Three-dimensional oil contamination degree detector

A technology of oil pollution degree and detector, applied in the field of detection circuits, can solve the problems of overlapping, affecting the accuracy of measurement results, and uneven particle distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

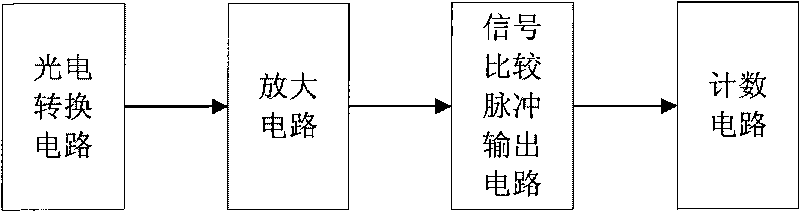

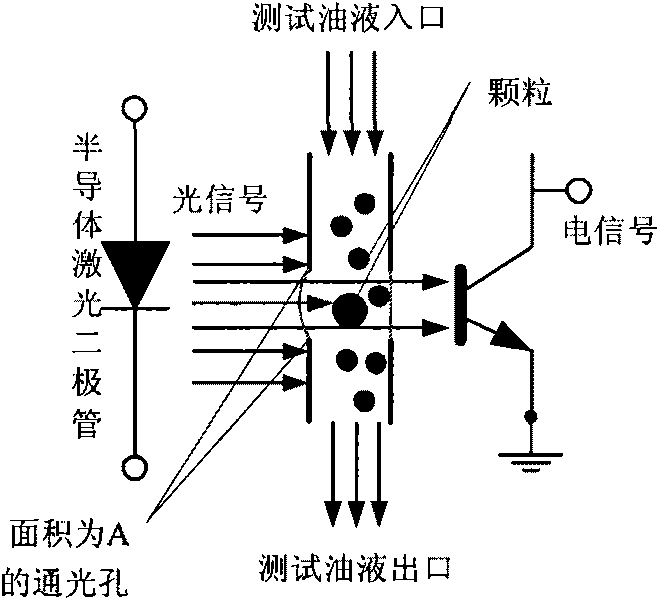

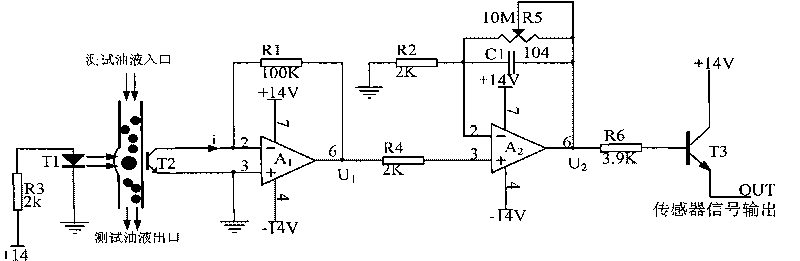

[0026] as attached figure 2 Shown: the present invention includes a housing, a semiconductor laser, a measuring probe, a photoelectric conversion circuit, an I-V conversion circuit, a comparison circuit and a counter counting circuit. A measuring probe is arranged in the casing, and optical glass windows are arranged on both side walls of the measuring probe. A group of lenses is set between the measuring probe and the semiconductor laser, and the right side wall of the measuring probe is provided with an optical glass window, and a photoelectric converter is provided on the corresponding side. The number of lenses in this embodiment is three, and they are relatively arranged on the left side of the measuring probe. side. The photoelectric converter of this embodiment uses a photosensitive element, and the photosensitive element is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com