Special oiling machine used for producing sliding rails of automobile seats

A technology for car seat slide rails and slide rails, which is applied to mechanical equipment, engine components, lubricating parts and other directions, can solve the problems of unstable oil application, easy pollution of oil sources, and high production labor costs, and achieve oil application. Stable, pollution-reducing, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

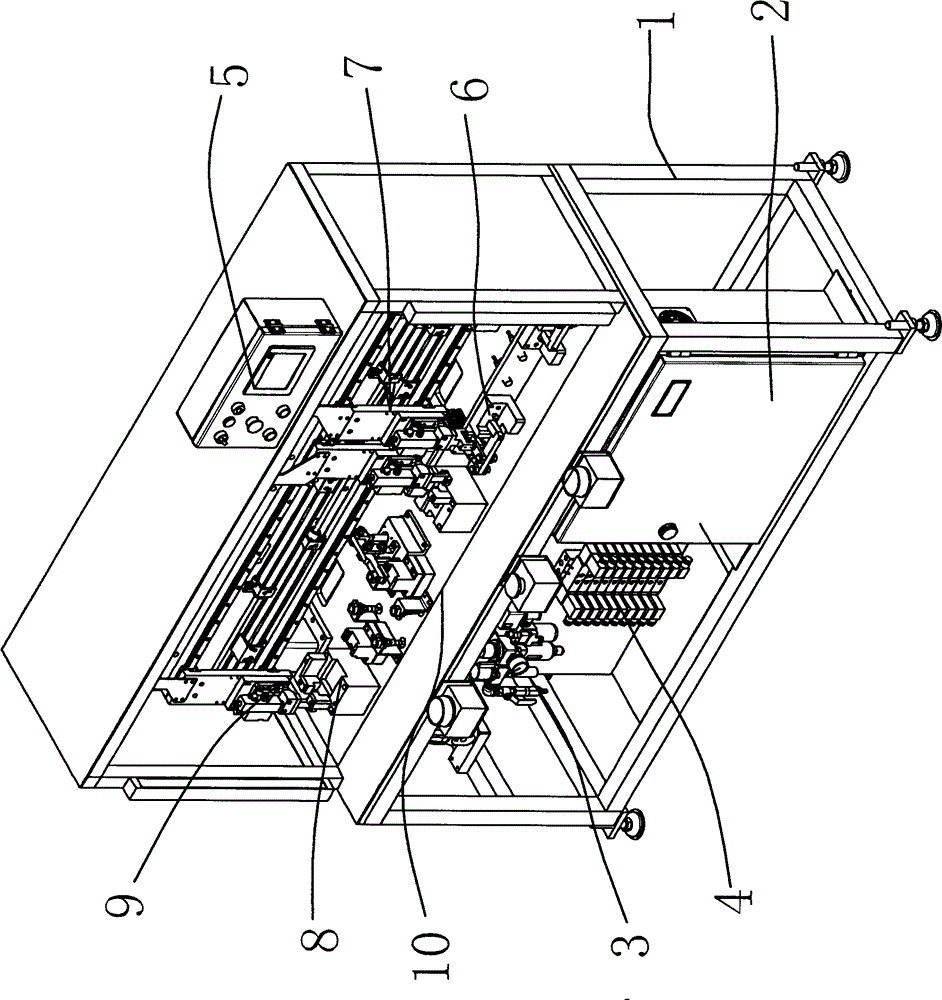

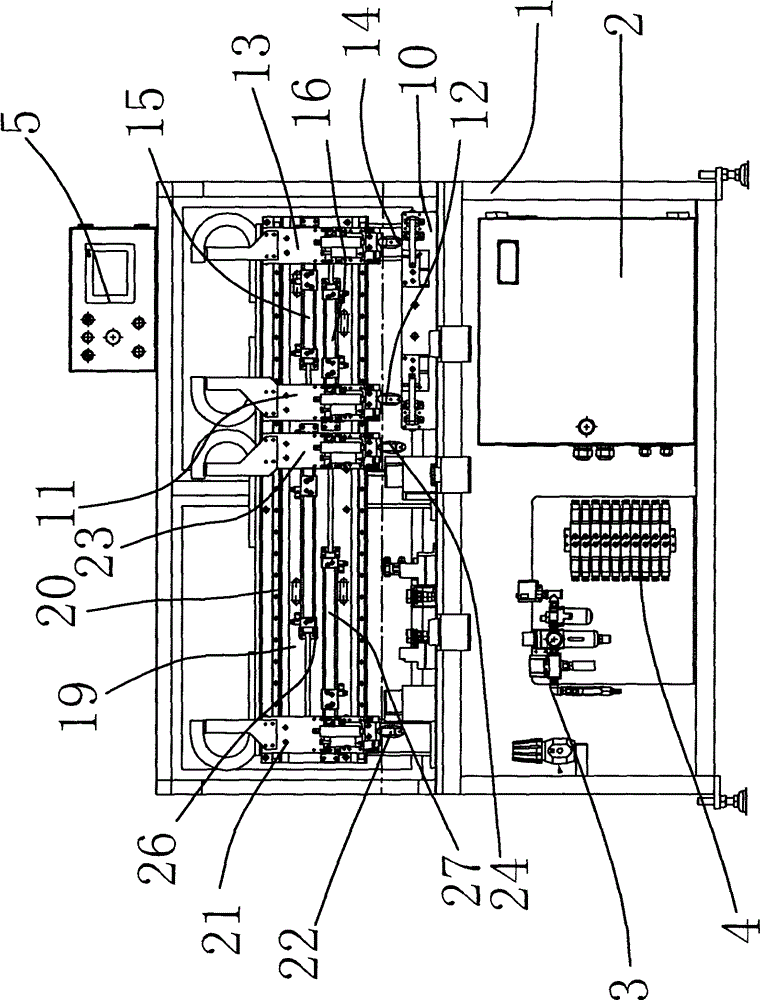

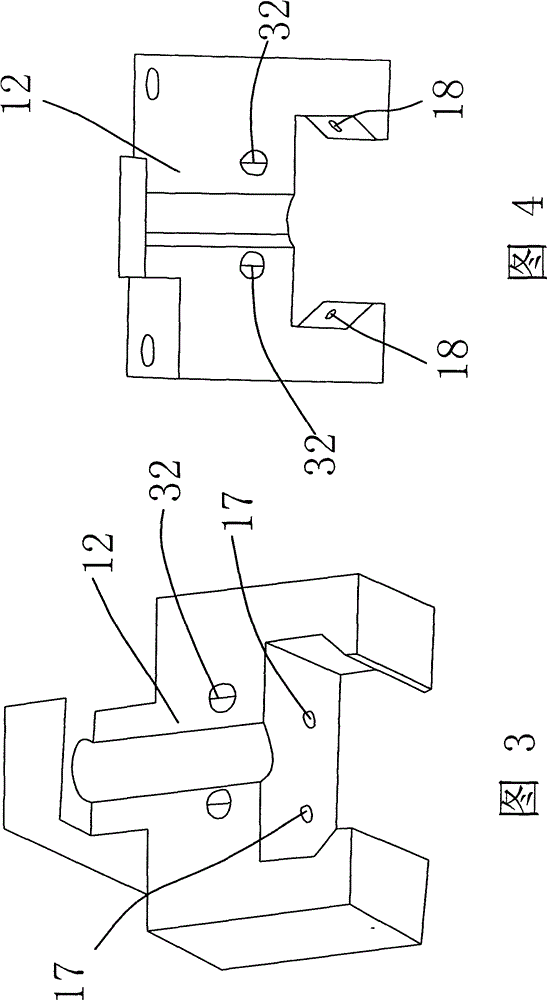

[0019] In the figure, frame 1; electric control system 2; air source assembly 3; oil circuit system 4; central control system 5; upper slide rail fixing fixture 6; upper slide rail oiling mechanism 7; lower slide rail fixing fixture 8; Lower rail oiling mechanism 9; working table 10; upper sliding rail left sliding block 11; upper sliding rail left oil injection nozzle 12; upper sliding rail right sliding block 13; upper sliding rail right oil injection nozzle 14; upper sliding rail left drive Cylinder 15; upper slide rail right drive cylinder 16; upper fuel injection hole 17; oblique fuel injection hole 18; vertical mounting plate 19; Right sliding block 23; right fuel injection nozzle 24 of the lower rail; left driving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com