Efficient sand mixer

A sand mixer and sand mixing technology, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems affecting the quality of molding sand, cleaning troubles, sand mixer damage, etc., to achieve The effect of shortening the mixing time, saving molding sand resources and improving sand mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

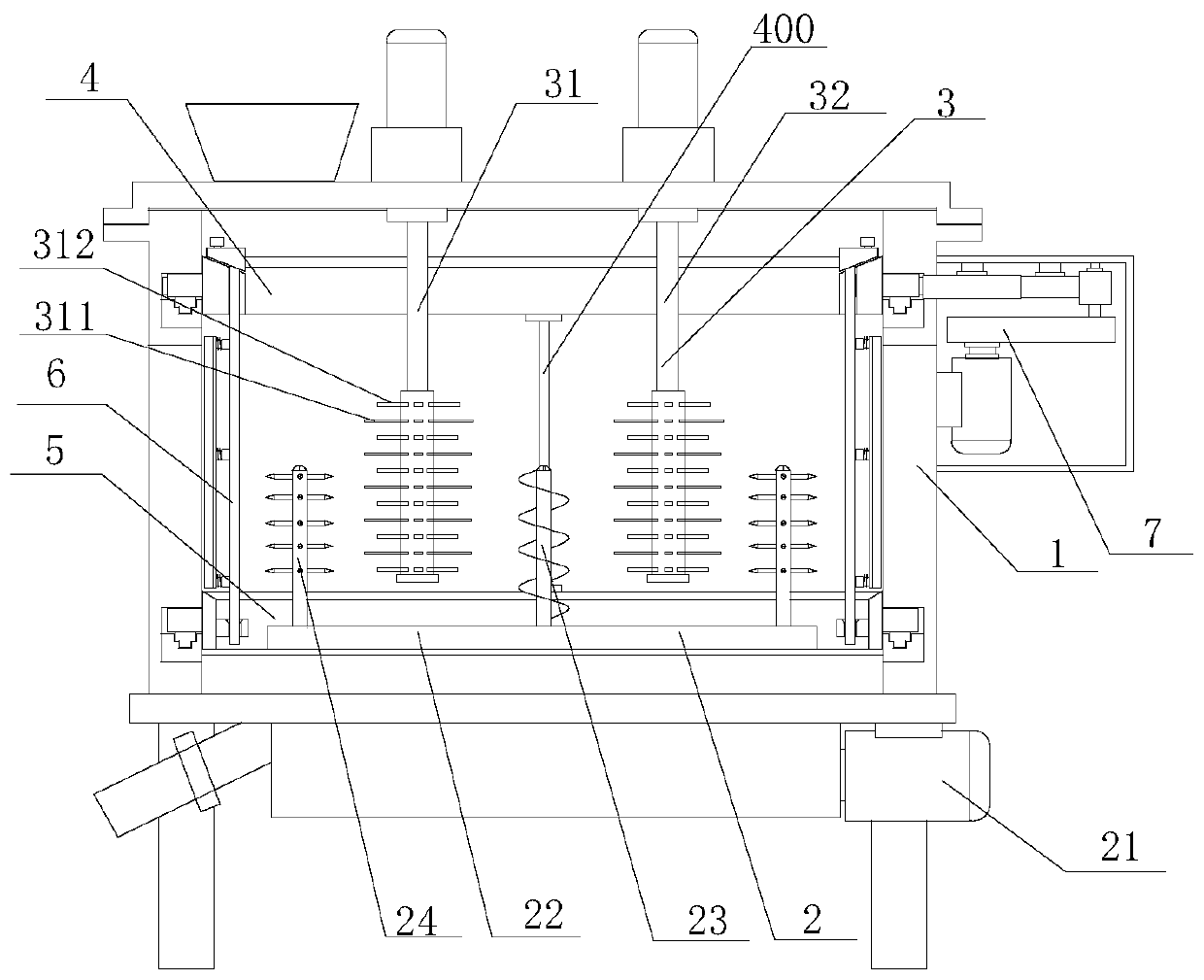

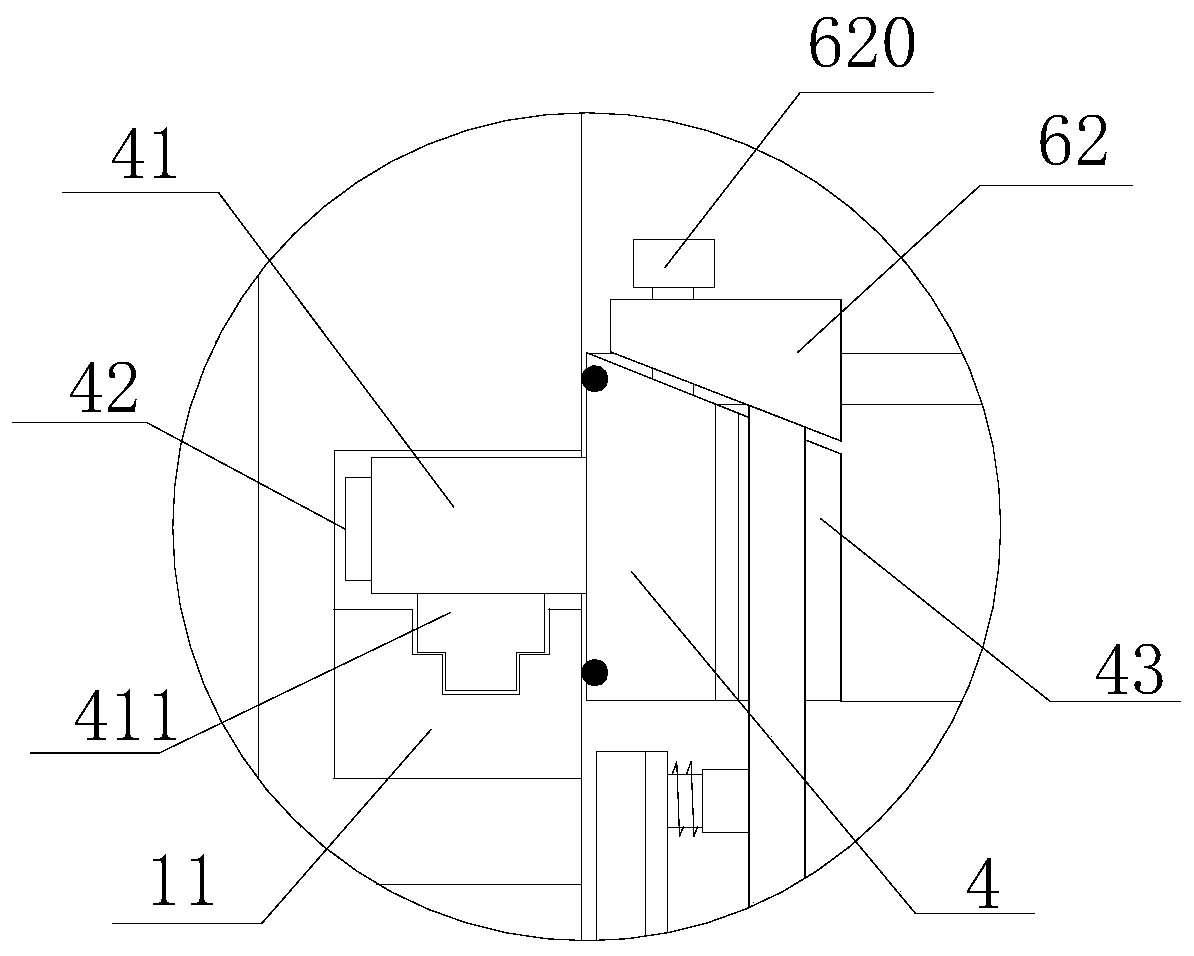

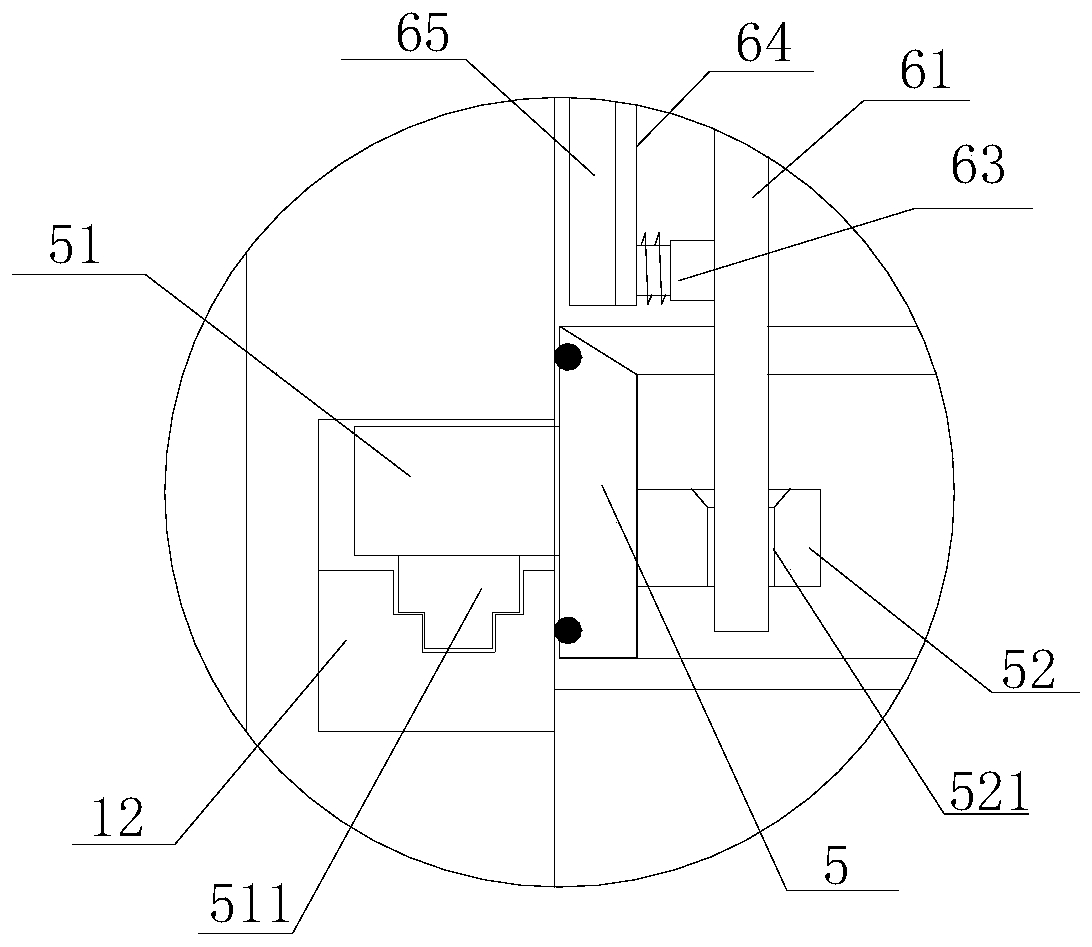

[0021] refer to Figure 1 to Figure 7 An efficient sand mixer of the present invention comprises a sand mixing cylinder 1, a chassis sand mixing mechanism 2, an eccentric stirring mechanism 3, an upper plate driven by a dial 4, a lower plate supported by a dial 5, a scraper dial assembly 6 and an upper plate A driving mechanism 7, a chassis sand mixing mechanism 2 is installed on the bottom of the sand mixing cylinder 1, and several auxiliary stirring mechanisms are arranged on the chassis sand mixing mechanism 2, and the auxiliary stirring mechanisms include a central mixing mechanism installed on the swivel seat 22 Spiral stirring shaft 23, two outer stirring shafts 24 and the first driving motor 21 that drives the rotation of the turntable 22, the central spiral stirring shaft 23 is installed at the center of the turntable 22, and the outer stirring shafts 24 are symmetrically distributed in the center On both sides of the spiral stirring shaft 23, several stirring rods are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com