Hydraulic oil inner circulation type fixed mold plate casting technology of injection molding machine

A casting process and fixed template technology, which is applied in the field of injection molding machine hydraulic oil internal circulation fixed template casting technology, which can solve the problems of poor surface quality, many pore defects, and poor cleanliness of the inner wall of the embedded steel pipe in the hydraulic oil internal circulation fixed template. , to achieve the effect of improving smoothness, increasing density and reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

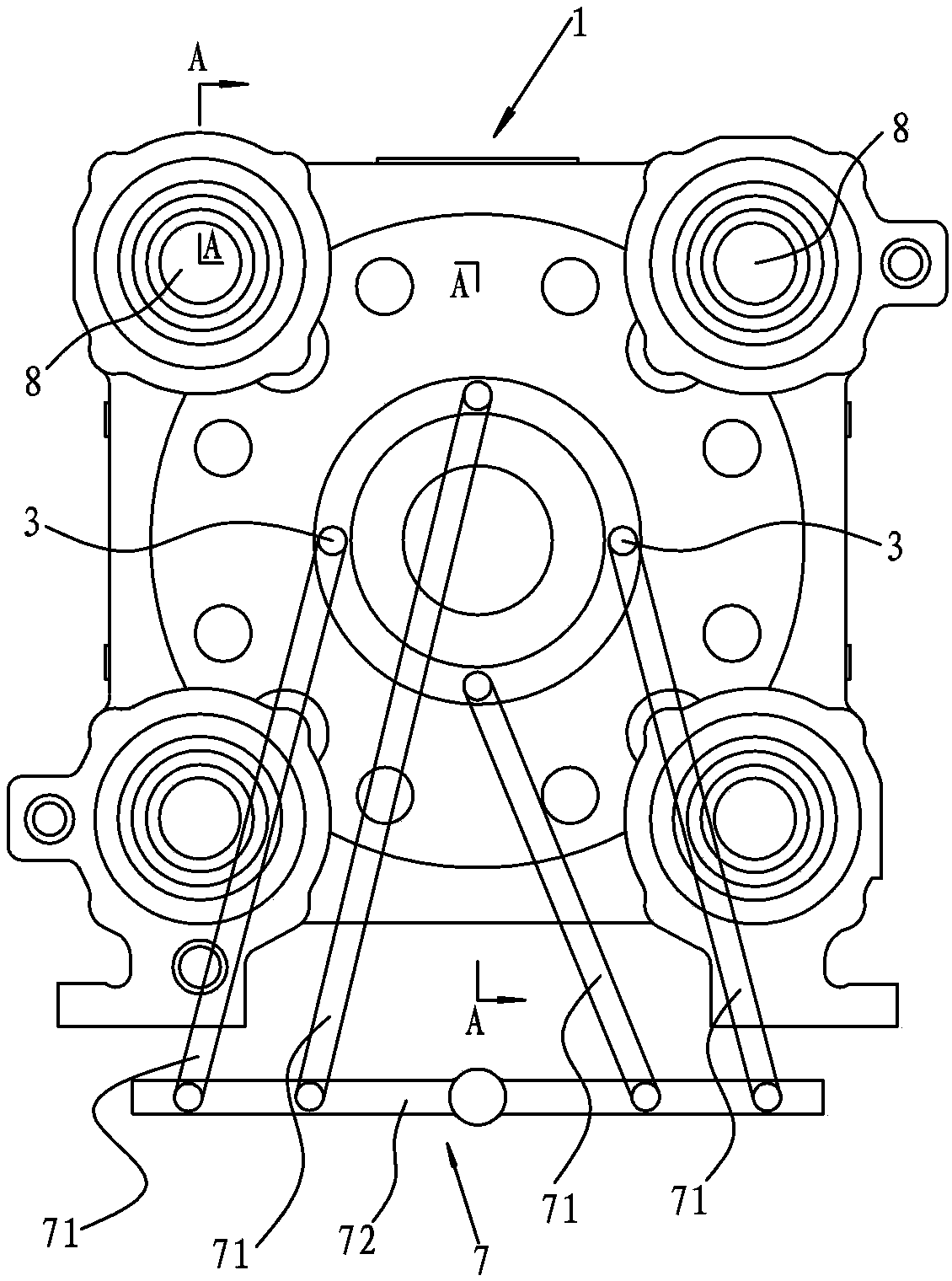

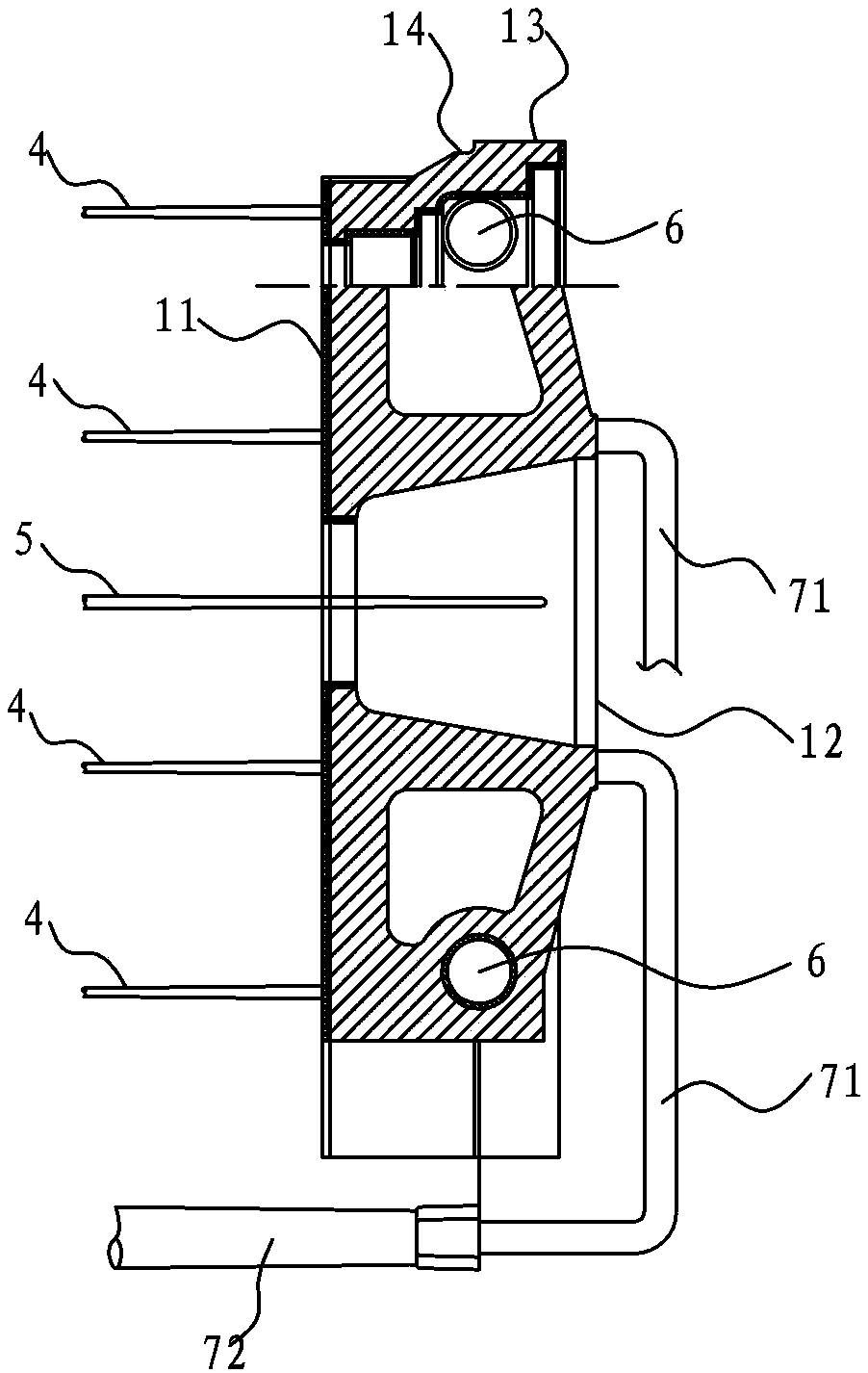

[0021] refer to figure 1 with figure 2 . The injection molding machine hydraulic oil internal circulation fixed template casting process of the present invention comprises the following steps:

[0022] a. Make the mold of the fixed formwork 1, adopt three-box shape, the three-box shape includes the upper box, the middle box and the lower box, the parting surface of the upper box and the middle box is located on the mold installation surface 11 of the fixed template, the lower box and the middle box The parting surface is located at the junction of the first side 13 and the second side 14 of the fixed template 1;

[0023] b. Pre-embed steel pipes in the upper and middle boxes, and the steel pipes correspond to the hydraulic oil passage 6 in the fixed formwork 1;

[0024] c. Set the position of the gate 3 on the lower box of step b. There are four gates 3, and they are evenly distributed around the center of the bottom surface 12 of the fixed formwork 1. The distance between...

Embodiment 2

[0033] The injection molding machine hydraulic oil internal circulation type fixed template casting process in this embodiment is basically the same as the casting process in Example 1, the difference is that in the pouring molding process, the pouring temperature is 1350°C, the pouring time is 33s, and the pouring time is 60s. The effect achieved by this embodiment is the same as that achieved by Embodiment 1.

Embodiment 3

[0035] The injection molding machine hydraulic oil internal circulation fixed template casting process of this embodiment is basically the same as the casting process of Example 1, the difference is that in the pouring molding process, the pouring temperature is 1335°C, the pouring time is 36s, and the pouring time is 55s. The effect achieved by this embodiment is the same as that achieved by Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com