A grouting anchor cable sealing device and a grouting anchor cable

A technology of grouting anchor cable and hole sealing device, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., and can solve the problems of poor grouting effect, low work efficiency, and automatic hole sealing of grouting anchor cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

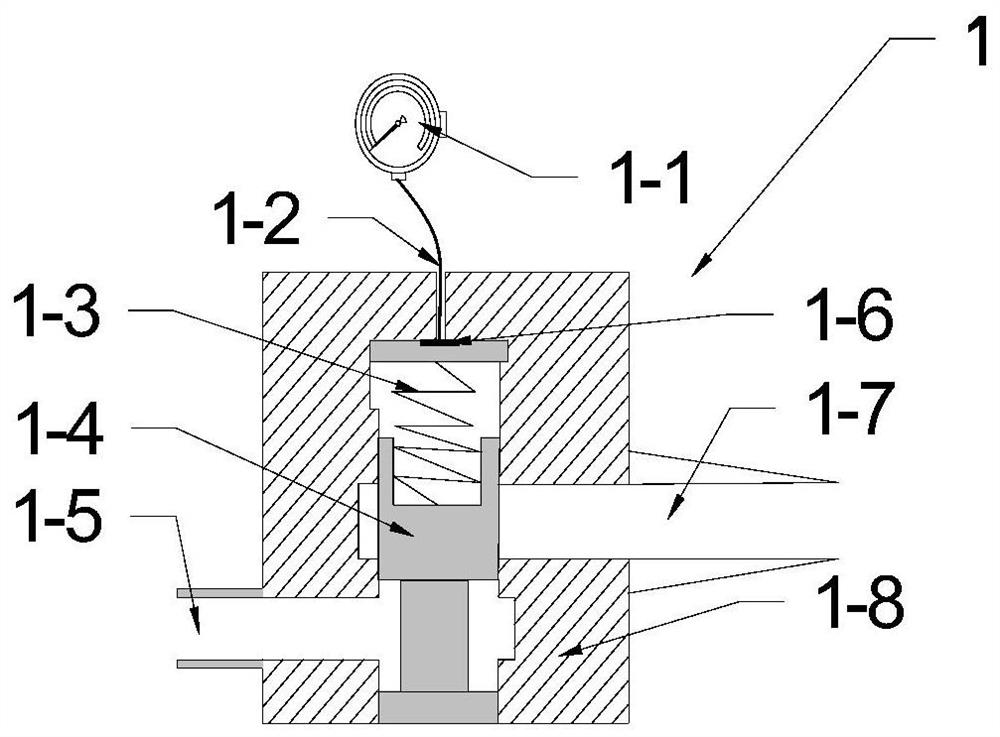

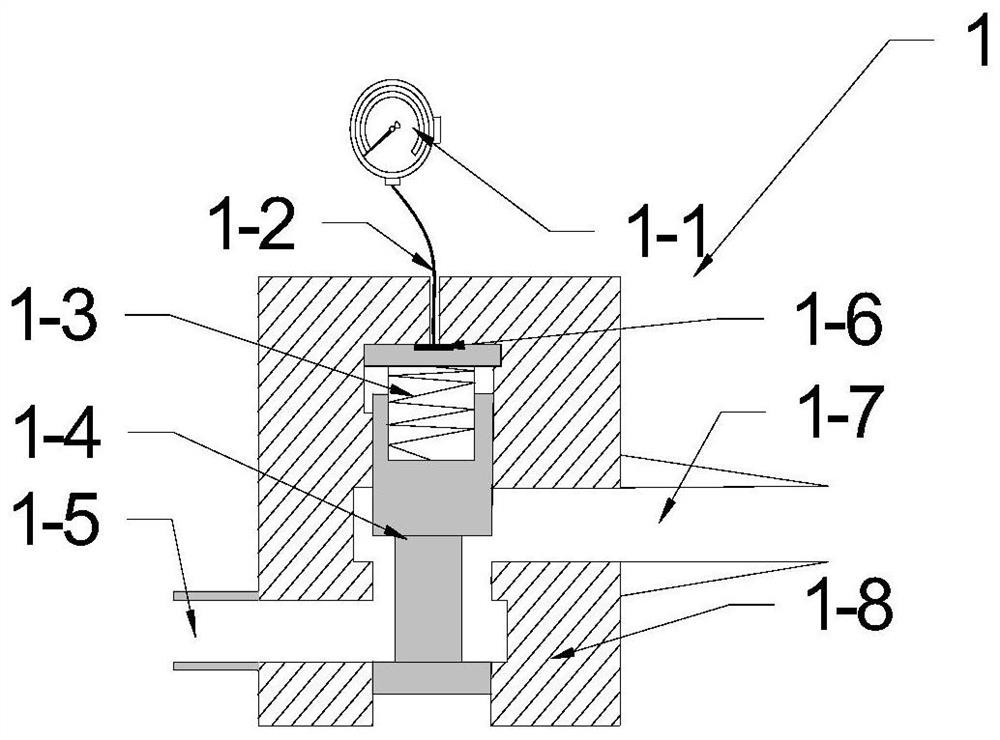

[0033] A specific embodiment of the present invention discloses a grouting anchor cable sealing device, such as Figure 1 to Figure 2 As shown, it includes housing 1-8, spring 1-3 and grout stop piston 1-4, housing 1-8 is provided with a piston chamber for installing grout stop piston 1-4, and grout stop piston 1-4 is located at inside the piston chamber, and can move in the piston chamber; one end of the grout stopper 1-4 is fixedly connected with the bottom wall of the piston chamber by a spring 1-3, and the other end of the grout stopper 1-4 is a free end, which can be In contact with the slurry entering the piston cavity, that is to say, the tail end of the slurry stopper 1-4 is connected to the spring 1-3, the head end of the slurry stopper 1-4 can contact the slurry in the piston cavity, and the slurry pressure can act On the end face of the head end of the stopper 1-4; the shell 1-8 is provided with an inflow channel 1-5 and an outflow channel 1-7, and the inflow channe...

