Method for preparing defect-free abrasion-resistant coating with assistance of synchronous ultrasonic shot blasting

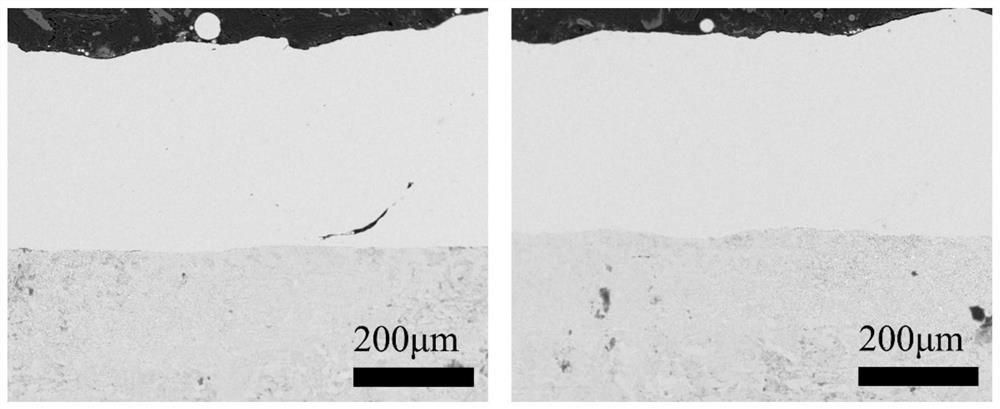

An ultrasonic shot peening and anti-corrosion technology, which is applied in coating and metal material coating processes, etc., can solve the problems of uneven strengthening effect of cladding layer, full coverage of refractory cladding layer, and unsatisfactory synchronous auxiliary strengthening effect. , to reduce defects such as cracks and pores, enhance compactness and interfacial bonding strength, and improve fatigue resistance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

