Polishing device easy to clean and capable of adapting to pipeline openings of different sizes

A technology adaptable to different pipe openings, applied in grinding/polishing safety devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., it can solve the problem of debris and dust easily entering the inner wall of the pipe, unfavorable cleaning, and low quality of pipe grinding And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

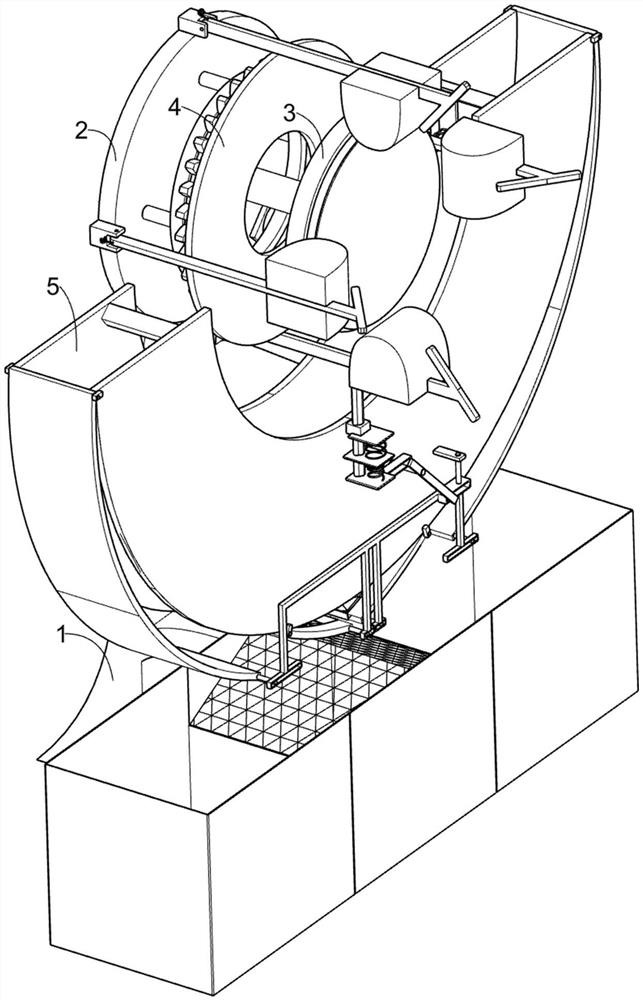

[0025] A pipe mouth grinding device that is easy to clean and can be adapted to different sizes, such as Figure 1-7 As shown, it includes a first support frame 1, an anti-deviation assembly 2, a sealing assembly 3 and a friction assembly 4. The first support frame 1 is provided with an anti-deviation assembly 2 for preventing pipeline deviation, and the sealing assembly 3 is located on On the anti-deviation assembly 2 , the friction assembly 4 for grinding the pipe mouth is also arranged on the anti-deviation assembly 2 .

