A coated sand mixer

A technology of sand mixer and coated sand, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., which can solve the problems of insufficient mixing and inconvenience of sand mixer, and achieve good quality , prevent environmental pollution, high sand mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

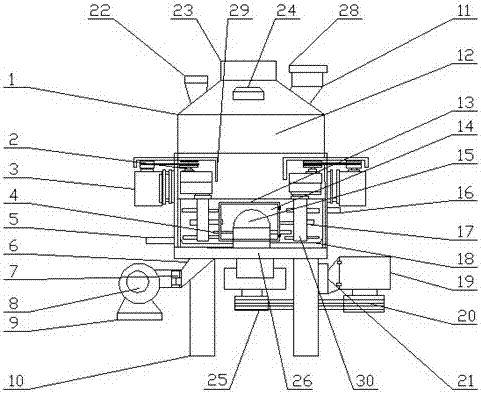

[0019] Example: see Figure 1-2 , a coated sand sand mixer according to the present invention, comprising a sand mixer body 1, the sand mixer body 1 includes a sand mixing cylinder 12, a base 26 and a foot 10, and a rotor reducer is arranged inside the sand mixing cylinder 12 2 and the main shaft 15, the top of the rotor reducer 2 is provided with a baffle 29, the baffle 29 is fixedly connected with the inner wall of the sand mixing cylinder 12, the bottom of the rotor reducer 2 is provided with a rotor 30, and the rotor 30 is connected with the rotor The reducer 2 is fixedly connected, the rotor 30 is provided with a sand stirring rod 17 outside, the rotor 30 is fixedly connected with the sand stirring rod 17, the main shaft 15 is provided with a short scraper 4 outside, and the short scraper 4 A long scraper 18 is provided below, and the top of the sand mixing cylinder 12 is provided with an air outlet 23, a resin inlet 22, a curing agent inlet 24 and a sand inlet 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com