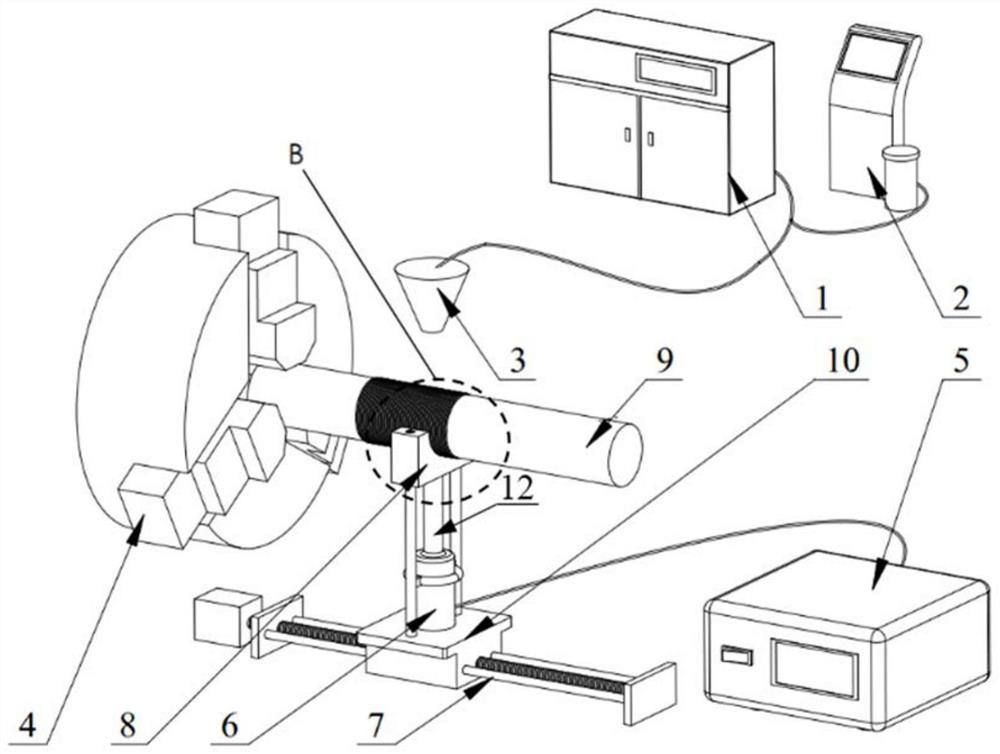

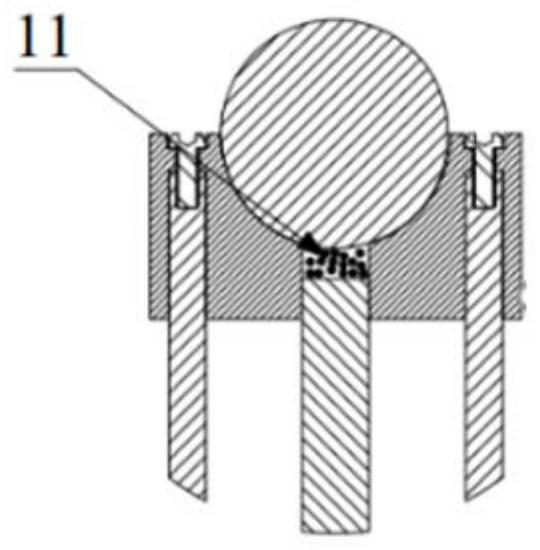

[0049] Such as Figure 1-2 As shown, a method for synchronous ultrasonic shot peening of the present invention to assist in the preparation of a defect-free and wear-resistant coating is specifically implemented according to the following steps:

[0050] First, the 45# steel substrate shaft is used as the processing shaft sample 9 to prepare a laser cladding wear-resistant coating on its surface, and the 45# steel substrate shaft sample is installed on the integrated processing platform 4 for surface cleaning and derusting Processing, using sandpaper or grinding wheel to remove rust and stains on the surface of the machining shaft sample 9;

[0051] The Stellite6 alloy powder with a particle size range of 40-150 μm is used as cladding powder and baked in a vacuum drying oven to avoid powder oxidation. The baking temperature is 120°C and the baking time is 30 minutes, and then the powder is poured into the synchronous powder feeder 2 middle;

[0052] Adjust and set the power ...

Embodiment 2

[0060] The present invention is a method for synchronous ultrasonic shot peening to assist in the preparation of a defect-free and wear-resistant coating, which is specifically implemented according to the following steps:

[0061] First, the 16Mn shaft sample is used as the processing shaft sample 9 to prepare a laser cladding wear-resistant coating on its surface, and the 16Mn shaft sample is installed on the integrated processing platform 4 for surface cleaning and derusting treatment, using sandpaper or grinding wheel Remove the rust and stains on the surface of the machining shaft sample 9;

[0062] Put 316L with a particle size range of 100-170 μm as cladding powder and bake in a vacuum drying oven to avoid powder oxidation. The baking temperature is 150°C and the baking time is 30 minutes, and then the powder is poured into the synchronous powder feeder 2 ;

[0063] Adjust and set the power of laser 1 to 1-3KW, the distance from cladding head 3 to the sample surface is...

Embodiment 3

[0070] The present invention is a method for synchronous ultrasonic shot peening to assist in the preparation of a defect-free and wear-resistant coating, which is specifically implemented according to the following steps:

[0071] First, the 45# steel substrate shaft is used as the processing shaft sample 9 to prepare a laser cladding wear-resistant coating on its surface, and the 45# steel substrate shaft sample is installed on the integrated processing platform 4 for surface cleaning and derusting Processing, using sandpaper or grinding wheel to remove rust and stains on the surface of the machining shaft sample 9;

[0072] Put the Ni60 alloy powder with a particle size of 10-60 μm as cladding powder in a vacuum drying oven to avoid powder oxidation. The baking temperature is 150°C and the baking time is 40 minutes, and then the powder is poured into the synchronous powder feeder 2 middle;

[0073] Adjust and set the power of laser 1 to 4KW, the distance from cladding head...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com