Continuous semispherical sand mixing device for fracture

A hemispherical, sand mixing technology, applied in mixers, mixers, wellbore/well components, etc. with rotating mixing devices, can solve the problems affecting the service life of mixing devices, need to be improved, impeller wear, etc., and achieve mixing. The effect of improving sand effect, reducing blade wear and improving sand mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

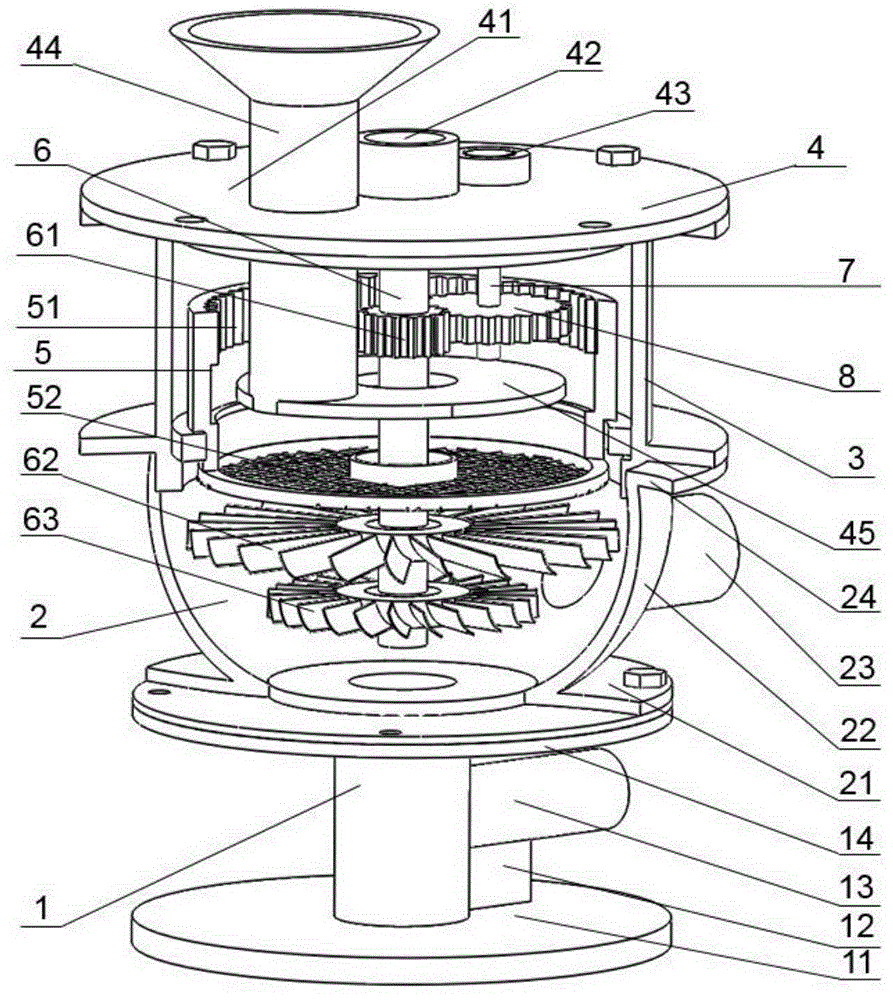

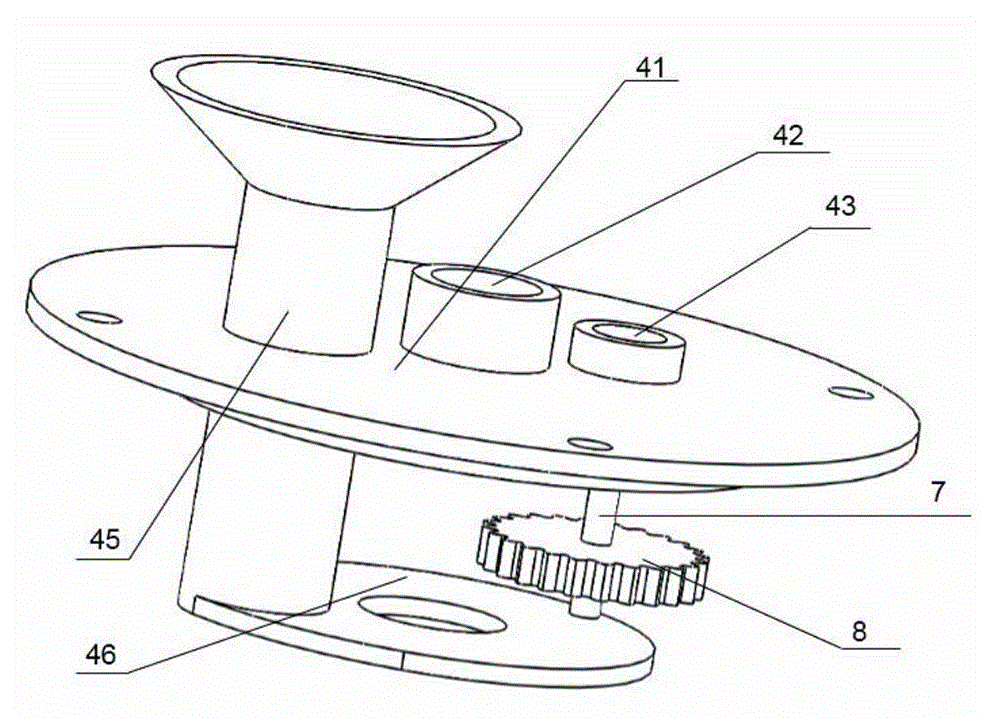

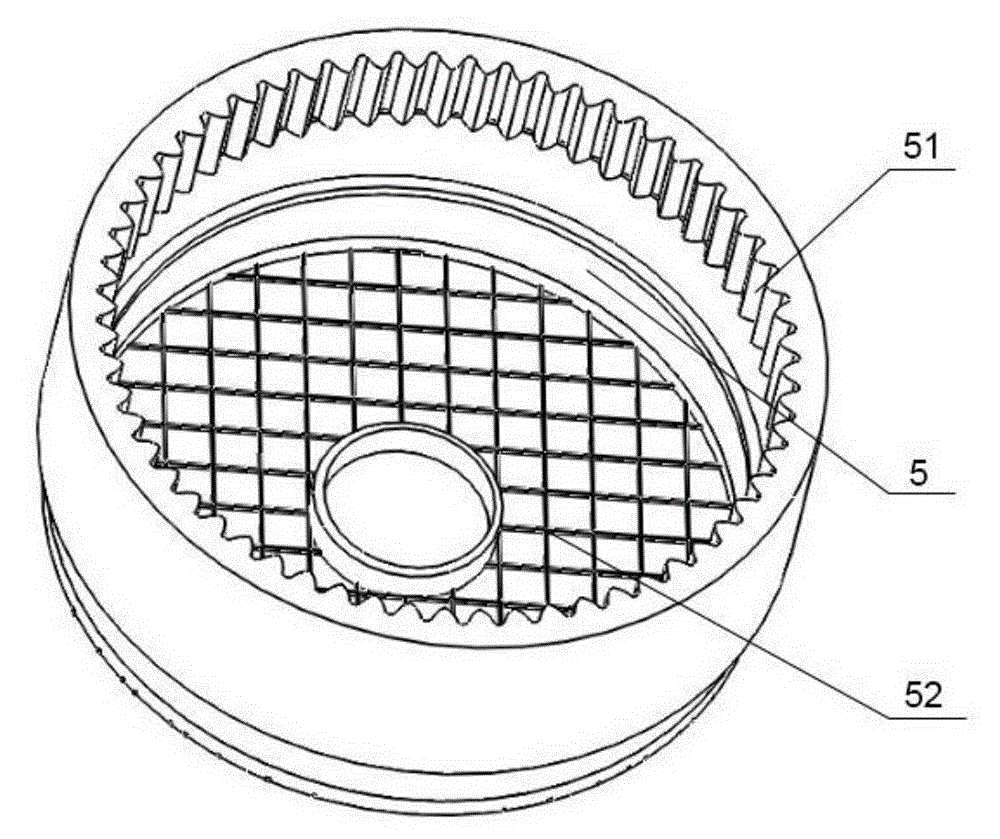

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the continuous hemispherical sand mixing device for fracturing includes: base 1, sand mixing chamber 2, transmission box 3, upper end cover 4, main shaft 5, and internal gear 6, in which:

[0021] Base 1, the lower part is a closed circular chassis 11, the middle is a T-shaped liquid inlet pipe 13, the upper part is a flange 14, and the lower part of the T-shaped liquid inlet pipe 13 is provided with a support plate 12 to support the T-shaped liquid inlet pipe 13; The cracking liquid enters the sand mixing device from the T-shaped liquid inlet pipe 13 of the base 1, and enters the sand mixing chamber 2 through the flange plate 14.

[0022] Sand mixing chamber 2, the lower part is the lower flange 21, the middle part is the hemispherical shell 22, the upper part is the upper flange 24, and the middle part of the hemispherical shell 22 is provided with a liquid outlet pipe 23; the lower flange 21, the hemispher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com