Metal and alloy vacuum die casting forming device and method

A vacuum die-casting and alloying technology, which is applied in the field of material processing, can solve problems such as porosity, shrinkage cavity, and poor composite effect, and achieve the effects of improving mechanical properties, improving production efficiency, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

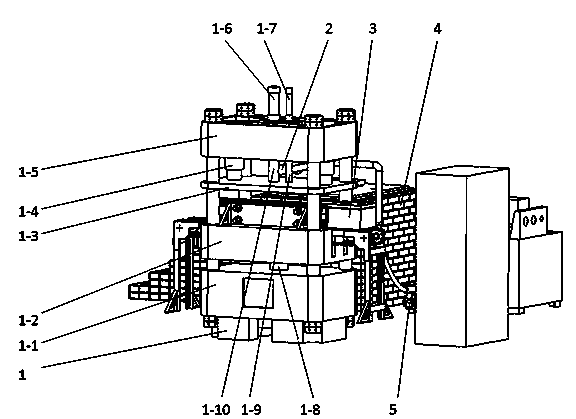

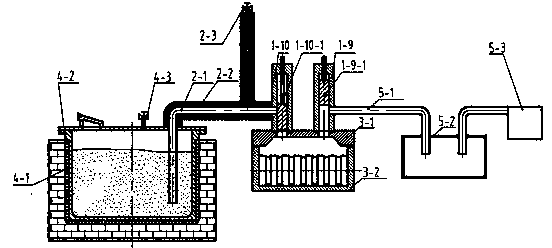

[0041] refer to figure 1 , figure 2 , The vacuum die-casting equipment for metals and their alloys in this embodiment includes a squeeze casting system 1 , a conveying system 2 , a mold 3 , a melting furnace 4 and a vacuum system 5 .

[0042]The squeeze casting system 1 includes a lower beam 1-1, a mold support beam 1-2, a clamping beam 1-3, and an upper beam 1-5 arranged in sequence from bottom to top.

[0043] A lower cylinder 1-8 is arranged between the lower beam 1-1 and the mold support beam 1-2, the lower cylinder 1-8 is located at the center of the lower beam 1-1, and the front end of the piston of the lower cylinder 1-8 is in contact with the mold support beam 1 -2 is connected by flanges and bolts, and the lower cylinder 1-8 serves as the power source for the up and down movement of the mold support beam 1-2.

[0044] Between the mold clamping beam 1-3 and the upper beam 1-5, a vacuum tube 1-9, a material injection tube 1-10 and two mold clamping cylinders 1-4 are ...

Embodiment 2

[0064] The difference between the metal and its alloy vacuum die-casting forming equipment of this embodiment and embodiment 1 is only that: the distance between the feed port and the lower end surface of the injection pipe 1-10 is 200mm, and the two mold clamping cylinders 1-4 are about The centerlines of tubes 1-10 are symmetrical. All the other are with embodiment 1.

[0065] The difference between the vacuum die-casting method for metals and their alloys in this embodiment and that in Embodiment 1 is that the pressing pressure is maintained for 30 minutes. All the other are with embodiment 1.

Embodiment 3

[0067] The difference between the metal and its alloy vacuum die-casting equipment of this embodiment and the first embodiment is that the distance between the feed port and the lower end surface of the injection pipe 1-10 is 400mm, and the rest are the same as the first embodiment.

[0068] The difference between the vacuum die-casting method for metals and their alloys in this embodiment and that in Embodiment 1 is that the pressing pressure is maintained for 50 minutes. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com