Patents

Literature

34results about How to "Improve sand mixing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

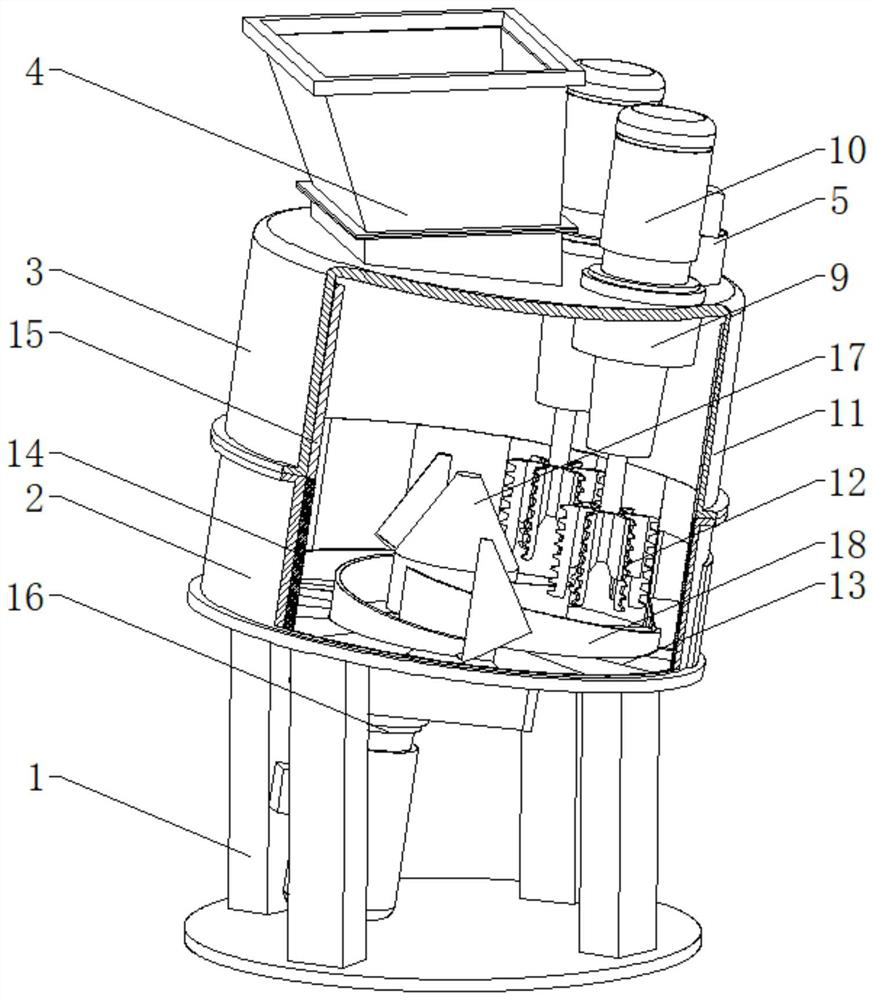

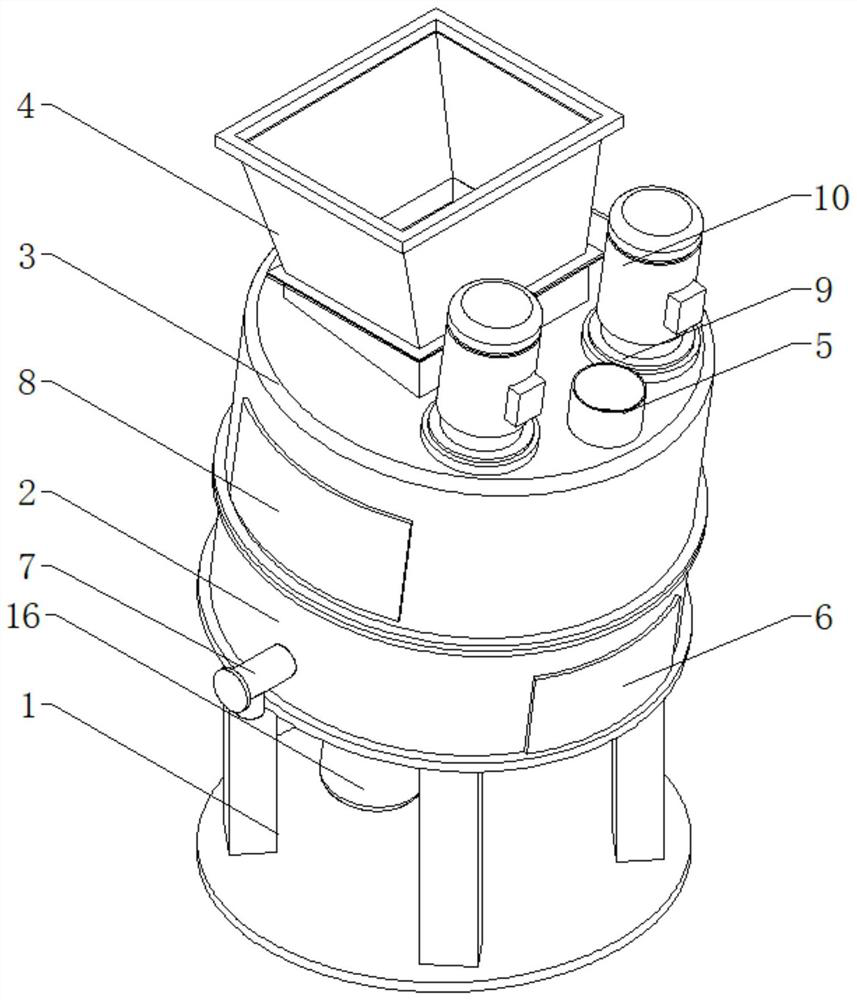

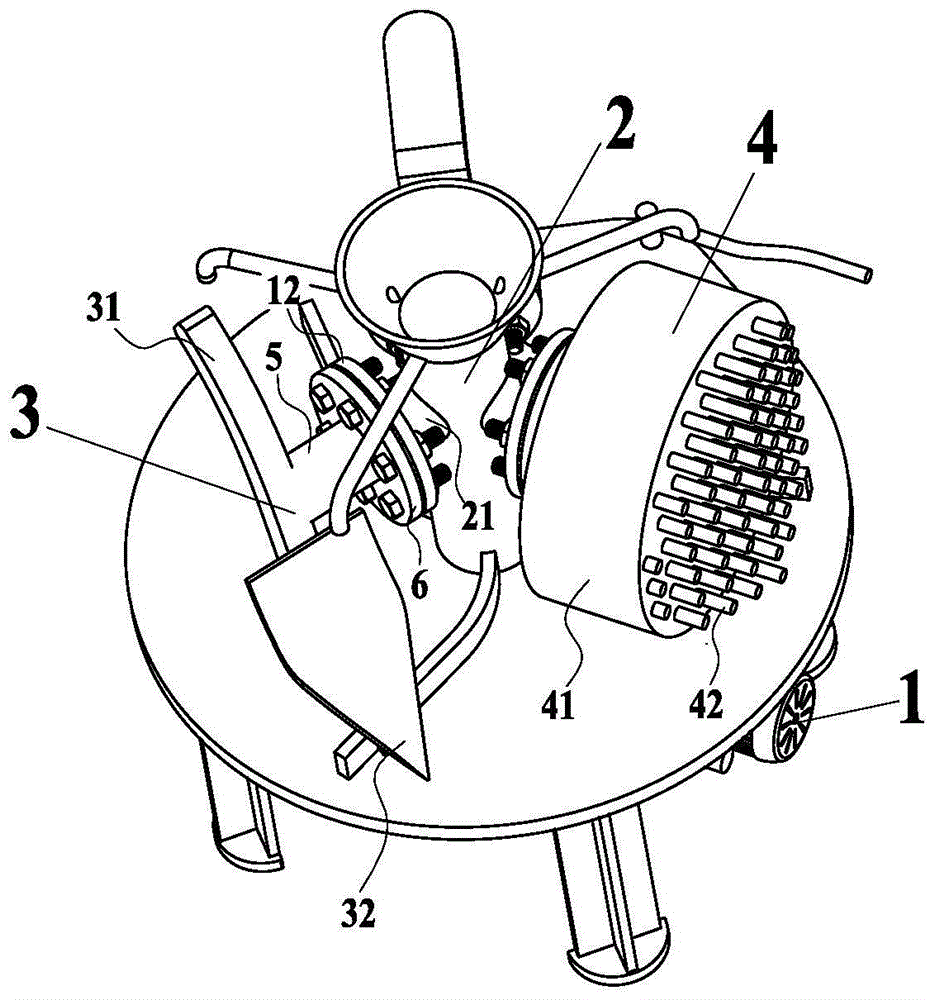

Sand mixing equipment

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

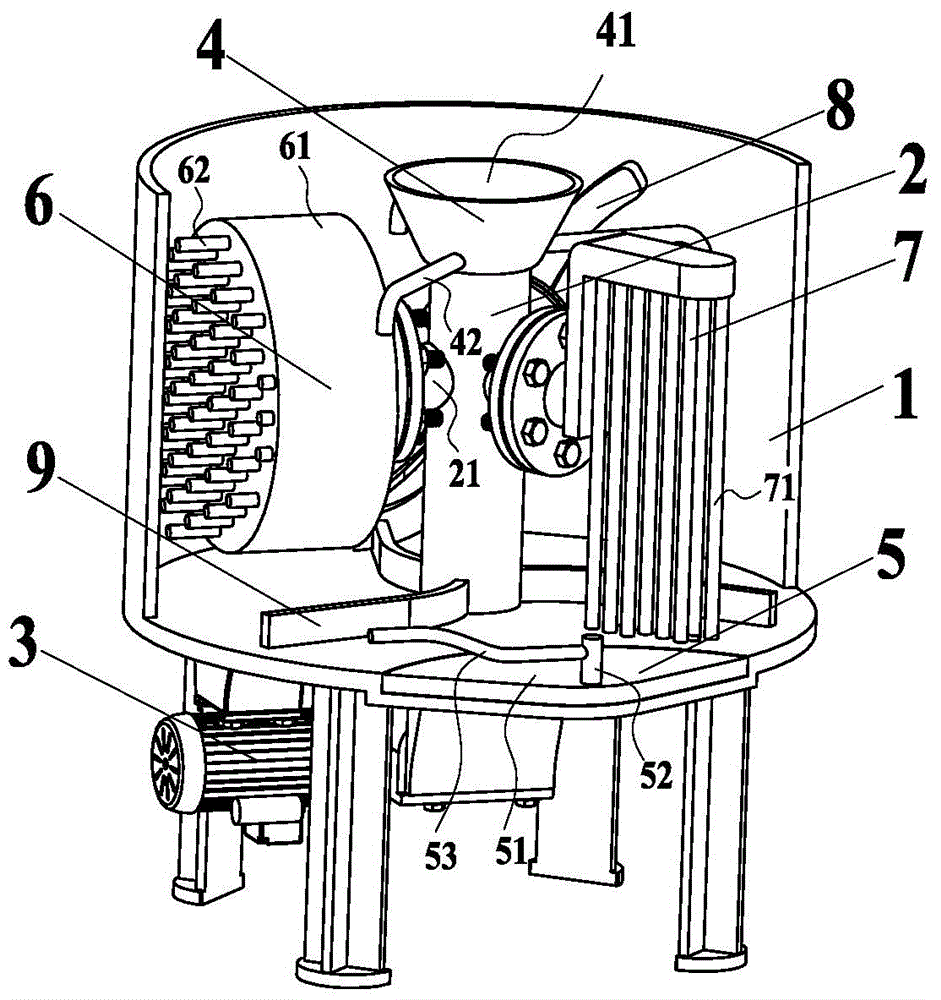

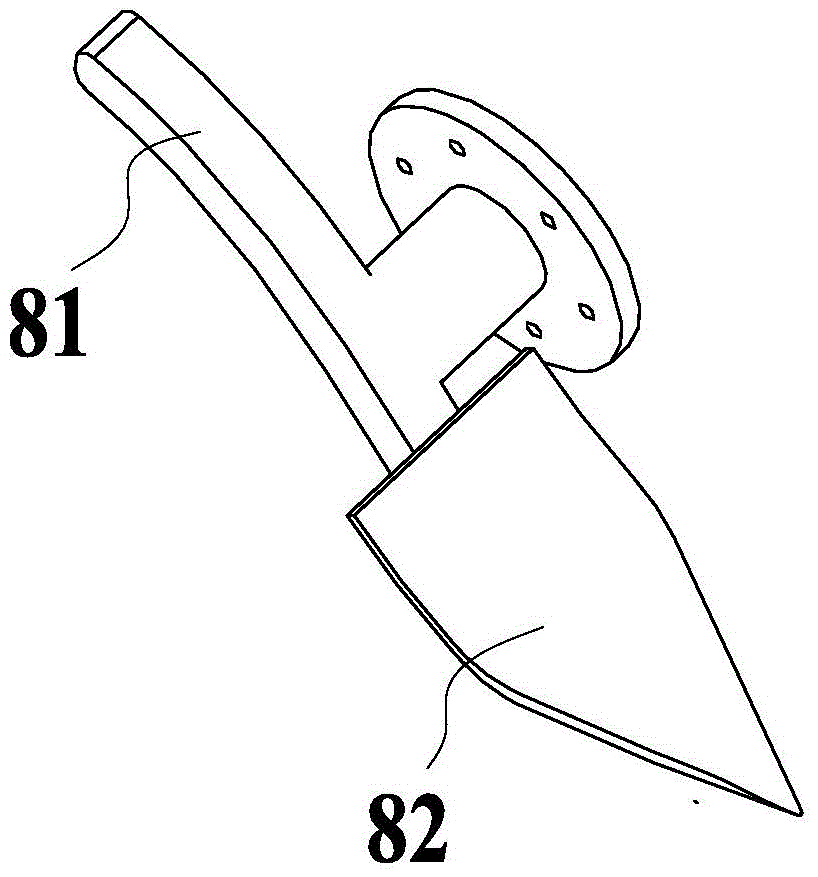

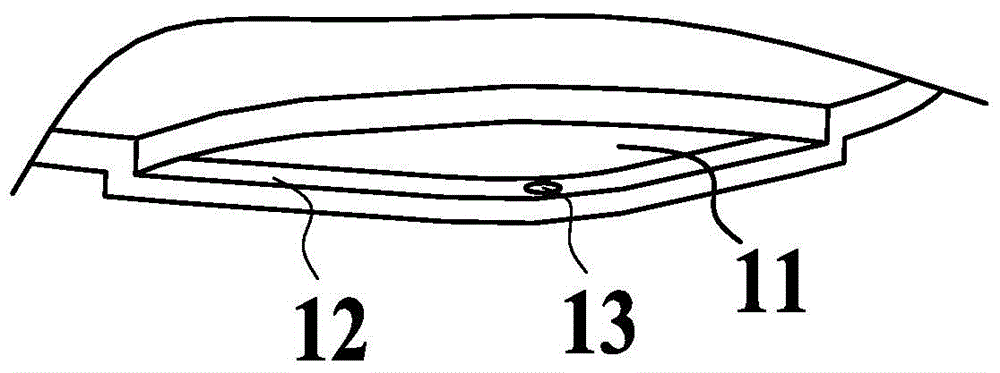

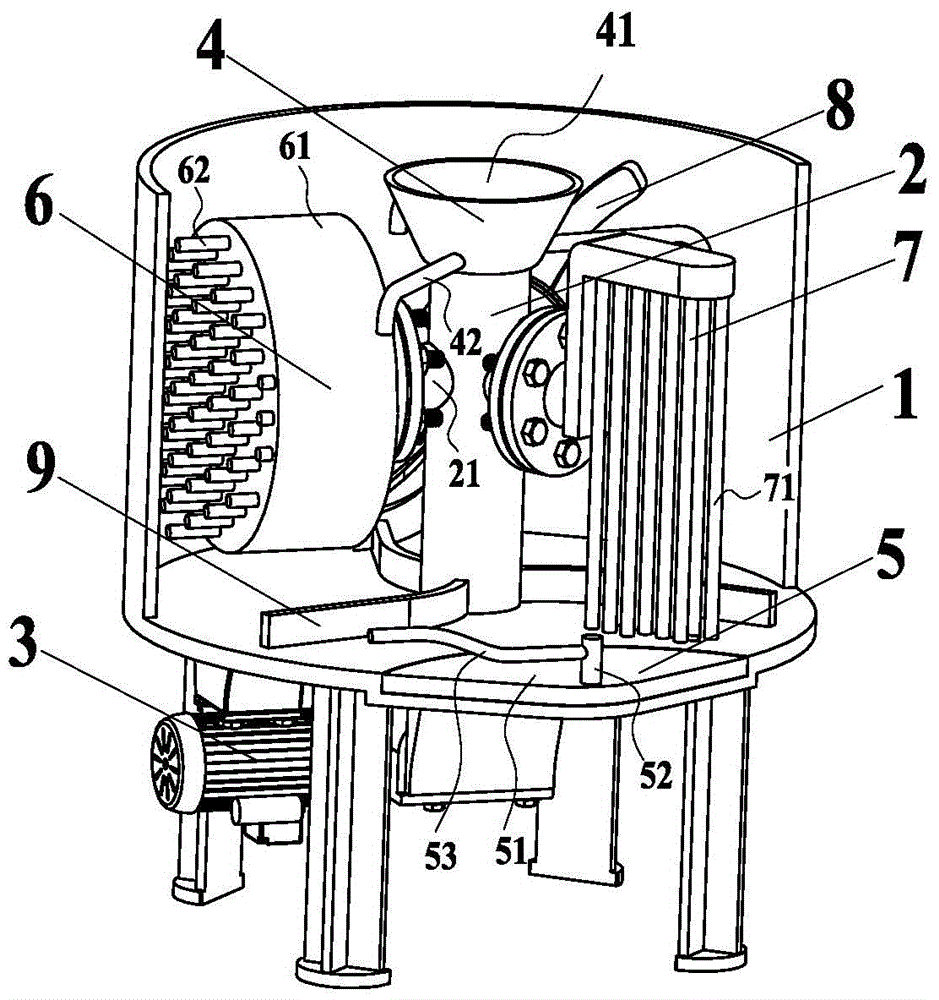

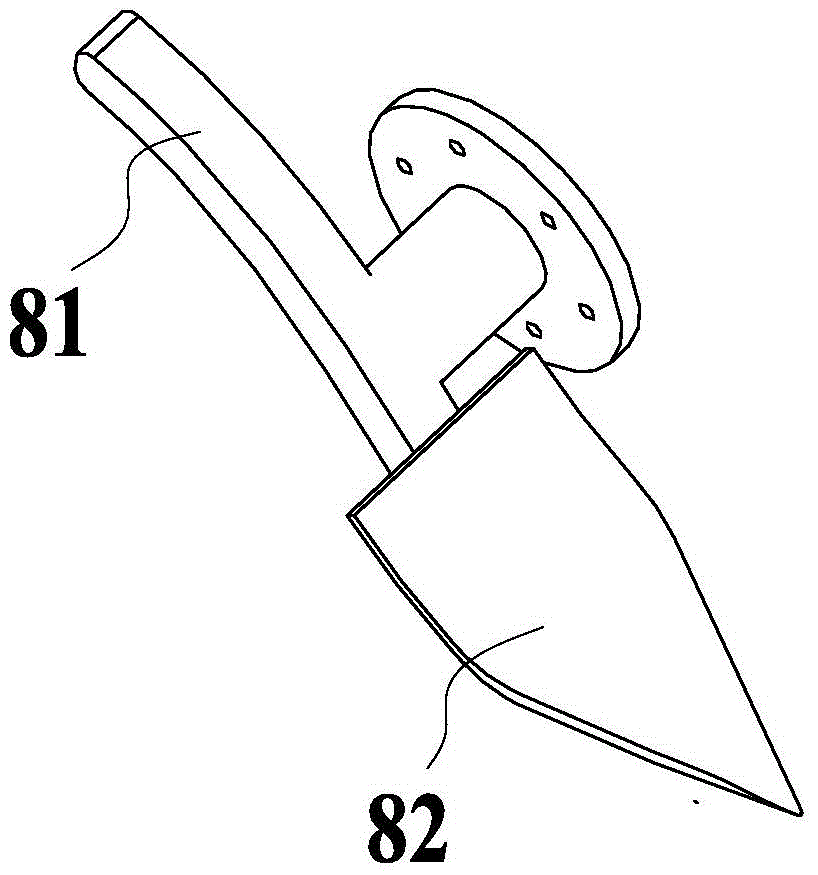

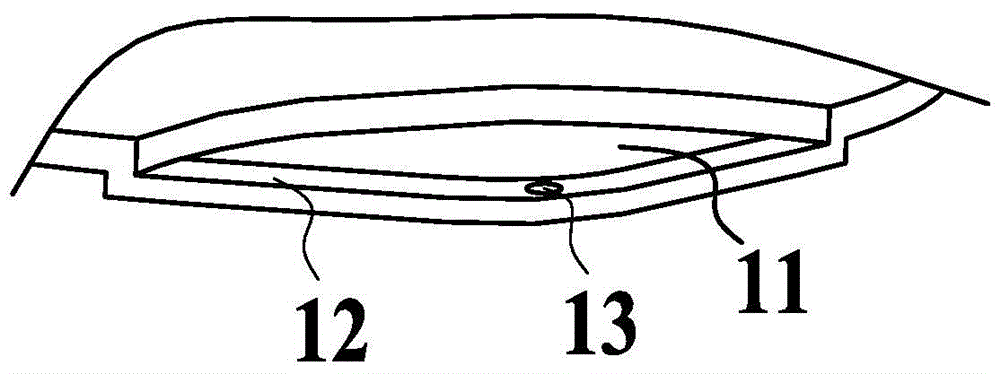

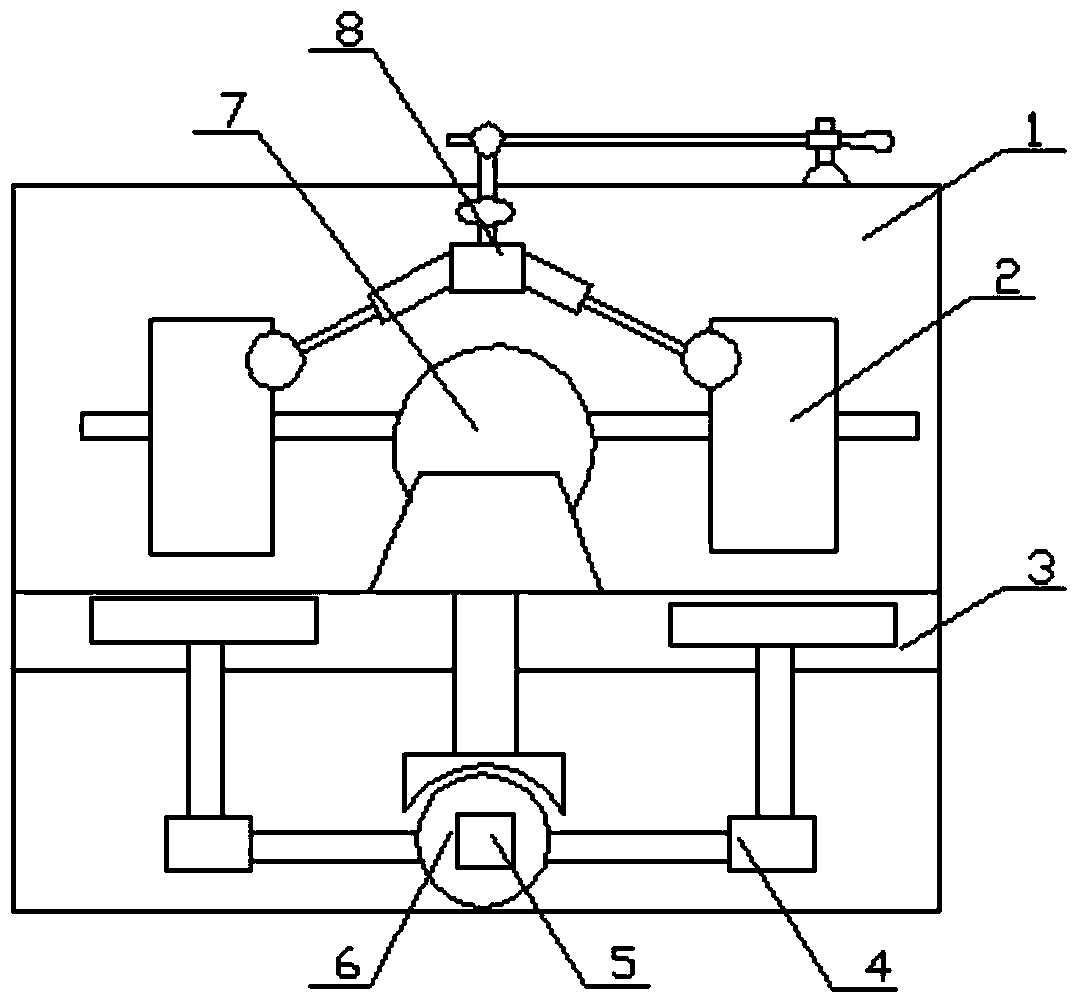

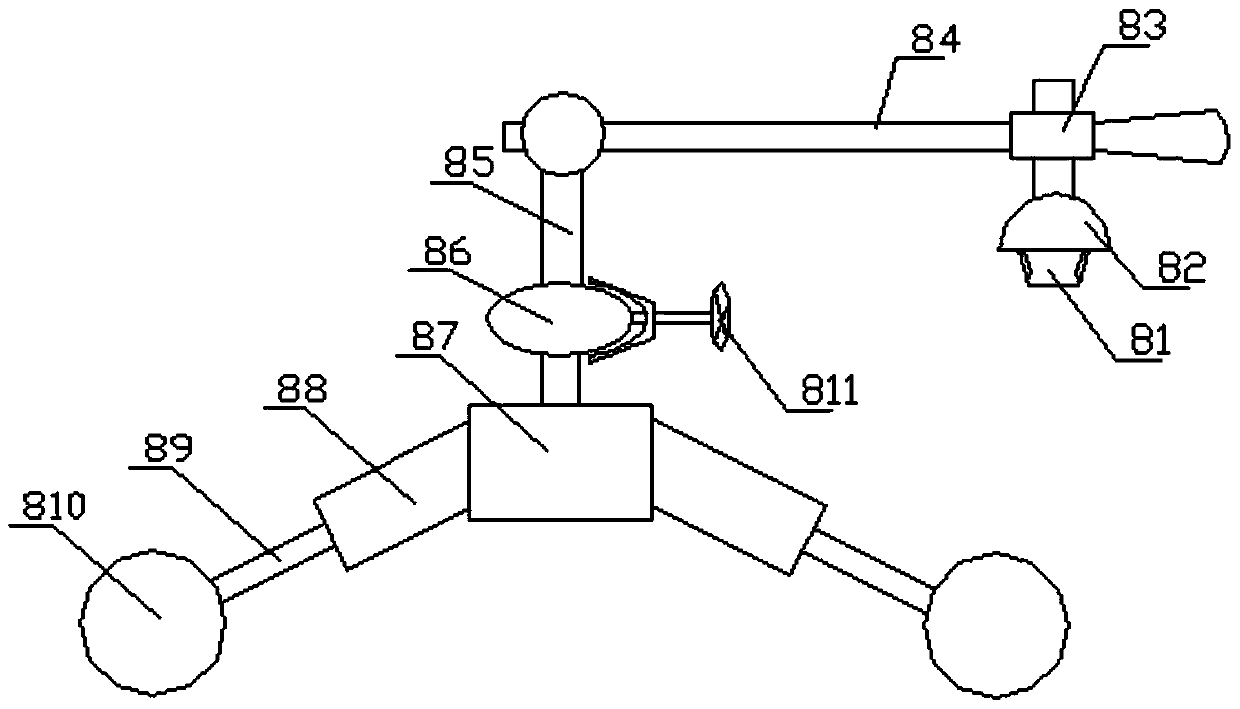

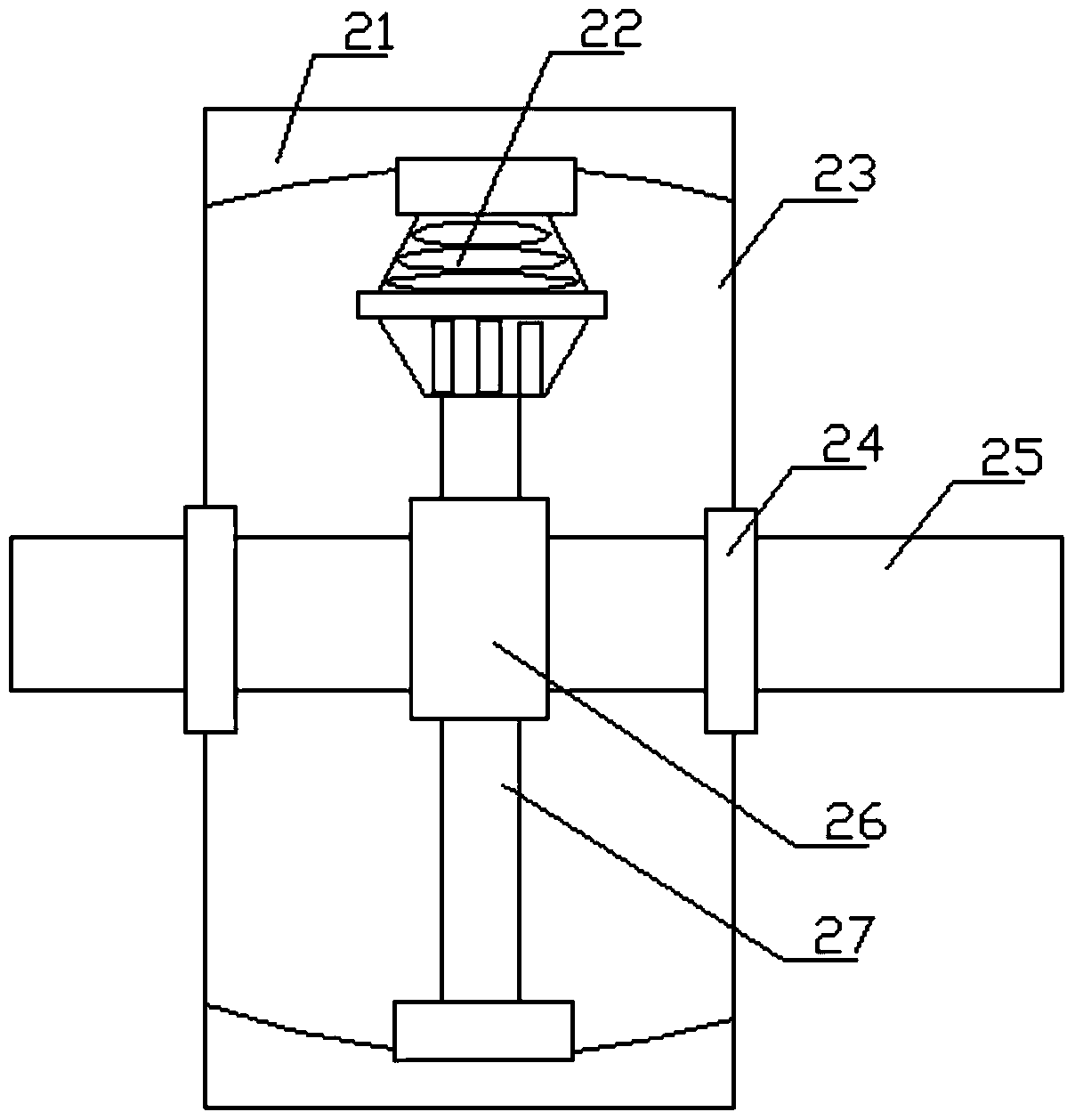

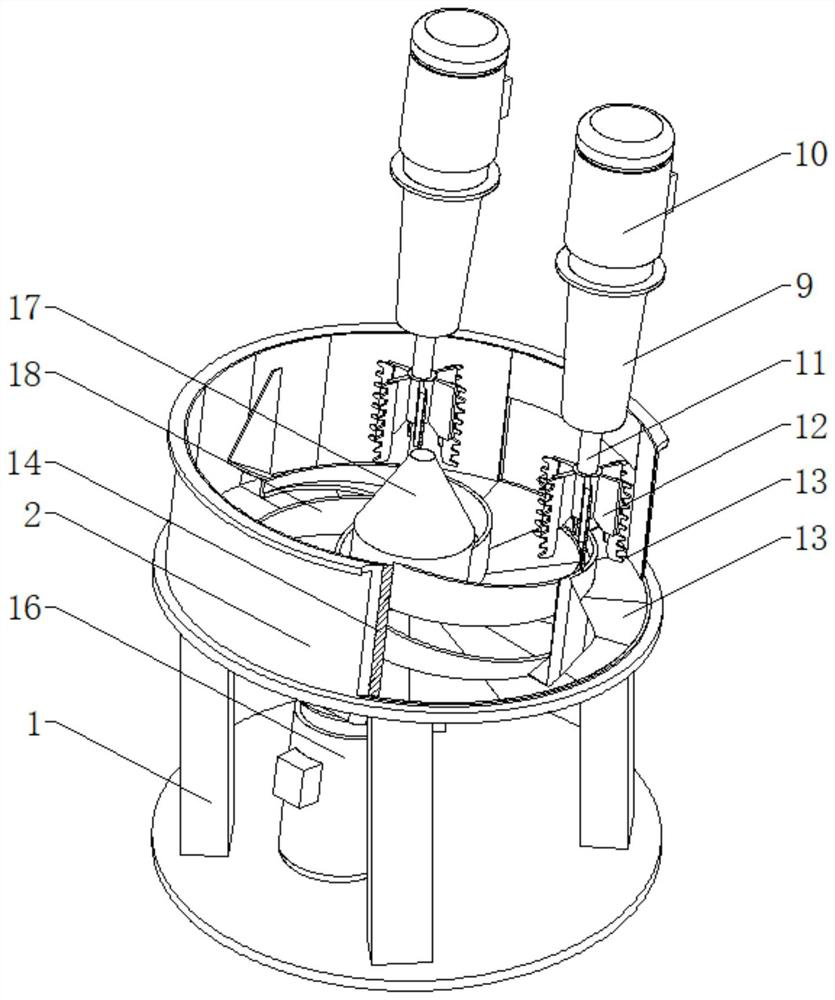

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

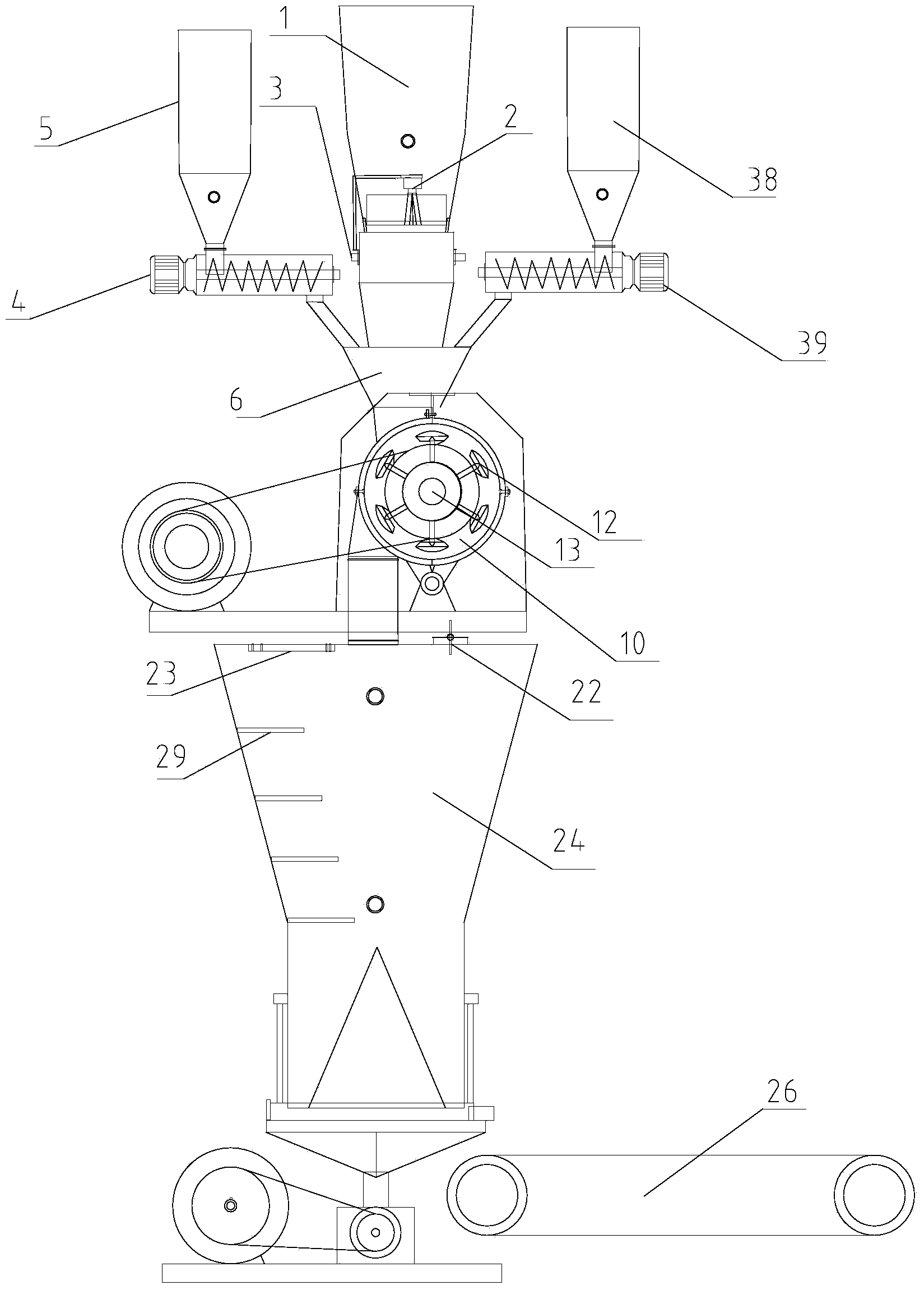

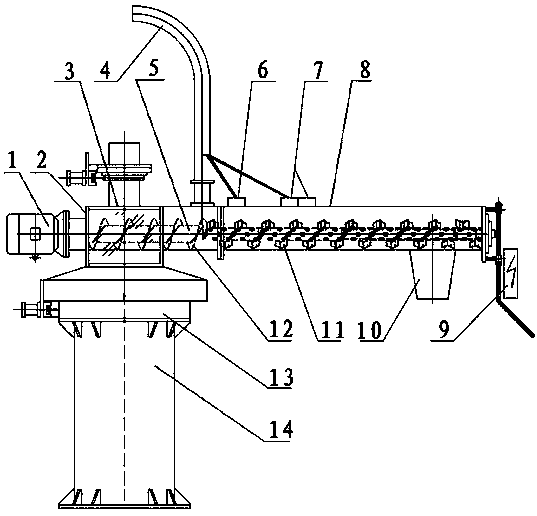

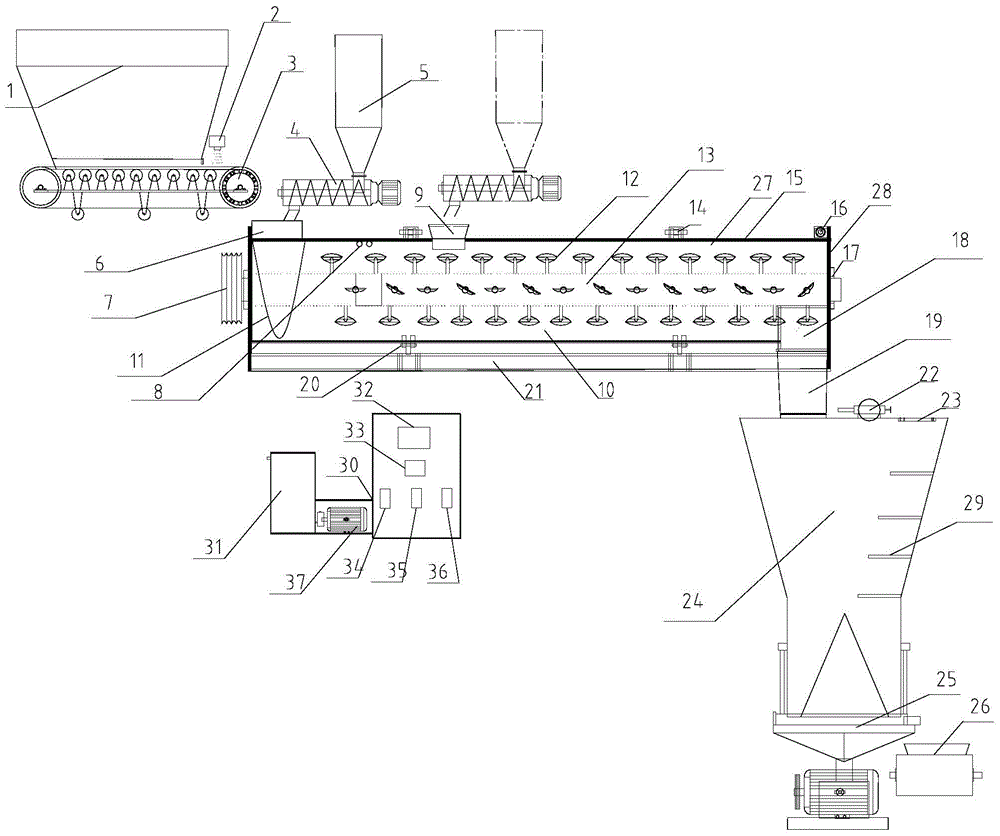

Continuous clay sand mixer

ActiveCN103785792AImprove performanceReduce consumption costMould handling/dressing devicesProduction rateElectricity

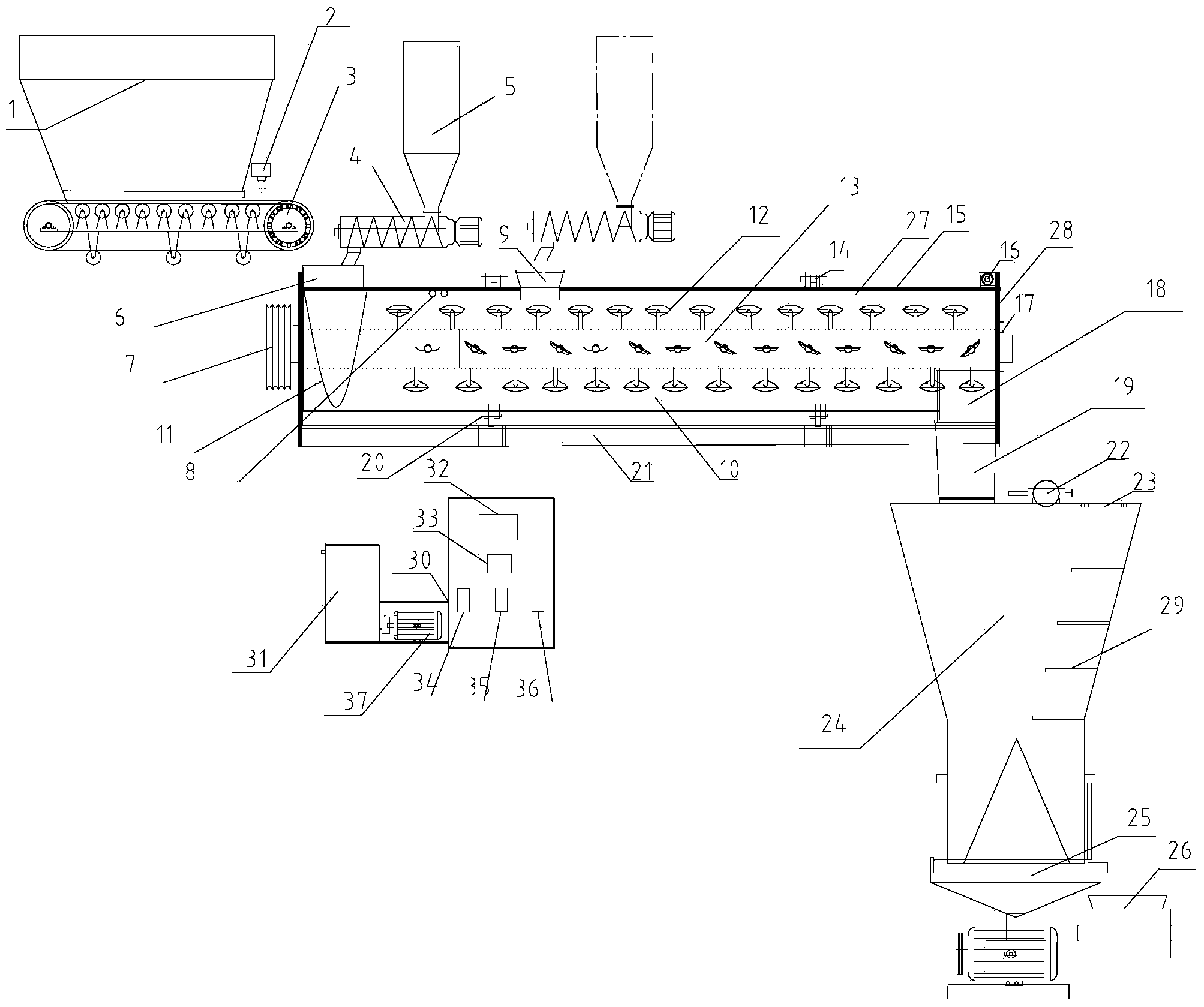

The invention belongs to the technical field of sand mixing equipment and relates to a continuous clay sand mixer. A new and old sand bin, a bentonite bin and a pulverized coal bin are arranged above a comprehensive charging hole, a moisture detector connected with a PLC control unit in an electric information mode is arranged under the new and old sand bin, and online detection of moisture of new and old sand before sand mixing can be achieved; after a human-machine control interface presets raw material parameters, the PLC control unit is used for analysis and calculation to control operation of a water pump frequency converter, a bentonite spiral feeding frequency converter and a pulverized coal spiral feeding frequency converter, and water, bentonite and pulverized coal are continuously added to a mixing