Casting sand grinding and mixing system

A mixing system and casting sand technology, which is applied to casting molding equipment, cleaning/processing machinery of casting mold materials, metal processing equipment, etc., can solve problems such as low efficiency, manpower and material resources, and inability to meet the needs of large-scale casting production , to achieve the effect of improving efficiency, reducing labor costs and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

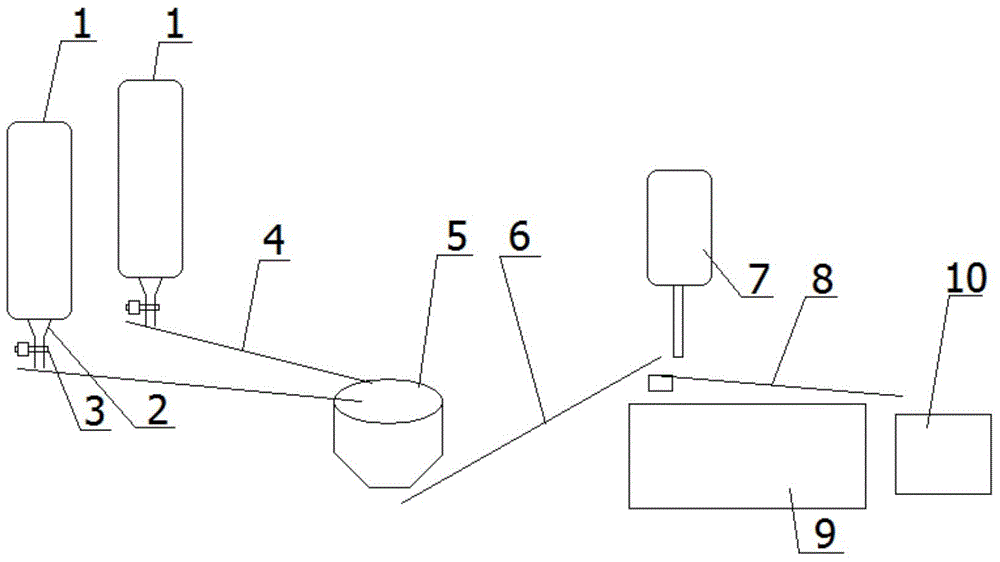

[0017] like figure 1 As shown, the casting sand grinding and mixing system is provided with at least two main bins 1, the number of main bins 1 can be set according to the type of main material to be ground, and the bottom of the main bin 1 is equipped with a discharge port, in order to facilitate unloading , the discharge port at the bottom of the main silo 1 is the flexible discharge port 2, and the flexible discharge port 2 is a hollow columnar discharge port made of canvas. In addition, a vibrator 3 is bound outside the flexible discharge port 2, so that When unloading, the vibrator 3 can drive the flexible discharge port 2 to vibrate to ensure smooth unloading and avoid material clogging and system interruption.

[0018] Below the discharge port of the main silo 1, there is a coarse material conveyor belt 4 that conveys the material (main material) to the grinder 5. The grinder 5 grinds the material and can mix two or more main materials at the same time. 5. The discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com