Embodiment 2

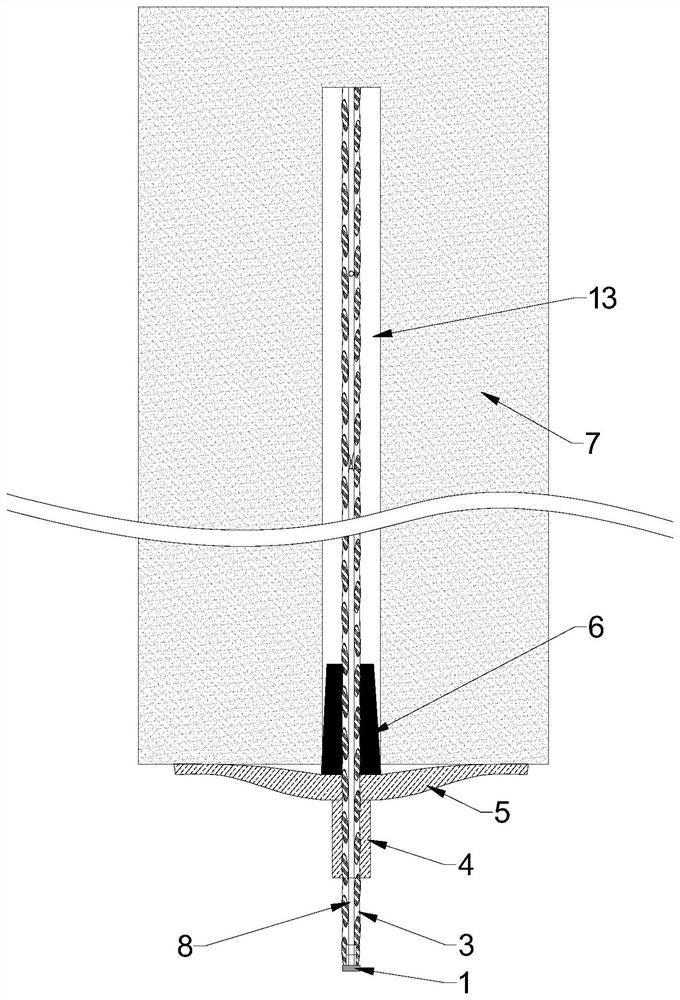

[0045] Yet another embodiment of the present invention discloses a grouting anchor cable. The grouting anchor cable sealing device in Embodiment 1 is used to seal the grouting port of the grouting pipe 8 of the grouting anchor cable, as shown in Figure 3 to Figure 5 As shown, the grouting anchor cable includes a cable body 3 and a grouting anchor cable sealing device 1. The cable body 3 is composed of a plurality of steel strands 11 spirally wound around the grouting pipe 8, and the spirally wound steel strands 11 connect the grouting pipe 8, the pitch of the wound steel strand 11 is greater than the diameter of the steel strand 11; the grouting pipe 8 is provided with a grout outlet 12; The grouting port connection.

[0046] During implementation, put the cable body 3 of the grouting anchor cable into the anchor cable hole, install the external grout stopper 6 and the tray 5 in sequence, pre-tighten the anchorage 4, connect the outflow channels 1-7 and the grouting pipe 8 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com