Sand mixing device with good sand discharging effect for casting machinery

A foundry machinery and sand mixing technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, manufacturing tools, etc., can solve the waste of molding sand mixing efficiency, adhesion inside the sand mixer, and inconvenient unloading of molding sand and other problems to achieve better mixing effect, improve mixing efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

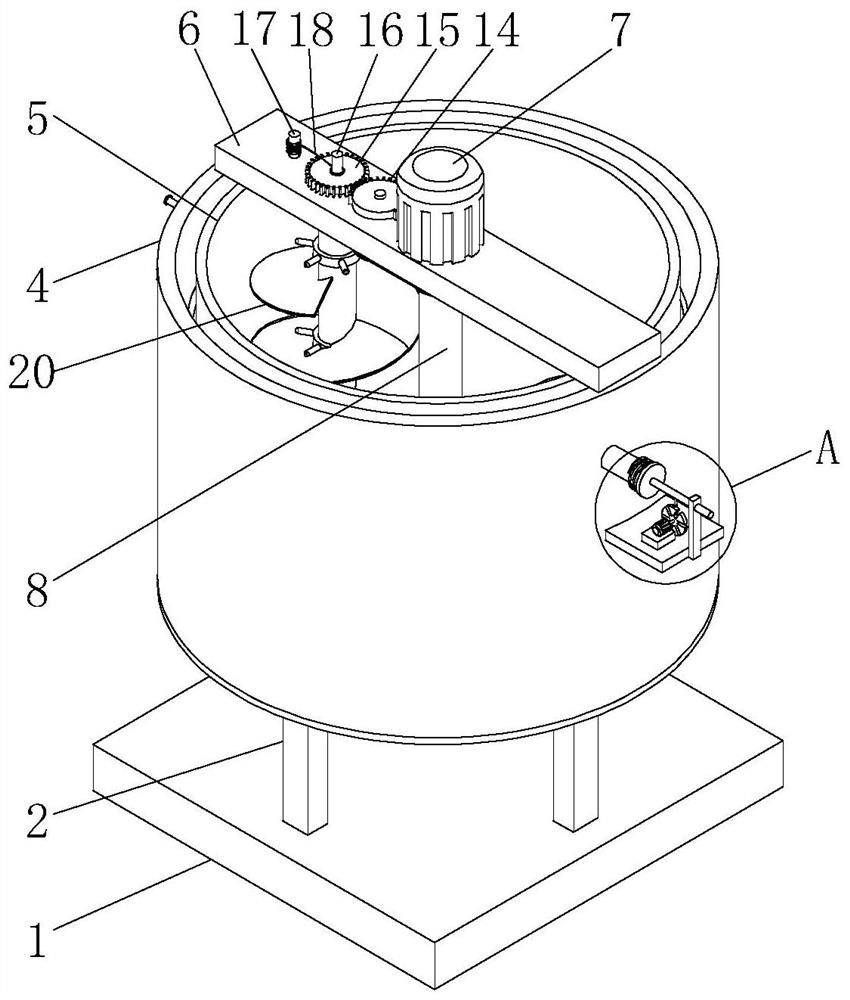

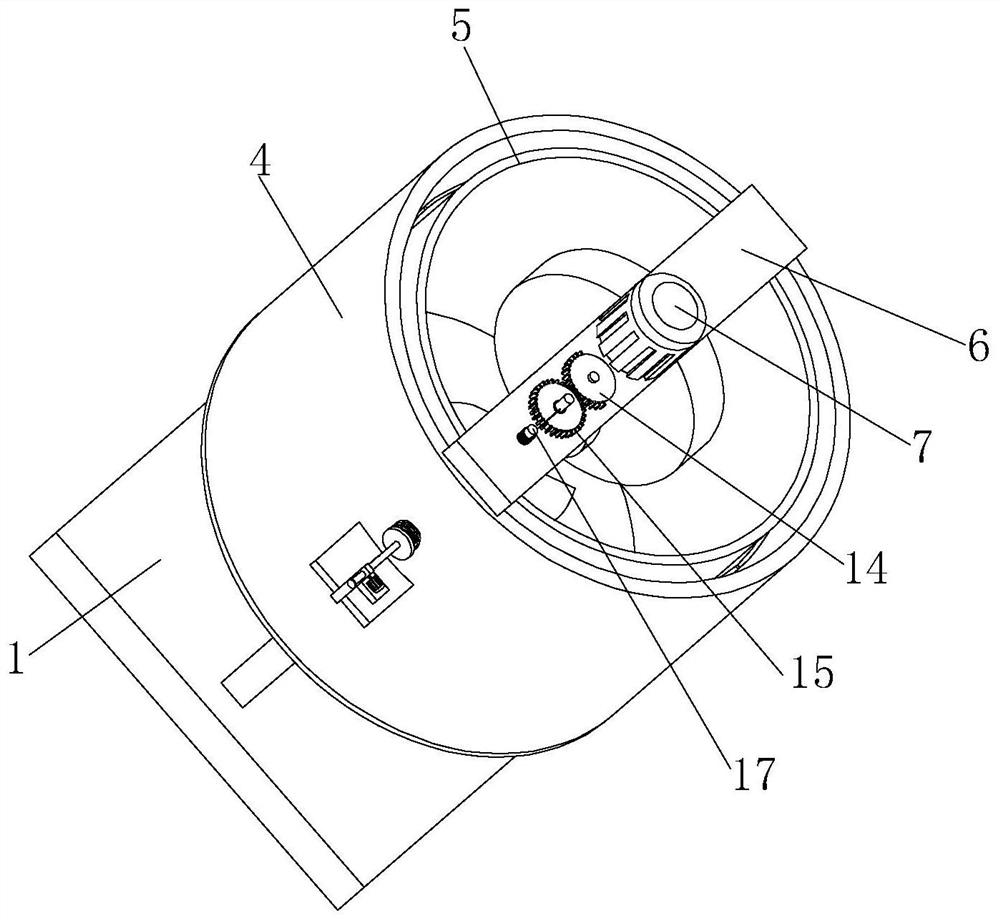

[0041] see Figure 1-Figure 7 , the present invention provides a technical solution: a sand mixing device with good sanding effect for foundry machinery, including a base 1 and a shaking device 21, the top outer wall of the base 1 is fixedly connected with a support column 2, and the support column 2 is far away from the base 1 One end of the fixed plate is fixedly connected with a fixed plate 3, the top outer wall of the fixed plate 3 is fixedly connected with the shell 4, the top outer wall of the fixed plate 3 is fixedly connected with the mixing box 5 inside the shell 4, the outer wall of the mixing box 5 is connected with the inner wall of the shell 4 A gap is provided between them for the movement of the second movable rod 29. The top outer wall of the housing 4 is fixedly connected with the first mounting plate 6, and the top outer wall of the first mounting plate 6 is fixedly connected with the first motor 7. The output of the first motor 7 The shaft is fixedly connect...

Embodiment 2