cage in real time in an online and quantified mode; a return bin with a discharging mechanism is arranged under the mixing cage, so that mixed moulding sand is conveyed to the next production link; the mixer is simple in structure, reasonable in design, scientific in principle, simple in operation, high in sand mixing efficiency, good in sand mixing effect and good in finished product performance, the production efficiency is improved, and production cost is lowered.

Owner:孙晓宇

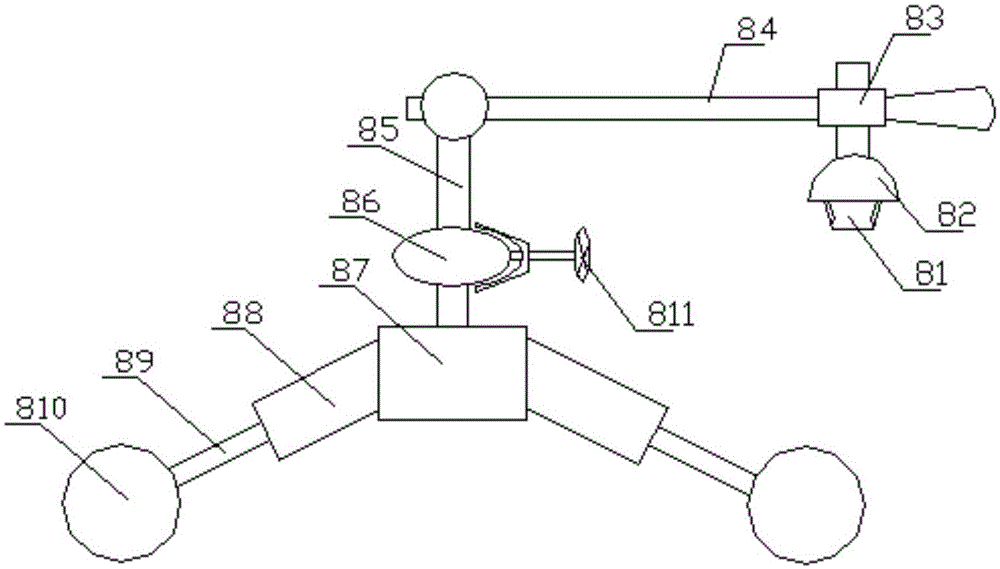

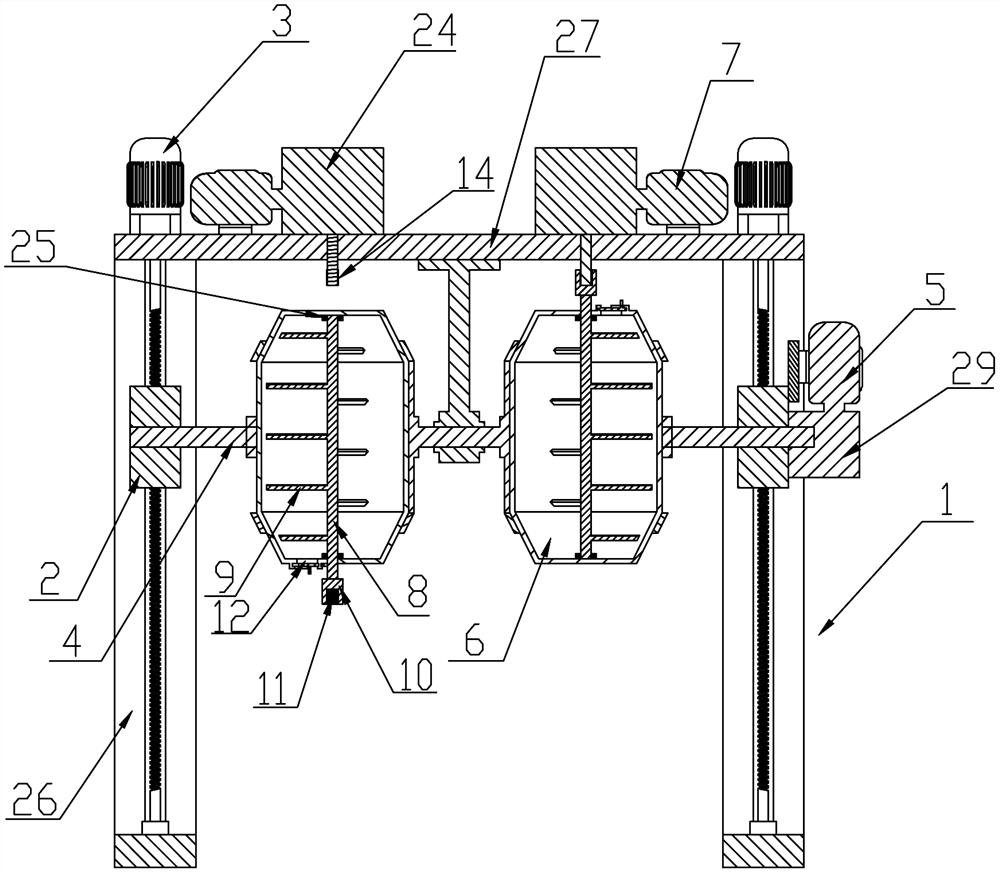

Sand mixer with uniform rolling function

InactiveCN105710288ASmooth rollingSimple structureMould handling/dressing devicesSand castingMaterials science

The invention discloses a sand mixing machine with uniform rolling and compaction, which comprises a sand mixing cylinder, a rotating shaft, a rolling device, a sand foundry device, a base, a first motor, and a second motor. The sand mixing cylinder is installed on the on the base; the rolling device includes a first rolling wheel and a second rolling wheel, the first rolling wheel is set on the first rotating shaft, and the first rotating shaft is erected on the first bracket; the second rolling wheel The two rolling wheels are set on the second rotating shaft, and the second rotating shaft is erected on the second bracket; the first rolling wheel and the second rolling wheel are symmetrically arranged, and are all connected to the sand mixing cylinder. The bottom abuts; the output end of the first motor is fixedly connected to the rotating shaft, and the rolling device is driven by the rotating shaft; the output end of the second motor is equipped with a gear, and the A ring gear intermeshing with the gear is installed on the lower part. The invention has the advantages of simple structure, convenient operation, high sand mixing efficiency, uniform rolling and good sand mixing quality.

