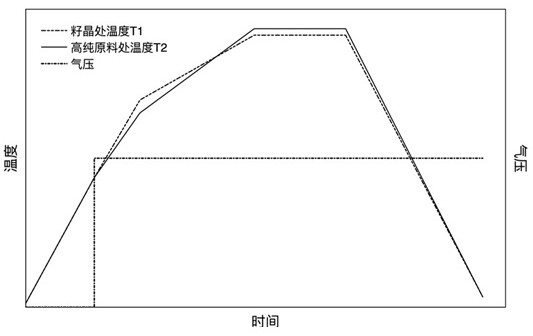

[0025] The aluminum nitride seed crystal high temperature bonding process of this embodiment is adopted figure 1 The crucible device, according to figure 2 The method of raw material assembly is performed, and the entire process includes the following steps:

[0026] (1) The aluminum nitride seed crystal is selected from the aluminum nitride seed wafer, a aluminum nitride circle having a diameter of 15 mm, which has a thickness of 1 mm, and has a double-sided fine polishing, and the surface roughness of its growth surface (RA ) Reaches 0.5 nm.

[0027] The aluminum nitride seed wafer is placed on the surface of the seed material of the tungsten material, and the surface of the support is treated with a mirror surface; the aluminum nitride material is selected from the aluminum nitride crystal crystal, place it. On the porous tungsten sheet, and to place as much as possible, ensure that the substance is volatilized and transmitted is transmitted. The seeded support placed in the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com