Method for preparing metal ceramic coating material with plasma/combustion synthesis/quasistatic pressing process

A metal-ceramic coating, self-propagating high temperature technology, applied in coating, metal material coating process, fusion spraying and other directions, can solve the problems of short service life, poor bonding strength, low fatigue strength, etc. Cost, meeting the requirements of use, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

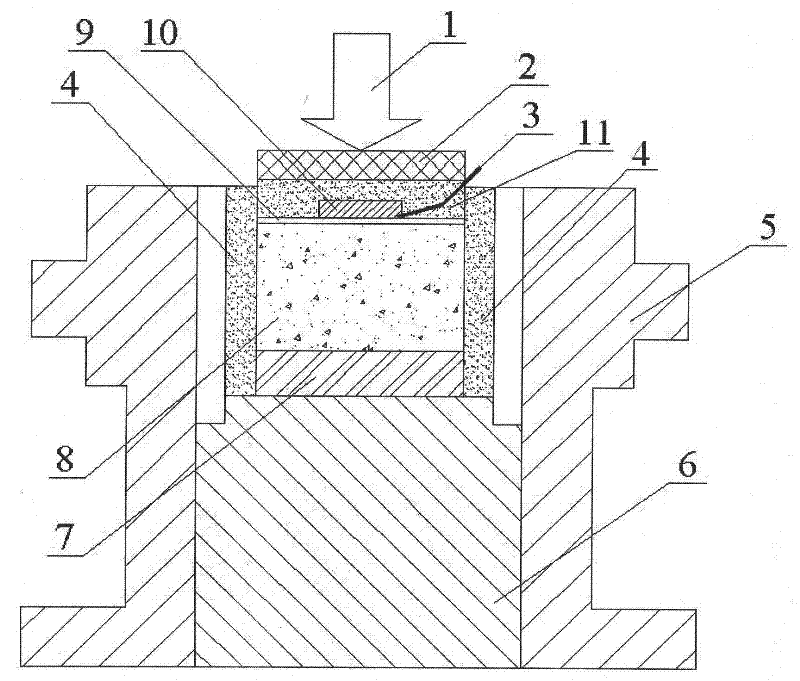

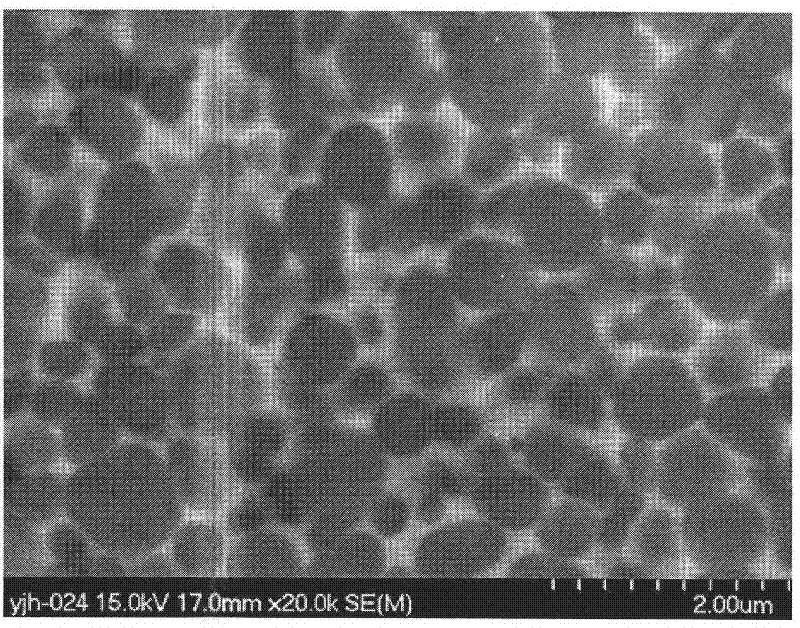

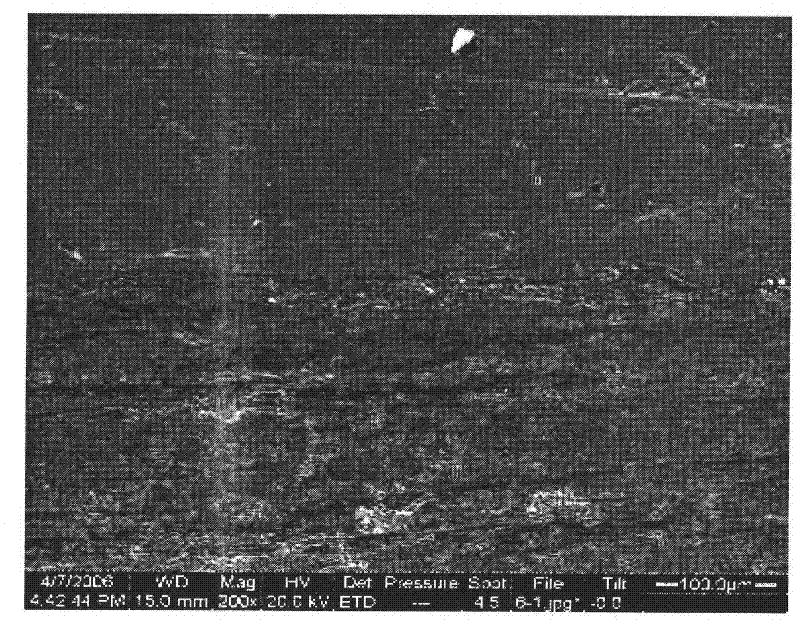

[0012] Specific embodiment one: the method for preparing the cermet coating material by plasma / self-propagating high-temperature synthesis / quasi-hot isostatic pressing process in this embodiment is carried out according to the following steps: 1. Weigh 48 ~64 parts of titanium powder, 20~40 parts of iron powder and 12~16 parts of carbon powder are mixed to obtain a mixture; 2. Put the mixture described in step 1 into a ball mill tank, and adopt the method of dry mixing or wet mixing Mix and dry to obtain a mixed powder; 3. Put the mixed powder obtained in step 2 into a stainless steel mold, and press it into a preform with a relative density of 50% to 60% (volume); 4. Put the metal substrate in acetone Ultrasonic cleaning, then sandblasting and roughening with 16-40 mesh brown corundum, and then plasma spraying NiCrBSi on the surface of the metal substrate, wherein the metal substrate is a steel plate; 5. Put the preform obtained in step 4 on the sprayed NiCrBSi metal substrate...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, 64 parts of titanium powder, 20 parts of iron powder and 16 parts of carbon powder are weighed in the first step. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, 56 parts of titanium powder, 30 parts of iron powder and 14 parts of carbon powder are respectively weighed according to the ratio of parts by weight. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com