Continuous resin sand mixing machine and sand mixing method

A resin sand and sand mixer technology, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., can solve the problems of increased processing time, low work efficiency, air pollution, etc. The effect of high production cost, high sand mixing efficiency and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

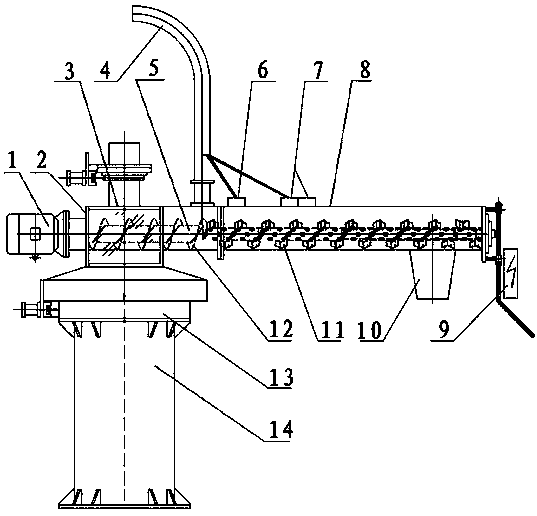

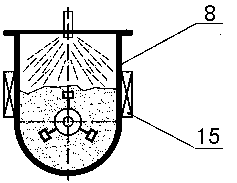

[0022] refer to Figure 1-Figure 2 , the resin sand continuous sand mixer of the present embodiment, it comprises support device 14, feeding box 2 and sand mixing cylinder 8, and feeding box and sand mixing cylinder pass are arranged horizontally, and described support device 14 top is provided with rotary device 13 , the feed box 2 is installed on the rotary device 13, the top of the feed box 2 is provided with a feed port 3, the feed port 3 is connected to the feeding system, and a motor 1 is installed on the horizontal side of the feed box, opposite to The other side of the sand mixing cylinder 8 communicates with the sand mixing cylinder 8. The section of the sand mixing cylinder 8 is U-shaped. The top of the sand mixing cylinder 8 is provided with a binder inlet, including a curing agent inlet 6 and a resin inlet 7. The curing agent One agent inlet 6 is provided, and the resin inlet 7 is provided with two.

[0023] The output shaft of the motor is equipped with a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com