Movement separation spiral multifunctional food mixing machine

A multi-functional food, spiral technology, applied to the structural parts of mixing/kneading machinery, mixing/kneading with vertical installation tools, etc., can solve the problem of increased manufacturing and use costs of food mixers, long mixing time, and insufficient mixing Adequate and other problems, to achieve the effect of shortening the mixing time, good mixing effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: Take the mixing of flour materials as an example.

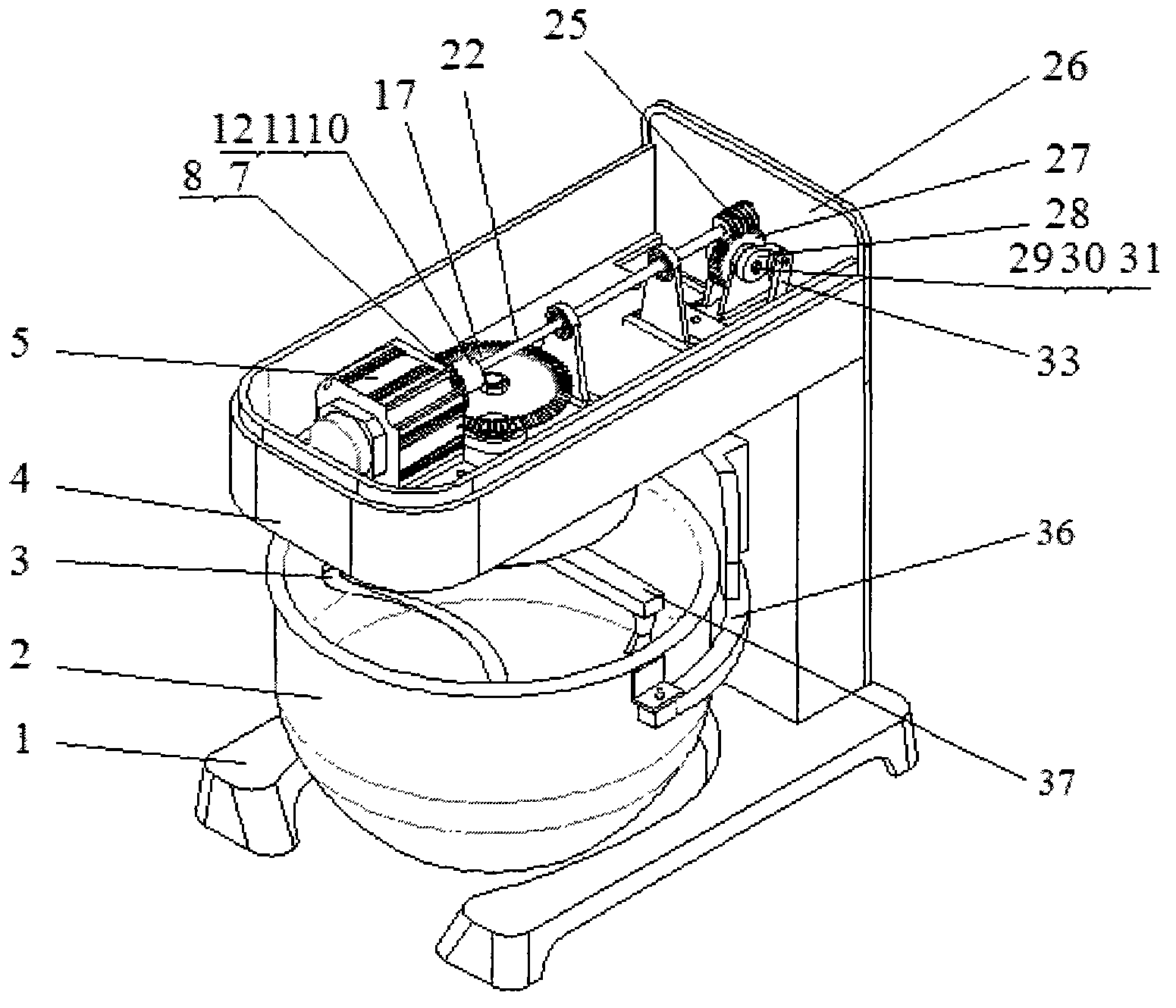

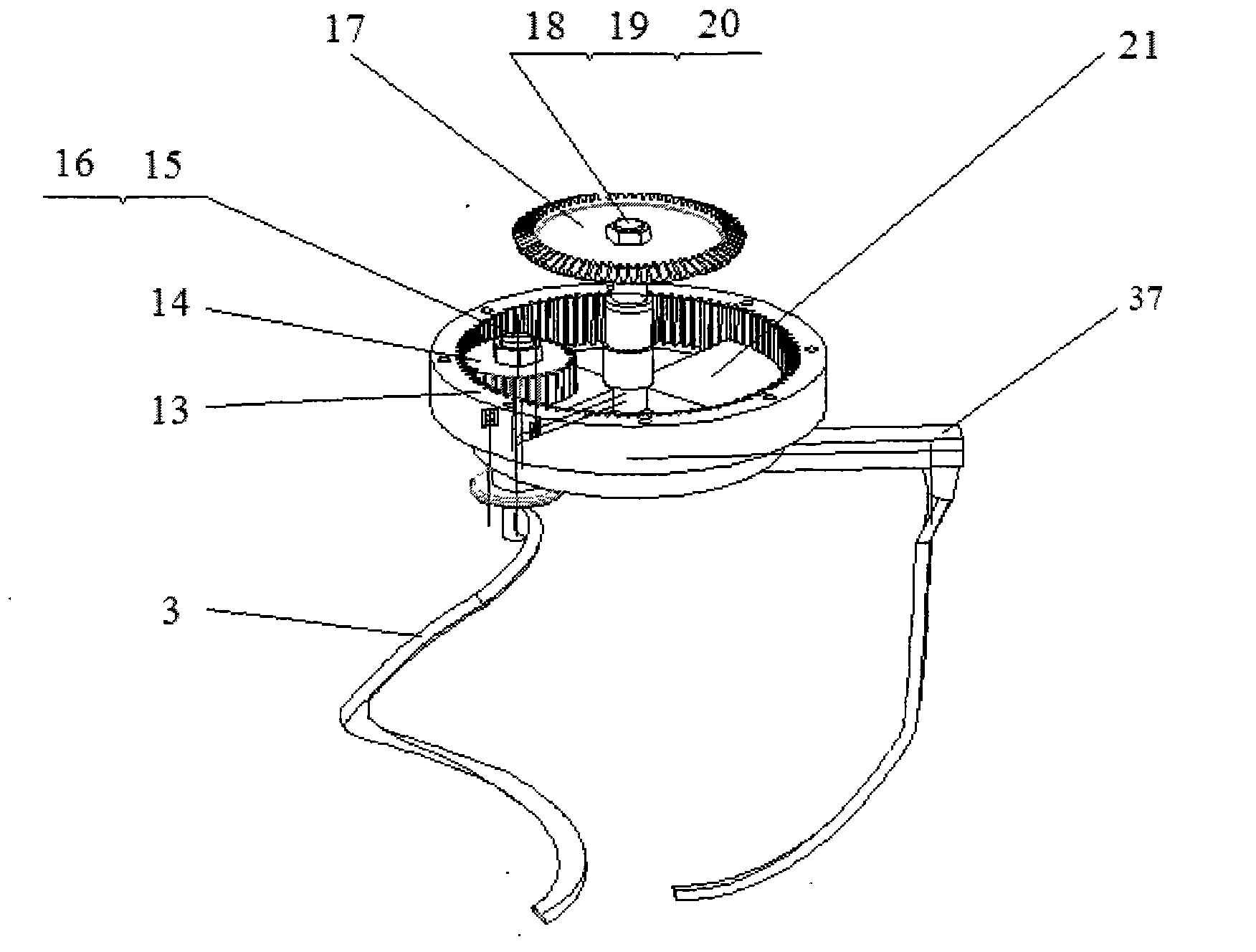

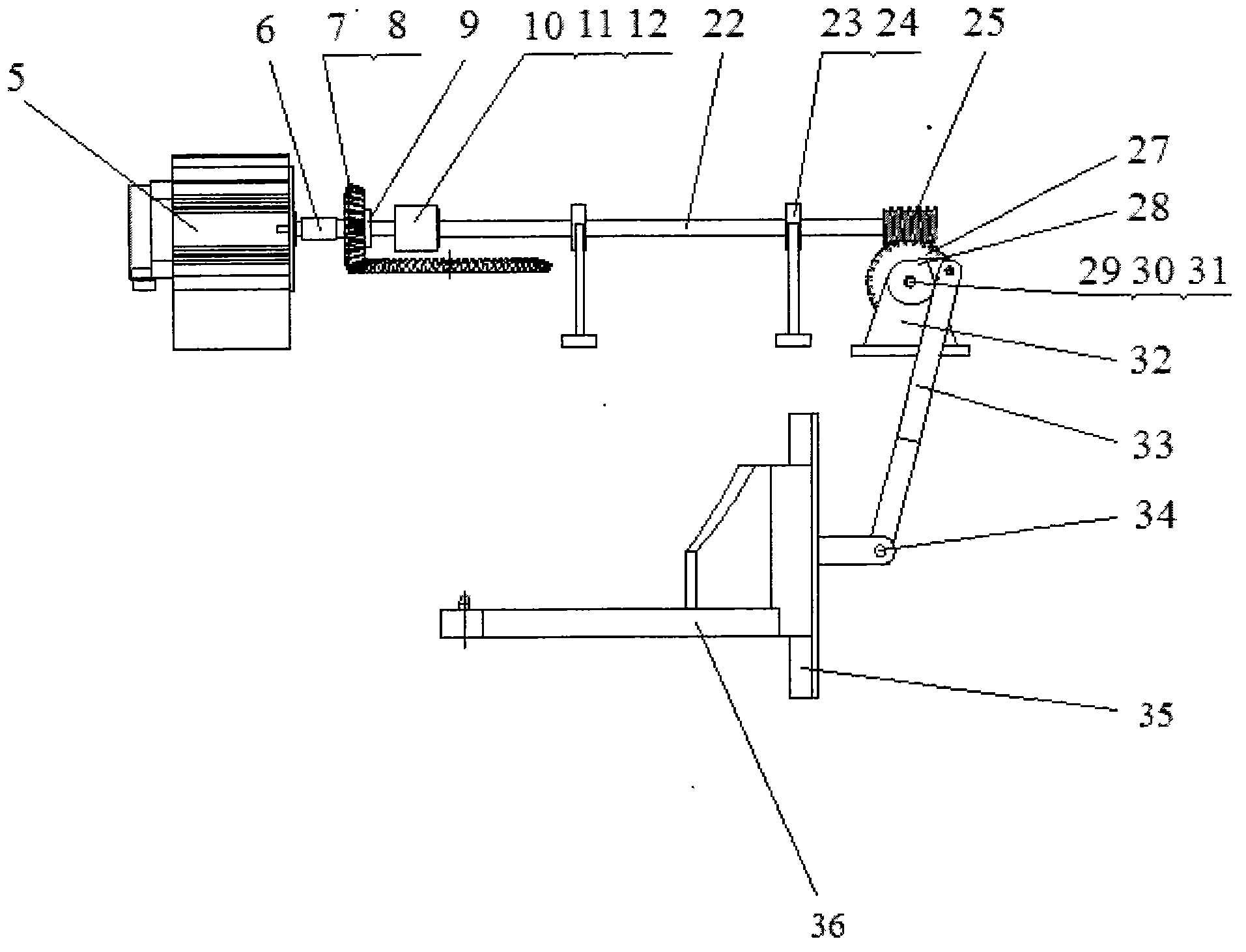

[0018] refer to figure 1 , 2 , 3. Motion separation spiral multifunctional food mixer, in the figure, 1- base, 2- mixing barrel, 3- agitator, 4- frame, 5- switched reluctance motor, 6- growth bushing, 7- small Bevel gear, 8-one-way bearing, 9-outer nut, 10-coupling, 11-one-way bearing, 13-inner ring gear, 14-planetary gear, 15-nut, 16-planetary shaft, 17-big cone Gear, 18-nut, 19-central shaft, 20-shaft sleeve, 21-planet carrier, 22-transverse shaft, 23-transverse shaft bracket, 24-deep groove ball bearing, 25-worm, 26-back cover, 27- Worm gear, 28-crank, 29-intermediate shaft, 30-deep groove ball bearing, 31-key, 32-bracket, 33-connecting rod, 34-central shaft, 35-guide rail, 36-lift frame, 37-scraper .

[0019] Put the mixing bucket 2 containing the flour to be stirred on the mixer lifting frame 36, when the switched reluctance motor 5 reverses, the one-way bearing 11 is locked, the one-way bearing 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com