Owner:DEQING DONGXU ALLOY STEEL CASTING

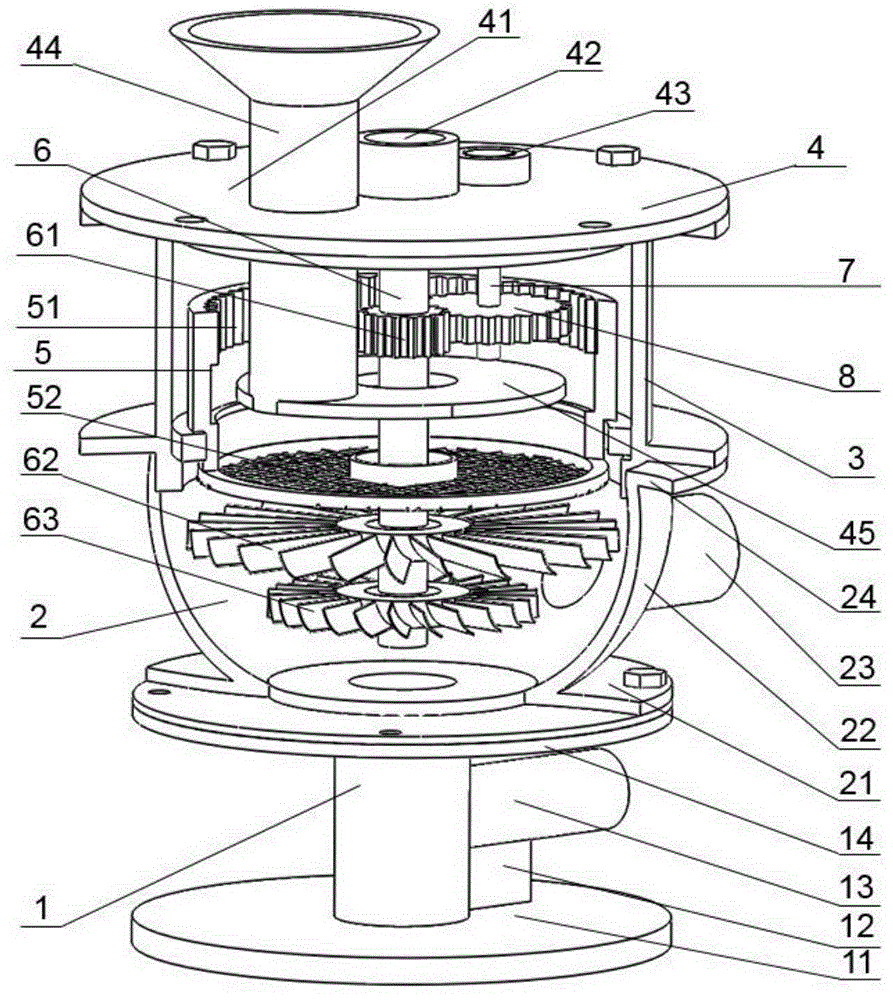

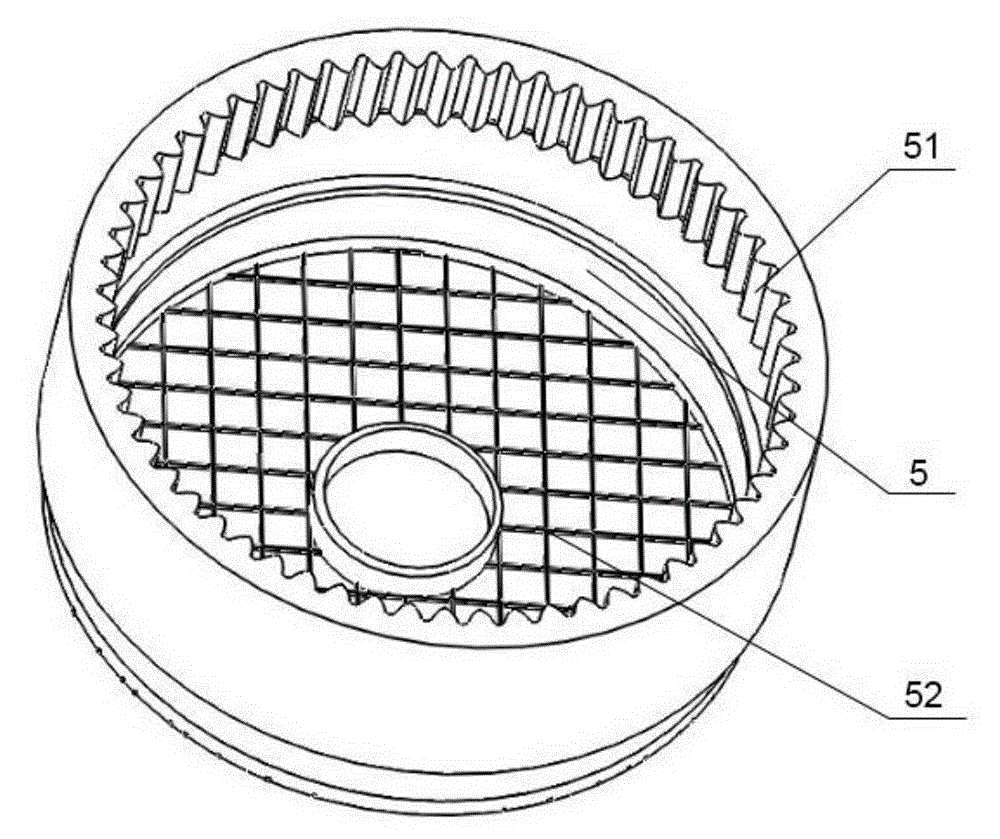

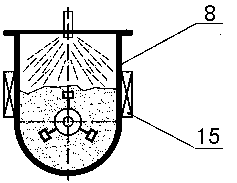

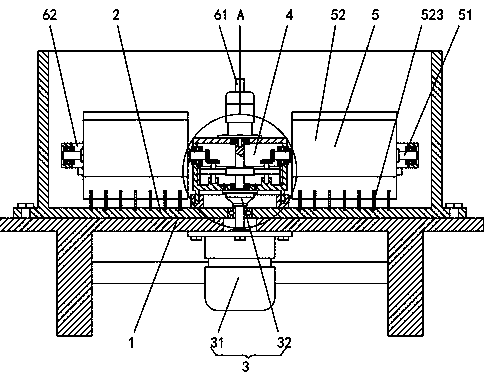

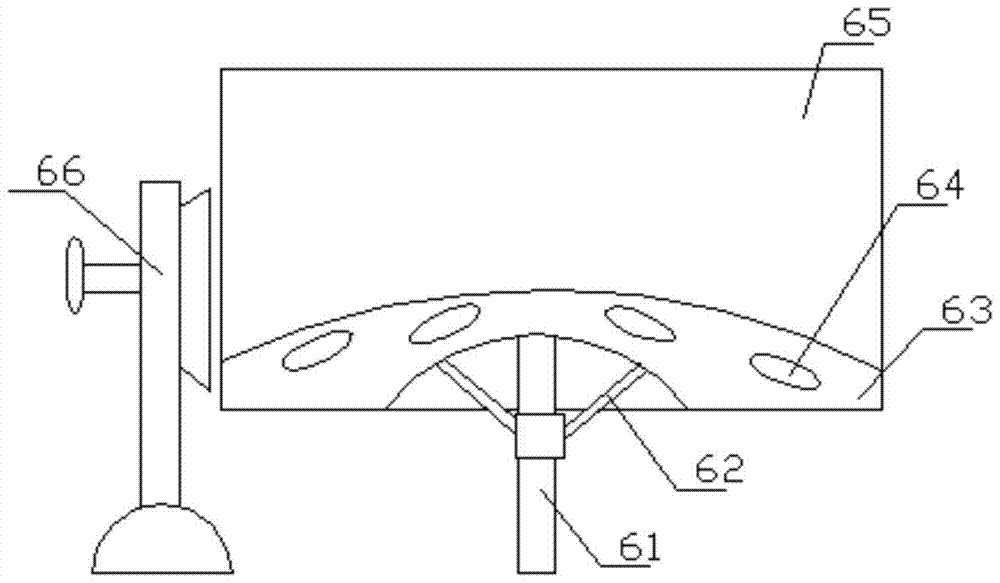

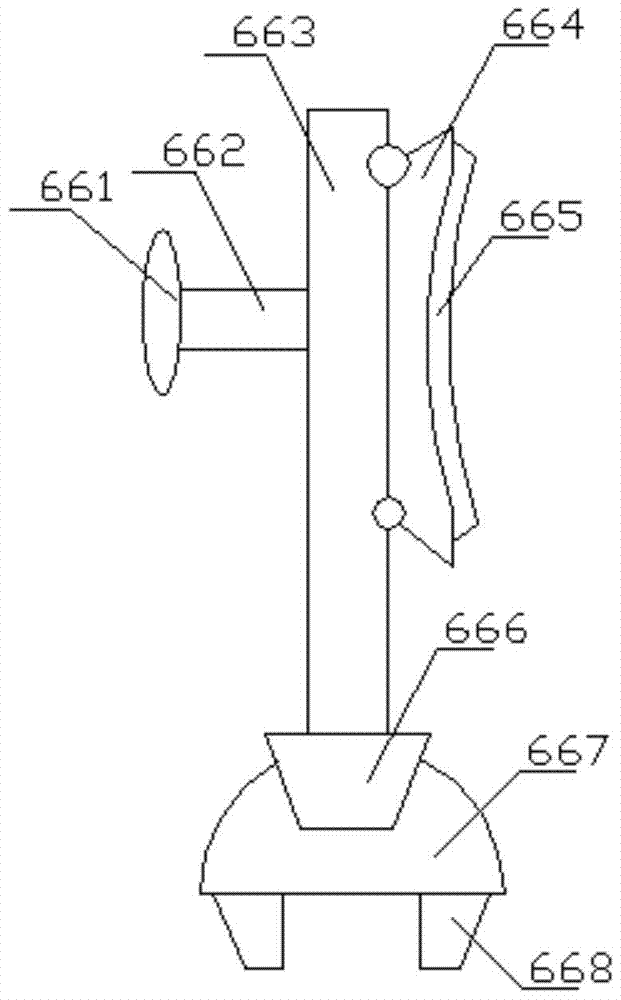

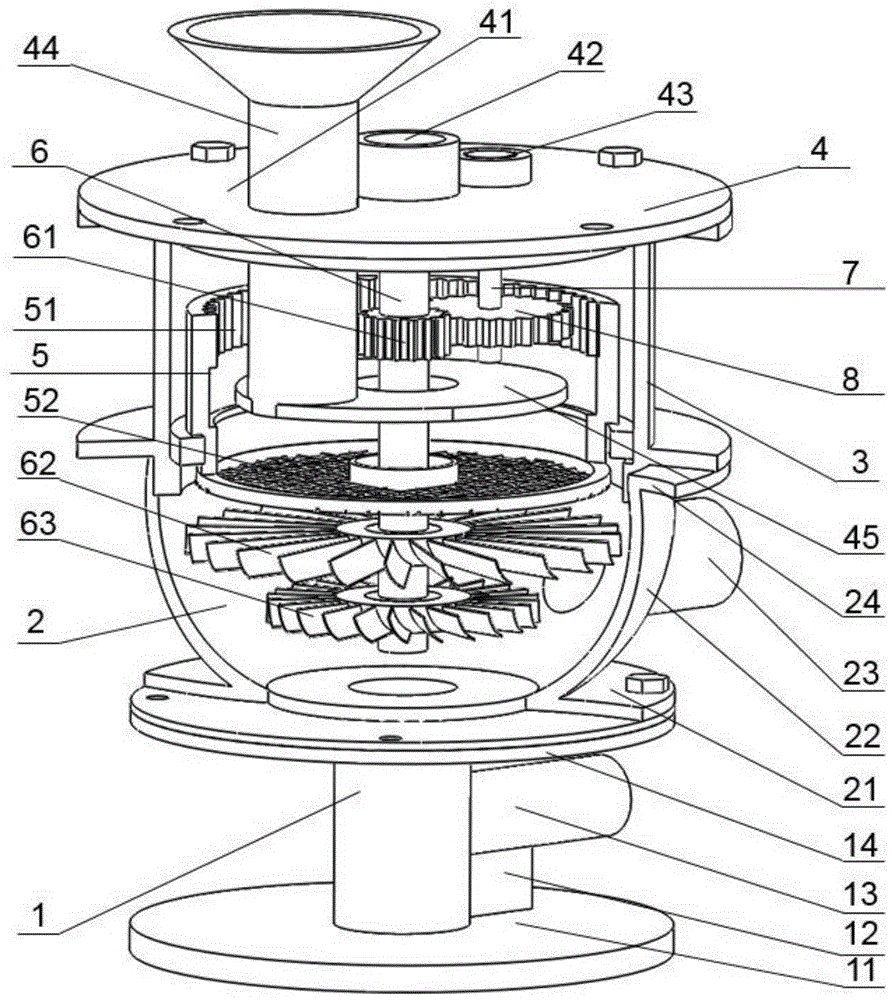

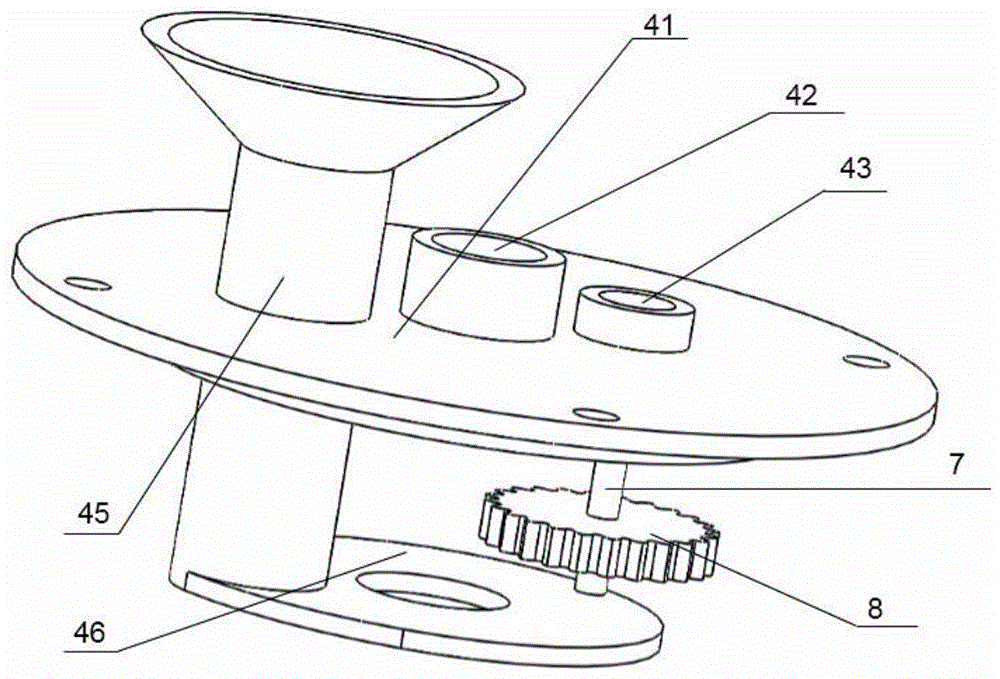

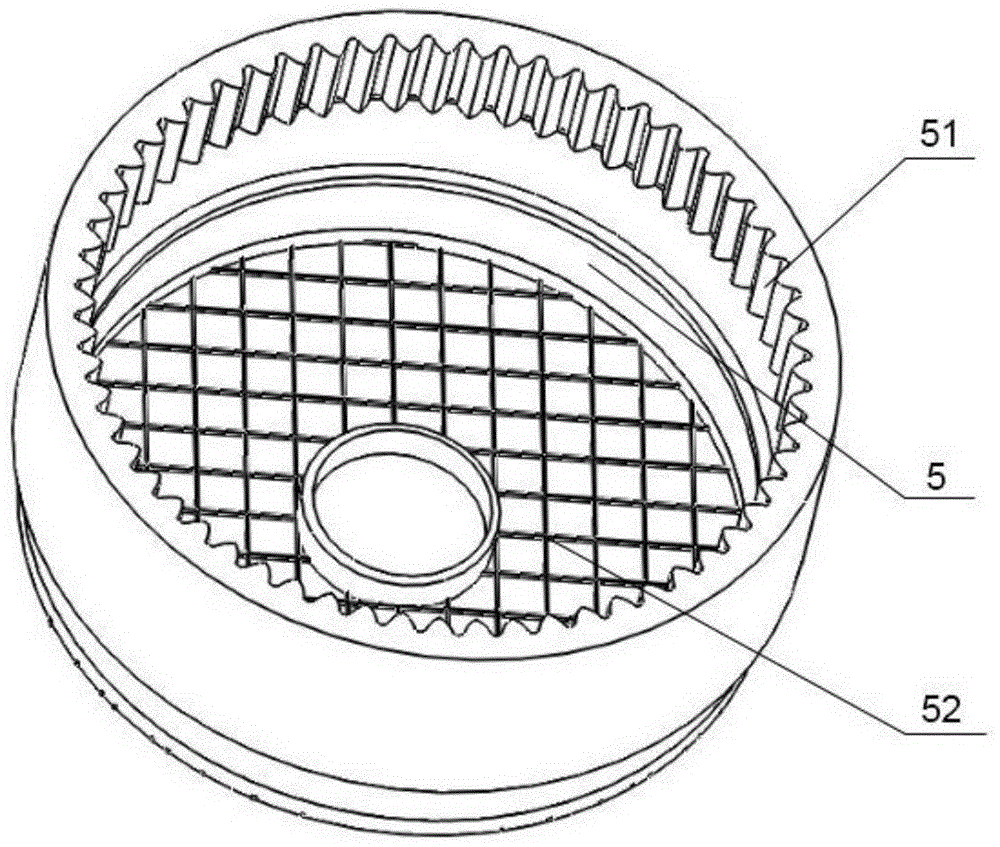

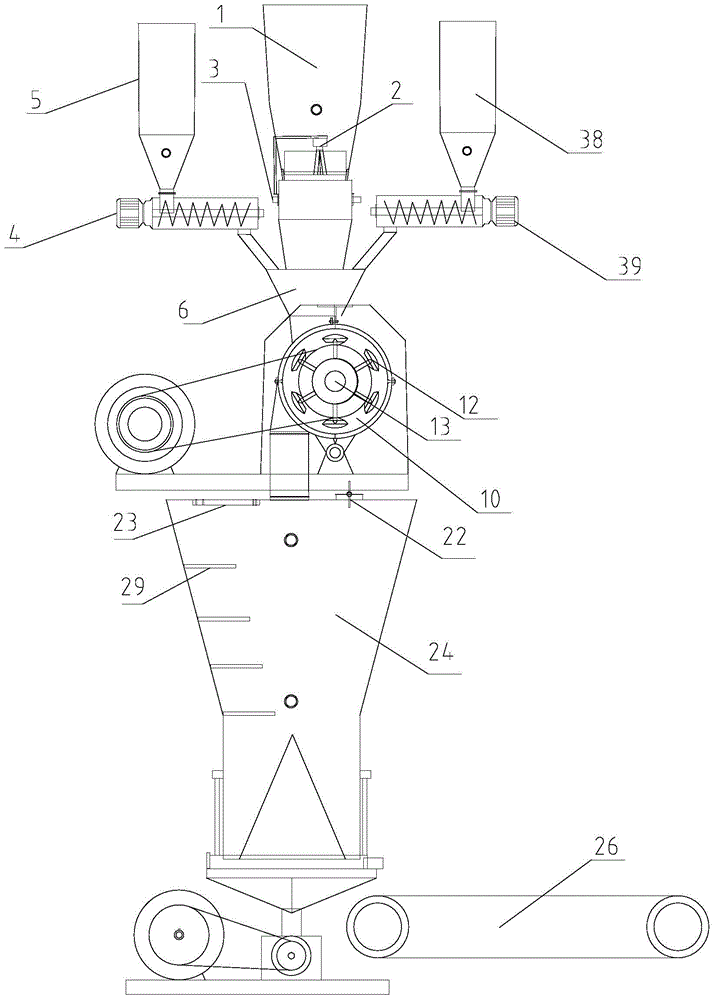

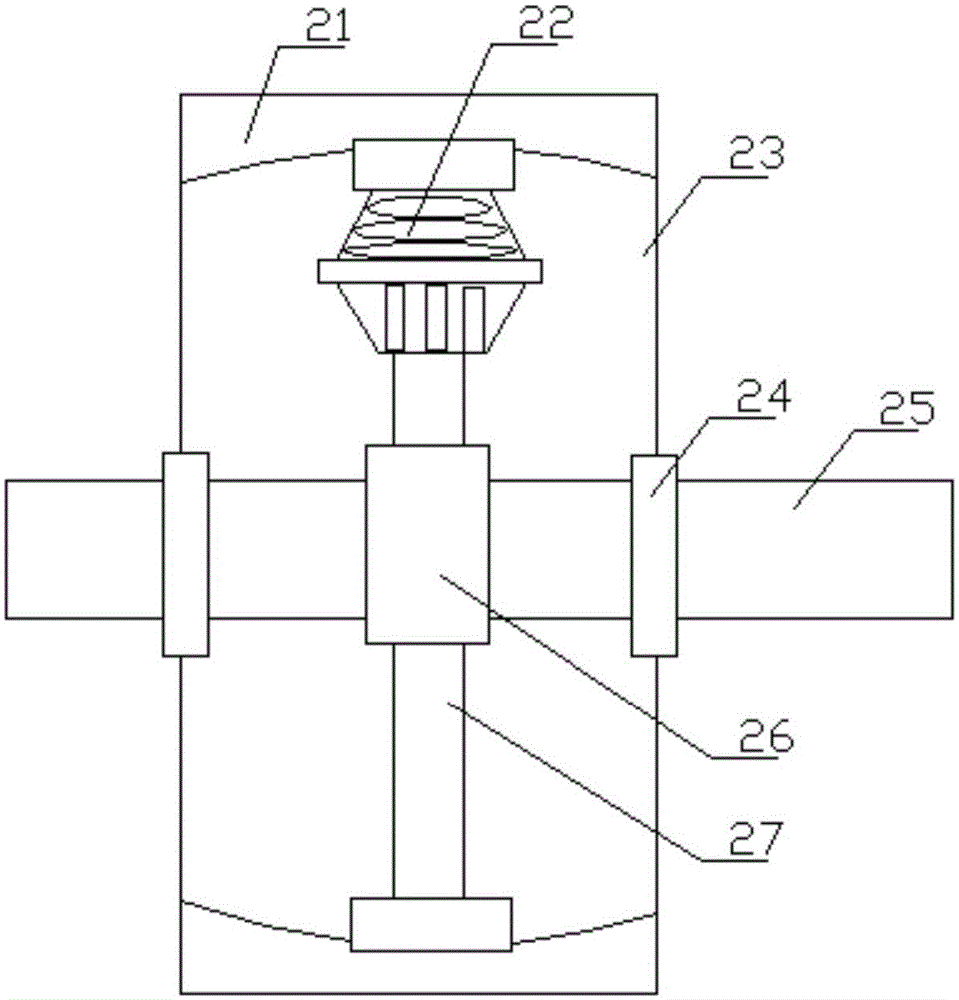

Continuous semispherical sand mixing device for fracture

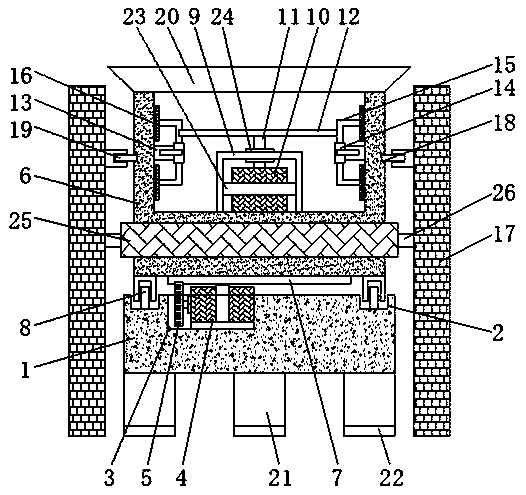

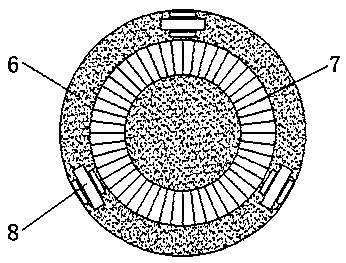

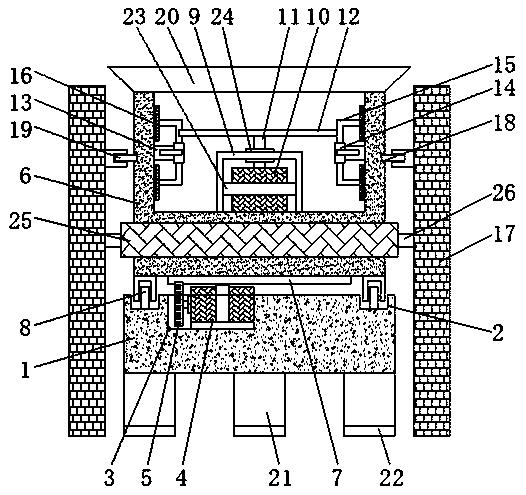

InactiveCN104929606AReduce wearWell mixedRotary stirring mixersFluid removalFracturing fluidEngineering

