Improved seal for side walls of electrostatic chuck

A technology of electrostatic adsorption and sealing parts, which is applied to the sealing of engines, electrical components, circuits, etc., can solve problems such as uneven distribution of tensile stress, uneven product qualification rate, failure of O-ring 140, etc., and achieve stable product qualification rate , Etching process safety, and the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

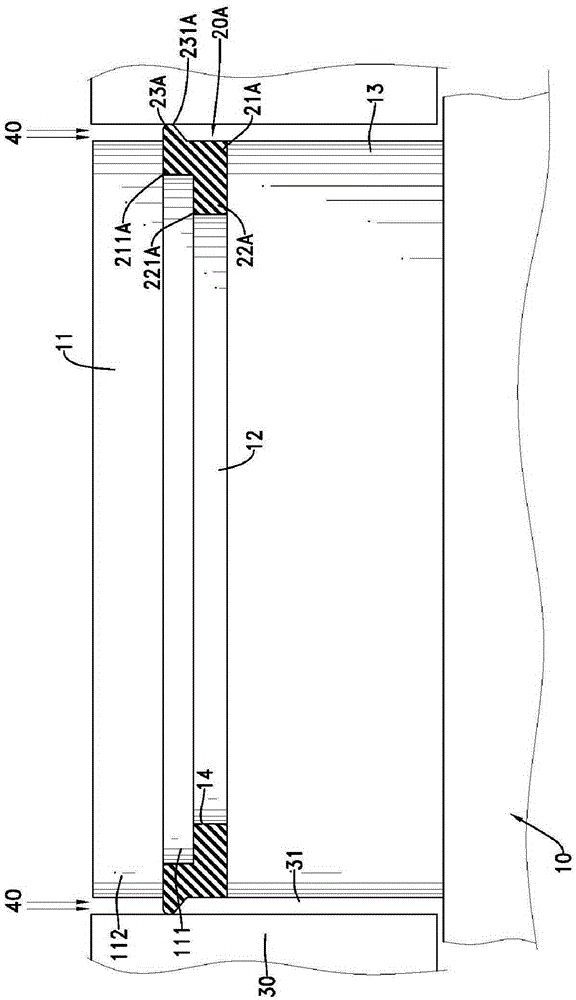

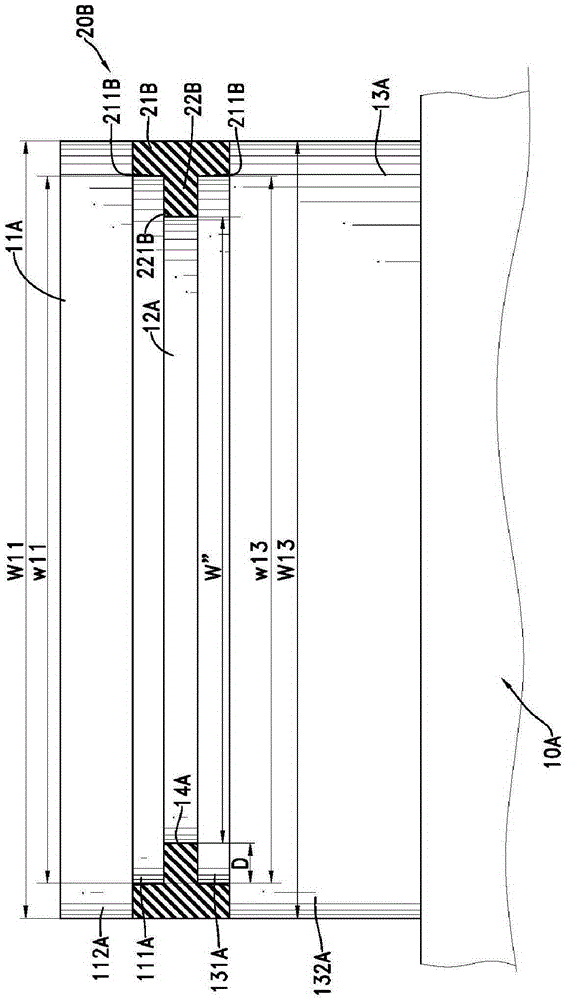

[0052] In the following, please cooperate with the accompanying drawings and preferred embodiments of the present invention to further elaborate the technical means adopted by the present invention to achieve the intended purpose of the invention.

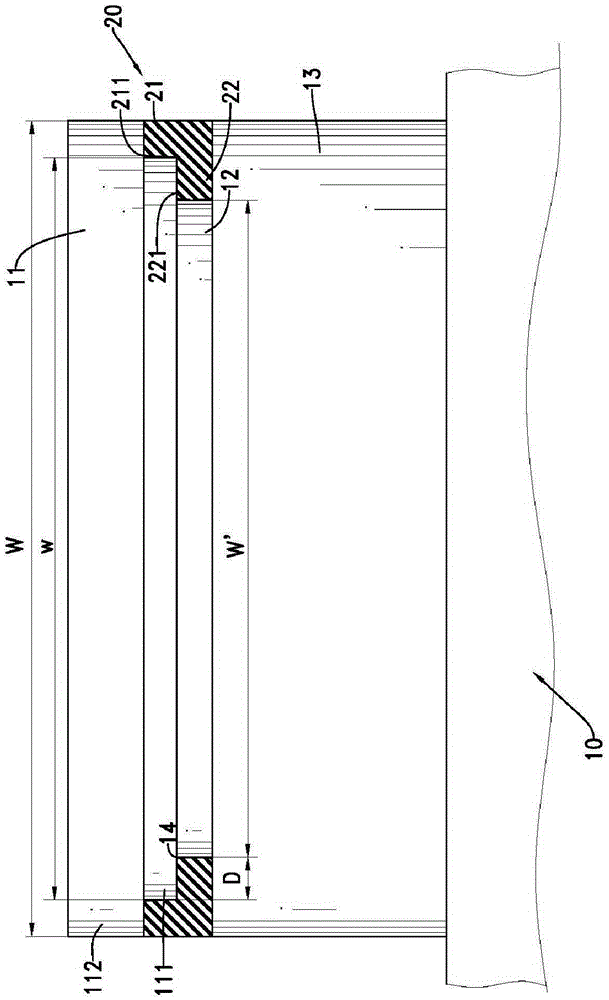

[0053] The improved seal for the side wall of the electrostatic adsorption chuck of the present invention is used on the side wall of the electrostatic adsorption chuck 10, wherein the electrostatic adsorption chuck 10 includes an upper member 11, a bonding layer 12 and a lower member 13, the upper The cross-sectional width w of the bottom 111 of the element 11 is smaller than the cross-sectional width W of the top 112, and the connecting layer 12 connects the bottom 111 of the upper element 11 and the lower element 13, and a groove 14 is formed on the side outer edge of the connecting layer 12, so The groove 14 is formed between the upper element 11 and the lower element 13 .

[0054] Before the improved seal of the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com