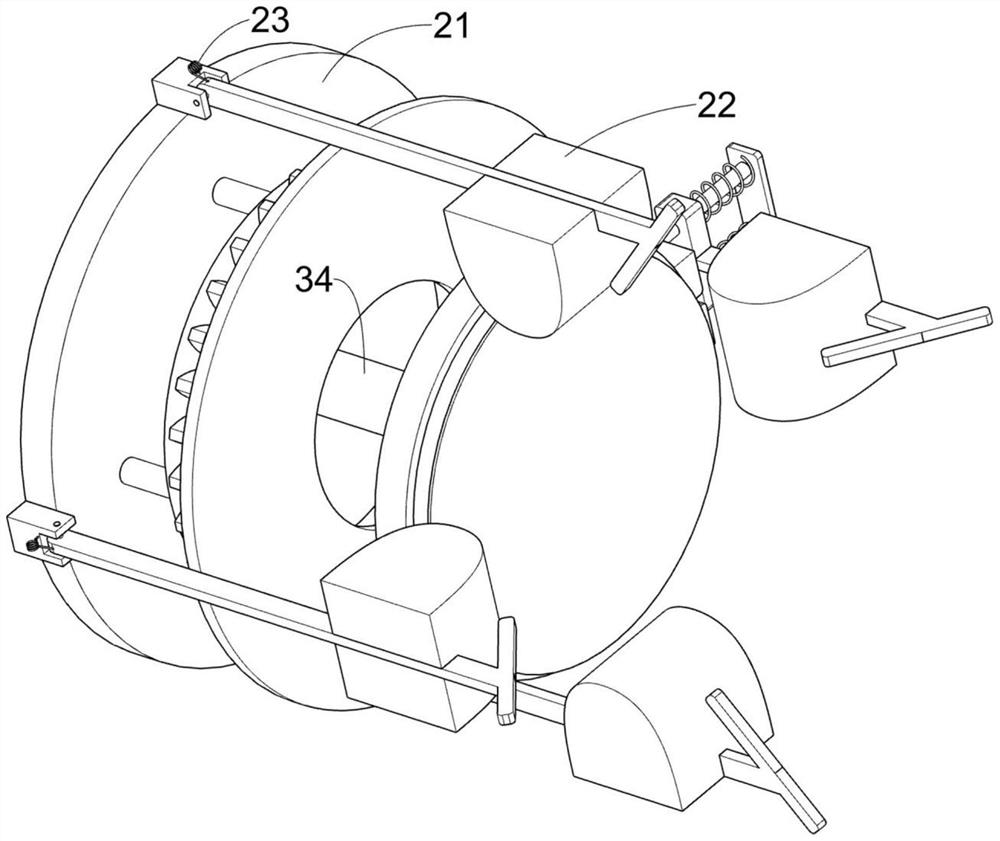

[0026] The anti-deflection assembly 2 includes a support plate 21, a clamping frame 22, a first torsion spring 23, a wedge frame 24, a first spring 25, a turret 26, a second torsion spring 261, a sliding bar 27 and a slotted sliding frame 28 , a support plate 21 is fixedly installed on the first support frame 1, and a clamping frame 22 is hinged on the support plate 21 in a centrally scattered manner, and the clamping frame 22 is used to clamp the outer wa...

Embodiment 2

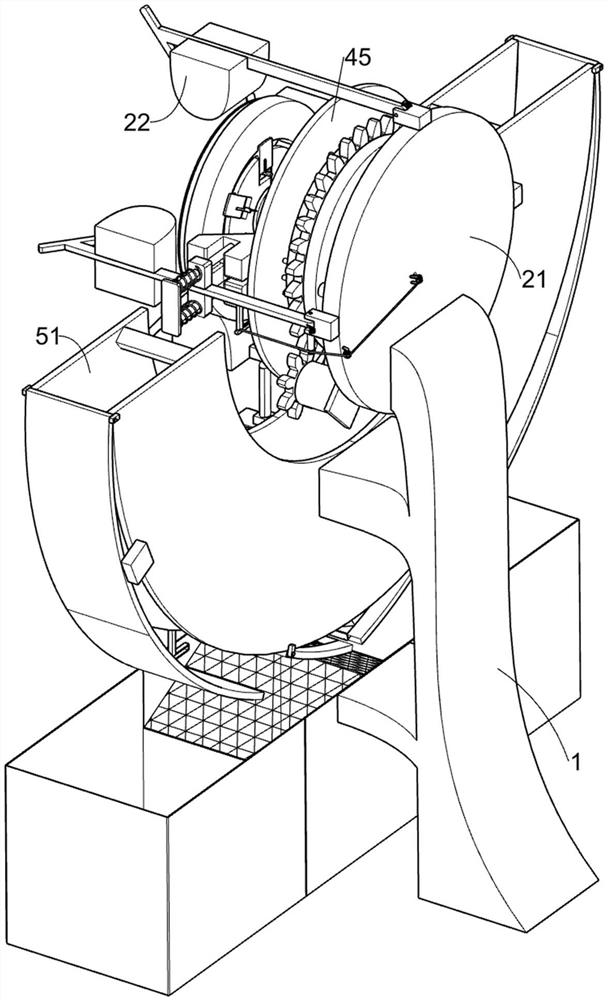

[0032] On the basis of Example 1, such as Figure 8-9 As shown, it also includes a debris recovery assembly 5, the debris recovery assembly 5 is located on the first support frame 1, the debris recovery assembly 5 is used to recover debris, and the debris recovery assembly 5 includes a support frame 51, a swing arc Shaped plate 52, swinging sieve plate 53, push frame 54, fourth spring 55, slotted plate 56, fifth spring 57, slotted frame 58, swing frame 59, limit post 510, collection frame 511 and fixed sieve plate 512 , the support frame 51 is fixedly installed on the first support frame 1, the swing arc plate 52 is connected symmetrically and rotationally above the support frame 51, and the swinging sieve plate 53 is connected symmetrically and rotationally below the support frame 51, and the swinging sieve plate 53 is used for The debris is screened, and the push frame 54 is connected to the support frame 51 in a liftable manner. The push frame 54 contacts with a clamp frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com