Sand mixer

A sand mixer and sand mixing technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of long downtime and low efficiency of sand mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

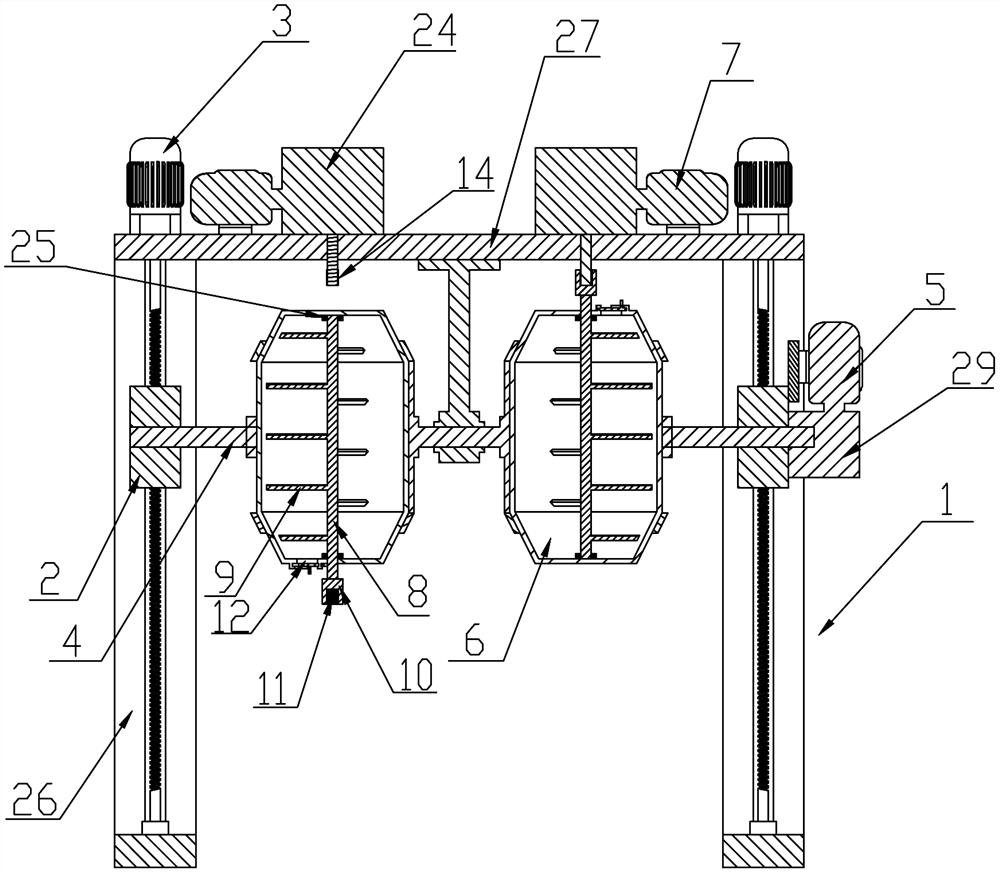

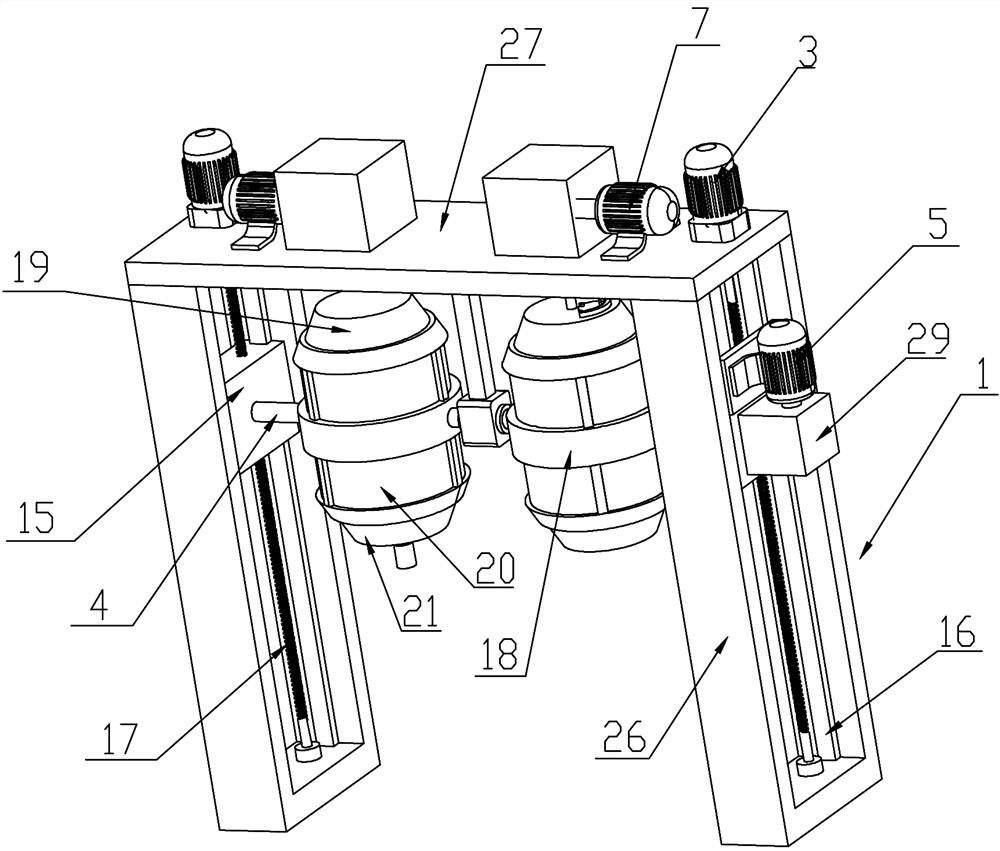

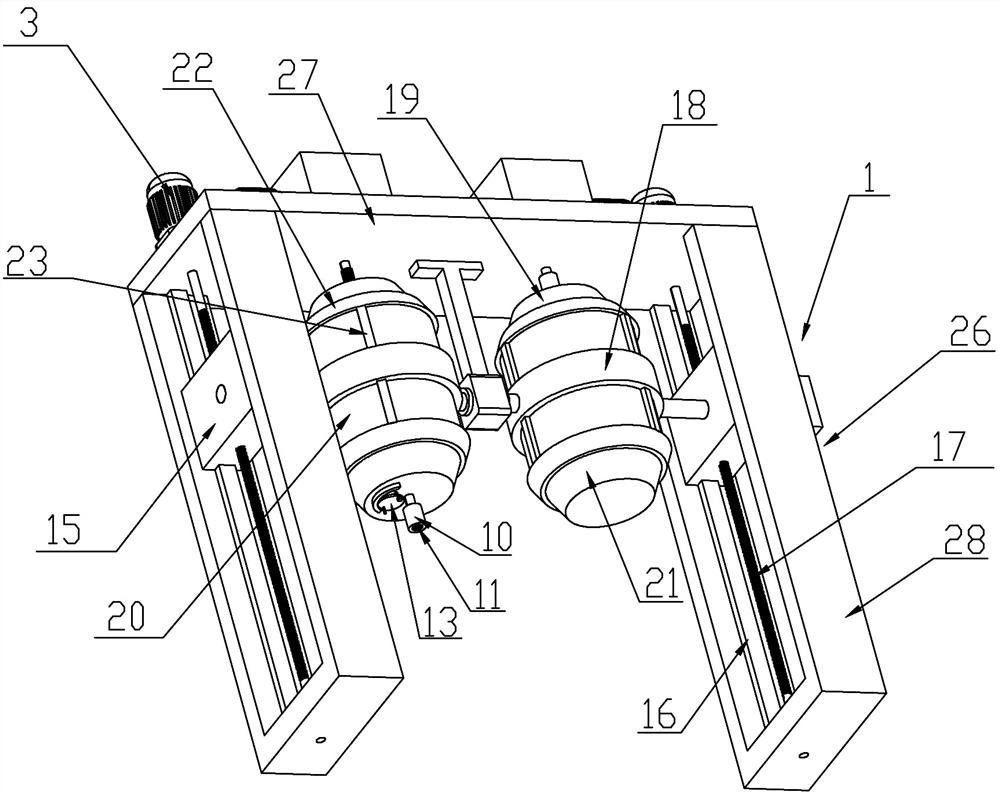

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1 to Figure 3 The sand mixer shown includes a frame 1, a lifting frame 2, a lifting motor 3, a turning frame 4, a turning motor 5, two sand mixing barrels 6 and two sand mixing motors 7, and the lifting frame 2 is arranged on On the frame 1 and constitute a vertical movement pair with the frame 1, the lifting motor 3 drives the lifting frame 2 to move vertically on the frame 1, and the turning motor 5 is installed on the lifting frame 2, and the turning frame 4 Rotation is set on the lift frame 2 and is turned over by the turning motor 5 relative to the lift frame 2. The two sand mixing buckets 6 are all arranged on the turn frame 4 and turn over with the turn over of the turn frame 4. A stirring shaft 8 is arranged in the sand barrel 6, and a stirring blade 9 is arranged on the stirring shaft 8, and one end of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com