The invention belongs to the field of petroleum machinery and particularly relates to a continuous semispherical sand mixing device for fracture. The continuous semispherical sand mixing device is applicable to exploitation of unconventional oil-gas (such as shale gas and the like). The continuous semispherical sand mixing device for fracture comprises a base, a sand mixing chamber, a transmission box, an upper end cover, a spindle, an internal gear, a cantilever shaft and a transmission gear and is characterized in that the base, the sand mixing chamber, the transmission box and the upper end cover are fixedly connected in sequence. Compared with a traditional open sand mixing device, the continuous semispherical sand mixing device for fracture has the advantages that continuous mixing and continuous output of fracturing fluid and sand are realized, so that sand mixing efficiency is improved; compared with a Jerry continuous sand mixing device, the continuous semispherical sand mixing device for fracture has the advantages that blade abrasion is greatly reduced, high uniformity in mixing of the fracturing fluid and the sand is achieved, and the whole sand mixing effect is improved remarkably.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

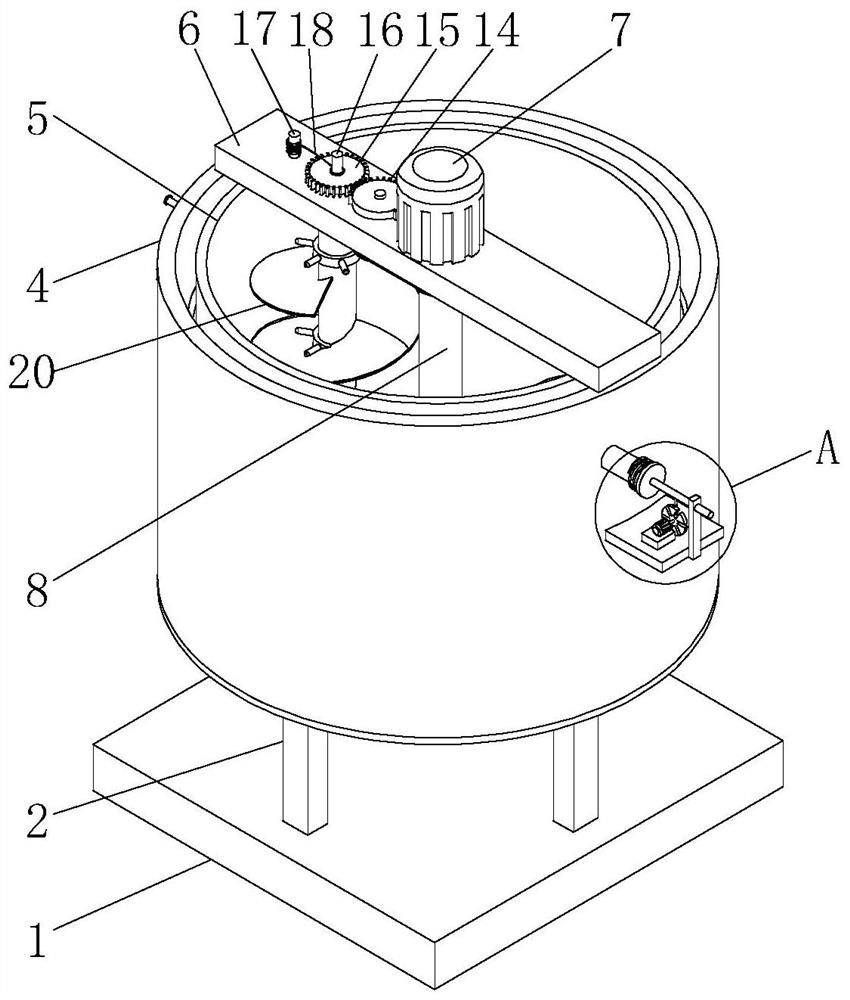

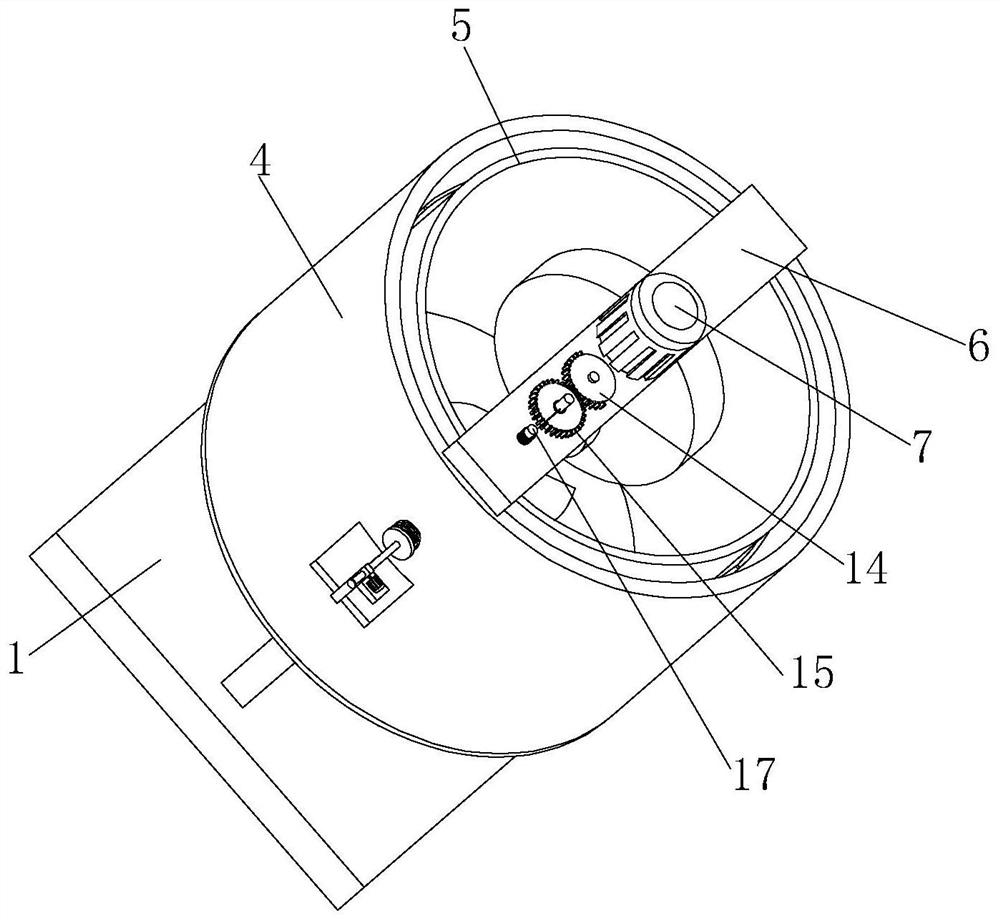

Efficient sand mixer

PendingCN109732039AShorten mixing timeImprove sand mixing efficiencyMould handling/dressing devicesGear driveEngineering

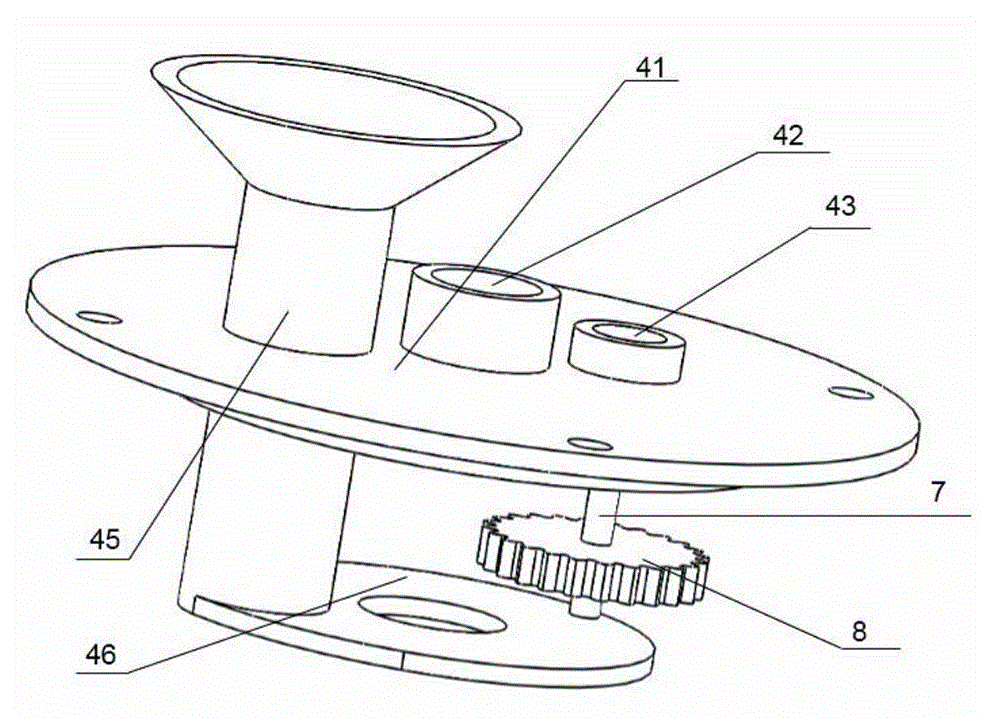

The invention provides an efficient sand mixer. The efficient sand mixer comprises a sand mixing cylinder, a base plate sand mixing mechanism, an eccentric stirring mechanism, a shifting plate drivingupper disc, a shifting plate supporting lower disc, material scraping shifting plate assemblies and an upper disc driving mechanism, wherein the bottom of the sand mixing cylinder is provided with the base plate sand mixing mechanism, an auxiliary stirring mechanism is arranged on the base plate sand mixing mechanism, the eccentric stirring mechanism comprises a first stirring mechanism and a second stirring mechanism, the upper disc driving mechanism controls the shifting plate driving upper disc to rotate through a gear driving mechanism, the plurality of material scraping shifting plate assemblies are distributed in the sand mixing cylinder at intervals in the circumferential direction, the upper ends and the lower ends of the material scraping shifting plate assemblies are arranged onthe shifting plate driving upper disc and the shifting plate supporting lower disc respectively, and scraping plates which are matched with the inner wall of the sand mixing cylinder in an abutting mode are arranged on the material scraping shifting plate assemblies. Thus, the mixing time can be shortened, the sand mixing efficiency is improved, molding sand sticking to the inner wall of a shellof the sand mixer can be timely removed, and uniform sand mixing is ensured.

Owner:杭州海伦铸钢有限公司

Cylinder type sand mixing equipment

InactiveCN105170899AEvenly distributedEasy to operateMould handling/dressing devicesEjection SeatsMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a cylinder type sand mixing equipment. The cylinder type sand mixing equipment comprises a main machine box, a feeding assembly, a filtering assembly, a mixing assembly, a driving assembly and a discharging assembly. The mixing assembly comprises a main output shaft, a transmission seat, first rotary connection pieces, stirring rods, mixing plates, fixing racks and a locking piece. The locking piece comprises an outer shield plate, a guide rod, a gasket, a squeezing piece, an adjusting spring and convex inserting-connection side plates. Each fixing rack comprises a rotary connection ring, a main ejection seat, a sub-ejection rod, a first rotary connection head, auxiliary rods and clamping connection heads; a first guide hole is formed in the axial direction of the main ejection seat in a penetrating mode; a first installing groove is formed in the first rotary connection head in a concave mode; a first connection thread is arranged on the side wall of the first rotating connection groove in an internally spiral and concave mode. The cylinder type sand mixing equipment is convenient to operate and adjust, high in sand mixing efficiency and good in sand mixing quality.

Owner:吴春艳

Continuous resin sand mixing machine and sand mixing method

The invention discloses a continuous resin sand mixing machine and a sand mixing method. The continuous resin sand mixing machine comprises a feeding box and a sand mixing barrel which are arranged horizontally, wherein a rotating device is arranged on the upper part of a supporting device; the feeding box is mounted on the rotating device; a feeding opening is formed in the top of the feeding boxand is connected with a feeder system; a motor is mounted on the horizontal side of the feeding box; the other opposite side of the feeding box communicates with the sand mixing barrel; the cross section of the sand mixing barrel is U-shaped; the resin sand cannot be adhered easily; the space is large; large space is reserved in the upper part of the sand mixing barrel to remove dust and odor effectively; the continuous resin sand mixing machine is environmentally friendly; the sand mixing method is simple and efficient; and the product cost is low.

Owner:QINGDAO HEDELONG MACHINERY

Sand mixing equipment

InactiveCN105170898AEasy to adjustEasy to operateMould handling/dressing devicesMechanical equipmentEngineering

The invention relates to the technical field of mechanical equipment, in particular to sand mixing equipment. The sand mixing equipment comprises a base and further comprises a mixing assembly arranged at one side of the upper end of the base, a first motor arranged at the lower end of the mixing assembly in a rotatable mode, a main machine frame, a motor installing base, a second motor and a sand mixing assembly which is arranged on the upper side of the main machine frame and connected to the second motor in a rotatable mode. The mixing assembly comprises an outer cylinder body, a bearing piece, a detecting cavity, a lifting shaft and a positioning and pressing piece. A pressure sensor is arranged in the detecting cavity. The positioning and pressing piece comprises a first rotary seat, inserted connection blocks, a first rotary head, a vertical pressing rod, an inner pressing frame, a pressure-resistant layer, a first adjusting rod and a handle. Rotary balls are installed between the vertical pressing rod and the inner pressing frame. The sand mixing equipment is convenient to operate and adjust, high in sand mixing efficiency and good in sand mixing quality.

Owner:陈红岩

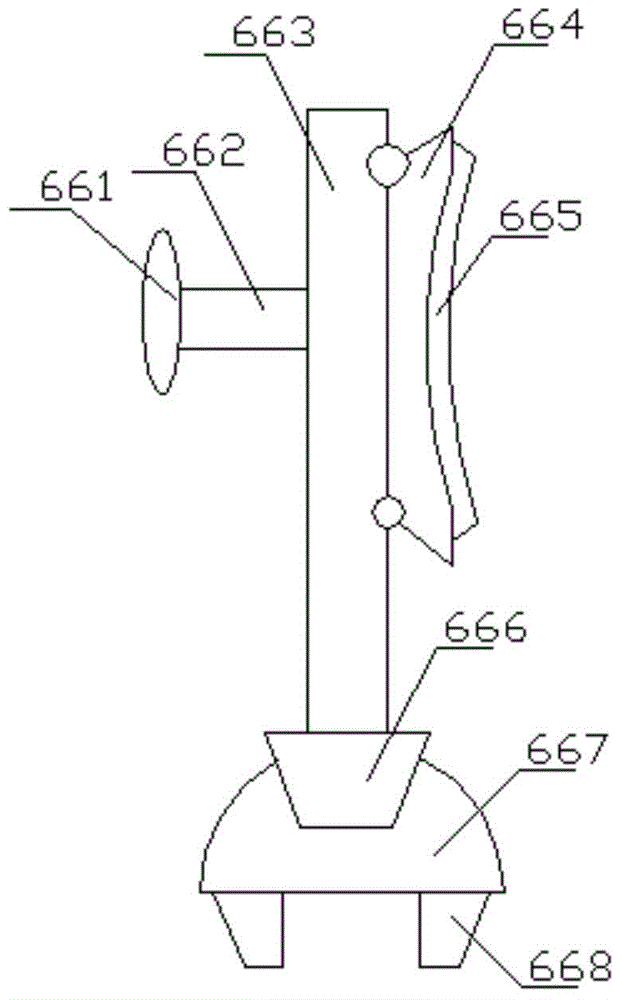

Sand mixing device with good sand discharging effect for casting machinery

InactiveCN112317684AWell mixedImprove mixing efficiencyMould handling/dressing devicesRotational axisElectric machinery

The invention discloses a sand mixing device with good sand discharging effect for a casting machinery. The sand mixing device with the good sand discharging effect for the casting machinery comprisesa base and a material shaking device, a supporting column is fixedly connected to the outer wall of the top of the base, a fixing plate is fixedly connected to the end, away from the base, of the supporting column, an outer shell is fixedly connected to the outer wall of the top of the fixing plate, a mixing box is fixedly connected to the outer wall of the top of the fixing plate and located inthe interior of the outer shell, a first mounting plate is fixedly connected to the outer wall of the top of the outer shell, a first motor is fixedly connected to the outer wall of the top of the first mounting plate, a rotating shaft is fixedly connected to an output shaft of the first motor, the outer wall of one side of the rotating shaft is fixedly connected with a connecting rod, and one end, away from the rotating shaft, of the connecting rod is rotationally connected with a grinding roller. By means of up-and-down rotating motion of molding sand, the molding sand is mixed more sufficiently, the mixing efficiency is higher, the working efficiency is improved to a certain extent, and compared with the prior art, the sand mixing efficiency of a casting machine is remarkably improved,and the use requirement is met.

Owner:岑威杰

A kind of sand mixing equipment

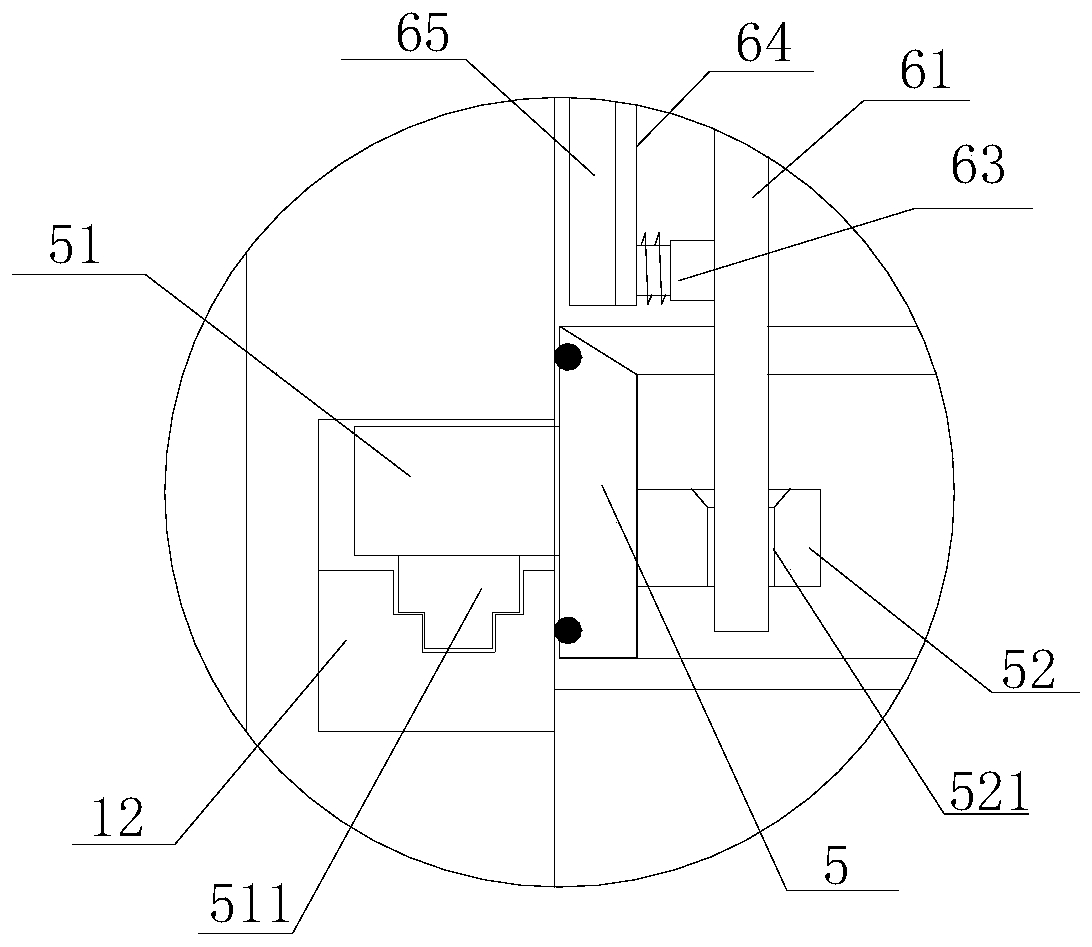

ActiveCN104815950BAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorSand casting

