Fringe field switching mode liquid crystal display and manufacturing method thereof

A liquid crystal display, fringe field switching technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve a lot of problems such as development cost and time

Active Publication Date: 2010-12-08

HYDIS TECH

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In other words, it requires a lot of development cost and time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

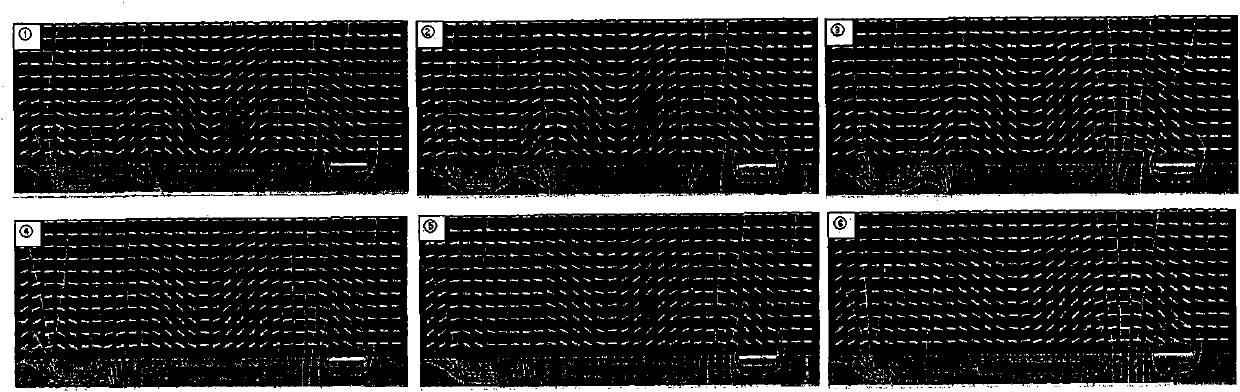

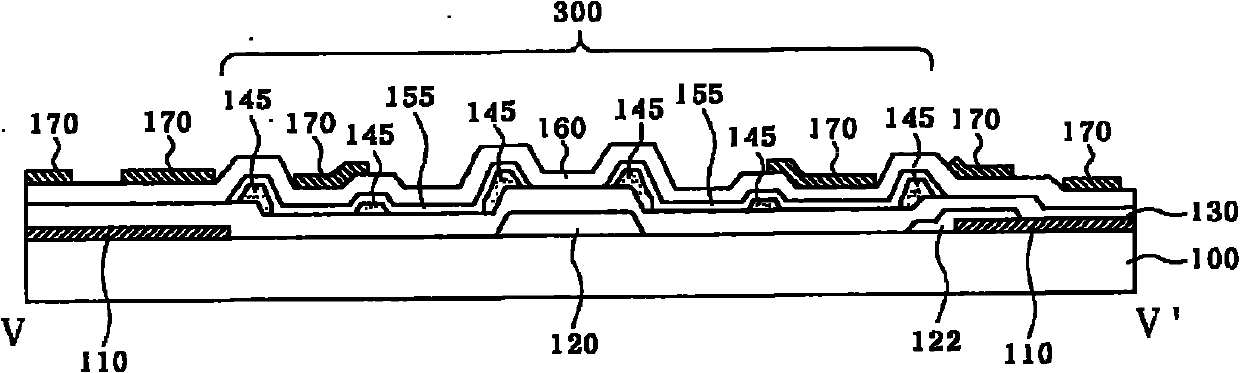

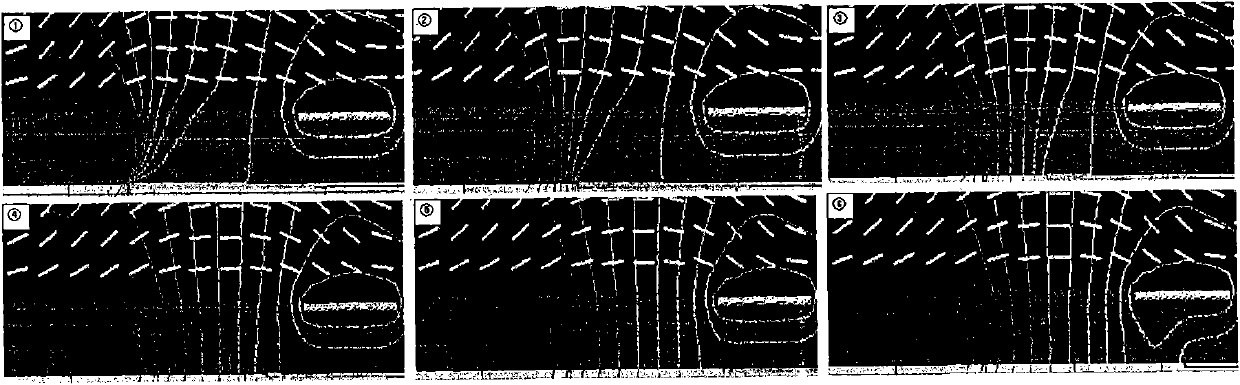

Provided is a fringe field switching mode liquid crystal display and manufacturing method thereof. The fringe field switching mode liquid crystal display device includes a lower substrate, an upper substrate, and a liquid crystal layer inserted between the lower substrate and the upper substrate, wherein the select line and the data line are mutually intersected, a pixel region is limited on the lower substrate, a switching device is provided at the intersecting part between the select line and the data line. The fringing field switching mode liquid crystal display device includes a transparent common electrode having a predetermined shape and formed within the pixel area to adjust light transmittance by applying a voltage to the liquid crystal layer, and a transparent pixel electrode having a plurality of slits and formed above the transparent common electrode with an insulating layer interposed between the transparent common electrode and the transparent pixel electrode. A rubbing direction for aligning the liquid crystal layer is within 5 DEG with respect to a direction of the gate line to remove a light shielding region above the data line, one end of the transparent common electrode is arranged between the data line and the transparent pixel electrode. A reflector is manufactured in an electrically independent type by using the material identical to that of the data line.

Description

This application is a divisional application of an invention patent application with an application date of January 29, 2008, an application number of 200810009150.3, and an invention title of "Fringe Field Switching Mode Liquid Crystal Display and Manufacturing Method". technical field The present invention relates to a fringe field switching (FFS) mode liquid crystal display and a manufacturing method thereof, wherein an aperture ratio is improved to reduce power consumption and internal reflection is increased to enhance outdoor clarity. Background technique A fringe field switching (FFS) mode liquid crystal display (LCD) has been proposed to improve the low aperture and transmittance of an in-plane switching (IPS) mode LCD. In FFS mode LCD, common electrode and pixel electrode are made of transparent conductive layer such as Indium Tin Oxide (ITO), so compared with IPS mode LCD, its aperture ratio and transmittance are improved, and between common electrode and A frin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02F1/1335G02F1/1343G02F1/1337G02F1/1333G02F1/1362

Inventor 崔硕白承埈张顺株申暎濬朴光玄李哲焕金香律全台贤

Owner HYDIS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com