Signal remote transmission gas relay

A relay and gas technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problem that the oil level of gas relays can only be monitored manually on site, and achieve the effect of improving the efficiency of oil level monitoring and perfecting the protection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

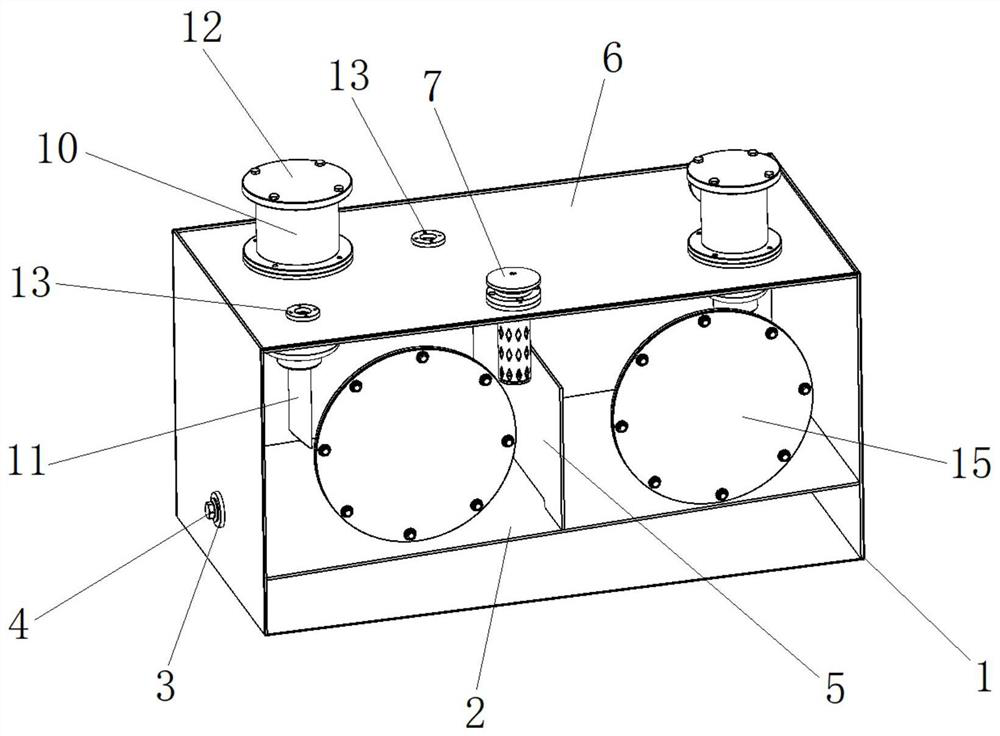

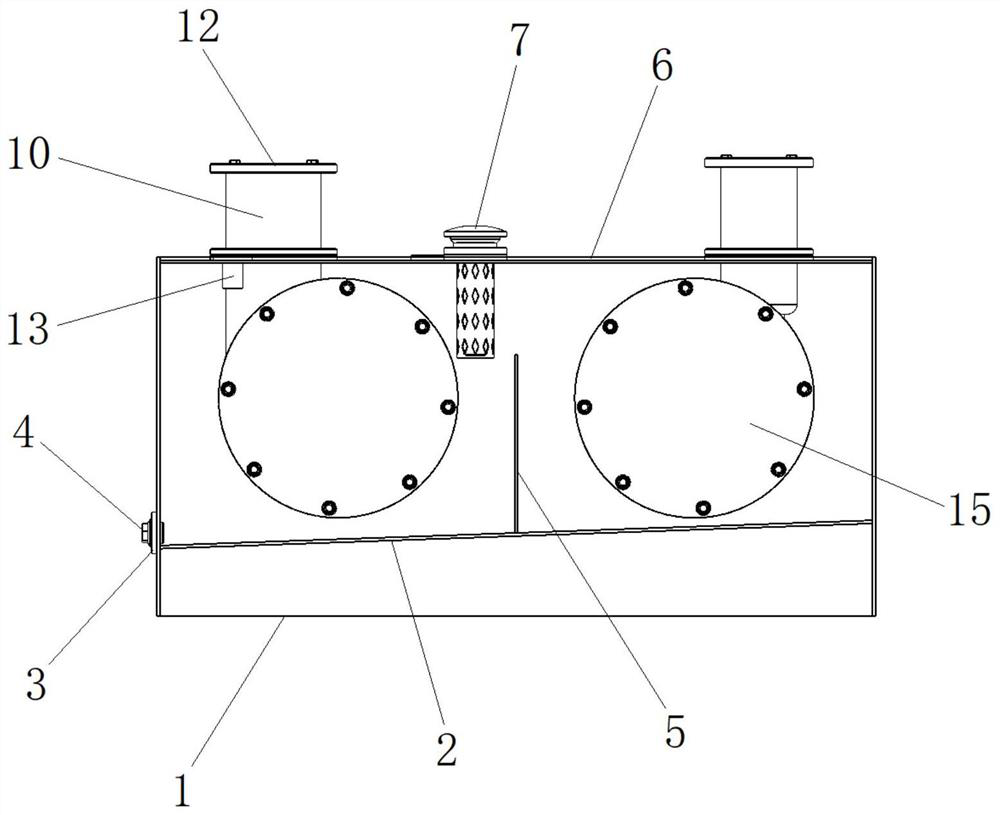

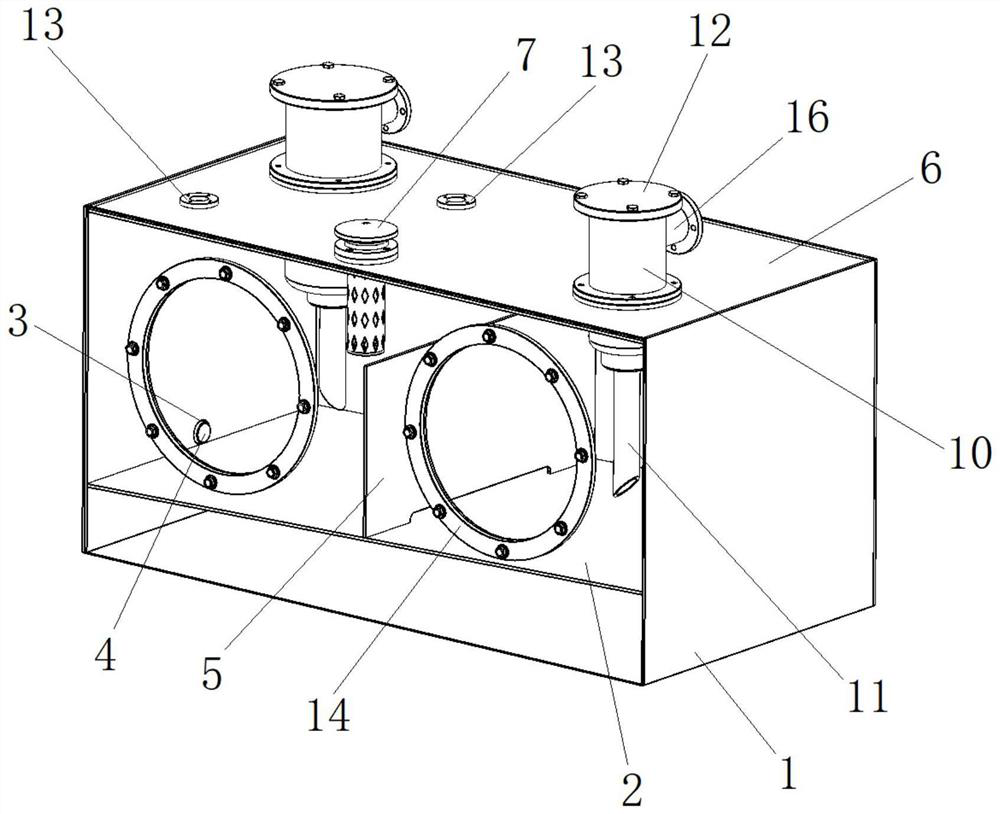

[0024]A signal remote transmission Buchholz relay, such asFigure 1~4As shown, it includes the housing 1, the inclined plate 2, the communication port 3, the plug 4, the central partition 5, the top surface 6, the air release valve 7, the cylinder 8, the diamond hole 9, the sleeve 10, the communication pipe 11, The flange cover 12, the camera 13, the front port 14, the front cover 15, and the bypass pipe 16, wherein a tilting plate 2 is fixedly connected to the inside of the housing 1, and is located at the end of the tilting plate 2 on the side wall of the housing 1 A communication port 3 is opened at the position of the communication port 3, and a plug 4 is provided at the communication port 3. A central partition 5 is vertically and fixedly connected to the inner wall of the housing 1. The central partition 5 is located above the inclined plate 2; An air release valve 7 is fixedly connected to the top surface 6 of the housing 1, and a cylinder 8 is provided at the lower end of the...

Embodiment 2

[0027]A signal remote transmission Buchholz relay, such asFigure 1~4As shown, it includes the housing 1, the inclined plate 2, the communication port 3, the plug 4, the central partition 5, the top surface 6, the air release valve 7, the cylinder 8, the diamond hole 9, the sleeve 10, the communication pipe 11, The flange cover 12, the camera 13, the front port 14, the front cover 15, and the bypass pipe 16, wherein a tilting plate 2 is fixedly connected to the inside of the housing 1, and is located at the end of the tilting plate 2 on the side wall of the housing 1 A communication port 3 is opened at the position of the communication port 3, and a plug 4 is provided at the communication port 3. A central partition 5 is vertically and fixedly connected to the inner wall of the housing 1. The central partition 5 is located above the inclined plate 2; An air release valve 7 is fixedly connected to the top surface 6 of the housing 1, and a cylinder 8 is provided at the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com