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

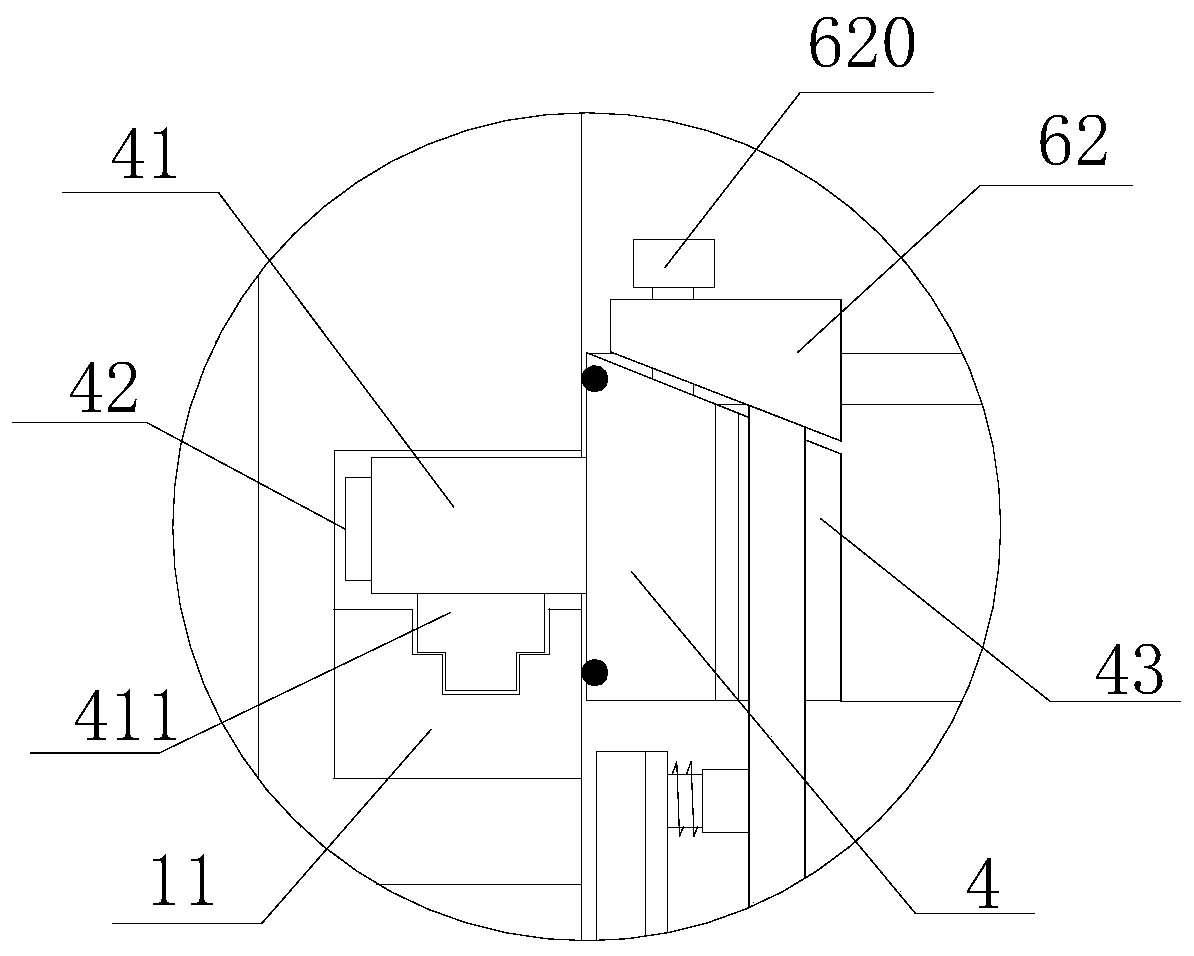

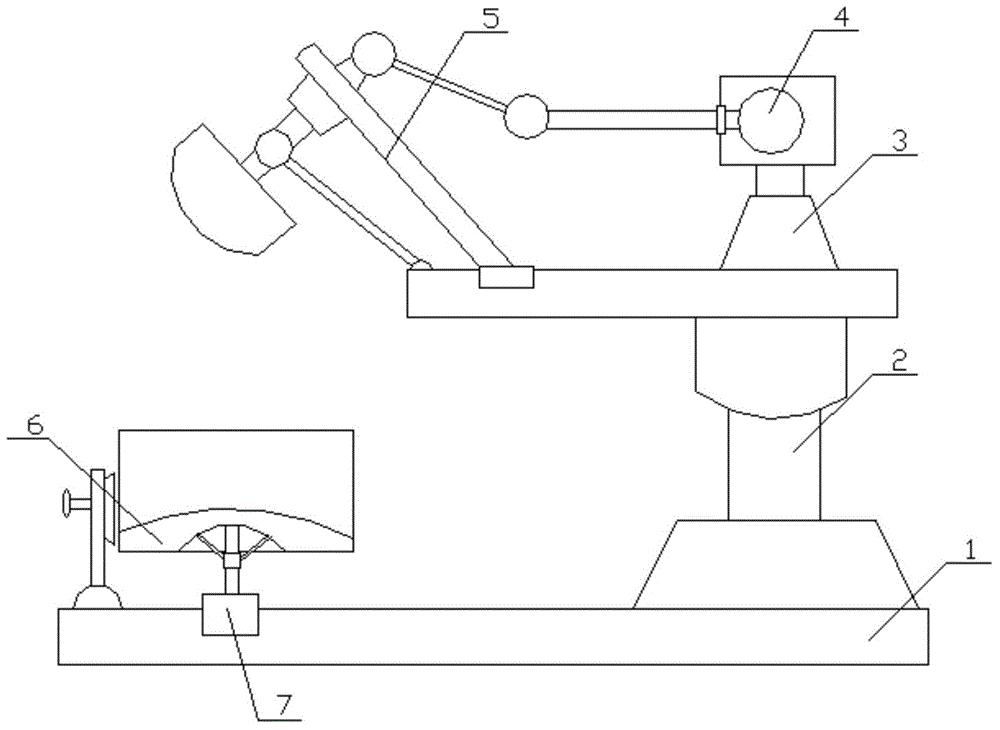

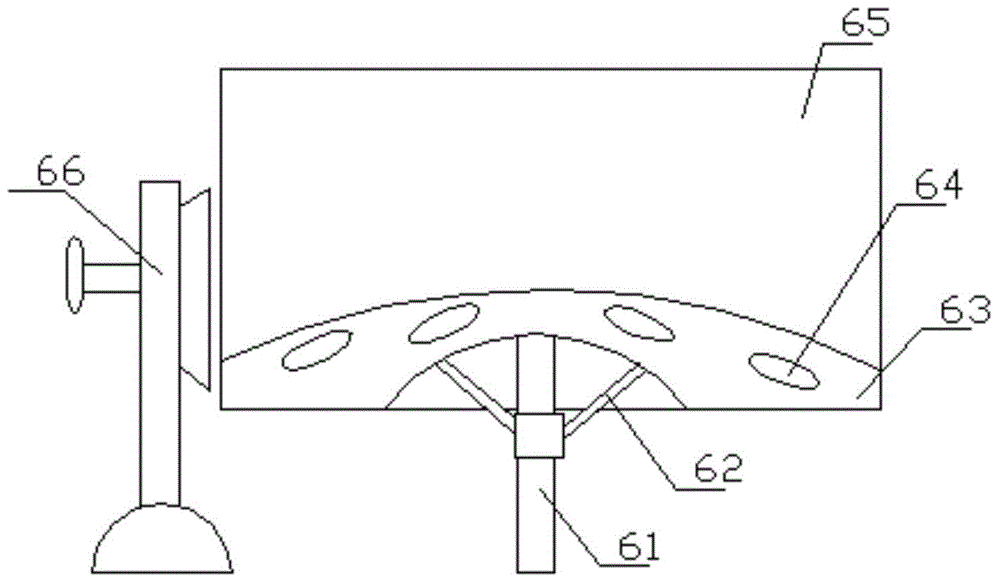

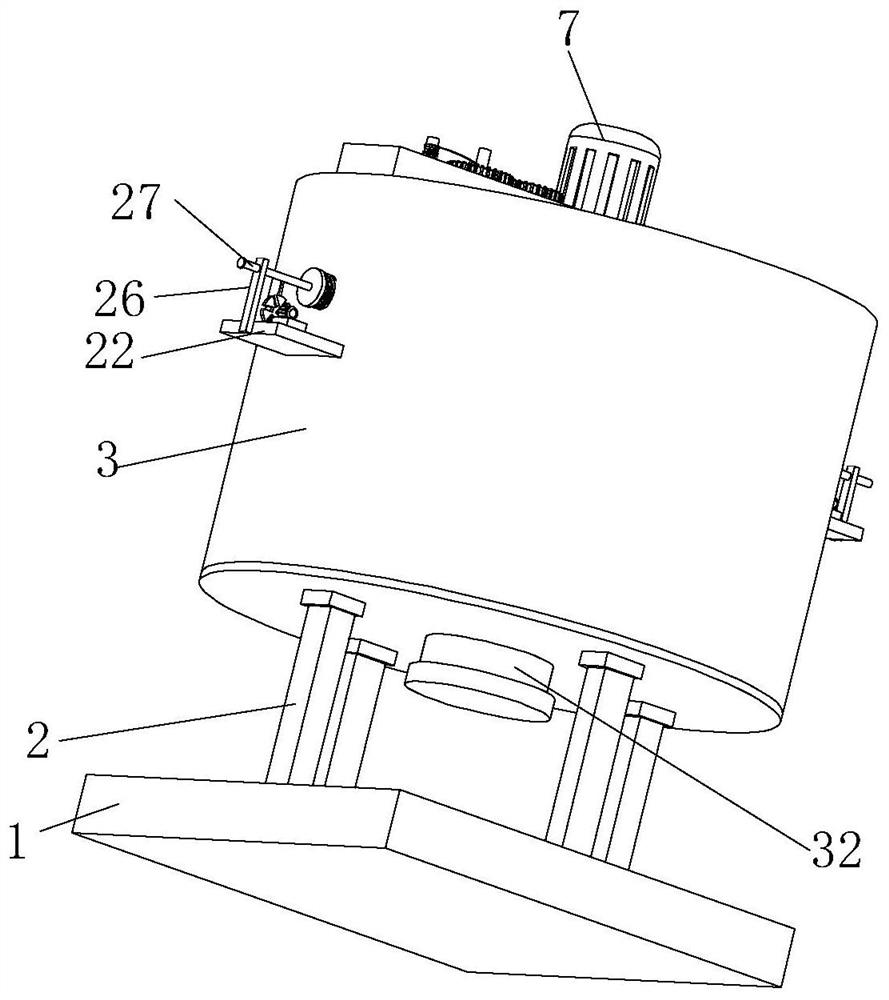

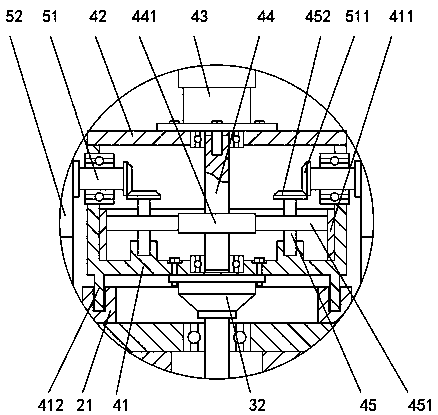

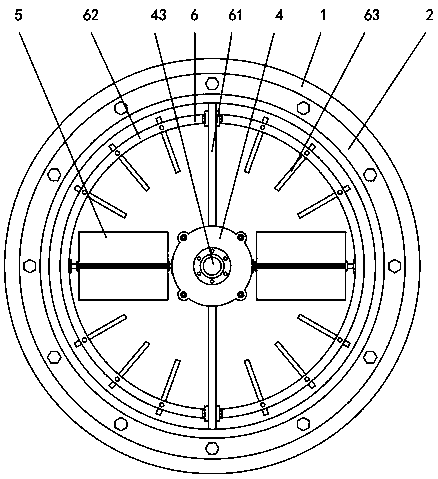

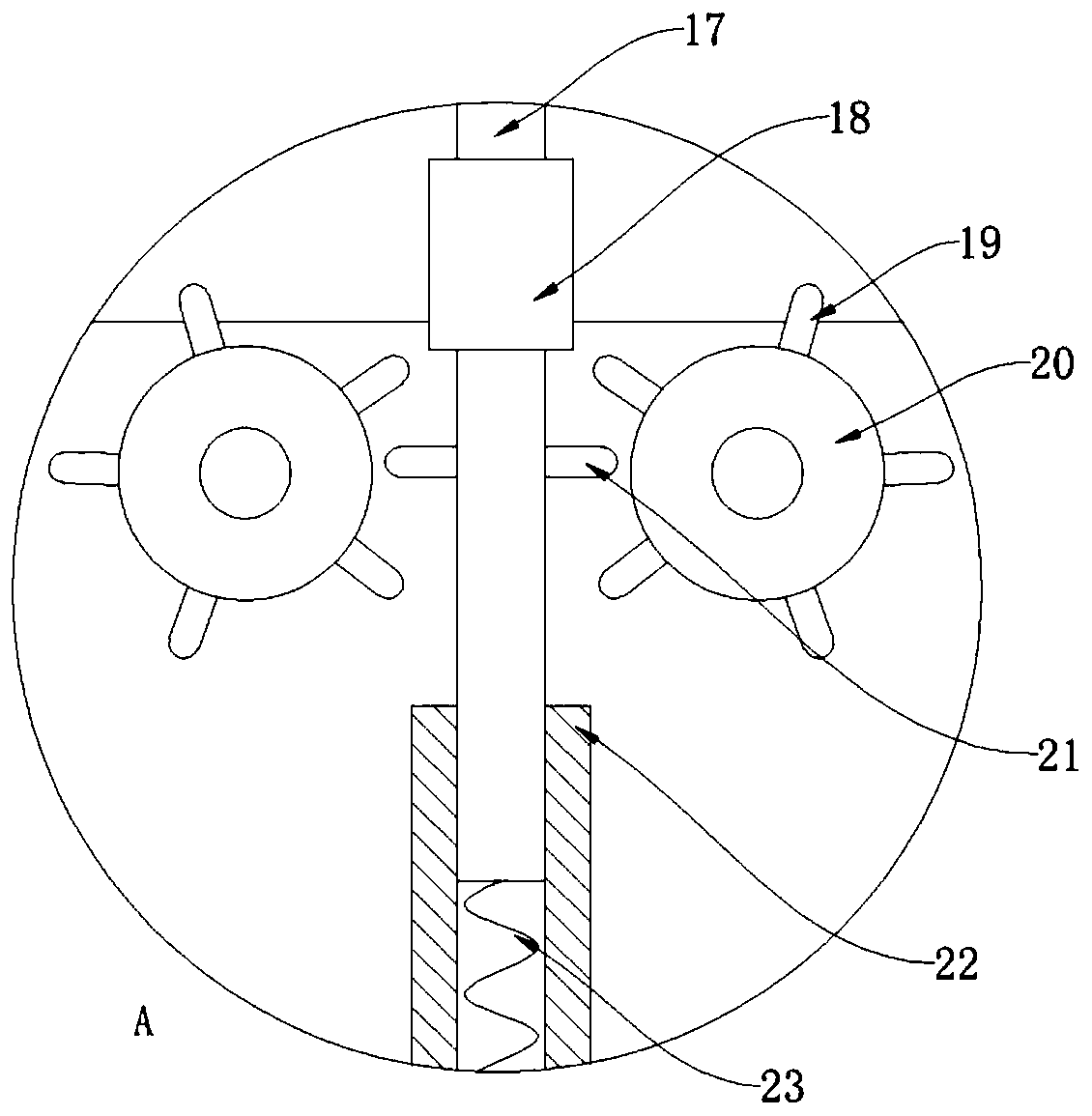

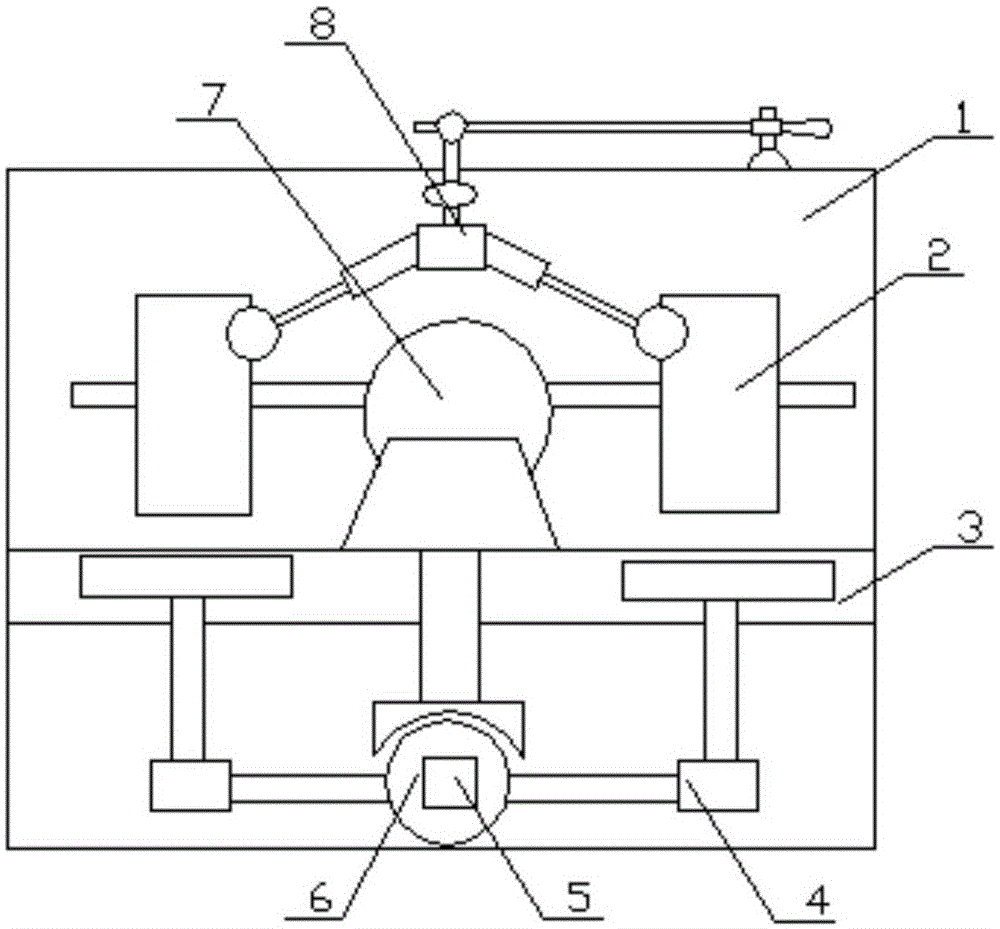

A foundry sand mixer

ActiveCN110315028BUniform and compact structureRealize and meet the needs of sand mixingMould handling/dressing devicesFoundryElectric machinery

The invention relates to a casting sand mixer. The casting sand mixer comprises a machine base, a round sand mixing hopper, a rotating motor assembly, a wheel train transmission mechanism, turning andgrinding assemblies and a scraping plate mechanism, the round sand mixing hopper is fixedly arranged on the machine base, the rotating motor assembly is fixedly arranged at the central position of the bottom of the machine base, the wheel train transmission mechanism is fixedly arranged at the top of the rotating motor assembly, the two turning assemblies are symmetrically and rotationally arranged on the wheel train transmission mechanism, and the scraping plate mechanism is fixedly arranged on the wheel train transmission mechanism; the rotating motor assembly can drive the wheel train transmission mechanism, the whole synchronous rotation formed by the turning and grinding assemblies and the scraping plate assembly is achieved, the wheel train transmission mechanism can drive the two turning and grinding assemblies to rotate. According to the casting sand mixer, the grinding roller and the sand turning structure of the casting sand mixer are uniform and compact in design and convenient to dismount and maintain, cleaning and rapid replacement of the grinding wheel structure are facilitated, and the efficiency and quality of sand mixing are ensured.

Owner:SHANXI HUAXIANG GRP CO LTD

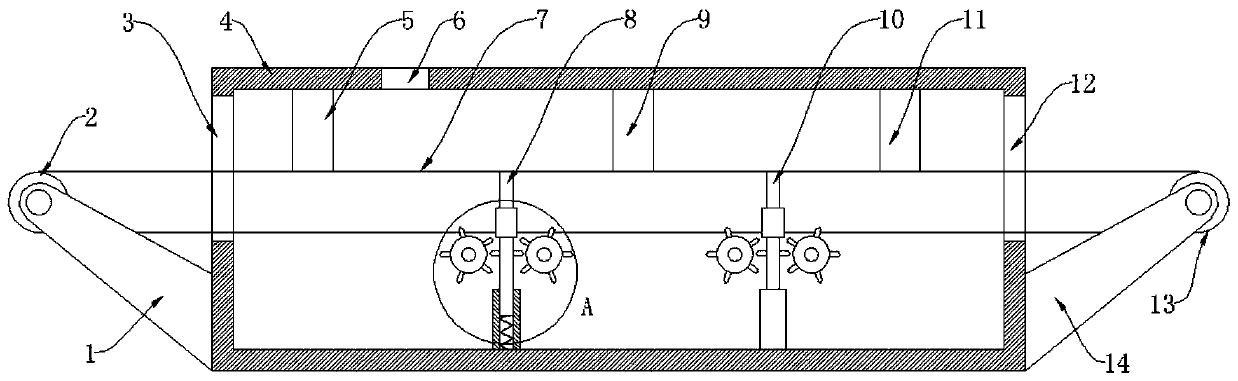

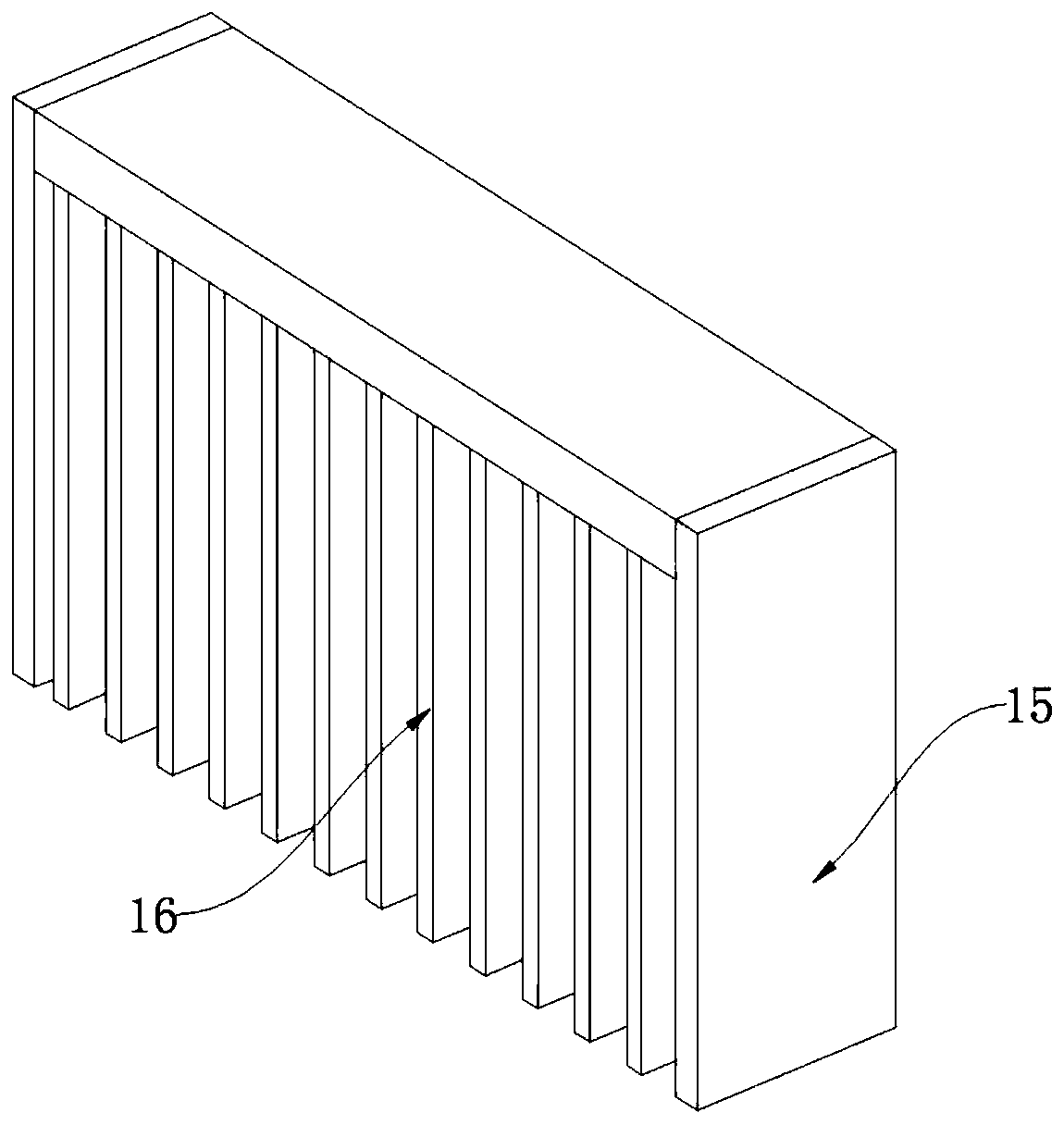

Efficient and continuous sand mixing device of precoated sand

ActiveCN111283137AContinuous and efficient sand mixing operationImprove sand mixing efficiencyMould handling/dressing devicesProcess engineeringConveyor belt

The invention provides an efficient and continuous sand mixing device of precoated sand, and belongs to the technical field of precoated sand processing. The efficient and continuous sand mixing device includes a box, wherein a feed port is formed in one side of the box, a discharge port is formed in the other side of the box, a first belt pulley is arranged on the outer part, located on one sideof the feed port, of the box, a second belt pulley is arranged on the outer part, located on one side of the discharge port, of the box, the first belt pulley and the second belt pulley are connectedby a conveyor belt in a sleeving mode, and the conveyor belt penetrates through the box from the feed port and the discharge port; a batching inlet is formed in the side, close to the feed port, of the upper part of the box, and the box is internally provided with a first material distributing assembly, a second material distributing assembly and a third material distributing assembly at intervalsin the direction of the conveyor belt; and the first material distributing assembly is located between the feed port and the batching inlet. According to the embodiment of the invention, continuous and efficient sand mixing operation of the precoated sand can be realized, and the efficient and continuous sand mixing device has the advantages of high sand mixing efficiency and good sand mixing effect.

