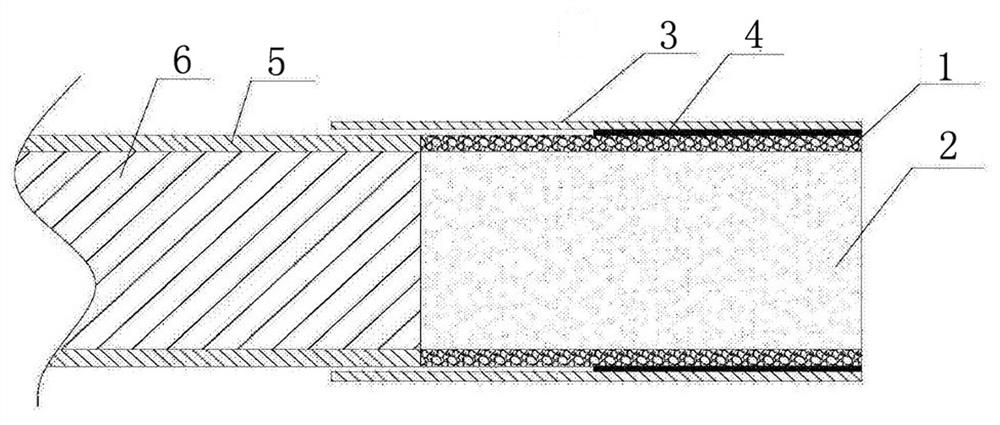

A detection method for conformity rate of cigarette glue-free area based on image detection method

A technology of image detection and detection method, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of lack of information on perforated cigarettes, and achieve the effects of accurate and reliable measurement results, improved detection efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

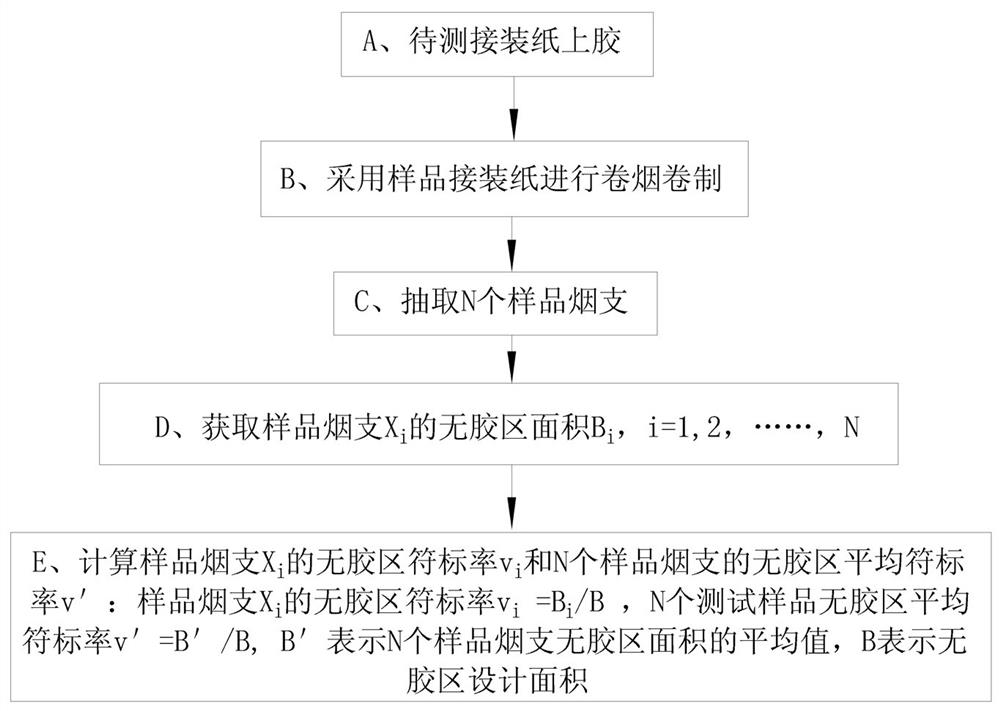

[0049] Such as figure 2 Shown, the present invention comprises the following steps:

[0050] A. Sample tipping paper gluing: the specific process is:

[0051] a1: Select sample tipping paper, the color of the glued side of the selected sample tipping paper is different from the color of the tipping glue in the dry state;

[0052] a2: Under the normal production conditions of the glue applicator, apply the tipping glue on the glued surface of the sample tipping paper;

[0053] B. Cigarette rolling with sample tipping paper: roll under the normal production conditions of the cigarette machine and tipping machine, and then use the glued sample tipping paper to overlap to obtain a cigarette sample;

[0054] C. Take N sample cigarettes: after the speed of the cigarette making machine is stable, take N cigarettes from the cigarette samples produced in step B as sample cigarettes;

[0055] D. Obtain sample cigarettes X i The glue-free zone area B i , i=1,2,...,N; sample cigaret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com