Water mist cooling control method of high-temperature molding sand

A technology of water mist cooling and control method, which is applied in the direction of manufacturing tools, casting molding equipment, cleaning/processing machinery of casting mold materials, etc. It can solve problems such as ineffective implementation, rising sand temperature, and blockage of conveying devices, etc., to achieve Improve the working efficiency of sand mixing, improve the overall performance, and avoid the effect of blocking the conveying device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

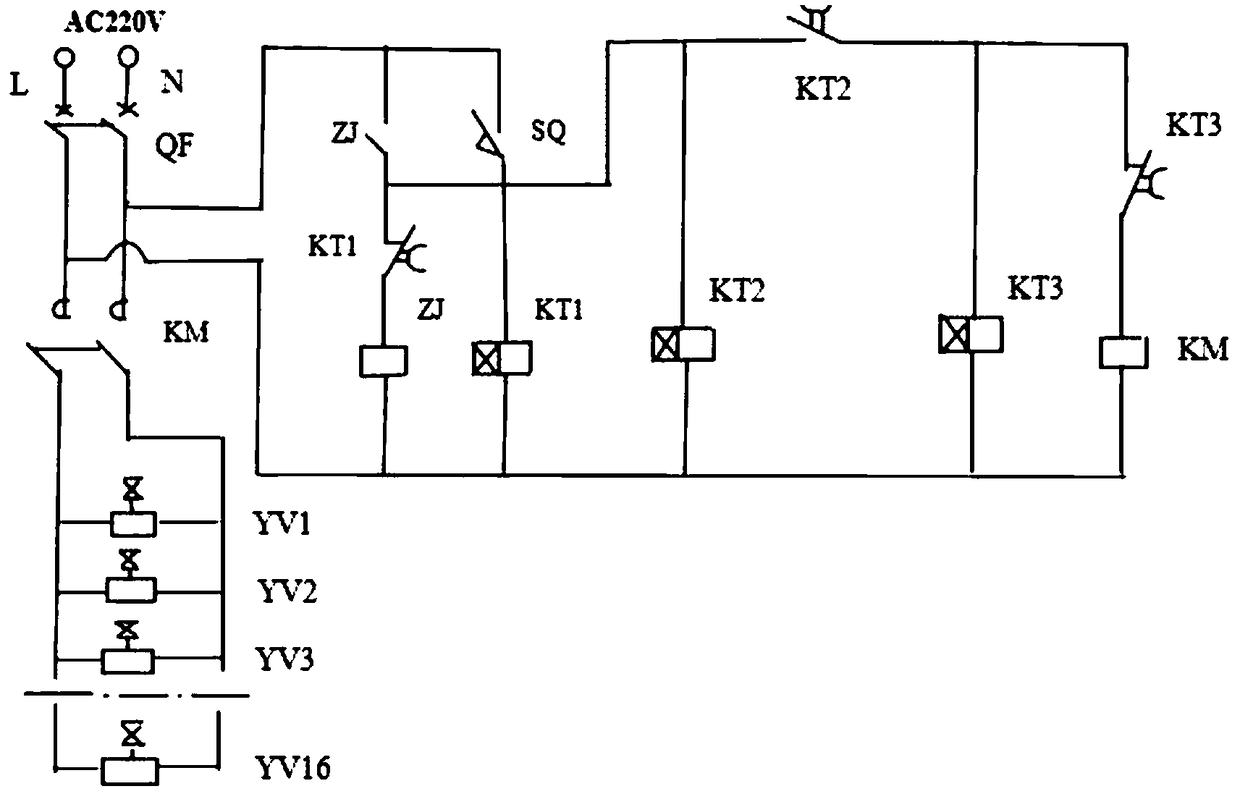

[0030] structured as figure 1 As shown, in the high-temperature molding sand water mist cooling control method provided in this embodiment, a travel switch SQ is set on the lifting device on the vibrating shakeout machine, which is used to trigger the contact with the hanging box, and an arc is made on the conveyor belt. The stainless steel semi-enclosed cover covers the conveyor belt, and installs multiple high-pressure atomizing water nozzles at equal intervals on the central axis of the semi-closed stainless steel cover. Each high-pressure atomizing water nozzle is controlled by a solenoid valve. The time taken from the vibration of the hanging box to the high-temperature sand all over the conveyor belt is recorded as t1,

[0031] When the vibrating sand falling device is turned on to start hanging the box, the box equipment moves to contact the travel switch to close it, and then open the solenoid valve after a delay of t1 to make the high-pressure atomizing water nozzle ...

Embodiment 2

[0033] This embodiment provides a high-temperature molding sand water mist cooling control device, which is used for vibrating shakeout machines Down Each water mist spray device set on the conveyor belt is controlled to achieve lifting Box casting and High-temperature sand, water mist cooling on the conveying device under the vibrating shakeout machine; including power supply, circuit breaker QF, travel switch SQ, time relay KT1, intermediate relay ZJ, delay control circuit, AC contactor KM and various solenoid valves YV ;

[0034] Among them, the power supply is connected to the input terminal of the delay control circuit through the circuit breaker QF, the time relay KT1, and the on-off actuator of the intermediate relay ZJ in sequence; at the same time, the power supply is connected to the input terminal of the delay control circuit through the circuit breaker QF, the travel switch SQ and the intermediate relay ZJ in sequence. The control terminal is connected; the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com