Owner:亚威新材料(徐州)有限公司

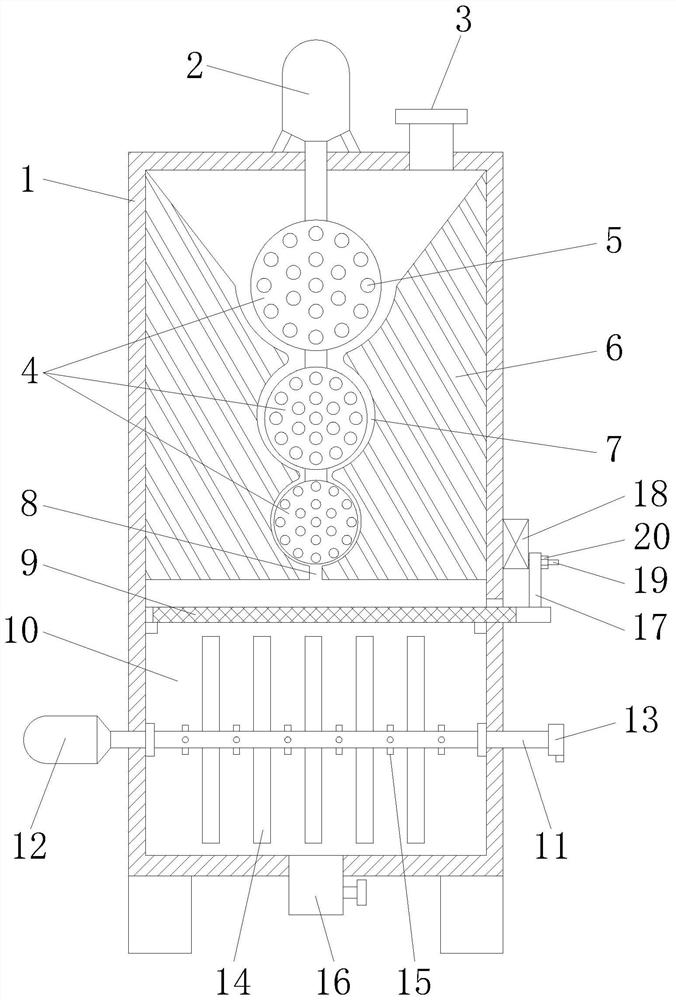

Molding sand casting sand mixing device and working method thereof

InactiveCN112872288AQuality improvementSimple structureMould handling/dressing devicesElectric machineryEngineering

The invention discloses a molding sand casting sand mixing device and a working method thereof. The molding sand casting sand mixing device comprises a mixing box body, wherein a grinding motor and a feeding port are arranged at the top of the mixing box body respectively; an output shaft of the grinding motor extends into the mixing box body; a plurality of grinding balls are arranged on the output shaft respectively; a plurality of grinding protrusions are arranged on the grinding balls; a grinding body is arranged between grinding balls and the inner wall of the mixing box body; a sand passing channel is reserved between the grinding body and the grinding balls; a discharging hole is formed in the lower end of the grinding body; a filtering sieve plate is arranged below the grinding body; a sand mixing area is formed below the filtering sieve plate; a stirring rod of a hollow structure is transversely arranged in the sand mixing area; a stirring motor is arranged at one end of the stirring rod; and a rotary joint is arranged at the other end of the stirring rod, and is externally connected with additive liquid. The grinding balls are arranged for sequential grinding, so that the probability of coarse sand is reduced; meanwhile, coarse sand particles can be screened out, fine sand enters the sand mixing area, and the additive liquid is sprayed while stirring is conducted, so that uniform sand mixing is achieved, and the sand mixing efficiency and the quality of finished molding sand are improved.

Owner:南通宏久金属制品有限公司

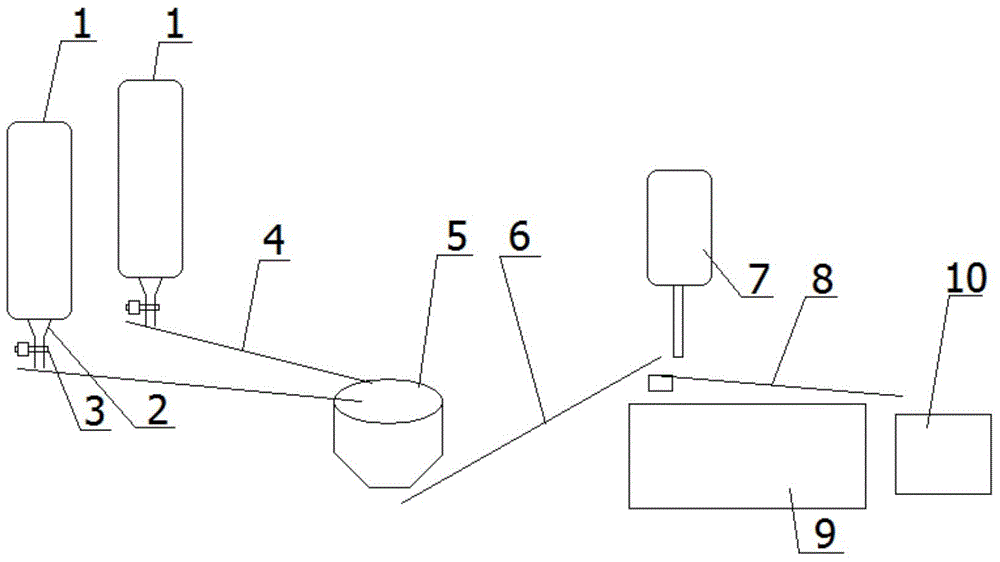

Casting sand grinding and mixing system

InactiveCN104907489ASimple structureHigh degree of automationMould handling/dressing devicesEngineeringSilo

The present invention discloses a casting sand grinding and mixing system, which is provided with at least two main silos, bottoms of the main silos are provided with discharge ports, a coarse material conveyor belt which is used to transport a material to a burnisher is arranged below the discharge port of the main silo, a fine conveyor belt which is used to transport the material to a storage silo is arranged at the discharge port at the bottom of the burnisher, and a vibrating screen is arranged below the fine conveyor belt and above the storage silo. The casting sand grinding and mixing system has the advantages simple structure, high degree of automation, improvement of the efficiency of sand mixing, and reducing of labor costs.

