Method and system for realizing zero emission of papermaking pulp residue and sludge

A papermaking pulp and zero-emission technology, applied in the field of papermaking, can solve problems such as environmental pollution, environmental pollution, and increased processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

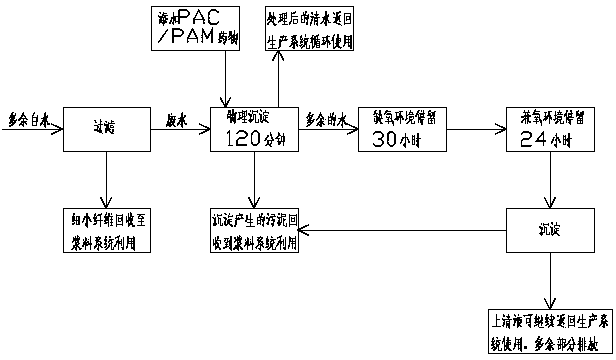

[0013] like figure 1 A method for zero discharge of papermaking pulp residue and sludge is shown: firstly filter the excess white water, recycle the fine fibers in it to the slurry system for utilization, and then use the physical precipitation method for the remaining wastewater, and add PAC and PAM Drugs, settling for 120 minutes to achieve solid-liquid separation, the sludge generated by settling is collected to the slurry system for recycling, the clear water after physical and chemical treatment is returned to the production system for closed cycle use, and the excess water is pumped to the biochemical system for use in anoxic and concurrently Aerobic microbial hydrolysis for further biochemical treatment, in which it stays in an anoxic environment for 30 hours, then transports it to a facultative environment for 24 hours, and then settles, and the sludge generated by the sedimentation is still collected in the slurry system for recycling. The treated supernatant can cont...

Embodiment 2

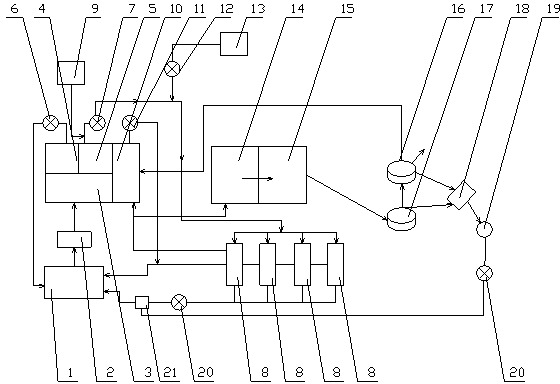

[0015] like figure 2 A papermaking pulp residue and sludge zero discharge system is shown: after the excess white water in the pulping and papermaking workshop 1 removes coarse plastic sheets and impurities through the grid machine 2, it enters the inclined screen 3 for filtration, and the fine fibers in the white water are separated to Sludge recovery pool 4 is transported to pulp and paper workshop 1 by pulp pump 6, and the remaining waste water flows into sump 5, and is transported to four high-efficiency purification towers with a height of 18 meters and a diameter of 16 meters by a waste water lifting pump 7 Coagulation and sedimentation are carried out in 8, at the same time, the medicinal liquid in the PAC dispensing pool 9 is transported to the sewage high-efficiency purification tower 8 through the waste water lifting pump 7, and the medicinal liquid in the PAM dispensing pool 13 is transported to the high-efficiency purification tower 8 through the dosing pump 12. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com