Continuous clay sand mixer

A clay sand and sand mixer technology, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc. Reduce production efficiency and other issues, to achieve the effect of reducing power consumption and maintenance costs, small footprint, and low equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

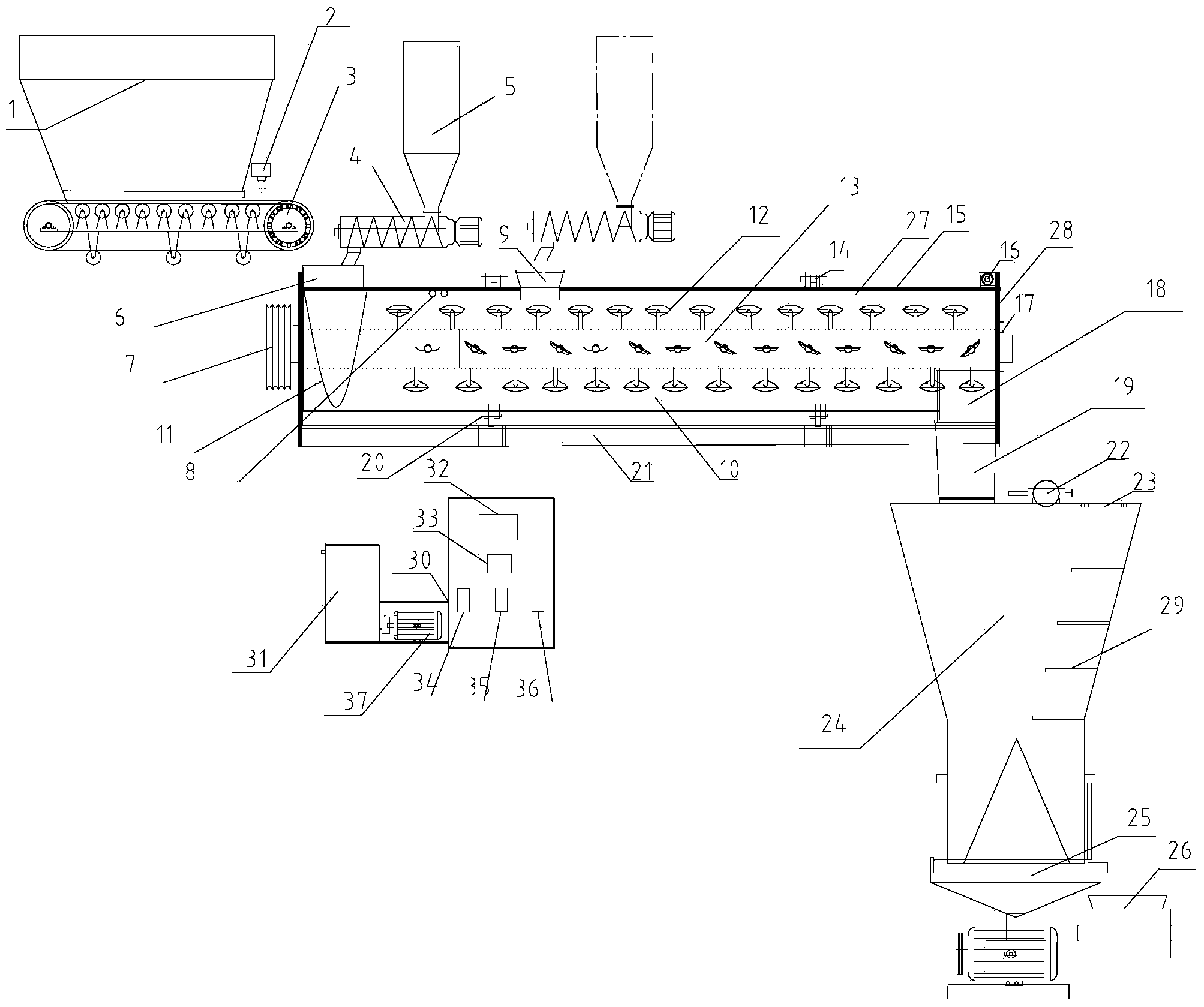

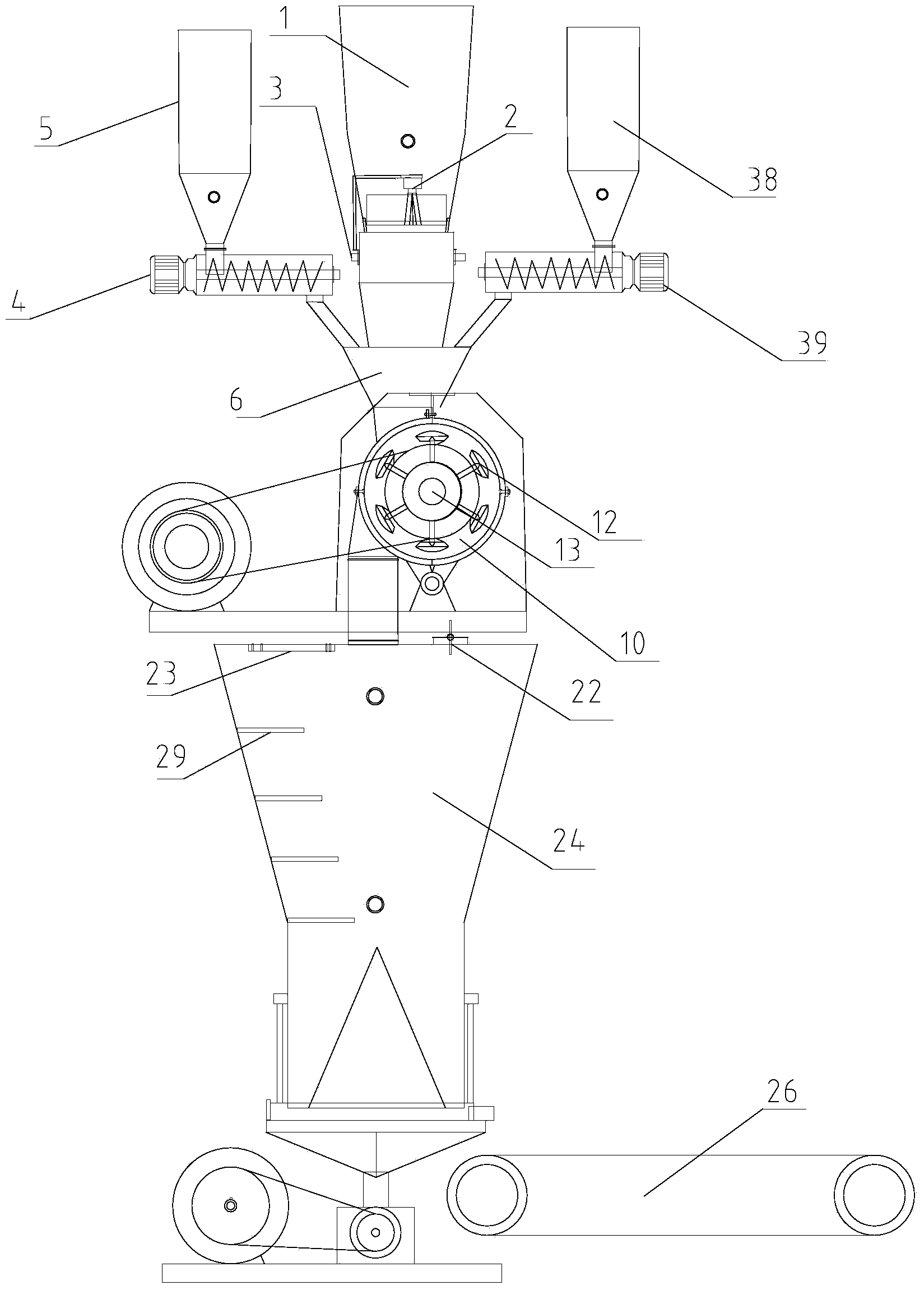

[0013] The main structure of the continuous clay sand mixer involved in this embodiment includes a new and old sand bin 1, a quantitative feeding belt conveyor 3, a bentonite screw feeder 4, a bentonite bin 5, a comprehensive feeding port 6, a pulley 7, and a water feeding port 8. Stirring cage 10, propulsion screw 11, stirring cage blade 12, stirring cage shaft 13, closing hinge 14, stirring cage shell 15, fixed splint 16, bearing 17, discharge port 18, soft connecting section 19, same Shaft support hinge mechanism 20, base 21, dust removal butterfly valve 22, inspection door 23, return bin 24, unloading mechanism 25, molding sand belt conveyor 26, inner lining plate of stirring cage 27, material retaining cover plate 28, inspection ladder 29, Continuous online water adding unit 30, water adding water tank 31, man-machine control interface 32, PLC control unit 33, water pump frequency converter 34, bentonite screw feeding frequency converter 35, coal powder screw feeding frequ...

Embodiment 2

[0019] The main structure of the continuous clay sand mixer involved in this embodiment also includes a wet mixing feeding port 9, which is fixedly arranged on the upper end of the stirring cage 10 and adjacent to the water feeding port 8, and is used in the wet mixing process. Addition of bentonite and coal powder.

[0020] The specific operation process when the continuous clay sand mixer involved in this embodiment is wet mixed is as follows: first, the parameters of water, bentonite and coal powder required for sand mixing are preset through the man-machine control interface 32, and then the old and new The sand is added into the stirring cage 10 through the comprehensive feeding port 6, and the moisture detector 2 transmits the moisture data contained in the new and old sand detected in real time to the PLC control unit 33, and the PLC control unit 33 is based on the received moisture data and the preset value. Comparing the moisture parameters to calculate the moisture v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com