Owner:WUHU CHENGTUO AUTO PARTS

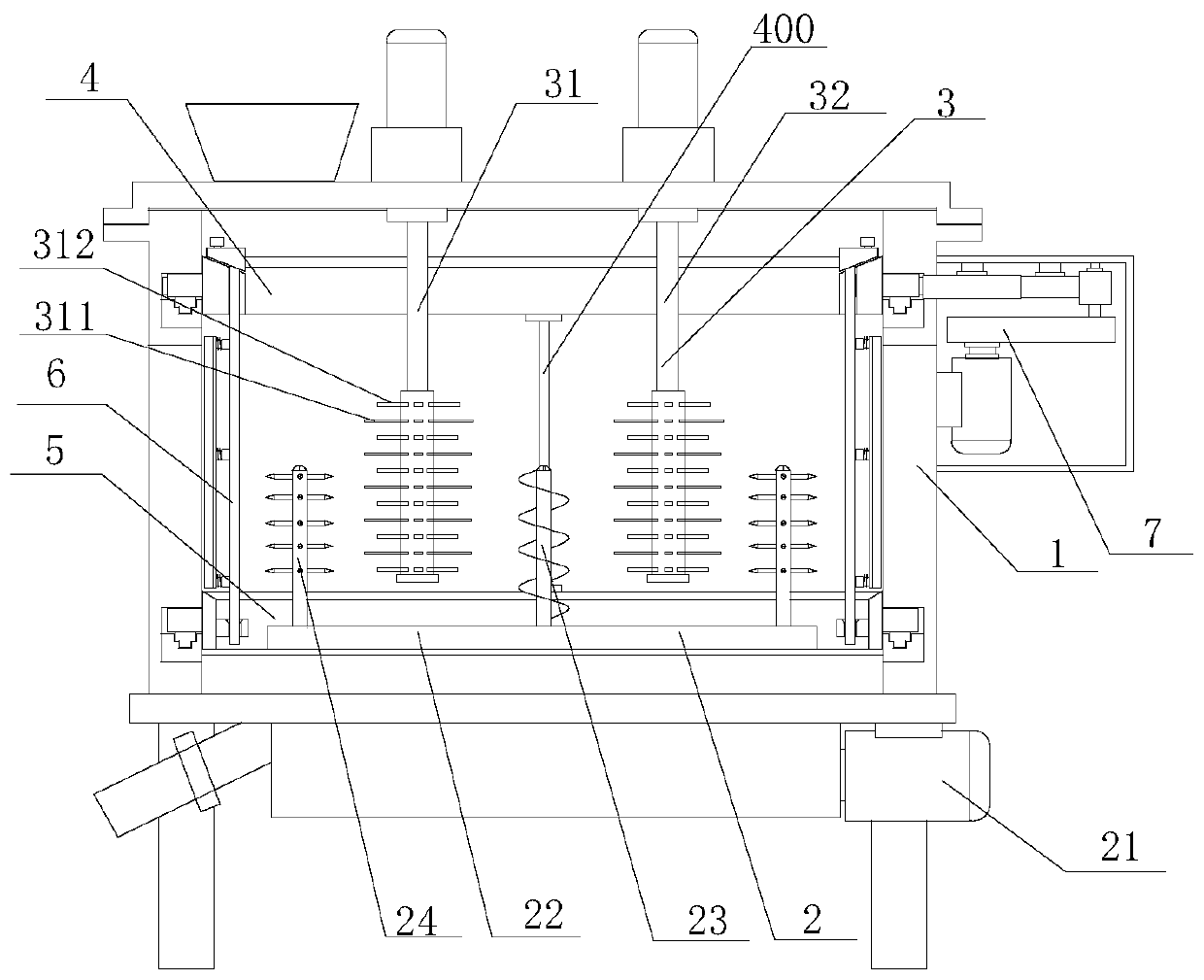

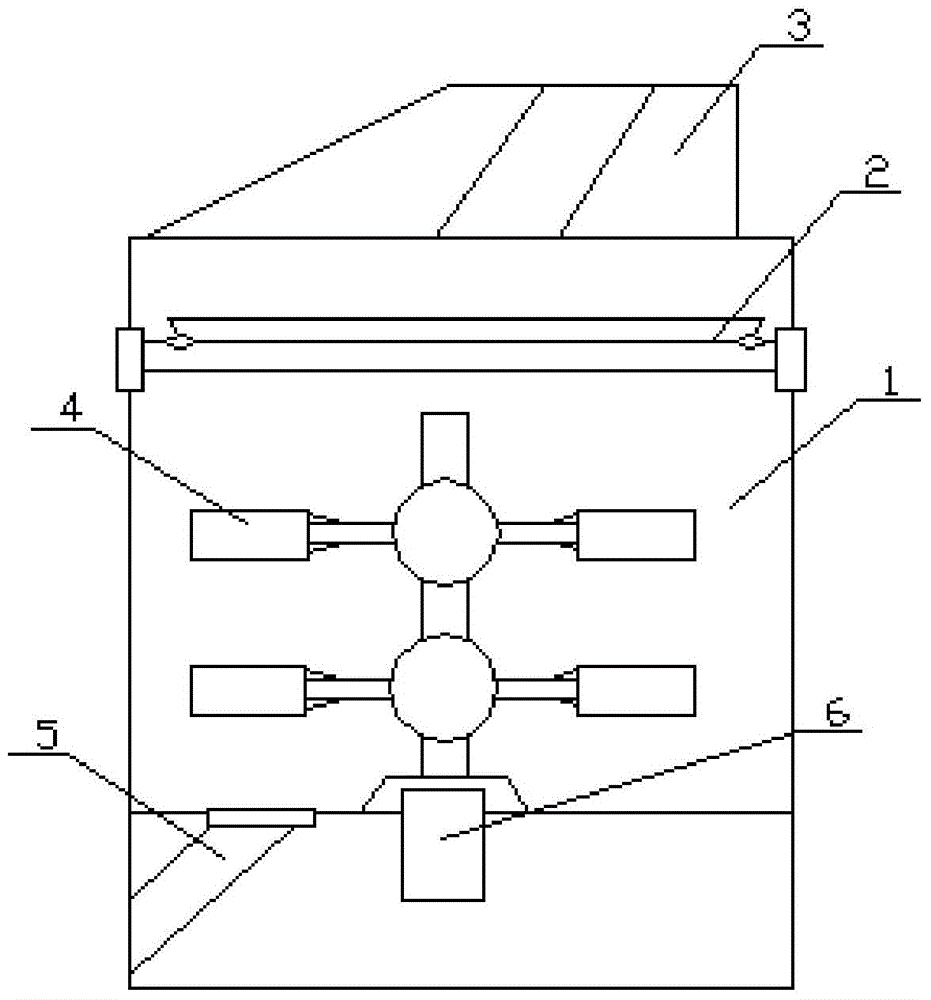

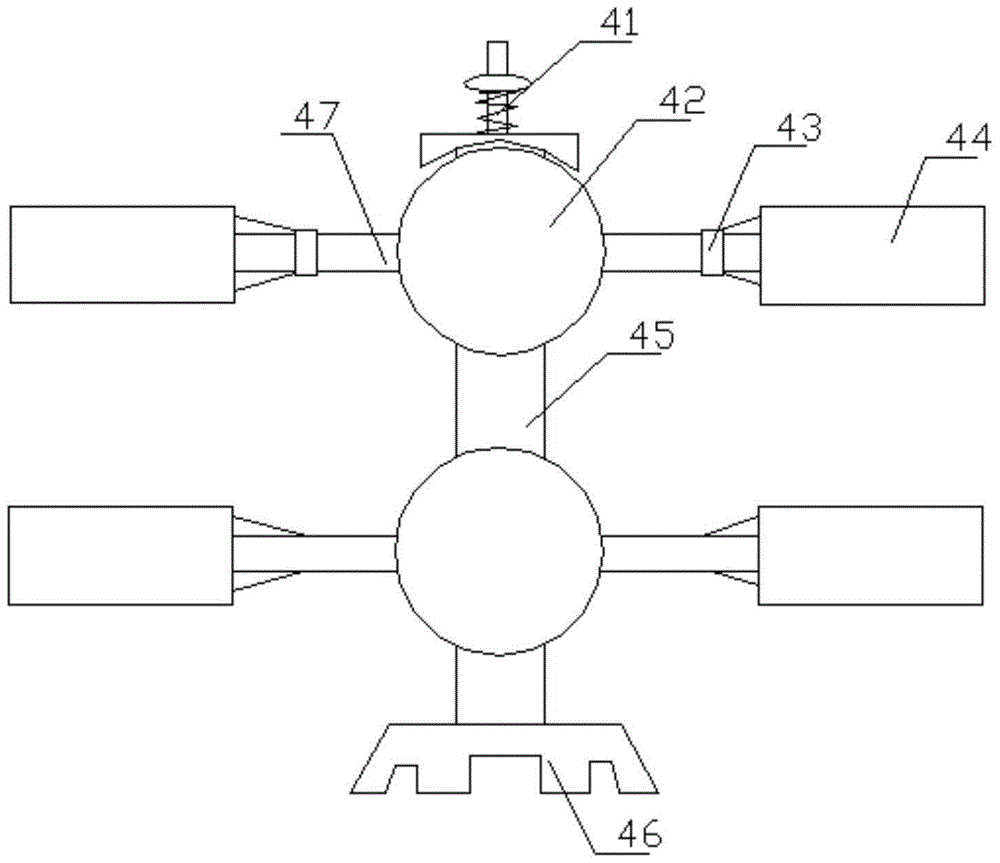

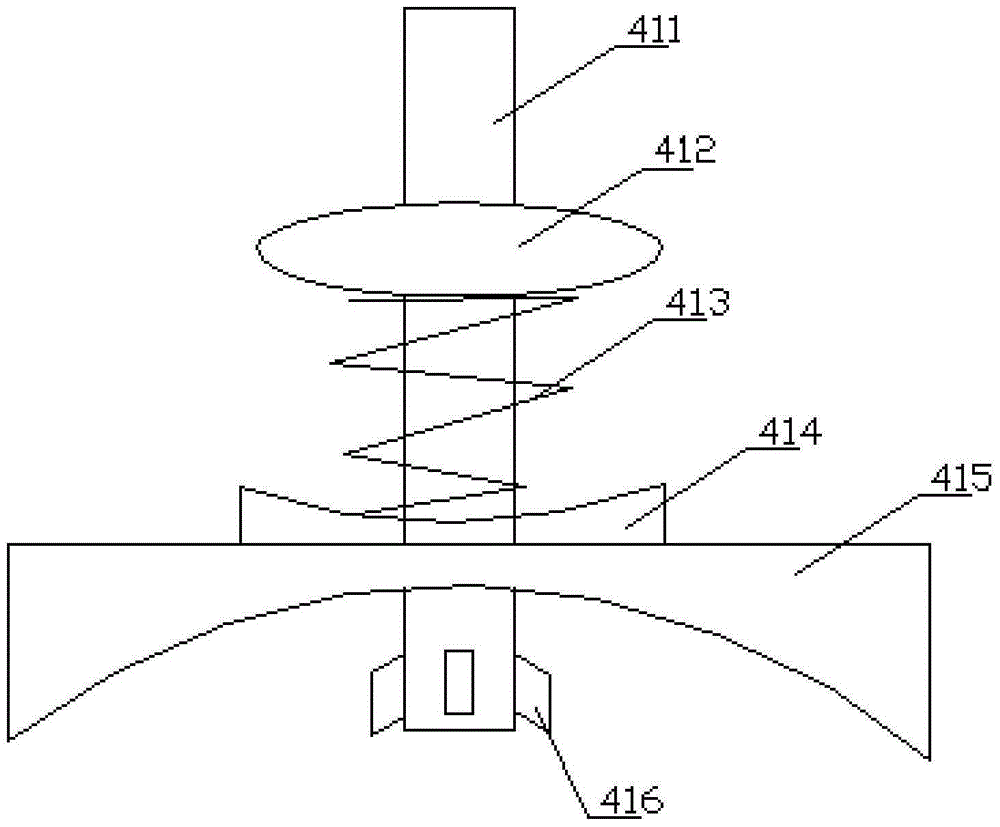

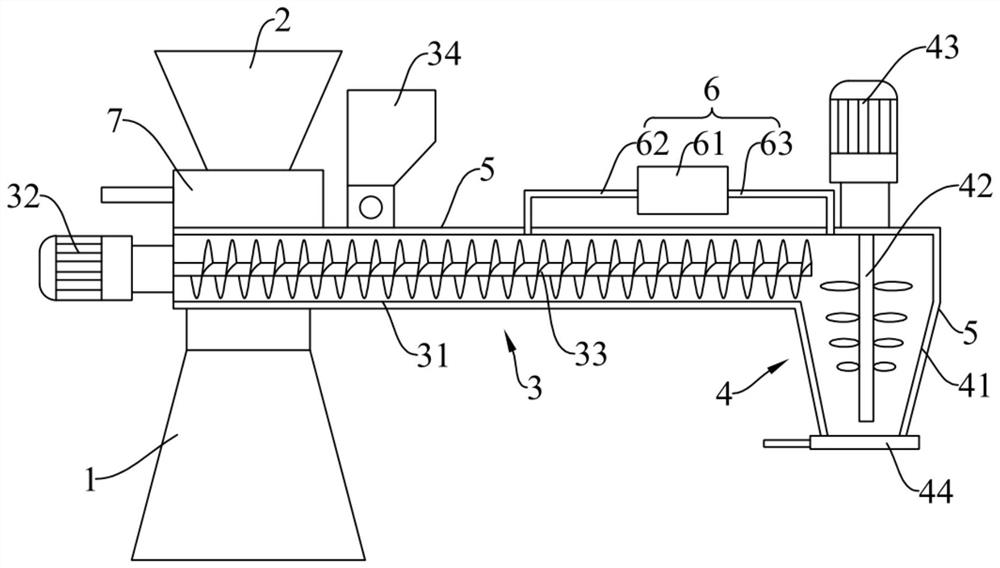

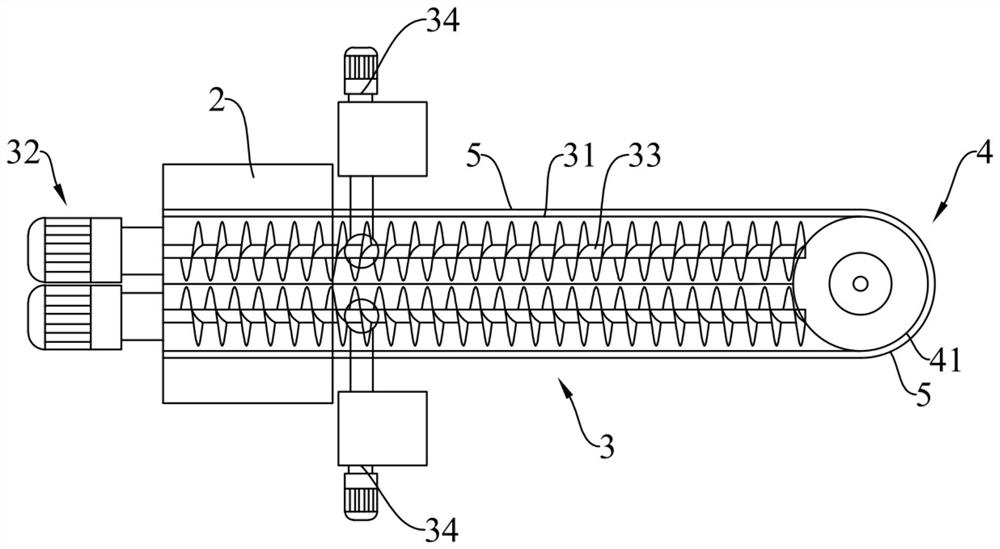

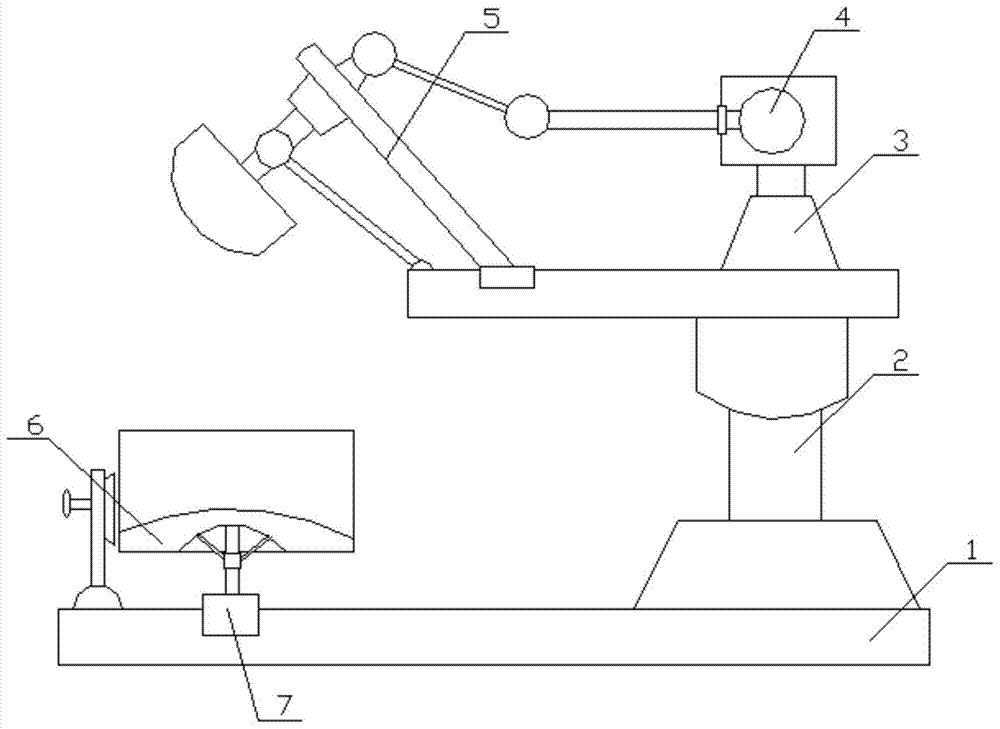

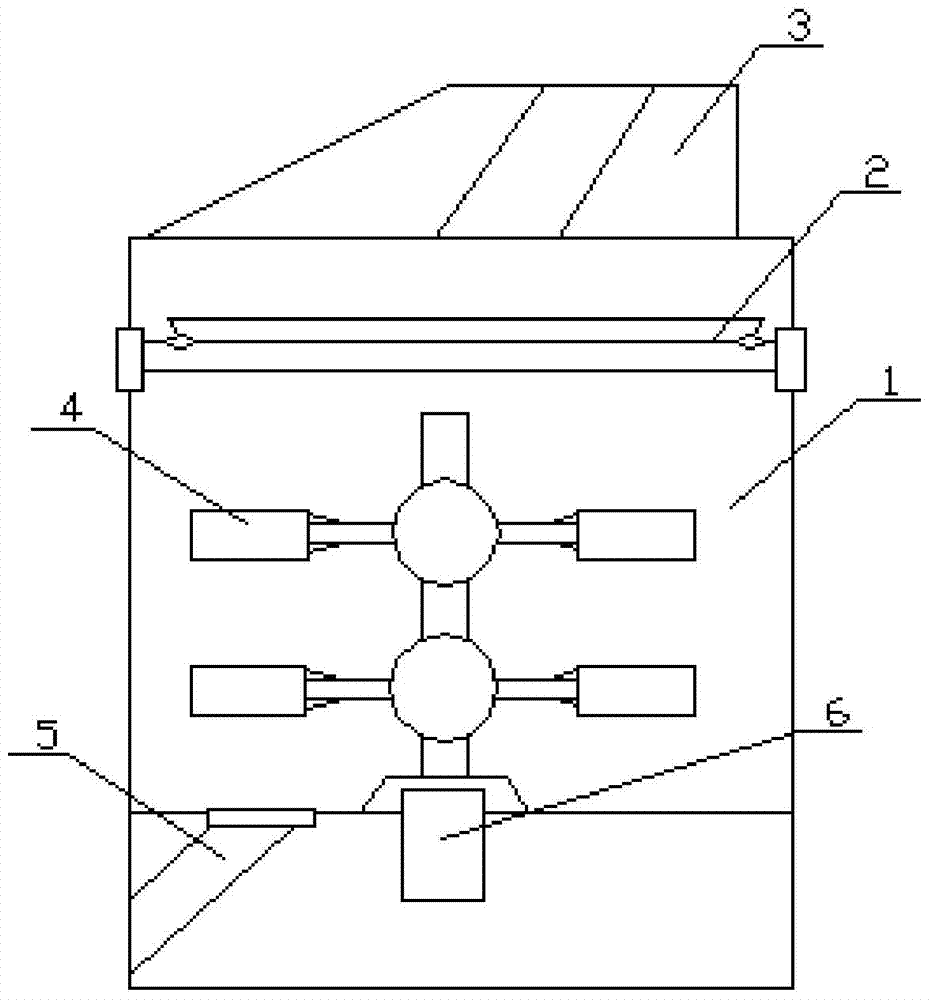

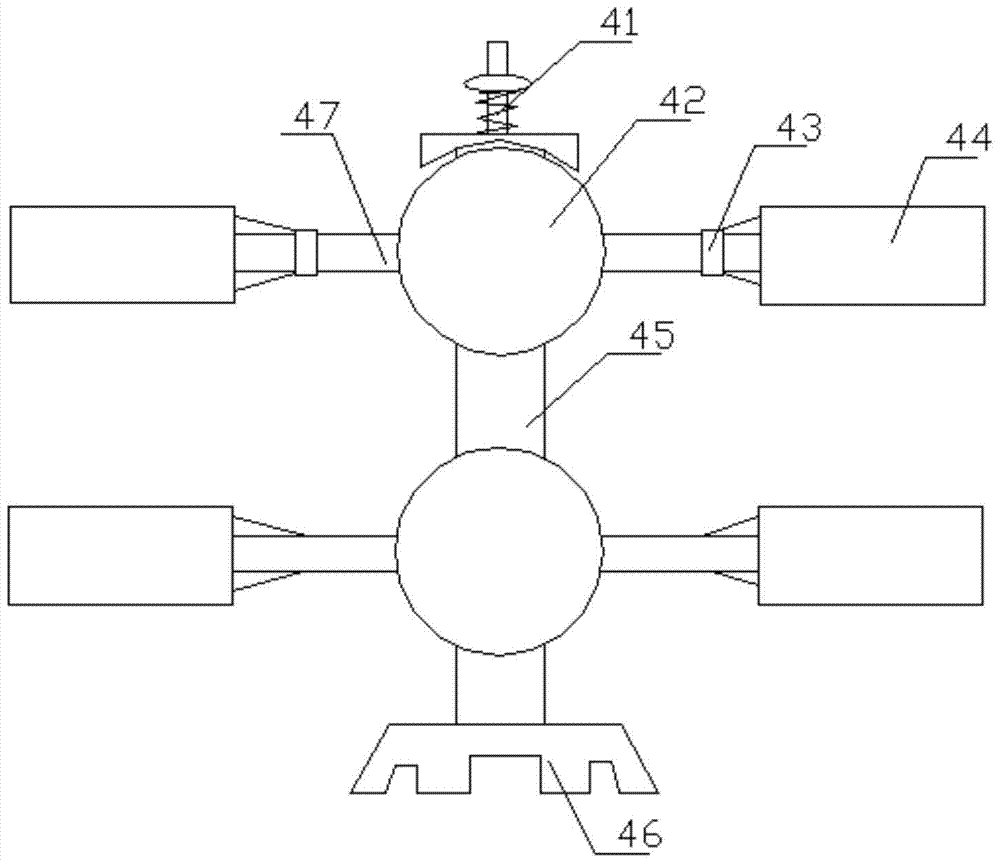

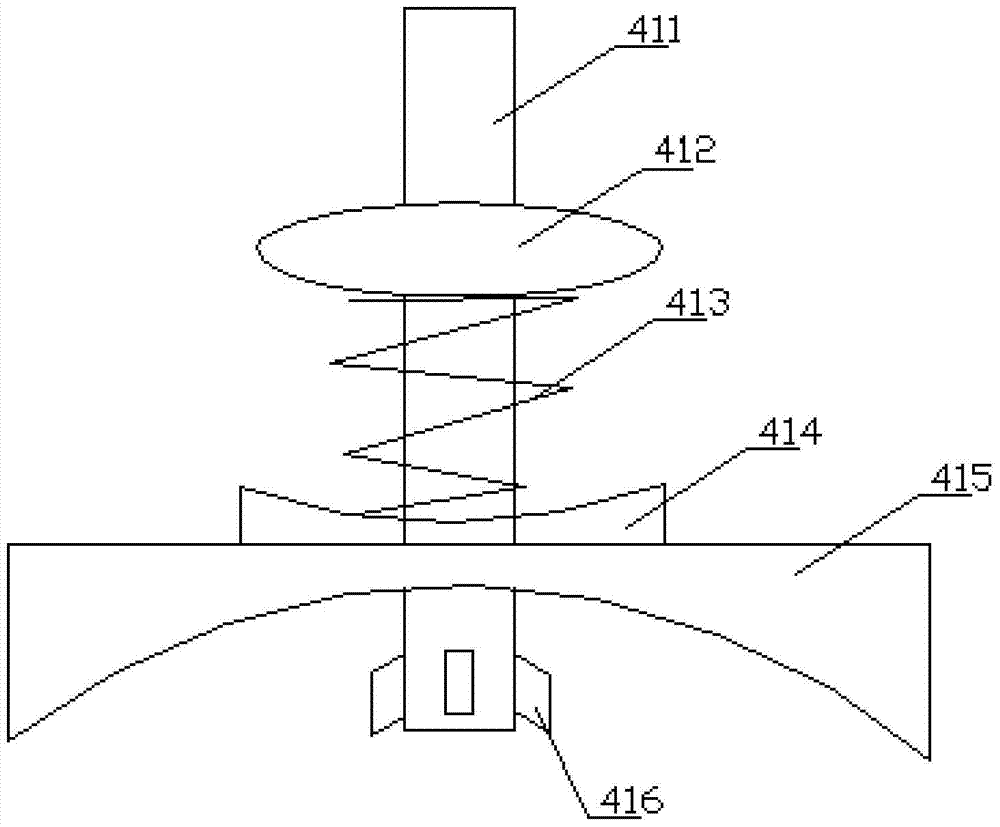

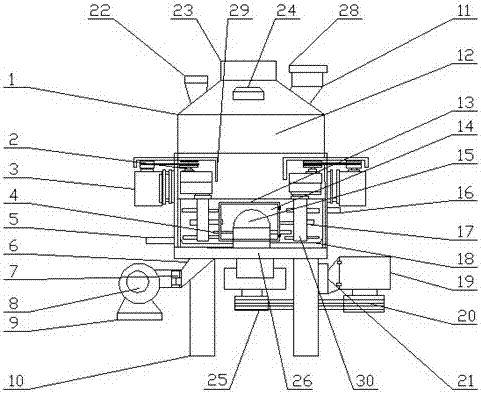

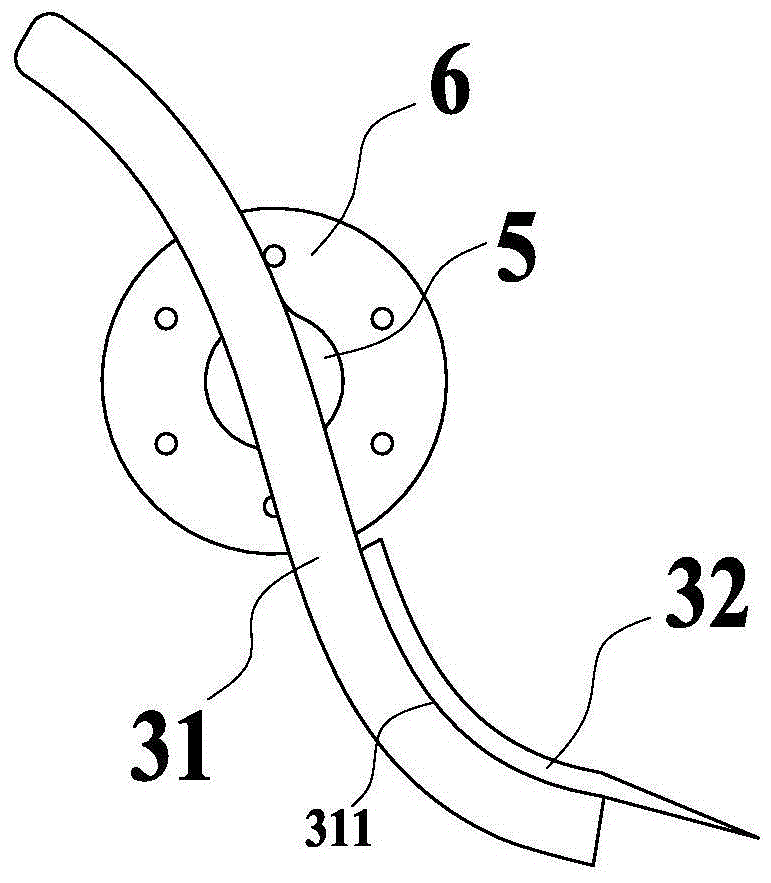

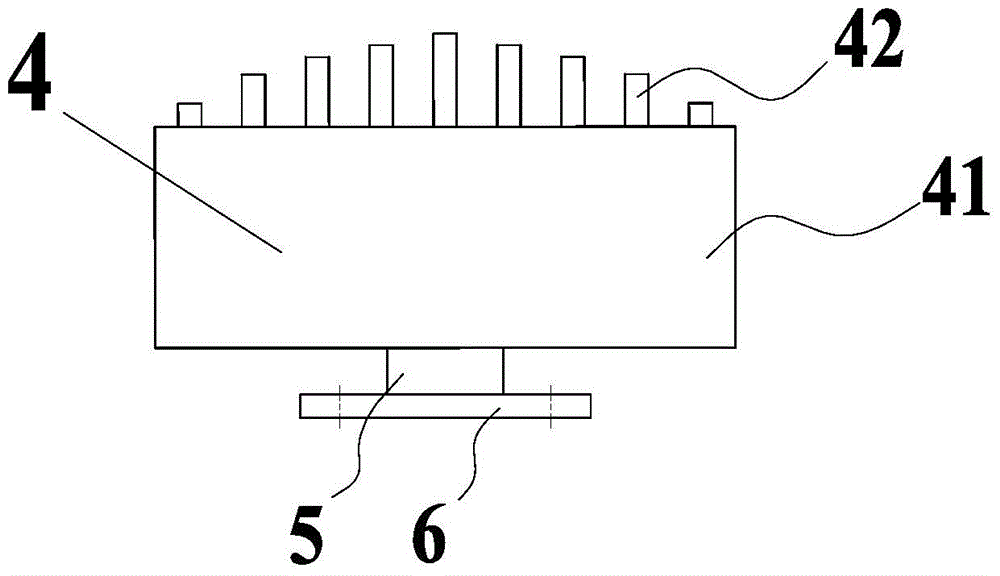

A continuous sand mixer and sand mixing process

ActiveCN107971457BImprove performanceGuaranteed to continueMould handling/dressing devicesTemperature controlThermodynamics

Disclosed is a sand mixer, comprising a machine base (1), a mixing device connected to the machine base, and a sand feeding hopper (2) and a water spray device (6) connected to the mixing device, wherein the mixing device comprises a sand conveying and mixing mechanism (3) and a final mixing mechanism (4), a first end of the sand conveying and mixing mechanism is connected to the sand feeding hopper, and a second end of the sand conveying and mixing mechanism is connected to the final mixing mechanism; the outside of both the sand conveying and mixing mechanism and the final mixing mechanism is sheathed with a temperature control cylinder (5), a gap for introducing a temperature control medium is provided between the temperature control cylinder and the sand conveying and mixing mechanism and between the temperature control cylinder and the final mixing mechanism; and the water spray device is respectively in communication with the sand conveying and mixing mechanism and the final mixing mechanism. A sand mixing process is further comprised. The sand mixer realises continuous sand mixing, and effectively controls the temperature of sand and the internal humidity, thereby improving the sand mixing efficiency and the performance of mixed sand.

Owner:SUZHOU MINGZHI TECH

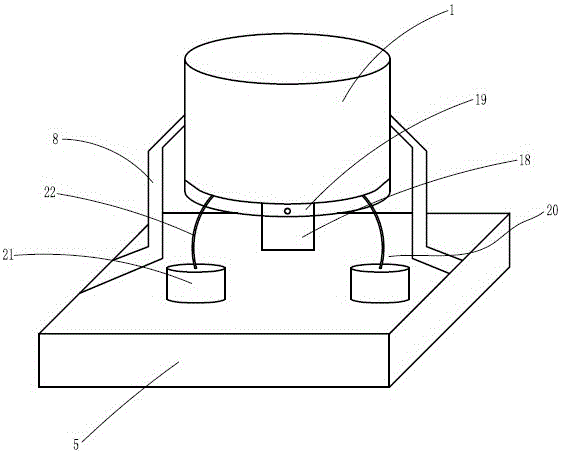

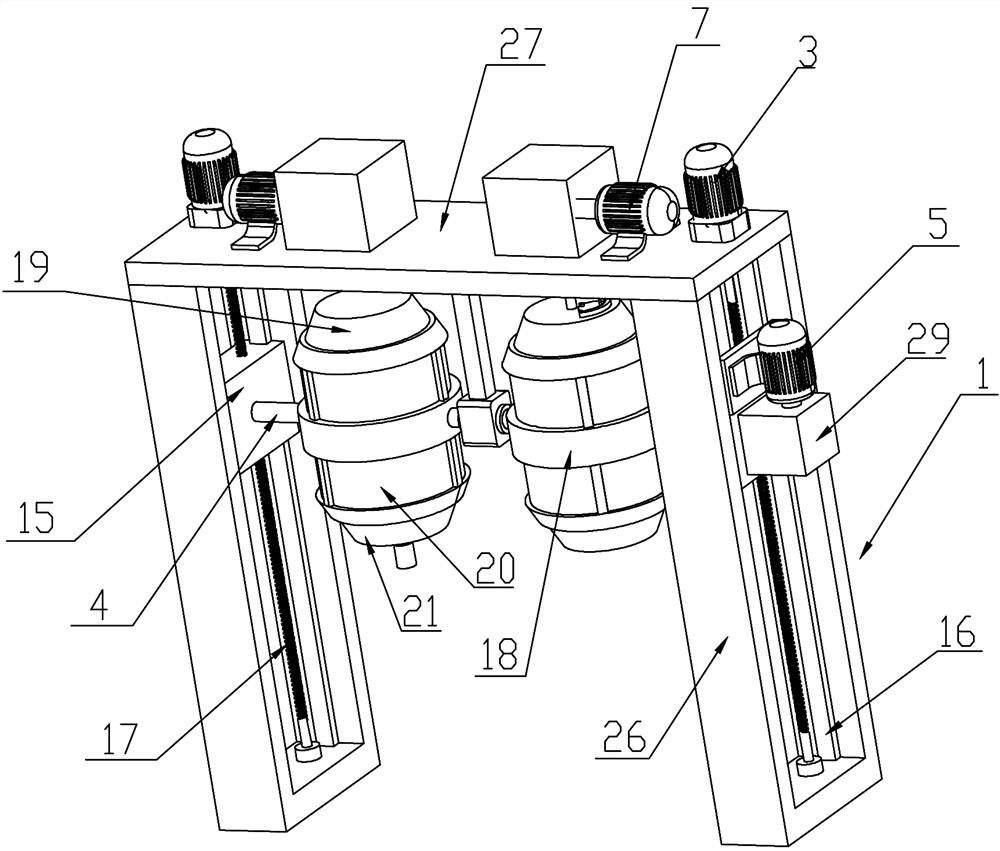

sand mixer

ActiveCN111842780BReduce downtimeImprove sand mixing efficiencyMould handling/dressing devicesElectric machineMechanical engineering

The invention discloses a sand mixing machine, which comprises a frame, a lifting frame, a lifting motor, a turning frame, a turning motor, two sand mixing buckets and two sand mixing motors, the lifting frame is arranged on the frame, and the turning motor is installed on On the lifting frame, the turning frame is rotated and set on the lifting frame, and the two sand mixing buckets are arranged on the turning frame. There is a stirring shaft in the sand mixing bucket, and a stirring blade is set on the stirring shaft. One end of the stirring shaft is connected from the sand mixing bucket. One end extends out of the sand mixing bucket, and the agitating shaft extends out of the sand mixing bucket. A connecting piece is provided at one end of the mixing bucket, and an internal spline is arranged on the connecting piece. The sand motor is arranged on the top of the frame, and the output shaft end of the sand mixing motor is provided with an external spline that can cooperate with the internal spline on the connecting key. The present invention is provided with two sand mixing tanks, and when one sand mixing tank is mixing sand, the other sand mixing tank discharges sand outwards, which reduces the downtime of sand discharging and improves the sand mixing efficiency of the present invention.

Owner:南京龙宁机床装备有限公司

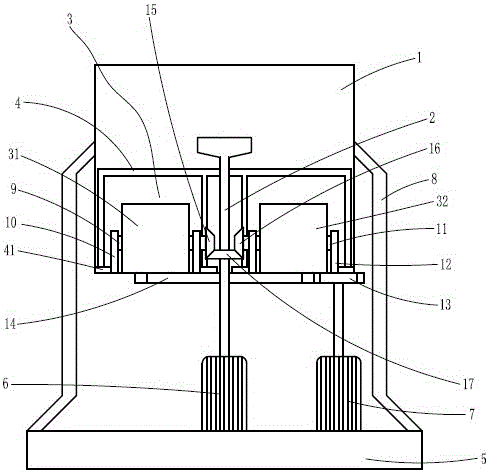

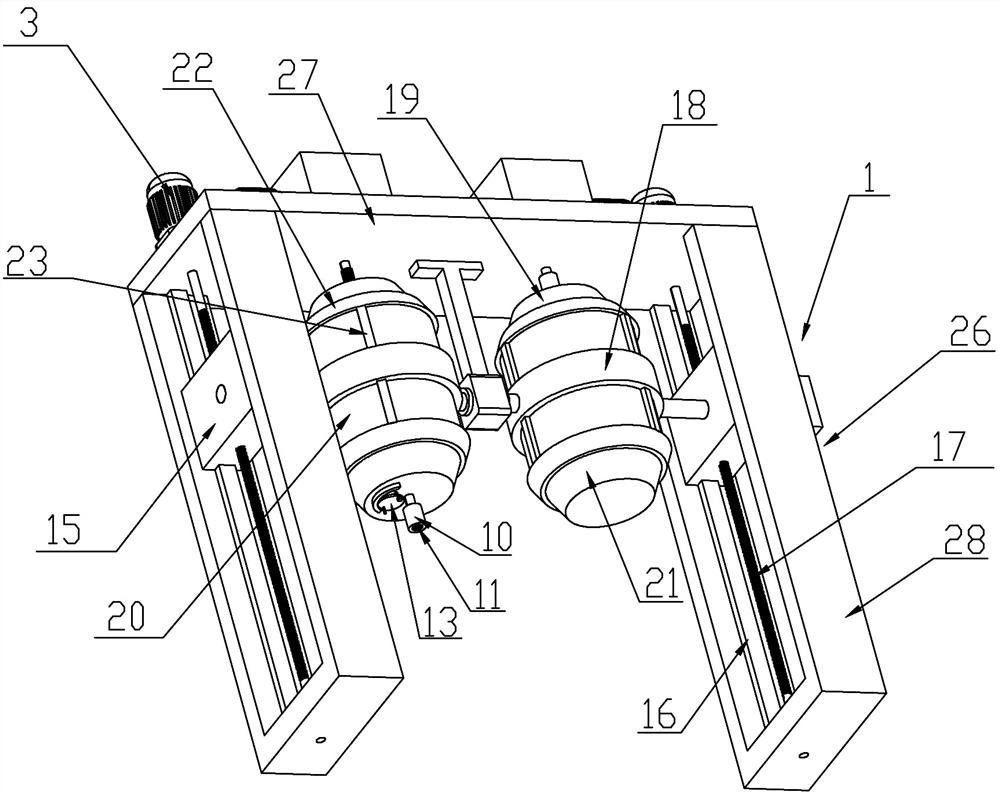

a sand mixer

ActiveCN105057582BEasy to operateEasy to adjustMould handling/dressing devicesElectric machineryEngineering

The present invention relates to the technical field of mechanical equipment, and in particular, to a sand mixer; the sand mixer of the present invention includes a main frame, and also includes a second motor arranged at the lower part of the main frame and arranged on the second motor The controller, the bearing member arranged on the main frame and located on the upper side of the second motor, the lifting member screwed on the second motor and pressed on the bearing member, and the lifting member arranged on the second motor The first motor on the upper end of the bearing member, the rolling member screwed on the first motor, and the adjusting member arranged on the upper part of the rolling member; High sand efficiency and good sand mixing quality.

Owner:JIASHAN JINYI PRECISION CASTING

A kind of sand mixing equipment

InactiveCN105170898BEasy to adjustEasy to operateMould handling/dressing devicesMechanical equipmentEngineering

The invention relates to the technical field of mechanical equipment, in particular to sand mixing equipment. The sand mixing equipment comprises a base and further comprises a mixing assembly arranged at one side of the upper end of the base, a first motor arranged at the lower end of the mixing assembly in a rotatable mode, a main machine frame, a motor installing base, a second motor and a sand mixing assembly which is arranged on the upper side of the main machine frame and connected to the second motor in a rotatable mode. The mixing assembly comprises an outer cylinder body, a bearing piece, a detecting cavity, a lifting shaft and a positioning and pressing piece. A pressure sensor is arranged in the detecting cavity. The positioning and pressing piece comprises a first rotary seat, inserted connection blocks, a first rotary head, a vertical pressing rod, an inner pressing frame, a pressure-resistant layer, a first adjusting rod and a handle. Rotary balls are installed between the vertical pressing rod and the inner pressing frame. The sand mixing equipment is convenient to operate and adjust, high in sand mixing efficiency and good in sand mixing quality.

Owner:陈红岩

A drum type sand mixing equipment

InactiveCN105170899BEvenly distributedEasy to operateMould handling/dressing devicesConvex sideEngineering

The present invention relates to the technical field of mechanical equipment, in particular to a drum-type sand mixing device; the drum-type sand mixing device of the present invention includes a main box, and also includes a feeding part, a filtering part, a mixing part, a driving part and a discharging part; The mixing component includes a main output shaft, a transmission seat, a first rotary joint, a stirring rod, a mixing plate, a fixed frame and a locking piece; the locking piece includes an outer cover plate, a guide rod, a gasket, an extrusion piece, and an adjustment spring And the male inserting side plate; the fixed frame includes a rotating ring, a main tight seat, a sub-rod, a first rotary joint, an auxiliary rod and a clip joint; along the axial direction of the main tight seat, it is inside A first guide hole is pierced; a first installation groove is recessed in the first rotary joint; a first connecting thread is provided in a concave recess in the outer wall of the first rotary joint; the cylindrical type of the present invention The sand mixing equipment is easy to operate, easy to adjust, high sand mixing efficiency, and good sand mixing quality.

