Oil slick collecting ship

A technology for oil slicks and oil slicks on water surfaces, which can be used in general water supply conservation, cleaning of open water surfaces, water conservancy projects, etc., and can solve problems such as low work efficiency, high difficulty, and difficulty in recovering oil slicks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

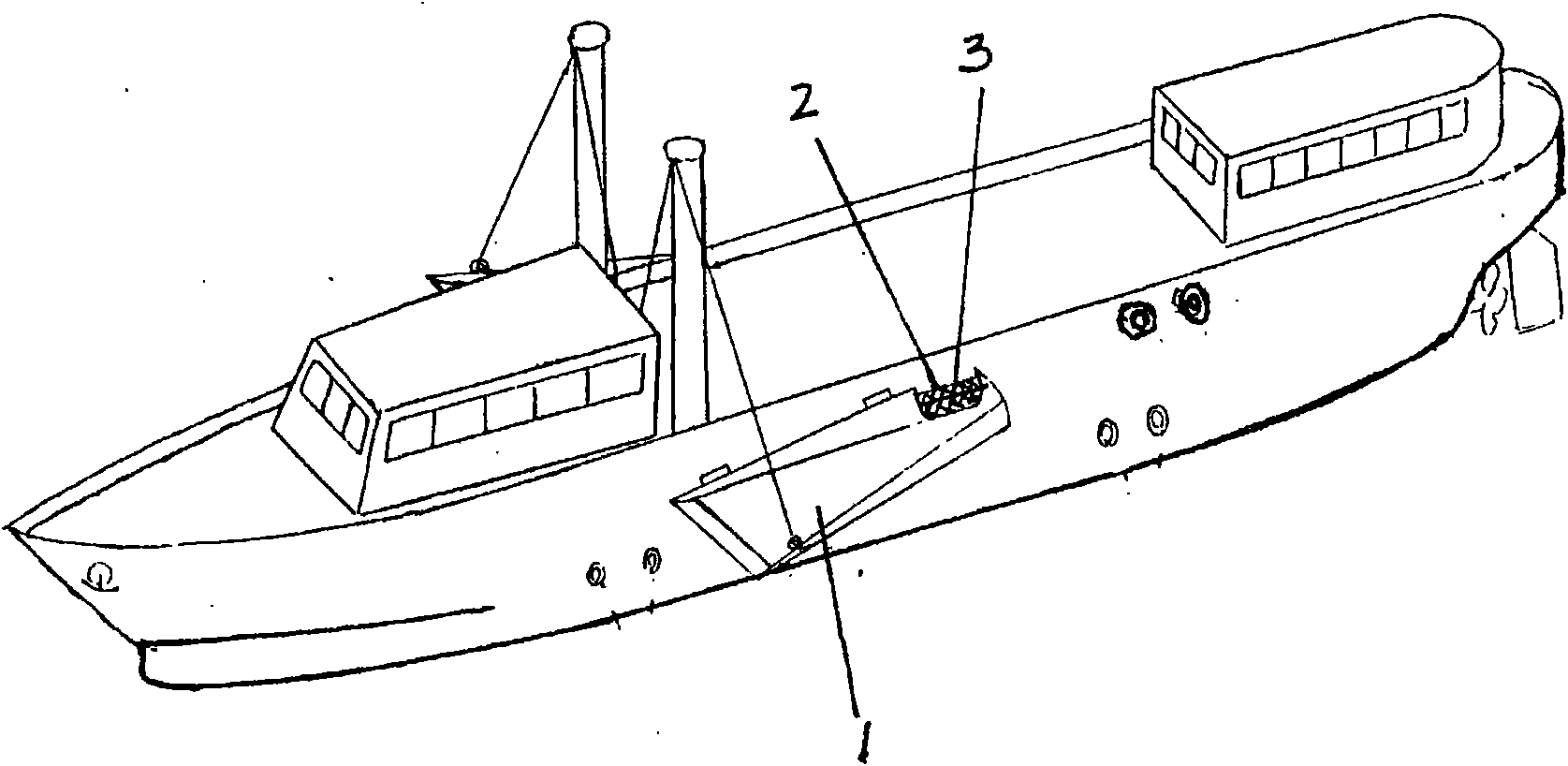

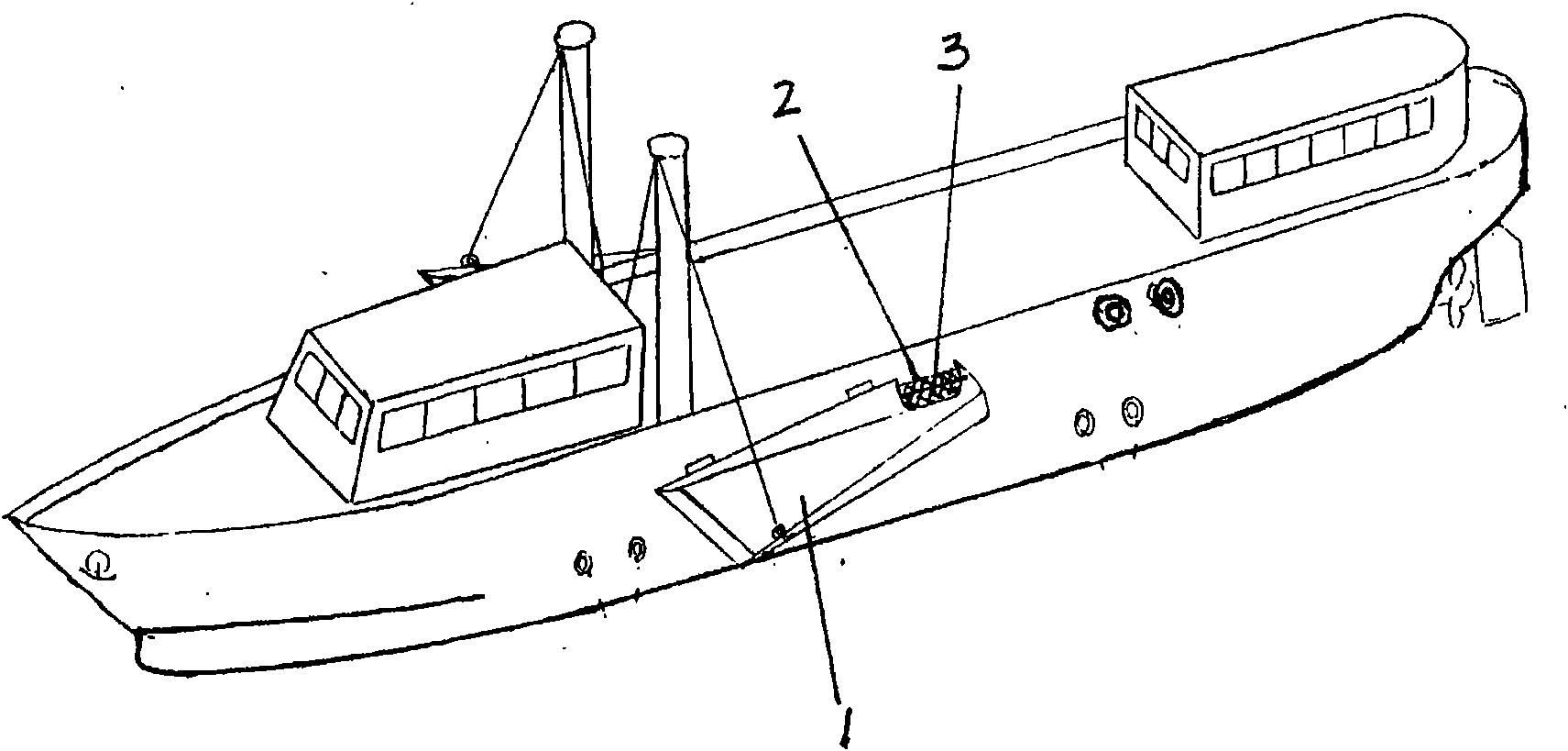

[0007] Such as figure 1 The shown oil slick collection ship has an oil slick collection tank, and its unique feature is that a dustpan-shaped oil-flicker 1 is provided on both sides of the ship's side. The rear end of the oil-slicker 1 communicates with the oil inlet 2 of the oil slick collection tank. The front end of the oil whipping plate 1 faces the bow and is inclined downward so that the bottom plane of the oil whipping plate forms an angle of 7-10 degrees with the horizontal plane.

[0008] At the working site, adjust the draft of the ship so that the front end of the oil-flicking plate is submerged 50-100 mm below the water surface, and the specific data depends on the thickness of the oil slick. As the hull moves forward, the oil slick plate pushes the oil slick surface to rise, and the slick oil surges upward along the oil slick plate, and flows into the oil slick collection compartment through the oil inlet. During the operation, the ballast is adjusted in good tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com