[0044] see Figure 1-Figure 5 , on the basis of Embodiment 1, the present invention provides a technical solution: a sand mixing device with good sanding effect for foundry machinery, the shaking device 21 includes an outer ring 211 and an inner ring 212, and the shaking rod 213 is along the outer ring 211 and the center of the inner ring 212 are distributed in an array, the inner wall of the shaking device 21 is socketed with the outer wall of the stirring shaft 19, the inner ring 212 is arranged inside the outer ring 211, and the outer wall of the outer ring 211 is fixedly connected with a shaking rod 213. The inner wall of the ring 212 is fixedly connected with the first spring 214, and the end of the first spring 214 away from the inner ring 212 is fixedly connected with the end of the shaking rod 213. The inner wall of the inner ring 212 is provided with a sliding groove 215, and the inner wall of the sliding groove 215 is slidingly connected with The sliding rod 216, the...

Embodiment 3

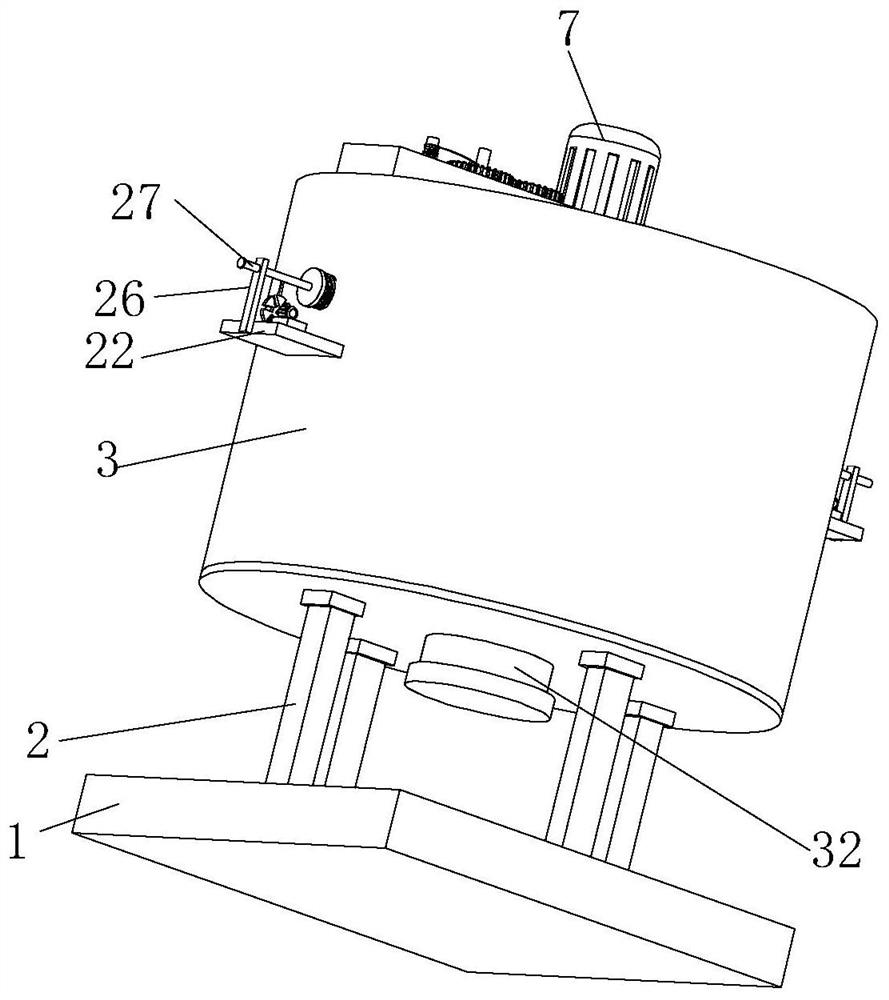

[0047] see Figure 8-Figure 9 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a sand mixing device with good sand output effect for foundry machinery, and the outer walls on both sides of the shell 4 are fixedly connected with a second mounting plate 22 , the top outer wall of the second mounting plate 22 is fixedly connected with the second motor 23, the output shaft of the second motor 23 is fixedly connected with the third runner 24, and the outer wall of the third runner 24 is provided with an empty groove 25, and the second mounting plate One side outer wall of 22 is fixedly connected with limit rod 26, and the inwall of limit rod 26 is movably connected with first movable rod 27, and the outer wall of first movable rod 27 is fixedly connected with fixed rod 33, and first movable rod 27 is far away from limit rod One end of 26 is fixedly connected with a push block 28, and the inner wall of the housing 4 is intersperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com