Owner:吴春艳

A coated sand mixer

ActiveCN105268912BQuality improvementQuality impactMould handling/dressing devicesEngineeringReducer

The invention belongs to the technical field of coated sand production equipment and discloses a coated sand sand mixer, which includes a sand mixer body, the sand mixer body includes a sand mixing cylinder, a base and a foot, and the inside of the sand mixing cylinder is equipped with a There is a rotor reducer and a main shaft, the top of the rotor reducer is provided with a baffle, the baffle is fixedly connected with the inner wall of the sand mixing cylinder, the bottom of the rotor reducer is provided with a rotor, and the rotor is fixedly connected with the rotor reducer, The rotor is provided with a sand stirring rod, and the rotor and the sand stirring rod are fixedly connected. The main shaft is provided with a short scraper, and the bottom of the short scraper is provided with a long scraper. The top of the sand mixing tube is There are air outlet, resin inlet, curing agent inlet and sand inlet. The resin inlet, curing agent inlet and sand inlet are all provided with pipe covers on the top, and the outside of the sand mixing cylinder is provided with a rotor motor. In the present invention, two rotor motors are provided to fully stir the sand, so that the coating is more complete, and the sand mixing efficiency is high and the quality is good.

Owner:烟台锐盛汽车模具有限公司

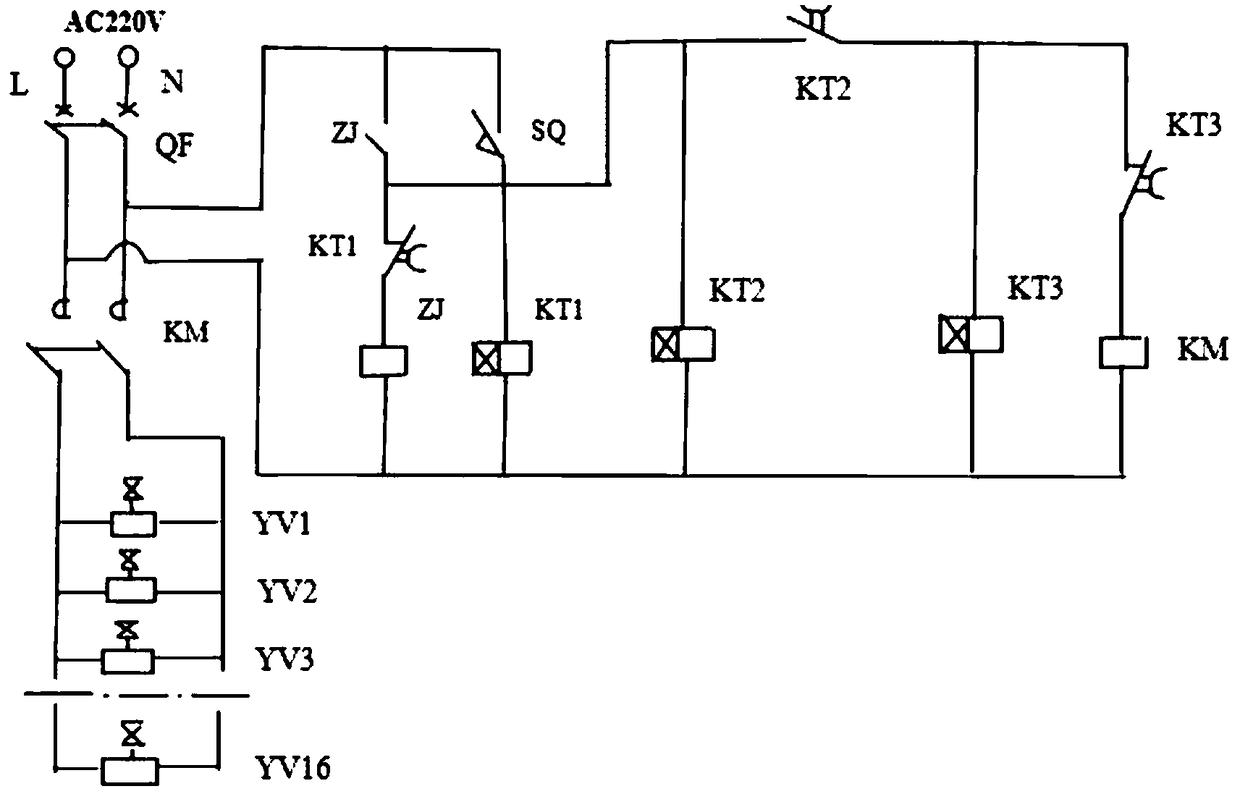

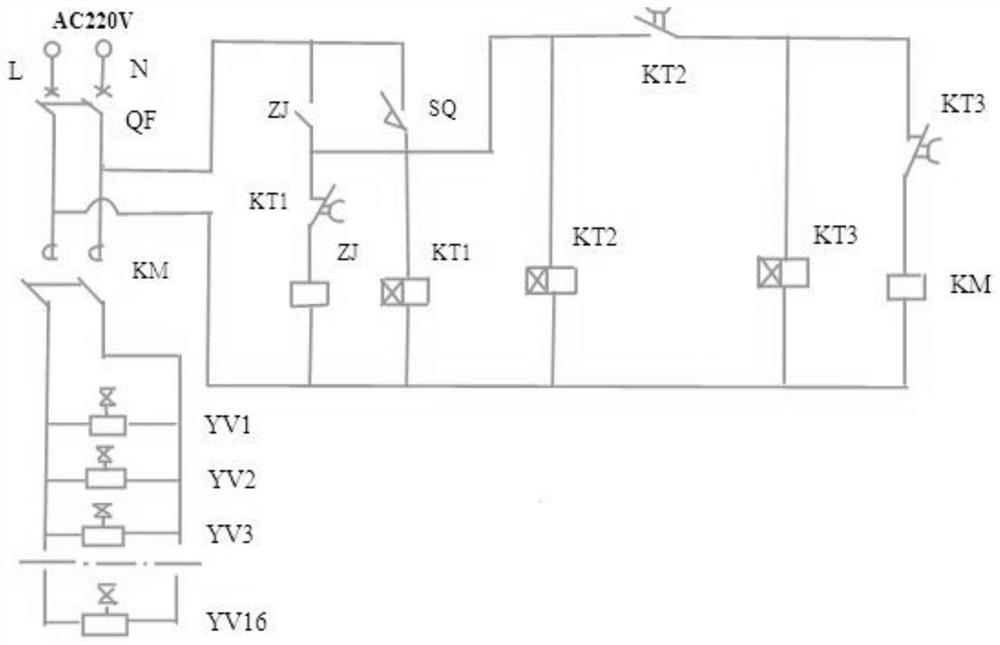

Water mist cooling control method of high-temperature molding sand

ActiveCN109434016AImprove performanceGuaranteed normal operationMould handling/dressing devicesSolenoid valveEngineering

The invention discloses a water mist cooling control method of high-temperature molding sand. A stroke switch SQ is arranged on a hoisting device on a vibration shakeout machine to be used for being in contact with a hoisting box to trigger, an arc-shaped stainless steel semi-closed cover is made on a conveyor belt to cover the conveyor belt, a plurality of high-pressure atomizing water injectionnozzles are installed on the central axis of the semi-closed stainless steel cover at equal intervals, each high-pressure atomizing water injection nozzle is controlled by a solenoid valve, the time taken form the hoisting box to vibrate sand falling to high temperature sand spreading over the conveyor belt is denoted as t1, when a vibration sand falling device is opened and the hoisting box is started, hoisting box equipment moves to be in contact with the stroke switch to enable the stroke switch close, the solenoid valve is opened again after delaying t1, thus the high-pressure atomizing water injection nozzles work, after working the time t2, the solenoid valve is closed, after waiting for a period of time, that is t3, thehoisting box equipment moves to be in contact with the travel switch again to enable the stroke switch close, and the steps are cycled and repeated in this way.

Owner:扬州广润机械有限公司

Continuous hemispherical sand mixing device for fracturing

InactiveCN104929606BReduce wearWell mixedRotary stirring mixersFluid removalSoil scienceFracturing fluid

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A high-temperature molding sand water mist cooling control method

ActiveCN109434016BImprove performanceGuaranteed normal operationMould handling/dressing devicesSolenoid valveEngineering

The invention discloses a water mist cooling control method of high-temperature molding sand. A stroke switch SQ is arranged on a hoisting device on a vibration shakeout machine to be used for being in contact with a hoisting box to trigger, an arc-shaped stainless steel semi-closed cover is made on a conveyor belt to cover the conveyor belt, a plurality of high-pressure atomizing water injectionnozzles are installed on the central axis of the semi-closed stainless steel cover at equal intervals, each high-pressure atomizing water injection nozzle is controlled by a solenoid valve, the time taken form the hoisting box to vibrate sand falling to high temperature sand spreading over the conveyor belt is denoted as t1, when a vibration sand falling device is opened and the hoisting box is started, hoisting box equipment moves to be in contact with the stroke switch to enable the stroke switch close, the solenoid valve is opened again after delaying t1, thus the high-pressure atomizing water injection nozzles work, after working the time t2, the solenoid valve is closed, after waiting for a period of time, that is t3, thehoisting box equipment moves to be in contact with the travel switch again to enable the stroke switch close, and the steps are cycled and repeated in this way.

Owner:扬州广润机械有限公司

Sand core material for brake disc casting mold as well as preparation method and application of sand core material

PendingCN114850392AGood collapsibilityImprove compromiseFoundry mouldsMould handling/dressing devicesBrakeFirming agent

The invention discloses a sand core material for a brake disc casting mold. The sand core material comprises 90-100 parts by weight of crude sand and 1.22-1.464 parts by weight of an additive, the crude sand comprises ceramic sand and quartz roasting sand in a weight ratio of (2-3): 7; the additives comprise 1.0-1.2 parts by weight of modified phenolic resin, an ammonia-free curing agent accounting for 12% of the added weight of the modified phenolic resin, a lubricant accounting for 8% of the added weight of the modified phenolic resin, a silane coupling agent accounting for 1% of the added weight of the modified phenolic resin and a collapsing agent accounting for 1% of the added weight of the modified phenolic resin. The invention further discloses a preparation method and application of the sand core material for the brake disc casting mold. The method has good collapsibility and deformability and low gas forming amount, the dimensional precision and the surface quality of products are guaranteed, and the defects of sand burning, sand inclusion and the like are not prone to being generated.

Owner:南京中盛铁路车辆配件有限公司 +1

A continuous clay sand mixer

ActiveCN103785792BImprove performanceReduce consumption costMould handling/dressing devicesElectricityProduction rate

The invention belongs to the technical field of sand mixing equipment and relates to a continuous clay sand mixer. A new and old sand bin, a bentonite bin and a pulverized coal bin are arranged above a comprehensive charging hole, a moisture detector connected with a PLC control unit in an electric information mode is arranged under the new and old sand bin, and online detection of moisture of new and old sand before sand mixing can be achieved; after a human-machine control interface presets raw material parameters, the PLC control unit is used for analysis and calculation to control operation of a water pump frequency converter, a bentonite spiral feeding frequency converter and a pulverized coal spiral feeding frequency converter, and water, bentonite and pulverized coal are continuously added to a mixing cage in real time in an online and quantified mode; a return bin with a discharging mechanism is arranged under the mixing cage, so that mixed moulding sand is conveyed to the next production link; the mixer is simple in structure, reasonable in design, scientific in principle, simple in operation, high in sand mixing efficiency, good in sand mixing effect and good in finished product performance, the production efficiency is improved, and production cost is lowered.

Owner:孙晓宇

Sand mixer

ActiveCN105057582AEasy to operateEasy to adjustMould handling/dressing devicesElectric machineryMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a sand mixer. The sand mixer comprises a main machine frame, and further comprises a second motor arranged on the lower portion of the main machine frame, a controller arranged on the second motor, bearing assemblies which are arranged on the main machine frame and located on the upper side of the second motor, lifting assemblies which are connected to the second motor in a screwed manner and tightly pressed to the corresponding bearing assemblies, a first motor arranged at the upper ends of the bearing assemblies, rolling assemblies which are connected to the first motor in a screwed manner and an adjusting assembly arranged on the upper portions of the rolling assemblies. The sand mixer is convenient to operate and adjust, high in sand mixing efficiency and good in sand mixing quality.

Owner:JIASHAN JINYI PRECISION CASTING

Novel efficient mixer with inclined fixed chassis

PendingCN112059108AImprove sand mixing efficiencyShort mixing cycleMould handling/dressing devicesThermodynamicsEngineering

The invention relates to the technical field of casting equipment, in particular to a novel efficient mixer with an inclined fixed chassis. The novel efficient mixer comprises a rack, the end face ofthe rack is connected to the bottom of an inclined sand mixing chamber, a sand mixing chamber upper cover is connected to a port of the inclined sand mixing chamber through bolts, and a used sand feeding hopper is arranged on the sand mixing chamber upper cover; and an accessory feeding port is formed in the position, on the end face of the sand mixing chamber upper cover, of the right side of theused sand feeding hopper. According to the novel efficient mixer, sand mixing and stirring are conducted through interaction of two sets of sand mixing rotor structures and a scraper blade structure,thus, the effects that the sand mixing efficiency is high and the sand mixing period is short are achieved, meanwhile, the sand mixing chamber is arranged to be inclined, and a molding sand discharging door is formed in the lowest position, so that rapid sand discharging is facilitated, the effects of the short sand discharging time, improvement of the production efficiency and reduction of the energy consumption are achieved, the problems of the low sand mixing efficiency, the long sand mixing period, the long sand discharging time and the high energy consumption of an existing sand mixer are solved, thus, the the applicability is higher, and the existing working requirements can be better met.

Owner:五洋百川(青岛)智能设备有限公司

Centrifugal sand mixer for mixing sand and soil

ActiveCN108705029BReduce the possibility of scatterPrevent sideslipMould handling/dressing devicesSoil scienceSoil mixing

The invention discloses a centrifugal sand mixer for mixing sandy soil. The centrifugal sand mixer comprises a fixing base, wherein annular sliding grooves are formed in the upper surface of the fixing base, a groove is formed in the upper surface of the fixing base, a first motor is fixedly connected to the inner bottom wall of the groove, the output end of the first motor is fixedly connected with a gear, a sand mixing barrel is arranged at the top of the fixing base, the bottom surface of the sand mixing barrel is fixedly connected with a tooth ring, the outer surface of the tooth ring is meshed with the outer surface of the gear, the bottom surface of the sand mixing barrel is fixedly hinged to first roller wheels through pin shafts, the first rolling wheels are clamped in the annularsliding grooves, the inner bottom wall of the sand mixing barrel is fixedly connected with a driving box, a second motor is arranged in the driving box, and a rotating rod is fixedly connected to theoutput end of the second motor. The sand mixing machine for mixing the sandy soil has the advantages that the inner side wall can be cleaned after the sand mixing is finished, and the sand mixing efficiency of the sand mixing machine is improved.

Owner:乳源瑶族自治县嘉旺商品混凝土搅拌有限公司

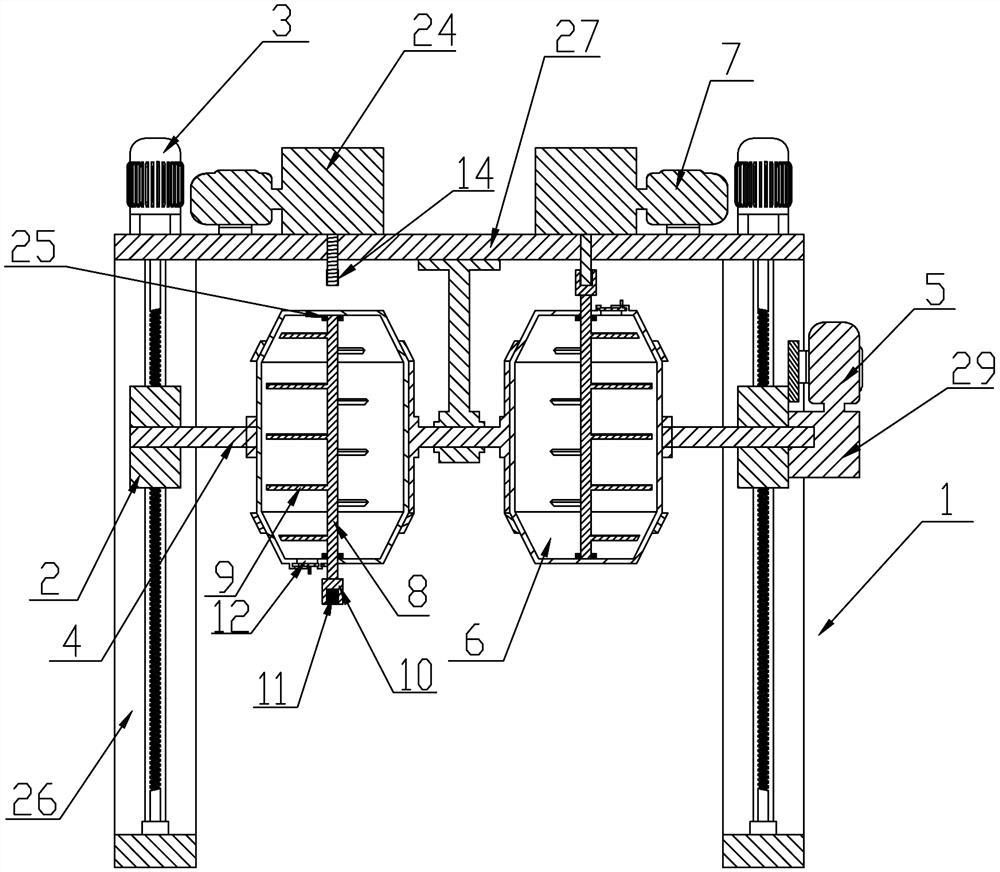

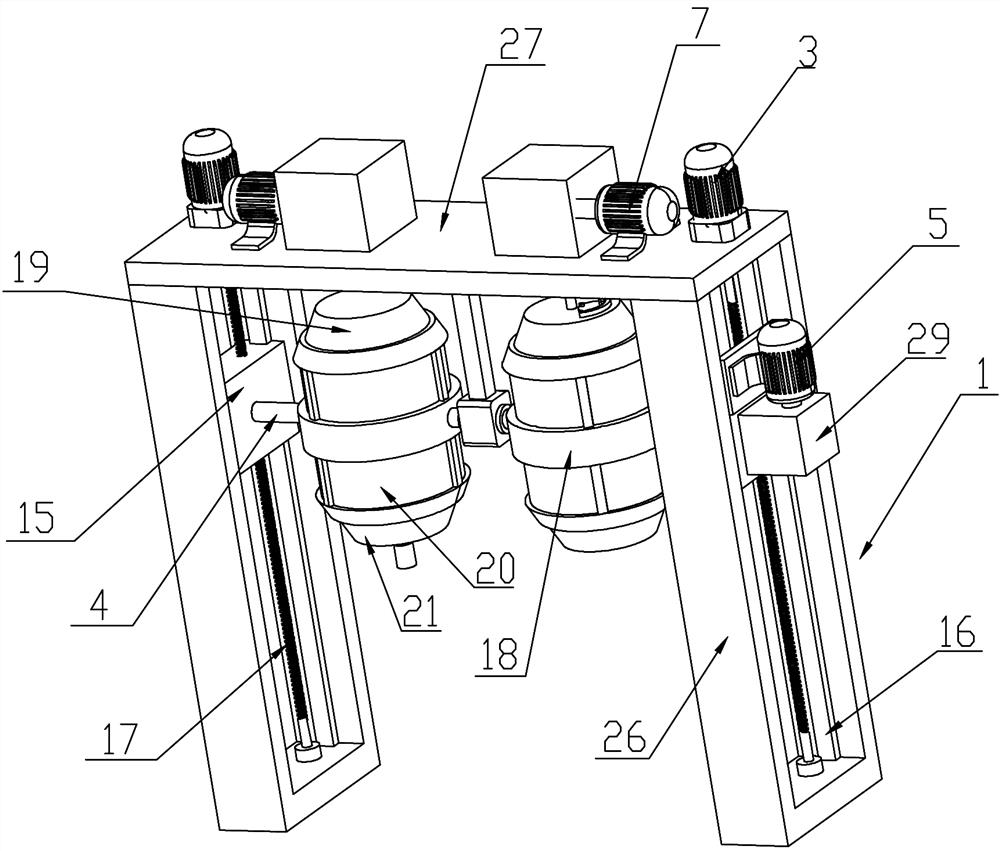

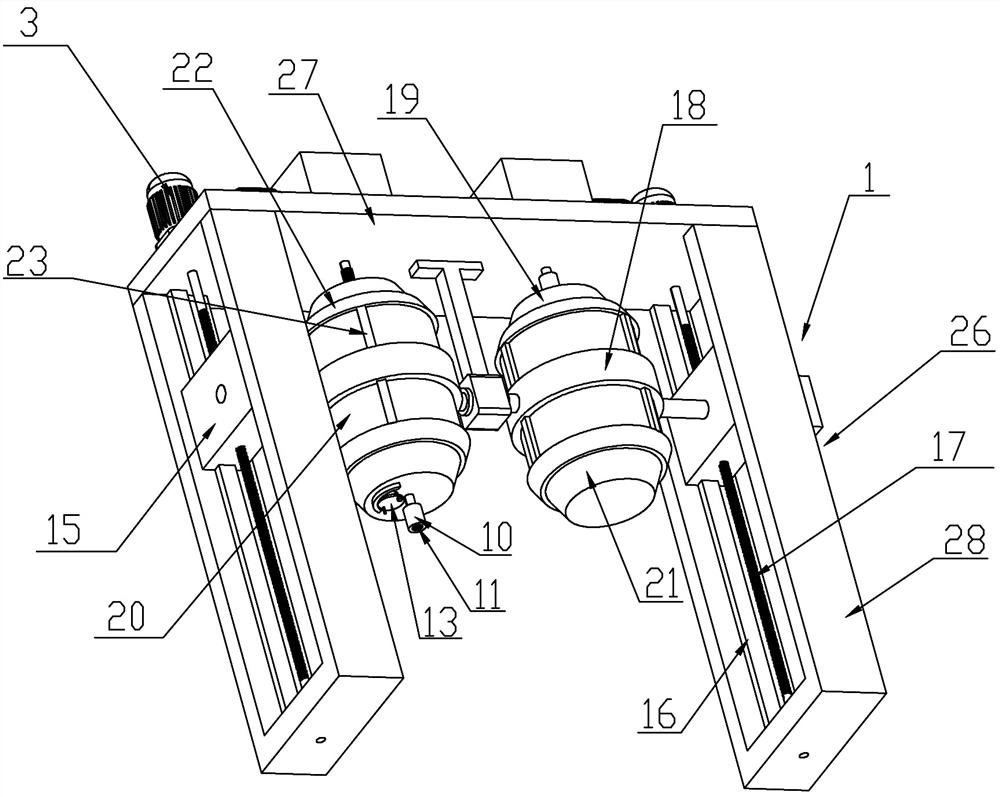

Sand mixer

ActiveCN111842780AReduce downtimeImprove sand mixing efficiencyMould handling/dressing devicesElectric machineMechanical engineering

The invention discloses a sand mixer. The sand mixer comprises a rack, a lifting frame, a lifting motor, a turning frame, a turning motor, two sand mixing barrels and two sand mixing motors, the lifting frame is arranged on the rack, the turning motor is installed on the lifting frame, the turning frame is rotationally arranged on the lifting frame, the two sand mixing barrels are arranged on theturning frame, stirring shafts are arranged in the sand mixing barrels, stirring blades are arranged on the stirring shafts, one ends of the stirring shafts extend out of the sand mixing barrels fromone ends of the sand mixing barrels, connecting pieces are arranged at the ends, extending out of the sand mixing barrels, of the stirring shafts, internal splines are arranged on the connecting pieces, sand inlet and outlet ports of the two sand mixing barrels are formed in the ends, away from each other, of the two sand mixing barrels correspondingly, the sand mixing motors are arranged at the top of the rack, and external splines capable of being matched with the internal splines on the connecting pieces are arranged at the ends of output shafts of the sand mixing motors. According to the sand mixer, the two sand mixing barrels are arranged, when one sand mixing barrel mixes sand, the other sand mixing barrel discharges the sand outwards, so that the downtime for discharging the sand isshortened, and the sand mixing efficiency of the sand mixer is improved.

Owner:南京龙宁机床装备有限公司

A sand-turning sand mixer

ActiveCN104815949BImprove the effect of foundryImprove sand mixing efficiencyMould handling/dressing devicesCouplingWhole body

Owner:南通乐士机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com