Road roller frame hinged structure

A road roller, hinged technology, applied to the substructure, roads, roads, etc., can solve the problems of easy loosening of lock nuts, wear and damage of bearings, labor-intensive commissioning and installation, etc., to shorten the production cycle, facilitate maintenance, and increase the amount of grouting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

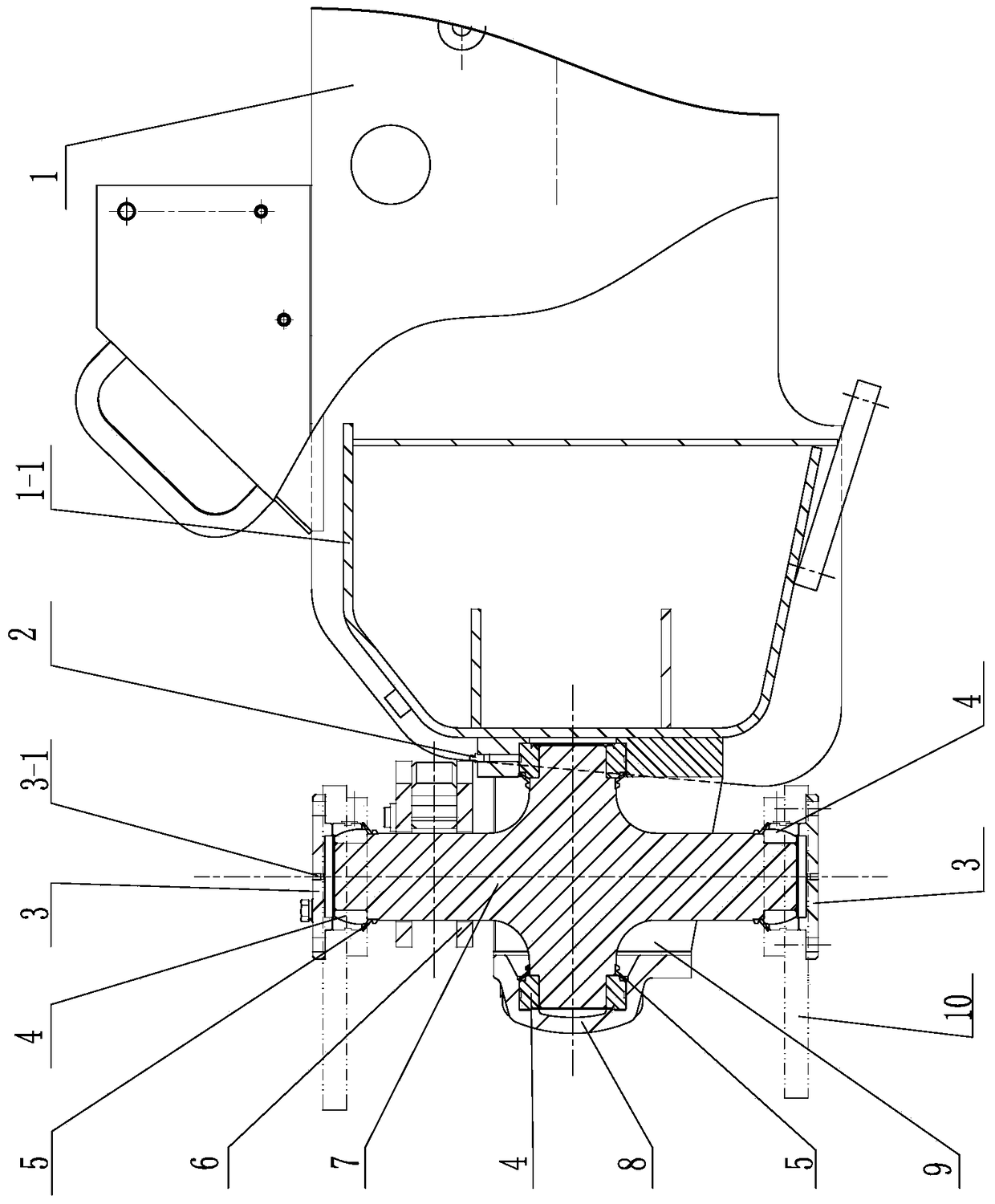

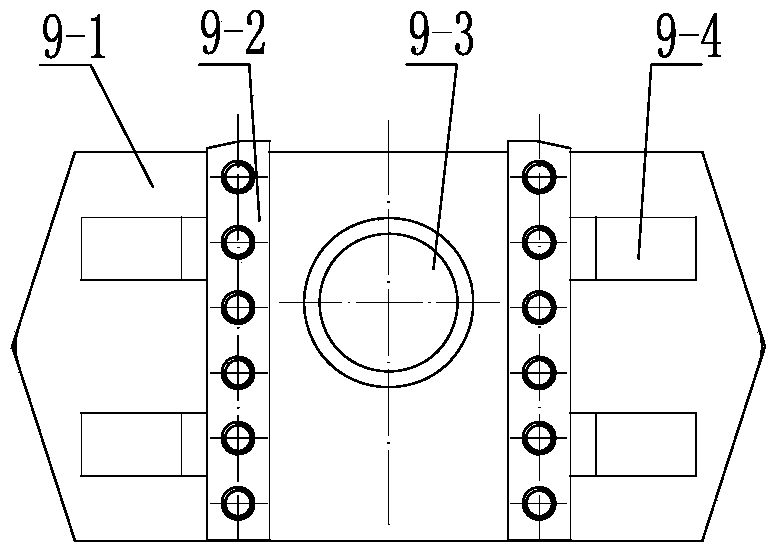

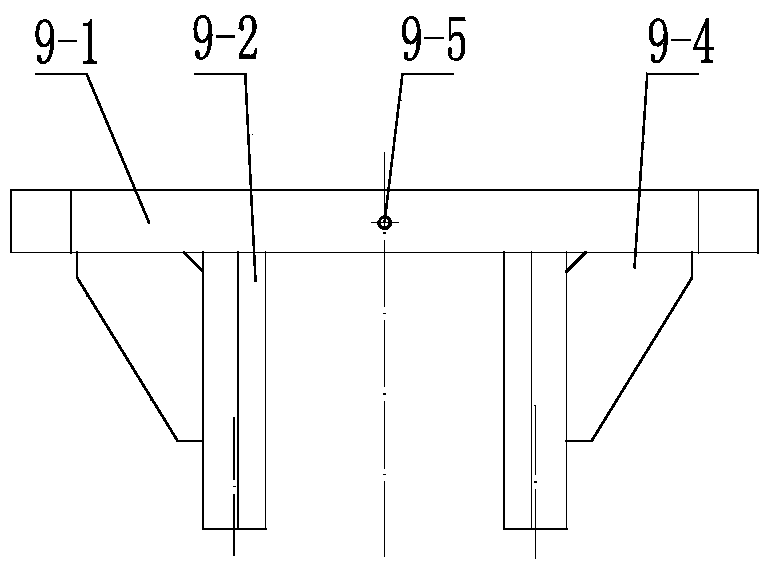

[0023] See Figure 1-9 As shown, the articulated structure of the road roller frame of the present invention includes an articulated frame 9 and a cross shaft assembly. See Figure 1~3 Shown, hinged frame 9 of the present invention comprises the seat plate 9-1 that is provided with bearing hole 9-3 and two risers 9-2 that are welded on the seat plate 9-1, and each riser 9-2 and seat plate 9 -1 is also provided with at least one reinforcing rib 9-4, and multiple reinforcing ribs 9-4 can be used to improve the rigidity and mechanical strength of the hinged frame 9 through the reinforcing ribs 9-4. See figure 1 Shown seat plate 9-1 of the present invention is welded on the rear side of the rear crossbeam 1-1 of front vehicle frame 1, so hinged frame 9 can not occupy the space of rear crossbeam 1-1 of front vehicle frame 1, and also because of hinge mechanism Compact, can increase the longitudinal dimension of the rear crossbeam 1-1, and increase the size of the grouting space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com